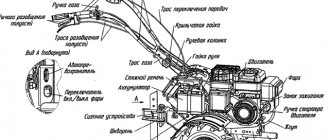

Starter for walk-behind tractor

The starter for the walk-behind tractor is responsible for starting the engine.

With its help, the engine starts properly and quickly. Many walk-behind tractors operate on manual starters. But it is possible to independently replace a manual starter with an electric one. To do this, you should follow a simple scheme. A simple algorithm will allow even a novice farmer to complete all installation work. To ensure proper operation of the starter, it is necessary to regularly perform preventative maintenance. Simple steps will keep the entire unit in good working order. The equipment will last longer and work smoothly.

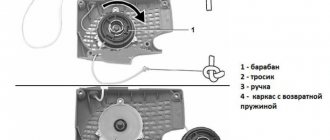

Motoblock starter device

All models of equipment have differences in design and are equipped with special mechanisms.

The latest equipment is equipped with two starters. A spring starter promotes faster starting of the main starter. The key mechanism is the manual starter, which is responsible for the movement of the motor. The design consists of the following parts:

- drum body;

- washers;

- large and small springs;

- coils;

- reeds;

- cord;

- fastening elements.

A reel with a wound cord is attached to a body with a drum.

There is a spring in the drum chamber that allows the mechanism to return to its original position after the cord is pulled out to its full length. Some models have starters with an electric ignition system. The electric starter for the walk-behind tractor is powered by a battery. Its capacity determines how long the engine starting mechanism can function.

A manual kickstarter, as well as an electric starter for a walk-behind tractor, are characterized by increased reliability, they are durable and resistant to various external influences.

Starters on walk-behind tractors:

- Spring-loaded. It is easy to install, it starts quickly - you just move the handle of the walk-behind tractor. The spring operates semi-automatically, its task is to accelerate the motor. All actions can be completed in two hours;

- Electric. This type of starter is powered by a rechargeable battery. The power of the mechanism and the duration of its operation depend on it.

It is important to understand that not all equipment with a manual release can adapt to the operation of an electric starter. Therefore, before starting replacement work, it is necessary to pay attention to the structural features of the unit.

Owners of walk-behind tractors can use the equipment with confidence. For a long time it does not need repair work. But it is important to periodically lubricate the parts, check them for serviceability, and control the force of the jerk. Simple maintenance will ensure a high degree of performance and a long service life of the unit.

Algorithm of actions: how to install a starter on a walk-behind tractor

Even novice operators can dismantle, disassemble and install the recoil starter.

But assembling and installing an electric starter is more difficult. If the repair procedures are performed incorrectly, the engine will not start. To install the starter on a walk-behind tractor with your own hands, you should follow these steps:

- To mount and secure the crown of the unit, the flywheel is removed. The air filter is removed from the unit to gain unhindered access to the external parts of the walk-behind tractor;

- The protective casing is removed, the screws that hold the recoil starter basket are unscrewed, and the flywheel is also completely dismantled. To avoid problems when removing the latter, it is worth acquiring a special removable key. After the flywheel is removed, you must unscrew the key located near it;

- The next step is to install the generator. The wires are pushed into the hole through the steel wall of the engine, the generator itself is installed in a specially designated place;

- Generator magnets are installed inside the flywheel; it is important that the holes on both parts match. The elements are connected with screws. Afterwards, the crown is installed, which is preheated with a special canister burner;

- The assembled system is reinstalled on the motor, and the keys are screwed in;

- The recoil starter basket is screwed in, the casing is secured and the air filter is mounted back;

- The starter mounting plug is removed and the starter itself is installed to the walk-behind tractor;

- The generator wire is connected to the charging station;

- The starter terminals are connected to the battery. Now you can start the walk-behind tractor.

Obviously, installing a starter yourself will not take much effort and time. It is important to strictly follow all rules and advice when carrying out repair work. The above algorithm of actions is relevant for mounting the starter on walk-behind tractors Neva, Agro, Cascade, as well as models from other manufacturers. Before you begin reinstallation, you need to make sure that your walk-behind tractor can work with a different type of starter.

Installing a starter on a walk-behind tractor

There are different designs of starters:

The most common is a manual starter for a walk-behind tractor, since this device is very easy to install on a walk-behind tractor, and its repair is easy to do yourself. If such a device is operated correctly, its durability is several years.

Let's look at what elements a starter for a walk-behind tractor consists of:

- a drum-shaped body;

- springs: large and small;

- washers;

- coil;

- cord;

- reeds;

- fastening parts.

In the center of the drum there is a reel on which the cord is attached. A large spring is located in the housing around an axis and is designed to return the reel to its original position after scrolling.

The mechanism of this device is quite simple; you can assemble it yourself.

The operation of a walk-behind tractor with a manual starter is carried out as follows. The driver starts the mechanism by pulling the handle of the device. At the same time, the device begins to work and starts the engine. In order for the device to successfully transfer the initial rotation to the motor, the handle of the device must be pulled twice.

Clutch

The transmission is a part of the Cascade walk-behind tractor, which is designed to transmit rotation from the engine to the shaft, and from it to the attachments.

The transmission of the Cascade walk-behind tractor consists of a clutch, gearbox, differential and final drive.

The most common problem is clutch adjustment.

If the Cascade walk-behind tractor “drives” during operation (the lever is fully pressed, but the machine is trying to move forward), then the adjusting screw should be tightened a little.

If the clutch slips (in other words, when the clutch is fully released, the device does not move, or produces a low number of revolutions), then it must be loosened.

After final adjustment, the clutch screw should be securely fixed so that during operation it is in one position and does not move.

If this does not help, then the problem may be in the flywheel. This is a device that transmits torque from the starter to the crankshaft.

Assembling and installing the flywheel clutch:

The most common wear is observed on the flywheel teeth. This is exactly the part that engages with the shaft and transmits rotation. And their teeth periodically break off.

Therefore, instead of replacing the entire flywheel, you can simply repair it by replacing the crown. This work should only be carried out in workshops.

How to repair a motor cultivator starter yourself

Let's look at how to repair a walk-behind tractor starter with your own hands. Before you start repairing a recoil starter, you need to find instructions for its operation, which contains a diagram of the device. Then you need to prepare a wrench to unscrew the mechanism.

Before dismantling the device, you need to photograph it so that you can then correctly assemble all the parts and components.

After this, unscrew the washer, which is located in the middle of the body. Having opened the lid, you need to carefully inspect all the parts that are located inside the drum and determine which of them are damaged. It is necessary to inspect small parts very carefully and carefully so as not to accidentally damage or lose them.

In most cases, repairing a kickstarter on a walk-behind tractor involves updating components that have failed. For example, the starter cord is replaced if it is torn or frayed.

If a large spring fails, you need to remove it from the drum. There are usually hooks at the spring attachment points. If the design does not have them, then you need to heat the ends of the spring and bend them in the desired direction. If the spring is completely out of order and there is severe metal fatigue, then there is no need to try to restore functionality to such a spring. In this case, it is best to replace it with another one. After this, we install the device in its place.

In addition to the manual starter, there are also spring and electric starters for walk-behind tractors. The spring mechanism has a simple design and starts easily. The device starts up after moving the handle of the cultivator. Acceleration of the motor occurs through semi-automatic operation of the spring. You can replace a manual starter with a mechanical one yourself.

The electric starter of the walk-behind tractor is connected to the battery, from which it receives power. Electric start of the device is carried out using the start button. The battery determines the power of the electric starter and the operating time of the device. Installation of the electric starter is carried out according to the electrical diagram of this design. A walk-behind tractor with an electric starter is durable, reliable, and has a long service life.

Unfortunately, not all designs of motor cultivators with a manual mechanism can be converted into a spring or electric one. Therefore, before starting work on replacing the manual mechanism, you need to study the instructions and capabilities of the walk-behind tractor and find out whether such a modification is possible.

Farmers should know that all motor cultivators are working properly when starting out. Gradually, various components of the assembled unit fail. In order to extend the life of the walk-behind tractor and all its parts and components, regular inspection of the mechanism and proper care of it are necessary. All units and components must be periodically lubricated with machine oil and checked for their functionality. To increase the productivity of the cultivator and extend its service life, constant proper care of this equipment is necessary.

What is an MTZ starter?

Gasoline starters at MTZ are of the PD-10 type. When it starts, the gearboxes begin to transmit torque to the power unit, spinning it up gradually. The advantage of a gasoline device is its unpretentiousness, the ability to use low-quality fuel for work, which does not affect performance at all.

An electrical device is also installed on the MTZ-80, the power of which is supplied through a special mechanism connected to the battery. Typically, this type is needed for tractors with powerful engines designed to perform long-term loads and constant work. Electric requires a mandatory connection to the motor so that the clutch can transmit torque to the flywheel.

Thus, which starter is better to install on MTZ, the tractor owner must choose independently. Modernization depends on the types of work performed and the technical characteristics of the machine itself. Climatic and weather conditions are also important. In the warm season or in regions where there is a lot of sun, a not very powerful motor is needed. Therefore, for winter it is recommended to use a regular gasoline type PD-10, and in summer it is preferred to replace it with an electric one.

Important Classification of tractor traction classes

Motoblock starter device - what does the mechanism consist of?

A modern starter for a walk-behind tractor consists of several important elements.

Its design includes:

- durable body, shaped like a drum;

- small and larger spring;

- washer and surrounding tabs;

- fasteners;

- reel and durable cord.

In the central part of the starter drum there is a reel on which the starter cord is tightly wound. A large built-in ring-type spring is located around the axis of the drum and is responsible for constantly returning the used drum to its original position after unwinding.

The starter for the walk-behind tractor works on a fairly simple principle. When the operator pulls the cord of the mechanism, the reel unwinds and transmits the force of its rotation to the motor of the unit. In this case, it is optimal to start the engine by pulling the cord twice.

Types of starters for walk-behind tractors - description and features

Commercially available starters for mounting on walk-behind tractors are divided into several types. Among them, the following types of mechanisms stand out:

- spring starters - mechanisms of this type are very popular due to their quick start properties, which was achieved thanks to the presence of a semi-automatic spring in its design. The spring starter is very easy to install - replacing a worn mechanism with a new one will take no more than 2 hours;

- electric starters - these mechanisms operate from built-in batteries. The charge capacity of the latter determines the power parameters of the electric starter. At the same time, an electric starter for a walk-behind tractor is not suitable for every model of agricultural implement. In this regard, before replacing the manual mechanism with an electric starter for a walk-behind tractor, you should study the manufacturer’s recommendations and the suitability of the element for the unit on the farm.

Self-repair of starter - algorithm in detail

Over time, the manual starter of the walk-behind tractor used often fails. In this case, the mechanism will need to be dismantled for repair or complete replacement of broken elements. In order to avoid mistakes when removing the starter, you will need to use the diagram from the walk-behind tractor manufacturer.

Repair of a walk-behind tractor starter is performed in the following sequence:

- There is a washer located in the central part of the starter drum. It will need to be unscrewed first;

- Carefully disconnect the starter housing cover, after which you need to inspect all the spare parts of the mechanism for damage;

- The kickstarter of a walk-behind tractor consists of a lot of small parts - it is very important not to lose them during repairs. To do this, all the elements should be laid out on a piece of old newspaper or fabric;

- Most often, starter repair involves replacing worn parts. In this case, the length and width of new spare parts is of great importance. If they are too large, the housing lid will not close and the walk-behind tractor will not start;

- Very often the large spring in the starter design must be replaced. At its ends there are special hooks, with the help of which the part clings to other elements of the mechanism. When replacing the spring, be extremely careful not to damage the hooks.

Replacing failed starter parts is not a complicated procedure. The main thing during repairs is not to try to restore the original form and functionality of heavily worn parts, otherwise the use of a walk-behind tractor with such parts will lead to accelerated wear of other important mechanisms of the agricultural machine.

Prevention

Selecting and installing a starter is only half the job. If you want the purchased part to work for as long as possible, you need to pay close attention to caring for it. New things always work well. For example, a factory starter requires only one pull to start the engine. However, after a year of active use, the situation will certainly change. To prevent such problems from occurring, you need to constantly lubricate before starting. In addition, you should not overdo it when pulling on the handle, as this can cause mechanical failure.

If the kickstarter fails, repairs usually involve updating the components that have stopped working. For example, the cord is replaced if it is frayed, and the spring from the MB-1 can be refilled only if there are problems with its operation.

Thus, the starter is an irreplaceable part that ensures the operation of the walk-behind tractor. In the selection process, you need to pay attention to the manufacturer, compatibility with the walk-behind tractor itself and the type of model. In addition, you need to pay attention to constant care of the starter, which will avoid breakdowns and rapid failure during active use.

To learn how to prevent starter operation, watch the video below.

All rights reserved, 14+

The use of any materials without our prior written consent is prohibited.

How to install a starter on a walk-behind tractor - the correct procedure

Even a beginner can remove the electric starter from the walk-behind tractor in order to further repair the broken mechanism. However, many novice farmers usually have problems installing the starter back onto the unit with their own hands. Due to improper installation, the starter does not start the walk-behind tractor engine even after several strong jerks. To avoid common mistakes, you should study the algorithm for installing a starter on a walk-behind tractor in more detail.

Installation of the starter should be done in this order:

- First you need to remove the flywheel - this will be required to install and fix the crown on it. To dismantle the flywheel, you need to dismantle the air filter, which will give free access directly to the internal structure of the walk-behind tractor on the farm;

- Then you will need to remove the protective casing and unscrew the screws that secure the starter mechanism basket, flywheel and its nut. Removing the flywheel, as a rule, causes certain difficulties, and therefore many experts advise purchasing a removable key immediately before repairing the walk-behind tractor. As soon as the flywheel is dismantled, you should unscrew the key, which is located immediately behind the flywheel;

- After this, the generator should be installed. The wiring in it must be inserted into a hole located in the metal wall of the engine. The generator will then need to be secured in place on the motor wall;

- Next, generator magnets must be installed inside the existing flywheel. In this case, all existing holes in the flywheel and generator must match. Both elements will need to be connected with fasteners, after which the crown of the walk-behind tractor used will be installed. Immediately before installing the crown, it must be heated using a spray burner;

- The assembled mechanism must be installed on the motor of the walk-behind tractor, simultaneously screwing in the nut and key of the flywheel;

- Next, you need to screw in the starter basket, fix the casing and firmly install the standard air purification filter in its regular place;

- Then you will need to remove the plug and install the starter itself on the engine;

- Next, you will need to connect the generator wiring to the charging relay;

- At the final stage, the starter terminals must be connected to the walk-behind tractor battery and the unit must be started.

Installing a starter on an existing walk-behind tractor is not as difficult as it seems at first glance. The most important thing is to be as careful as possible and adhere to the correct assembly algorithm.

All of the listed methods for repairing a starter are suitable for owners of Neva, Cascade and Agro walk-behind tractors. The procedure for removing and reassembling the mechanism will be similar for agricultural machines of all listed equipment manufacturers.

Starter for walk-behind tractor - design, types, repair, installation

The starter is the mechanism responsible for starting the walk-behind tractor. The ability to use agricultural machinery in certain weather and operating conditions directly depends on the serviceability of the starter.

Sooner or later, even the most reliable starter for a walk-behind tractor becomes unusable.

In order to be able to repair or replace it yourself, you must adhere to the correct procedure - this will be the key to the proper operation of the walk-behind tractor in the future.

Motoblock starter device - what does the mechanism consist of?

A modern starter for a walk-behind tractor consists of several important elements.

Its design includes:

- durable body, shaped like a drum;

- small and larger spring;

- washer and surrounding tabs;

- fasteners;

- reel and durable cord.

In the central part of the starter drum there is a reel on which the starter cord is tightly wound. A large built-in ring-type spring is located around the axis of the drum and is responsible for constantly returning the used drum to its original position after unwinding.

The starter for the walk-behind tractor works on a fairly simple principle. When the operator pulls the cord of the mechanism, the reel unwinds and transmits the force of its rotation to the motor of the unit. In this case, it is optimal to start the engine by pulling the cord twice.

Types of starters for walk-behind tractors - description and features

Commercially available starters for mounting on walk-behind tractors are divided into several types. Among them, the following types of mechanisms stand out:

- spring starters - mechanisms of this type are very popular due to their quick start properties, which was achieved thanks to the presence of a semi-automatic spring in its design. The spring starter is very easy to install - replacing a worn mechanism with a new one will take no more than 2 hours;

- electric starters - these mechanisms operate from built-in batteries. The charge capacity of the latter determines the power parameters of the electric starter. At the same time, an electric starter for a walk-behind tractor is not suitable for every model of agricultural implement. In this regard, before replacing the manual mechanism with an electric starter for a walk-behind tractor, you should study the manufacturer’s recommendations and the suitability of the element for the unit on the farm.

Each of the listed types of starters has a reliable design and long service life.

However, it should be understood that without regular inspection and timely application of lubricant to the rubbing parts of the starter used, the mechanism will quickly fail.

This will lead to breakdowns of other elements and mechanisms of the walk-behind tractor.

Self-repair of starter - algorithm in detail

Over time, the manual starter of the walk-behind tractor used often fails. In this case, the mechanism will need to be dismantled for repair or complete replacement of broken elements. In order to avoid mistakes when removing the starter, you will need to use the diagram from the walk-behind tractor manufacturer.

Repair of a walk-behind tractor starter is performed in the following sequence:

- There is a washer located in the central part of the starter drum. It will need to be unscrewed first;

- Carefully disconnect the starter housing cover, after which you need to inspect all the spare parts of the mechanism for damage;

- The kickstarter of a walk-behind tractor consists of a lot of small parts - it is very important not to lose them during repairs. To do this, all the elements should be laid out on a piece of old newspaper or fabric;

- Most often, starter repair involves replacing worn parts. In this case, the length and width of new spare parts is of great importance. If they are too large, the housing lid will not close and the walk-behind tractor will not start;

- Very often the large spring in the starter design must be replaced. At its ends there are special hooks, with the help of which the part clings to other elements of the mechanism. When replacing the spring, be extremely careful not to damage the hooks.

Replacing failed starter parts is not a complicated procedure. The main thing during repairs is not to try to restore the original form and functionality of heavily worn parts, otherwise the use of a walk-behind tractor with such parts will lead to accelerated wear of other important mechanisms of the agricultural machine.

How to install a starter on a walk-behind tractor - the correct procedure

Even a beginner can remove the electric starter from the walk-behind tractor in order to further repair the broken mechanism.

However, many novice farmers usually have problems installing the starter back onto the unit with their own hands.

Due to improper installation, the starter does not start the walk-behind tractor engine even after several strong jerks. To avoid common mistakes, you should study the algorithm for installing a starter on a walk-behind tractor in more detail.

Installation of the starter should be done in this order:

- First you need to remove the flywheel - this will be required to install and fix the crown on it. To dismantle the flywheel, you need to dismantle the air filter, which will give free access directly to the internal structure of the walk-behind tractor on the farm;

- Then you will need to remove the protective casing and unscrew the screws that secure the starter mechanism basket, flywheel and its nut. Removing the flywheel, as a rule, causes certain difficulties, and therefore many experts advise purchasing a removable key immediately before repairing the walk-behind tractor. As soon as the flywheel is dismantled, you should unscrew the key, which is located immediately behind the flywheel;

- After this, the generator should be installed. The wiring in it must be inserted into a hole located in the metal wall of the engine. The generator will then need to be secured in place on the motor wall;

- Next, generator magnets must be installed inside the existing flywheel. In this case, all existing holes in the flywheel and generator must match. Both elements will need to be connected with fasteners, after which the crown of the walk-behind tractor used will be installed. Immediately before installing the crown, it must be heated using a spray burner;

- The assembled mechanism must be installed on the motor of the walk-behind tractor, simultaneously screwing in the nut and key of the flywheel;

- Next, you need to screw in the starter basket, fix the casing and firmly install the standard air purification filter in its regular place;

- Then you will need to remove the plug and install the starter itself on the engine;

- Next, you will need to connect the generator wiring to the charging relay;

- At the final stage, the starter terminals must be connected to the walk-behind tractor battery and the unit must be started.

Installing a starter on an existing walk-behind tractor is not as difficult as it seems at first glance. The most important thing is to be as careful as possible and adhere to the correct assembly algorithm.

All of the listed methods for repairing a starter are suitable for owners of Neva, Cascade and Agro walk-behind tractors. The procedure for removing and reassembling the mechanism will be similar for agricultural machines of all listed equipment manufacturers.

Do-it-yourself walk-behind tractor starter repair

Despite the high quality and reliability of modern starters, some owners sometimes face the need to repair them. Most often, mechanism breakdowns are minor, which allows you to quickly fix the problem yourself. The procedure for dismantling and further repairing the mechanism is as follows:

- Repairing a unit should begin by studying its diagram. If the design of the walk-behind tractor includes an electric starter, then before dismantling the mechanism you need to familiarize yourself with the location of its terminals;

- Using the wrench included with the walk-behind tractor, unscrew all the screws and nuts holding the mechanism in the walk-behind tractor structure;

- If the unit is being dismantled for the first time, we advise you to photograph the starter before finally removing the mechanism from the unit;

- Next, unscrew the washer located in the central part of the drum housing and carefully inspect the internal parts for damage;

- All further actions depend on the malfunction of the starter parts. If the cord fails - it is worn out or torn, then to replace it you will need to wind a new product, adhering to the marks on the drum body of the mechanism;

- Another common failure is a malfunction of the spring, or more precisely, its antennae, the edges of which should be bent in the shape of hooks. If the tendrils break, then the edges of the spring will need to be heated and bent so that the spring can be hooked onto the holes in the drum. In this case, the remaining length of the spring is of great importance - make sure that the part does not stretch too much. If you find that the spring is very short, or it has already begun to rust, then it is better to replace it entirely.

Before mounting the starter back onto the walk-behind tractor, we recommend that you first clean the space inside the unit structure. This will prevent debris from getting into the engine, carburetor, and spark plug.

Disassembly of the starter unit

The starting mechanism is disassembled in order to install new parts instead of broken ones in the following sequence:

- use a screwdriver to unscrew the screw that secures the pulley with the starter cover;

- remove the spring and antennae;

- carefully remove the pulley (you need to turn your head away or work while wearing glasses and gloves);

- determine why the trigger mechanism broke down;

- if the spring has collapsed almost completely, then it is replaced;

- when the spring leaves the hook, it is installed in its original place, bending the antennae first (the photographs show the installation process);

After the spring plate is installed inside the groove, carefully twist it. To change the spring, you should work carefully and carefully: it may accidentally burst under the influence of the force caused by installing it in place

Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges

To change the spring, you should work carefully and carefully: it may accidentally burst under the influence of the force caused by installing it in place

Even if you carefully remove the roller, the spring strip very quickly flies off the reel and can injure your hand with its sharp edges

It is not always possible to immediately put the spring plate back in its original place. It often slips, so attempts must be repeated until the desired result is achieved.

How to install a starter on a walk-behind tractor - the algorithm in detail

Even novice farmers do not have problems dismantling, disassembling and installing a walk-behind tractor's manual starter. However, the assembly and installation of an electric starter raises a number of questions for inexperienced owners of walk-behind tractors. As a result of incorrectly performed procedures, the engine starting mechanism refuses to work, which is why the starter has to be taken to the workshop. To avoid this need, let’s learn how to install a starter on a walk-behind tractor at home. The installation looks like this:

- To install and secure the crown on the walk-behind tractor flywheel, the flywheel will need to be removed. To do this, remove the air filter of the unit to gain free access to the internal structure of the walk-behind tractor;

- After this, remove the protective cover, unscrew the screws holding the recoil starter basket, the flywheel nut and the flywheel itself. Dismantling the walk-behind tractor starter flywheel can cause certain difficulties, so to remove this part it is better to purchase a special removable key in advance. After removing the flywheel, do not forget to unscrew the key located immediately behind it;

- Next you need to install the generator. In this case, insert its wires into the hole in the steel wall of the motor, and install the generator into the seats on the engine wall;

- Then install the generator magnets inside the flywheel so that the holes in both elements match. Connect both parts with screws and install the crown. Before this, the crown needs to be heated using a burner in the form of a spray can;

- Install the assembled assembly back onto the engine, simultaneously screwing in the keys and flywheel hook;

- Screw in the recoil starter basket, secure the casing and reinstall the walk-behind tractor air filter;

- Next, remove the starter installation plug and install the starter itself on the walk-behind tractor;

- After this, connect the generator wires to the charging relay;

- Connect the starter terminals to the unit’s battery and start the walk-behind tractor.

As you can see, installing a starter to a walk-behind tractor is not as difficult as it might seem at first glance. The main thing when assembling it yourself is to strictly follow all the rules and recommendations listed in the algorithm.

All described methods for repairing and installing a starter are suitable for installing the mechanism on walk-behind tractors Neva, Cascade, Agro and agricultural machines of other well-known manufacturers.

Offers for the sale of walk-behind tractors / cultivators

- 10 thousand km Quantity not specified Not specified

Selling a walk-behind tractor as unnecessary. In great condition. Diesel. I ran very little. There are original wheels. As well as a mill and a plow. Everything is like new.

- 10 thousand km of Brovary Not specified Not specified

I'll give you an extra new carburetor and magnet.

- 3 thousand km. Sumy Gasoline Manual / Mechanical

I’m selling a NEVA MB-2 walk-behind tractor in good condition, they didn’t work much. It starts off easy. I'll give him more. Metal discs with tabs. Plow with regulator. Soil cutter. Weight mixture. Plow for digging potatoes. Cultivator (grip 90 cm) Fully ready for work, reliable. I'm selling because I don't need it. I live in Akhtyrka. I am inferior to the real buyer in price.

- 2 thousand km Kosovo Not specified Not specified

The walk-behind tractor is new with 900 documents and the possibility of exchanging for a car with Polish license plates with the possibility of moving to Ukraine.

- 110 thousand km Not specified Not specified

A walk-behind tractor with an electric starter in front of the train, with virtually no need to win, only for the most influential consumers. The kit includes a cutter, a plow, a good sweeper, a cardboard cutter and a possible replacement on the machine.

- 10 thousand km Ivano-Frankivsk Not specified Manual / Mechanics

Walk-behind tractor New trailed adapter for the cultivator. This is a delivery set, there are brushes, there are stamps from the set 1650 with bison, you can return 1050 s, you can deliver to an area of 150 kilometers to call home, we will buy all the krill, buying and delivering.

- 10 thousand km Lviv Not specified Not specified

I will sell a Forte walk-behind tractor with a trailer, mill, plow, and hillers. Everything is at work. Start the battery to handle. Inserted turn signals, signal, general height of passage to the exit in the dark. The radio is inserted with 4 speakers. Technology is not in the place of robots, but technology is. For detailed information call.

- 1 thousand km Storozhinets diesel, 1 liter manual / manual

I find a walk-behind tractor to rob all the documents, in addition, I give the plow to the milling machine for the real buyer's deal!!

- 10 thousand km Uzhgorod Not specified Not specified

I will sell it to the entire Mukachevo region.

- 5 thousand km Kodyma Diesel, 6.1 liter manual transmission / manual transmission

READ How to Convert a Ural Motoblock to a Chinese Engine

Motoblock in a good apartment. Equipment: rotary mower, mower, plow, adapter, trailer with brakes. More by phone.

- 2 thousand km Gusyatin Diesel, 12 l. Manual / Mechanics

.Selling a walk-behind mill on a film set. Tel: 0965158550.0961409298.

- 11 thousand km Krivoy Rog Not specified Not specified

The walk-behind tractor was unpacked in the summer. And do a little work.

- 2 thousand km Priazovskoe Not specified Not specified

Diesel, water cooling, lightweight 1.2 m milling machine with it, single body plow. New walk-behind tractor 2021.

- 1 thousand km Novy Rozdol Not specified Not specified

ROTATIONAL FRESHNESS. PLUS UNIVERSAL. Hitch. POTATO EXCAVATOR. GROUND CLAMPS. RALO. TRAILER.

- 2 thousand km Korosten Diesel Not specified

Great horse with a powerful trailer, cutter, plow, 8 HP, with a little standing work in the garage.

- 10 thousand km diesel fox, 6.5 l. Not indicated

Rock Motoblock Zubr 2021. In a good camp. The walk-behind tractor has a milling machine, a harrow with a rotor, an adapter for a walk-behind tractor, a potato harvester, and spare Zhiguli wheels.

- 100 thousand km Ternopil Diesel Not specified

Walk-behind tractor for repairs, on the go, etc.

- 100 thousand km. Kharkov Diesel Manual / Mechanical

New, purchased in the spring of 2021, adapter, rotary mower, 2-body plow, 1.1 m cutter, rake, tug, 2 branches 10 horses, starter, exchange for a car.

- 100 thousand km Ternopil Diesel, 12 l. Manual / Mechanics

Many farmers ask how to install a starter on a walk-behind tractor. When using a motor cultivator, starters are used: primary and secondary.