Why does the engine on a walk-behind tractor smoke?

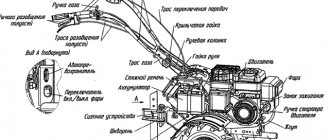

In this section we will analyze the malfunctions of walk-behind tractors and cultivators of all Salyut brands. Neva, Zubr, etc., and their removal and repair. Most problems are common to all types of engine blocks, their engines and other components.

Engine power has dropped

It often happens that a previously maintained walk-behind tractor, which has served for several years, suddenly loses its power.

— If power has dropped after long-term storage, the walk-behind tractor may have been stored with a wet carburetor and fuel system, which led to sediment accumulation. In this case, you can start the engine and let it run, this will often restore power. If you have the skills, you can disassemble and clean it; if you don’t have the skills, it’s better to contact the service.

— The carburetor is probably clogged. clean

— The gasoline hose is clogged. Need to blow.

— Possible loss of performance of the crankcase cuff. Remove the gearbox housing and cover and inspect the cuff.

— Carbon deposits on the cylinder, muffler. Clean.

— The air filter is clogged. Clean.

- Without compression. Change piston rings, cylinder, piston.

Engine won't start

— If the engine is tilted, they should be positioned horizontally.

— Fuel may not be supplied to the carburetor. It is necessary to disassemble and pass through the fuel system.

Motoblock "Ugra" engine "Lifan". smoke like 2x tactician

There is no smoke from the walk-behind tractor.

Lifan LIFAN smoke engine, causes, heated carburetor.

The engine, after repair and adjustment, worked fine for an hour. An hour later he started smoking and 20 minutes later.

— The filter may be clogged. The filter needs to be replaced or cleaned.

— The outlet hole in the gas tank cap may be clogged. Needs cleaning.

- Maybe it's a candle. It is necessary to check the connection of the wires, the engine stop button, remove the spark plug and clean it. Replace if necessary.

- May refuse magneto. Replace.

Engine intermittent, stalls

— The engine is not warming up yet. Needs to be reheated

— Possible contamination of the spark plug. It is necessary to clean the candle by removing the deposit.

— The end of the wire is in weak contact with the spark plug. Press the end of the wire firmly onto the plug.

— Magnetic malfunction. Replace.

Unstable idle speed

— The gearbox cover may be too large. Make a gap 0.2-0.5

Motoblock foggy smoke

White smoke pours out of the walk-behind tractor and begins to work in a “chow”.

— It may be flooded with low-quality gasoline, or this is due to the strong tilt of the engine block. The oil from the crankcase slopes down and onto the valve until it burns, smoke pours out of the furnace. Also read the material “Repairing engine blocks”,

The starter screams, the cord comes out

- May scream if there is a lot of lube on the balls. It is necessary to clean the balls and the places in the ratchet where they are inserted.

The cultivator released several pops and began to “float”

- Most likely, the power system is not coping, or the fuel level in the tank is low, the float axis may be skewed and perhaps there is debris under the needle valve, you need to remove everything and check the air filter, jets.

The material will be updated, we will be waiting for questions, stories about the detection of a particular malfunction and ways to eliminate it. Also see Answers to questions about a particular walk-behind tractor model on its description page.

Repair: why the walk-behind tractor stalls under load, shoots into the muffler, works intermittently, and more

A walk-behind tractor is one of the most useful household units. Even a simple and not particularly powerful machine can make caring for your garden and surrounding area much easier. At the same time, a walk-behind tractor is a piece of equipment that tends to break down. Let's look at the most common breakdowns of an agricultural unit, their causes and methods of eliminating them on our own.

Why does the walk-behind tractor stall under load?

Almost every owner of a walk-behind tractor, regardless of the brand and model of the agricultural machine, has encountered a problem in which the walk-behind tractor starts and stalls after 5 minutes of operation. The main reasons for this breakdown lie in problems with the fuel supply and breakdown of the car’s ignition system.

As practice shows, if a walk-behind tractor stalls during operation, its owner should immediately inspect the parts of the fuel supply system. First of all, unscrew and look at the spark plug - if it is completely dry, this indicates that fuel is not getting into the engine cylinder.

After this, you need to make sure that there is a sufficient amount of fuel in the fuel tank. If there is gasoline and there is enough of it for work, inspect the fuel valve - it is quite possible that it is in the closed position.

To start the walk-behind tractor, just open the fuel tap and continue working with the unit.

Another reason why the walk-behind tractor starts up and then stalls after 5 minutes of operation is a breakdown of the ignition system. It is quite simple to determine that the unit is faulty for this very reason - look at the spark plugs - if they are wet, it means that the fault has appeared in the ignition system of the walk-behind tractor. The best way out of this situation is to re-adjust the unit’s ignition system. All actions must be performed in this order:

- Remove the cover that protects the elements of the ignition system;

- Turn the motor flywheel until the contacts in the magneto open;

- Using a special feeler gauge, measure the gap between the “anvil” and the “hammer” of the walk-behind tractor’s ignition system;

- After this, turn the flywheel until the piston of the walk-behind tractor compresses. In this case, the latter must reach its highest point;

- Turn the flywheel again until you hear a characteristic knock - this means that the overrunning clutch has engaged;

- Then turn the flywheel in the opposite direction so that the mark on it coincides with the mark on the walk-behind tractor body;

- Set the gap between the interrupting contact and the cam - it should be 0.3 mm;

- At the end, fix the cam with a screw located on top of the part and install the protective cover back into the walk-behind tractor body.

After the above steps, the walk-behind tractor will no longer stall under load. The main thing when similar problems arise in the future is to try to fix the breakdown as quickly as possible, so as not to subject the main mechanisms of the walk-behind tractor to increased wear.

Also, the utility unit often stalls when tilted. This indicates an insufficient amount of fuel in the fuel tank. If you put the unit in a horizontal position, pull out the starter cable, and the engine starts, it means that you will need to add gasoline to the tank.

The walk-behind tractor starts and stalls - causes and repairs

Repairing walk-behind tractors if they start and, after a few seconds, stall, must begin by searching for the main causes of this malfunction. To do this you need to inspect:

- Plugs, wires and electrodes - in most cases, the unit starts and immediately stalls due to too large a gap between the electrodes of the ignition system, poor contact between the wires, and a dirty spark plug. Repairs should begin by cleaning the spark plug. If this does not help, then you need to check the integrity of the wires. If this does not bring the desired result, then you will need to re-adjust the gap between the electrodes of the ignition system;

- Carburetor for contamination and sufficient fuel supply - if you used low-quality gasoline and added too much motor oil to it, you will need to replace the fuel and reduce the amount of oil. In addition, you need to dismantle, disassemble, and thoroughly clean the carburetor;

- The presence of gasoline in the fuel tank - if the walk-behind tractor does not gain speed, this often indicates a lack of fuel necessary for the proper operation of the engine. Very often, owners of walk-behind tractors are faced with a problem in which gasoline spills through a small hole or crack in the fuel tank of the machine. In this case, you need to try to repair the defect, and if this fails, you will need to completely replace the walk-behind tractor tank.

Silencer for walk-behind tractor - manufacturing, shoots, flames, video

When a problem-free walk-behind tractor begins to act up, the owner falls into a kind of stupor and begins to look for the cause of the problems. The appearance of such a situation is doubly annoying when there is a lot of work and there is no time for downtime.

Often, troubles arise with the muffler, which, for certain reasons, begins to make strange sounds or even behave suspiciously. The main thing is not to panic, but to deal with everything with a cool mind. Let's get acquainted with several problems that occur most often.

The walk-behind tractor shoots into the muffler: what to do?

The owner of such useful and multifunctional equipment needs to know that interruptions in the operation of the muffler can occur due to:

- thin and low-quality metal;

- frequent potholes;

- excessive loads;

- difficult work;

- fastenings of an ill-conceived plan.

Often the cause of popping noises in the muffler are gaps in the process of supplying sparks and spark plugs. To get rid of the problem, you need to unscrew the spark plug, combine its body and mass, turning the crankshaft using the existing starting handle.

At the same time, you should pay attention to whether a spark appears. If even after these manipulations the situation does not change, it is advisable to thoroughly clean the spark plug.

Flame from the muffler of a walk-behind tractor and black smoke: looking for the cause and solution

Many experts believe that such problems arise due to incomplete combustion of fuel in the unit. It is possible that a misfire, the use of an overly rich mixture, a drop in power or overheating may be detected.

If, after trying to start work, not only a flame appears, but also black smoke, then we are talking about the use of low-quality oil or seriously contaminated injectors. Naturally, it is advisable to purchase a higher quality lubricant and thoroughly clean the injectors of all excess.

When a muffler, in addition to the indicated points, also produces serious noise, and a person wants to make it quiet, then it is necessary to increase the weight of the parts, because such problems often arise due to the lightness of the components.

You can get acquainted with other problems that arise with silencers Neva, Centaur, Garden Scout, etc., as well as their solutions, thanks to the video below, where a specialist presents everything in an accessible way and gives answers to the most frequently asked questions.

Malfunctions of walk-behind tractors - why they stall, do-it-yourself repairs

The walk-behind tractor is a useful household unit that greatly simplifies land and house work. Like any other equipment, units can break down. But it is quite possible to repair a walk-behind tractor engine yourself, following simple recommendations.

Why does the walk-behind tractor stall under load?

A fairly common problem is that the equipment stalls after 5 minutes of operation. Often the reason is a fuel supply failure and ignition problems.

If the equipment stalls during operation, you need to check how well the fuel is supplied:

- The candle is taken out and examined. It is overdried - this indicates a lack of fuel;

- There must be enough fuel in the gas tank for the normal functioning of the machine;

- The condition of the fuel valve is inspected. It may simply be blocked. Sometimes it is enough to open it for further use of the unit.

The walk-behind tractor starts and stalls if there is a problem with the ignition. First you need to check the spark plugs. Wet elements indicate breakdown. It is necessary to re-adjust the ignition system of the equipment.

Resetting is done as follows:

- The cover is removed, which protects the parts of the ignition system;

- The engine flywheel rotates until the contacts in the magneto open;

- A special feeler gauge measures the gap from the “anvil” to the “hammer”;

- The flywheel rotates until the piston is compressed. The latter must reach its peak;

- The flywheel turns again until a characteristic knocking sound is heard, which will indicate the operation of the overrunning clutch;

- The flywheel turns in the other direction until the mark of this element coincides with the mark on the body of the unit;

- The gap from the interrupting contact to the cam is set to 0.3 millimeters;

- The cam is fixed with a screw, which is located above the element, and a protective cover is installed in the equipment body.

If the above steps are performed correctly, the walk-behind tractor will not stall under load. When tilted, equipment may stall if there is not enough fuel in the gas tank. The unit must be installed straight and the starter cable removed. If the engine starts, you need to fill the tank with fuel.

Why does the walk-behind tractor work intermittently?

There are other faults that are worth considering:

- The walk-behind tractor engine is running backwards. The reason is often the use of bad fuel. It will not be enough to replace the fuel. The pump and fuel supply hoses are washed;

- The equipment works in jerks. The engine does not warm up completely. You need to turn off the engine and wait for it to cool completely. Then restart it and warm it up for at least ten minutes;

- The engine does not pull, therefore the engine power decreases. The filter system is checked and cleaned. The problem can be caused by wear of the ignition magneto. In this case, the part is replaced.

Owners of both gasoline and diesel vehicles may encounter such problems. Regardless of the specifics of the breakdown, you must urgently stop using the unit and start fixing the problem.

Why does the walk-behind tractor shoot into the muffler?

Sometimes the operation of equipment is accompanied by unusual sounds from the muffler. The walk-behind tractor smokes and stalls. To eliminate such a malfunction, it is necessary to first determine what caused it.

Such problems may occur in the following cases:

- Excess motor oil in fuel. The remaining fuel is drained, the fuel pump and hose system are washed, and new fuel is added;

- Incorrectly set ignition. It is necessary to check how correctly the gap between the electrodes is set;

- The fuel in the engine cylinder does not burn completely. In this case, it is necessary to disassemble the piston system, thoroughly wash and dry the cylinder, and adjust the carburetor.

In the above cases, it is not difficult to repair walk-behind tractors yourself. It is important to strictly adhere to the algorithm of actions.

Why does the walk-behind tractor start and stall?

If the equipment starts and immediately stalls, this may indicate the following problems:

- There may be a large distance between the electrodes, problems with contacts in the electronics, or the spark plug may be dirty. First, the candle is cleaned. Then the integrity of the wires is checked. The normal distance between the electrodes is set;

- The carburetor may become dirty, too little fuel is supplied. Sometimes it is necessary to change the fuel and reduce the amount of oil. The carburetor is dismantled, disassembled and thoroughly cleaned;

- If the unit does not pick up speed, this indicates a lack of fuel. Gasoline may simply spill. The defect must be eliminated or the fuel tank replaced;

- The walk-behind tractor does not develop speed when the gearbox breaks down. This is indicated by the presence of extraneous sound from the gearbox. The malfunction can be eliminated by replacing the oil that lubricates the components.

Why does a walk-behind tractor engine have difficulty starting when hot?

The equipment may stall when heated. This problem can be resolved relatively easily. This is often caused by excess air being supplied to the carburetor. It is mixed with gasoline and motor oil and acts as a carburetor coolant. So the temperature of the latter is much lower than the temperature of the walk-behind tractor engine.

To fix the problem, you need to follow a certain algorithm. It is important to start the engine. To do this, perform the following steps:

- When starting the engine, the throttle trigger is squeezed halfway;

- You should not regularly press the gas trigger, as this may cause the engine to flood;

- After starting the engine with the throttle trigger pressed halfway, you need to throttle it thoroughly. Afterwards you can continue working.

Simple actions will prevent an increase in the load on a heated engine; the main elements and systems are not subject to increased wear. The listed methods will allow you to eliminate any malfunctions with the unit. They are equally effective for owners of the following brands: Agro, Honda, Neva, Cascade.

Source: https://sadovaja-tehnika.com/motobloki/neispravnosti/

Why does the engine smoke black and how to fix it?

Good afternoon. The topic of today's article is why does the engine smoke black smoke? The article discusses the main reasons for the appearance of black smoke in carburetor, injection and diesel engines, and also provides a troubleshooting technique.

Causes of black smoke.

For clarity, remember the Russian stove. If you close the ashpit before the wood burns out, large black coals will remain in the stove. If the stove burns out with the ashpit open, only gray ash will remain in it. The blower in a Russian stove regulates the ratio of air and fuel. If there is not enough air, there will be a lot of soot in the stove, and coals will remain; if there is enough air, the firewood will burn to ash, and the chimney will remain clean.

The situation is exactly the same with the internal combustion engine. It has an optimal air-fuel mixture. If there is more fuel in the mixture than necessary, some of it will inevitably not burn completely and will come out of the exhaust pipe as black smoke. Not only will the engine smoke, soot will clog the catalyst and contaminate the spark plugs! In any case, black smoke from the exhaust pipe is bad and its cause is always a rich air-fuel mixture.

In this article we look at the reasons why warm engines smoke. We have a separate article on our website about black smoke in cold weather.

Reasons why a carburetor engine smokes black?

The main problem for cars equipped with a carburetor power system is the inability of the carburetor to prepare the optimal combustible mixture in transient conditions and under heavy loads, but due to the simplicity of the design, they can be repaired on the knee.

For those who don’t know, a short video about how a carburetor works:

The carburetor prepares the fuel mixture for the engine.

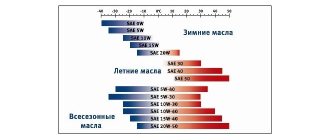

The optimal fuel mixture is 1 liter of fuel per 15 liters of air. Depending on the operating conditions of the engine, rich, enriched, normal and lean mixtures are used. For example:

— to start a cold engine, a rich mixture is used, since part of the fuel condenses on the walls of the cylinder and the intake manifold, as a result, the working mixture in the cylinder will be optimal for ignition.

— at idle, to ensure stable and uniform operation of the engine, an enriched mixture is used.

— in partial load mode (throttle opening up to 80%), a lean mixture is used, this is done for better fuel efficiency, since in which case the power can be increased by fully opening the throttle.

— in maximum power mode (throttle valve fully open), the optimal fuel mixture is used.

Lean and optimal mixtures burn with virtually no smoke! The rich mixture burns with visible black smoke, the rich mixture smokes like this:

Obviously, when the mixture is enriched, the carburetor is faulty or the air filter is catastrophically clogged.

A little theory about the design of the carburetor:

A modern carburetor is a rather complex mechanical device that combines several systems:

Idle system - prepares a rich mixture at low vacuum behind the throttle valve. The operation of this system is ensured by 2 jets - air and fuel; in fact, the idle system is a separate, simple carburetor.

Transition system - ensures that the engine operates during the transition from idle to partial load mode, before the main metering system begins to operate.

The main dosing system ensures the preparation of the mixture in all engine operating modes, except idle and transition mode. The main dosing system also includes an accelerator pump.

How to find out which carburetor system is faulty?

- If black smoke is observed both at idle and at rpm, the air filter is most likely clogged or the fuel level in the float chamber is higher than recommended.

- If black smoke is observed only at idle, either the air jet is clogged or the adjustments are out of order.

- If black smoke is observed while driving at medium speeds, it is necessary to check the main air and fuel jets

- If black smoke is observed when the throttle is wide open, the economizer system is faulty.

Any malfunction of the carburetor (except for smoking at idle) requires its disassembly and maintenance.

We agreed - we check the air filter, and if it is in order, we repair the carburetor.

Reasons why an injection engine smokes black?

The injector is nothing more than an electronic carburetor. If in the carburetor the composition of the fuel mixture changed due to mechanics and pressure drops, then in the injector this is done by electronics.

Our main assistant in diagnosing an injection engine is the “check engine” lamp on the dashboard. If this lamp on the dashboard lights up and black smoke is observed from the exhaust pipe, then you are on the right path to diagnosis. After diagnostics, you will recognize failed sensors and quickly restore the engine.

Everything becomes dramatically more complicated when the diagnostic lamp does not indicate a malfunction, and the engine smokes like a steam locomotive. In this case, the mechanical part has failed, and computer diagnostics will not yield anything; you will have to work with your hands.

How does the injector dose fuel?

An important part of the injector is the fuel rail with injectors. The rail maintains constant gasoline pressure (3.0 bar for most cars). Are the injectors opening? an electrical impulse for a calculated time and due to this, an exact portion of gasoline is injected.

The walk-behind tractor smokes white smoke, what to do - Special equipment

Like any equipment, the walk-behind tractor requires timely maintenance and repair. And it is advisable to entrust their implementation to specialists who have the necessary tools and equipment and know their job well.

However, if you are also familiar with the structure of internal combustion engines and understand the topic of mechanical engineering, then you can do a lot of what may be required to restore the machine’s performance on your own.

Why does the walk-behind tractor smoke black smoke?

Only the lazy did not see how our pride was going. The only and unsinkable aircraft carrier "Kuzya". He even walked across the English Channel without drowning! Holy shit! Well done, however! But there is one very noticeable problem. It smokes, it’s an infection! It smokes so much that the environmentalists from Greenpeace are all speechless at once! Our boat polluted the environment with its black smoke! It’s not clear why there is so much smoke. Not for them, not for me! There are many versions, but mine is cooler! Someone wrote, they say, the smoke is from old fuel, it burns out. Why is it not clear? But I think this smoke is for intimidation! A company of discharged sailors is sitting in the engine compartment, stocked up with a bag of selected hemp, and smoking, releasing smoke into the chimney, frightening the enemies! What a cunning move! They are scared, but we are thrilled! Well done to our strategists! All of Europe and America were scared! And now they are enjoying themselves on deck, sunbathing! Have you seen the photos of our sailors sunbathing on deck? This is a company that has given up its shift to another company. Then they will change again. These are in the engine compartment, and those are on the deck! My version is good and may well turn out to be plausible. One thing is not clear: Why is the smoke black? Who paints it in the pipe? Glory to the Russian fleet! Forever and at all times.

In this section we will analyze the malfunctions of walk-behind tractors and cultivators of all Salyut brands. Neva, Zubr, etc., and their removal and repair. Most problems are common to all types of engine blocks, their engines and other components.

Timing belt faulty and other reasons

Oil smoke can be caused by the following:

- Burnt or damaged valves.

- Worn valve stems and guides.

- Malfunctions in valve stem seals.

Why blue smoke is emitted on a warm engine can be explained by relying on the fact that the oil dilutes with increasing temperature of the internal combustion engine. The following example can be given. This can always be observed when tractors are operating.

It often happens that when the engine is idling, oil accumulates on parts, forming films, thereby accumulating in the exhaust system. Then when the tractor driver presses the gas pedal, the exhaust pipe splashes out thick blue smoke.

The fuel supply system may be faulty or the valves may not be tight. All this can cause a diesel unit to smoke blue. A burnt-out valve gives the exhaust gases a white-bluish tint. This valve defect can be traced to the low compression of the faulty cylinder. Plugs are also susceptible to carbon deposits and deposits, which will indicate this deficiency.

Turbine malfunctions are possible. They may resemble the symptoms of unhealthy valve stem seals. To make sure of this, you can probe the turbocharger pipes for the presence of oils. Turbocharger seal problems are more difficult to identify because the oil that enters the exhaust system burns completely.

Also, the causes of blue smoke may be malfunctions of the crankcase ventilation or problems with ignition in the cylinder. Very often, blue smoke is accompanied by a decrease in thrust, and atmospheric and turbo diesel engines may have seal leaks, etc.

It is worth noting that the reasons for this behavior of the car may be poor fuel quality. Therefore, you should only refuel from those companies that provide good quality fluids. Beware of gas stations that offer diesel fuel at a low price.

Engine power has dropped

It often happens that a previously maintained walk-behind tractor, which has served for several years, suddenly loses its power.

— If the power has dropped after long-term storage

, perhaps the walk-behind tractor was stored with a wet carburetor and fuel system, which led to sediment accumulation. In this case, you can start the engine and let it run, this will often restore power. If you have the skills, you can disassemble and clean it; if you don’t have the skills, it’s better to contact the service.

— The carburetor is probably clogged

. clean

— The gas hose gets clogged

. Need to blow.

— Possible loss of performance of the crankcase cuff

. Remove the gearbox housing and cover and inspect the cuff.

— Carbon deposits on the cylinder, muffler

. Clean.

- Without compression

. Change piston rings, cylinder, piston.

Malfunctions of gasoline and diesel garden walk-behind tractors

A garden walk-behind tractor is a very useful thing in the household. With a good walk-behind tractor, work on personal plots goes much faster. But walk-behind tractors, like other household equipment, sometimes break down.

The most common malfunctions of garden walk-behind tractors:

- the walk-behind tractor stalls under load;

- The walk-behind tractor works intermittently;

- the walk-behind tractor smokes, stalls, the muffler makes unusual sounds;

- the walk-behind tractor does not start;

- The walk-behind tractor starts, but quickly stalls;

- The walk-behind tractor stalls when it heats up.

Malfunction: walk-behind tractor stalls under load

If the walk-behind tractor operates normally for a few minutes and then stalls, the cause is usually a failure in the fuel supply or problems in the ignition system.

To find out what is the cause of the malfunction of the walk-behind tractor, you must first check how the fuel is supplied:

- take out the spark plug and inspect it - if it is dry, it means there is not enough fuel;

- check whether there is enough fuel in the gas tank of the walk-behind tractor;

- make sure that the fuel tap is open - a closed tap can be a simple reason that the walk-behind tractor stalls.

If the problem is a malfunction of a gasoline walk-behind tractor in the ignition system, it must be re-adjusted as follows:

- remove the cover protecting the ignition system;

- turn the engine flywheel until the contacts in the magneto open;

- using a feeler gauge, measure the distance from the anvil to the hammer;

- turn the flywheel until the piston is compressed to maximum;

- turn the flywheel again until a knock appears, indicating the operation of the overrunning clutch;

- turn the flywheel in the other direction so that its mark coincides with the mark on the body of the walk-behind tractor;

- set the distance from the interrupting contact to the cam to 0.3 mm;

- fix the cam with the screw located above the element;

- install the cover into the walk-behind tractor body.

If the adjustment is made correctly, the walk-behind tractor will not stall during operation.

Malfunction: the walk-behind tractor operates jerkily, intermittently or at reduced power

If a walk-behind tractor with a gasoline or diesel engine begins to work intermittently, you must immediately turn off the unit and begin troubleshooting.

Continuing to work with a faulty walk-behind tractor means leading it to more serious breakdowns.

What to do:

- if the engine of a gasoline walk-behind tractor makes reverse movements, it is necessary to rinse the pump and hoses for supplying fuel and replace the fuel with a higher quality one;

- when the walk-behind tractor operates jerkily due to incomplete warming up of the engine, you need to turn off the engine, let it cool completely, start it and warm it up for ten minutes;

- if engine power has dropped, you need to check and clean the filter system;

- If the ignition magneto wears out, the part must be replaced with a new one.

Malfunction: the walk-behind tractor smokes and stalls, the muffler makes unusual sounds

Possible causes of the malfunction:

- too much motor oil in the fuel;

- the ignition is set incorrectly;

- The fuel in the engine cylinder does not burn completely.

Troubleshooting methods:

- if there is excess oil, drain the fuel, flush the fuel pump and hose system, and add new fuel;

- check that the gap between the electrodes is set correctly;

- if it becomes obvious that the fuel is not completely burned, disassemble the piston system, wash and dry the cylinder, and adjust the carburetor correctly.

Malfunction: the walk-behind tractor starts, but quickly stalls

This malfunction occurs if there are problems with the contacts. What to do:

- clean the candle;

- check the integrity of the wires;

- set the correct distance between the electrodes.

Malfunction: the walk-behind tractor stalls when heated

This problem occurs due to excess air entering the carburetor. In case of such a malfunction, the throttle trigger should be squeezed halfway. After starting the engine, you need to give it a good gas before starting work.

If you cannot cope with the malfunctions of the garden walk-behind tractor, the walk-behind tractor stalls, the walk-behind tractor does not start, contact the Alfa-Rost walk-behind tractor repair shop in Rostov-on-Don. We guarantee high-quality repairs of gasoline walk-behind tractors using original components, which are always available in our warehouse.

Source: https://alfa-rost.ru/neispravnosti-motoblokov-i-sposoby-ih-remonta/

Lifan LIFAN smoke engine, causes, heated carburetor.

The engine, after repair and adjustment, worked fine for an hour. An hour later he started smoking and 20 minutes later.

— The filter may be clogged

. The filter needs to be replaced or cleaned.

— The outlet hole in the gas tank cap may be clogged

. Needs cleaning.

- Maybe it's a candle

. It is necessary to check the connection of the wires, the engine stop button, remove the spark plug and clean it. Replace if necessary.

- Can refuse magneto

. Replace.

Blue or gray

The main reason why the engine of a vibrating plate or walk-behind tractor smokes blue or gray is oil getting into the cylinder. The color of the smoke can vary from thick white to transparent blue.

First of all, you need to check the type of oil that was poured into the vibrating plate. Perhaps oil for two-stroke engines was filled in, which caused increased smoke. Please note that the oil level should not exceed the maximum level, this may also cause oil to enter the cylinder.

The difference between white smoke and steam is that steam dissipates much faster than smoke. Oil smoke also increases oil consumption. There are several other reasons why oil gets into the engine:

1. Wear of piston group parts

The most common reason. Wear occurs on the piston rings, cylinder liner, and piston grooves. Due to the gaps in the piston grooves, a pump effect occurs that pumps oil into the cylinder. Also, changing the shape of the rings worsens their properties, creating gaps. Loss of compression is added to these malfunctions.

2. Breakage of the bridges between the piston grooves, “occlusion” of the piston rings

The cause of this malfunction is engine detonation or overheating. As a rule, engines installed on vibrating plates are conventional four-stroke, single-cylinder, air-cooled engines. When working with a vibrating plate, it is necessary to take short breaks, for example after every hour of work, so that the engine has time to cool down.

The need for breaks is especially important in hot weather, when the air temperature is more than 25 degrees C. The key to long-term operation of the vibrating plate is the correct running-in of the new engine. If you start using the vibrating plate without running it at full power, you can damage the engine.

3. Use of low-quality oil and late maintenance

This is a fairly common cause of oil getting into the cylinder. Old oil burns, causing the rings to lie in the grooves, losing their elasticity.

4. Aging of valve stem, oil cap and bushing

These defects cause the engine to smoke after warming up, because the heated oil becomes more liquid and penetrates through the gaps more easily.

5. Lack of valve tightness

If such a defect is present, it is very easy to recognize. The smoke acquires a white-blue tint and occurs during operation. There is practically no compression in the cylinder; strong black carbon deposits can be observed on the spark plug, possibly in the form of growths.

In any case, if blue smoke appears from the vibrating plate, it is necessary to measure the compression in the engine. If compression is normal, GlavTraktor recommends:

— change the oil in the vibrating plate, choose high-quality oil specifically for this engine.

— Replace the spark plug. Perhaps the old spark plug is not working properly.

— check the purity of gasoline; if foreign particles are detected, completely drain the old fuel and refill with new one.

— remove the muffler from the engine and wash it with gasoline. It is possible that during the operation of the vibrating plate, a one-time penetration of oil into the cylinder and then into the muffler occurred. Even a small amount of oil that gets into the muffler can burn out and smoke for a very long time.

During operation of the vibrating plate, you should pay attention to changes in its operation, because at first glance, insignificant moments, in the form of uncharacteristic smoke, sound or oil leakage into the exhaust system, may indicate a serious engine malfunction.

Technical characteristics of the stacker: load capacity 1400 kg, lifting height 5350 mm, fork free travel 1761 mm, battery capacity 375 Ah, Aquamatic.

Load capacity 1000 kg, lifting height 3260 mm, mast with free-lift forks, built-in charger - these are the main characteristics of the Yale MS10E electric stacker.

The GlavTraktor company has expanded its range of construction equipment for rent. Now you can rent optical levels and theodolites at reasonable prices for a period of 1 day.

Malfunctions of the walk-behind tractor engine during operation

The units and components of motors that are installed on mini-agricultural equipment are subject to significant loads. They can also fail during operation of the unit, which will very quickly lead to serious failures.

If you detect suspicious noises, jerks and disturbances in the operation of the walk-behind tractor systems, it is very important to immediately turn off the engine and then let it cool down - only after that will it be possible to fix the problem.

If during operation the motor begins to gain speed on its own, i.e. is “peddling”, most likely this means that the fastening of the regulator and thrust levers has become loose. In this case, the user will have to readjust the motor control drive.

Sometimes, when the throttle is fully open, the engine does not accelerate when the throttle is pressed, but rather begins to lose power until it comes to a complete stop. This is a clear sign of overheating, so you need to turn off the walk-behind tractor and wait until its components have completely cooled down. After this, you should check the oil level in the crankcase, and also check the cleanliness of the finned surfaces of the blocks and cylinder heads.

Under increased loads on the engine, it may seize. There may be several reasons for this:

If the motor of a walk-behind tractor is jammed, you will have to disassemble it and check the condition of the main components and components: faulty, deformed, melted, etc. subject to replacement.

The starter screams, the cord comes out

- May scream if there is a lot of lube on the balls. It is necessary to clean the balls and the places in the ratchet where they are inserted.

The cultivator released several pops and began to “float”

- Most likely, the power system is not coping, or the fuel level in the tank is low, the float axis may be skewed and perhaps there is debris under the needle valve, you need to remove everything and check the air filter, jets.

The material will be updated, we will be waiting for questions, stories about the detection of a particular malfunction and ways to eliminate it. Also see Answers to questions about a particular walk-behind tractor model on its description page.

Prerequisites for smoke in the common rail system. Many articles have already been written about the smoke in diesel engines, so we would like to address the smoke in turbodiesel engines running under common rail accounting software. How can diesel smoke

Rich black smoke is a consequence of incomplete combustion of fuel.

There are several circumstances that you will like better, this is the wrong injection time - which is practically unrealistic for a common rail, the wrong injection quantity, the wrong injection pressure, incorrect atomization conditions, incorrect combustion conditions, lack of air. You will like the bluish and grayish smoke of unburned fuel due to a lack of compression, low pressure in the fuel line or severe wear of the injector nozzles. Snow-white smoke (steam) is the entry of antifreeze into the combustion chamber. Let's look at these prerequisites in more detail. Incorrect injection time on the common rail system is impossible, because the injection time is controlled by the system control unit, and it takes data from the crankshaft and camshaft position sensors, however, in some cars an error is likely. For example, a Hyundai Starex with camshafts positioned 90 degrees earlier than the crankshaft arrived on our website, but the system continued to work. Such a malfunction will be the cause of completely different smoke and other symptoms, alas, the first symptom is obviously incorrect operating sounds, a sharp decrease in power and problems with starting.

A prerequisite for an incorrect amount of injected fuel may be a mechanical or electrical malfunction of the injectors, injection pressure regulator, fuel pressure sensor or ECU (electrical control unit) of the engine. Injectors come in variations of “pouring” due to wear or mechanical damage to the nozzle and/as it is also called the valve. This malfunction is accompanied by knocking noises when the engine is running; most of the knocking noises are heard when operating in the operating load version mode. And then we advise you to contact our specialists for the diagnosis and repair of injectors and the common rail itself.

A faulty pressure regulator can maintain very high pressure in the fuel line, which is why a lot of fuel is injected, and a faulty pressure sensor is also a reason for high pressure. A malfunction associated with high pressure can be detected by the corresponding harsh “early” sound of the engine and black smoke in the exhaust. Incorrect spray conditions occur due to the incorrect position of the atomizer in the combustion chamber, for example, if the nozzle is installed on a sealing washer that is not of suitable thickness, as well as its called for 5 pucks. Because of this, the nozzle sprays fuel not into the combustion chamber, into the well of the atomizer, and the correct spray does not come out. Under such conditions, abundant black smoke and knocking are likely. Incorrect combustion conditions are insufficient compression of the fuel-air mixture - low compression, very high compression, lack of air. With low compression, the engine is difficult to start, power is lost, smoke is likely, when cool it turns gray (unburned fuel), and under load it turns black. When the compression is too high, the engine runs noisily with detonation knocks, starting in hot weather is difficult (can’t be cranked with the starter), such a malfunction occurs very rarely, usually associated with an error during engine assembly. If there is a lack of air, for example, with a faulty turbine (turbine control) or an unsealed intake tract, black smoke comes out under load, and the engine also significantly loses power.

Walk-behind tractor engine is difficult to start when hot

The question of why the motor of a walk-behind tractor stalls when heated is quite simple to solve. The whole essence of the problem lies in the excess air supplied to the carburetor of the walk-behind tractor. Part of it is mixed with a mixture of gasoline and motor oil, and the second part cools the carburetor. As a result, the carburetor temperature becomes much lower than the temperature of the unit’s engine. This problem is observed only during the operation of the walk-behind tractor. When its engine is turned off, the carburetor, on the contrary, is heated by the hot walls of the engine.

As the carburetor of the walk-behind tractor heats up, the remaining fuel begins to actively evaporate, filling all the voids in the walk-behind tractor, including the air filter and the intake manifold. This leads to the complete disappearance of fuel, which is why the walk-behind tractor will not start when the engine is hot.

To fix this problem, it is necessary to follow a certain algorithm every time you start the walk-behind tractor “hot”. Your main task is to ensure that the mixture combines so that the engine can start. To do this you will need:

- When starting a hot engine, squeeze the throttle trigger halfway;

- Do not try to press the gas trigger over and over again, otherwise you will only aggravate the situation, since when you press the gas trigger frequently, the fuel pump will supply new portions of fuel to the carburetor, which will lead to flooding of the engine;

- After several attempts to start with the gas trigger pressed halfway, you will start the engine of the walk-behind tractor, after which you will need to rev it up 2-3 times and continue working.

This procedure will eliminate the increased load on the hot motor, due to which the main parts and mechanisms of the walk-behind tractor will not be subject to excessive wear.

All of the above methods will help to effectively cope with typical breakdowns of the most famous manufacturers of walk-behind tractors. They are equally successfully used by owners of agricultural implements of the Honda, Agro, Cascade and Neva brands.

In this section we will analyze the malfunctions of walk-behind tractors and cultivators of all Salyut brands. Neva, Zubr, etc., and their removal and repair. Most problems are common to all types of engine blocks, their engines and other components.