Neva walk-behind tractor engine

The main working unit of a walk-behind tractor is the engine. It is activated only by turning the key; if the Neva walk-behind tractor does not start, then there are several possible reasons.

The walk-behind tractor does not start

No spark

In this case, it is necessary to check its functionality. Remove the spark plug from the engine and insert it into a special candle holder, and place the housing on the cylinder. Next, turn on the engine. If there is no spark, then you can replace the spark plug; if it does not appear, you should check the starting mechanism and ignition operation. Most often, it is the start button that fails; it can be replaced with a new one.

How to remove a candle correctly?

A special key is used to remove the spark plug. You must be careful, because the spark plug heats up during operation, so remove the spark plug before starting or after the walk-behind tractor engine has cooled down. We install a new one, and then check the clearance. It must be, but not big. The recommended lumen width is 0.5-0.6 mm.

Gasoline does not reach the engine

The second reason that the engine does not start is a problem in the supply of the fuel mixture. In this case, you should go through the complete gasoline delivery scheme. From the fuel tank to the carburetor.

- First check if there is fuel in the gas tank. It should not only be, but be 2-3 cm higher than the bottom, since the gas tank in the Neva walk-behind tractor is designed in such a way that fuel is taken at exactly this height.

- If there is fuel, you should check the operation of the gasoline intake valve. To do this, remove it from the hose and look, if gasoline flows out, then everything is fine, if not, you can clean the tap itself or replace it with a new one.

- Next, check the hose that connects the faucet to the carburetor. Remove it and try to blow it out. If air flows freely, it is functioning well. If not, clean it or replace it.

- And the last in this chain is the carburetor. Disassemble it and thoroughly wash all parts with 95 gasoline. Thanks to this, carbon deposits and impurities will be washed off. After completing the work, thoroughly blow all joints and joints with a compressor to minimize residual gasoline, which evaporates under air pressure. After this, put all the parts back together.

Here are a few more problems that may arise with the engine of the Neva walk-behind tractor:

The walk-behind tractor turns off during operation. Here the main reason is the low amount of fuel, since if it starts, it means it is in good condition. Since we discussed the design of the gas tank earlier, for reliable operation the fuel should be approximately 5 cm above the bottom.

The walk-behind tractor does not start the first time. Check the performance of the spark plugs and replace them with new ones if necessary. Also use a primer to additionally pump gasoline to the carburetor.

Running in the walk-behind tractor

After you have purchased a walk-behind tractor, you need to test it. This process must be carried out efficiently. Because it is the basis for the correct and durable use of equipment.

Running in a walk-behind tractor is, in essence, not operating it at full capacity. Here you need to select the correct load on the walk-behind tractor.

It is recommended to run-in the Neva walk-behind tractor with Subaru engines at half the maximum power. For example, if a plow in working condition should be lowered into the ground by 30 cm, then during operation it should be submerged only 15 cm.

The break-in period is prescribed for each individual model. It is measured in engine hours and usually ranges from 5 to 20 hours.

For a more gentle operation, it can be done without any attachments at all.

Important! Before starting the break-in, you should fill the crankcase with oil. Starting operation with an empty crankcase is not allowed. The choice of oil brand must be made in accordance with the operating instructions. Typically 10W series motor oil is used.

The walk-behind tractor smokes at idle

Most often the reason is that the air filter is clogged and dirty. In this case, you can remove it and see if the smoke continues to come out. If it stops, then the cause has been found.

If it still smokes, check the oil level. Perhaps there is too much of it and it gets thrown away.

Speed adjustment

The working spring is responsible for the number of revolutions. The opening and closing of the throttle valve depends on how it is tensioned. One end of it is connected to the working lever, it goes from the handle to the spring. And, when the position of the handle on the Neva walk-behind tractor changes, its position will also change. To adjust the number of revolutions, you need to adjust its tension.

Adjustment of valves

In operating condition, the gap on the intake valves should be 0.15 mm, and the exhaust valves should be 0.2 mm. In this case, the dipstick should be freely located under the valves. If this is real, then everything is fine. If not, then they should be adjusted.

- To do this, you need to do the following:

- Warm up the engine and then allow time to cool

- Remove the casing

- Remove the valve cover to gain access to the flywheels

- Unscrew the locknuts

- Adjust their position with a key so that the thin blade can pass freely under them.

- Reassemble everything in reverse order.

Features of repair of Neva walk-behind tractors

The Neva walk-behind tractor is widely used in suburban dachas, mostly for planting seasonal vegetables. In this light, this device is indispensable for arranging landscape design and designing gardens and adjacent areas. Serial production of the Neva MB 2 and Neva MB2K units was introduced in the 2nd half of the 1980s; since that time, many lovers of gardening and vegetable gardening have not parted with this device.

Adjustment of devices Neva mb 2, Zirka 105

The process of adjusting the valves on the Neva MB 2 walk-behind tractor and a similar Zirka 105 walk-behind tractor:

- Let the engine run and then cool slightly.

- We remove the casing.

- We remove the valve cover and get to the flywheels that are under it.

- Unscrew the locknut.

- The blade that we insert into the gap should pass very freely between the piston and the valve.

- We screw the whole system back.

Device and main characteristics

The MB 2 device is very popular these days; it is simply irreplaceable in agriculture. This line of Kompakt walk-behind tractors is produced under the same brand, but has a difference in the engine:

- “Neva” with index 2K is equipped with a Russian-made engine, therefore the cost of such a device is much less than that of foreign analogues;

- The 2nd 2B abbreviation indicates that this mini-tractor has an imported engine;

- The abbreviation 2C denotes professional elements in the structure of the apparatus that are used for cultivating the land.

The characteristics of the motor should be taken into account when choosing a unit in order to successfully process the required amount of land, be it tens of acres of land or a much larger area. The design of the unit is a subsequent system.

- The gear chain type gearbox is housed in a special case made of aluminum. Its main task is the highest speed of operation of the unit. The device has four forward gears and a couple back to perform a revolution. Its maximum speed is 12 km per hour, so this device can even be used for transporting goods.

- To start this small tractor, a motor with a starter is used.

- The frame, which acts as a support, has special fasteners, which are placed at the back and in front and are used as devices for working in weight.

- There are certain levers on the steering wheel that are used during operation of the mini-tractor.

- The V-belt type transmission produces a clutch assembly box from a pulley, a special lever and a V-belt.

- The unit is small-sized and lightweight, even the very heavy version weighs only 97 kg. This device can be easily transported anywhere, even in an ordinary car.

The unit with the abbreviation MB 2 has great capabilities; it can do a huge amount of work in agriculture, such as: plowing, cultivation, planting seeds, the process of hilling and weeding between rows and harvesting. “Neva” produces all this using a huge selection of equipment that is used suspended, also thanks to a large number of innovations. Features of the technical plan are presented by the Neva

» MB 2 like this:

- It is recommended to refuel the unit only with gasoline;

- hardware power 7.6 l. With.;

- Russian motor DM-1K, 4-stroke engine with a single cylinder;

- there is an engine with a volume of 317 cubic meters;

- the engine is started manually;

- cooling with air and liquid;

- tank volume 2.8 l;

- gear, chain editor;

- fuel consumption is 2.9 liters per hour.

Other relevant features are:

- during cultivation the grip is 160 cm;

- the depth of the land plot is 16-26 cm;

- tractor length 1750 mm, height 1350 mm, width 630 mm;

- This mini-tractor can handle about 12 acres per hour.

Useful tips

The box has 5 positions. When the user presses the gearshift lever, the fork moves the clutch out of the engagement position. When the user throws the handle, it returns to its original position.

The gearbox is responsible for transmitting torque from the motor to the wheels and additional equipment. In order to avoid failures during operation, it is necessary to carry out technical maintenance of the motor on time.

To lubricate the bearings in the housing, it is recommended to choose Tsiatim-201, and wash them with A-92 or A-95 gasoline.

READ Adjusting Valves on a Walk-behind tractor

Checking and adjusting the clutch

- When the clutch handle is in the "Off" position, the cable should be loose. The tension roller moves to the lower position and comes into contact with the drive belt.

- When the handle is in the “On” position, the cable tensions the roller, and the lower part of the belt is pressed tightly against it. The small type pulley transmits the impulse of movement to the larger pulley, thereby transmitting power.

- If it knocks out 2nd gear with the clutch engaged. It must be moved to the correct position. To do this, you need to place parallel V-belts on both sides of the motor pulley.

- If 2nd gear slips out when the clutch is disengaged. It is necessary to constantly monitor the position of the V-belts; they must be parallel to each other.

How to adjust the carburetor on a walk-behind tractor?

In the equipment of different manufacturers, adjustment of the walk-behind tractor carburetor is done differently. Below we will look at how to correctly and accurately configure fuel units in agricultural implements of various brands.

Carburetor, malfunctions, adjustment

Below is an algorithm for setting up a carburetor on a Neva walk-behind tractor with a Subaru engine.

The diagram shows three screws that are responsible for the amount of fuel supplied.

- Screw 1 - number of full throttle revolutions;

- Screw 2 - number of idle speeds;

- Screw 3 - responsible for idling.

To adjust the carburetor, you must perform the following manipulations:

- Tighten screws 1 and 2 until they stop;

- Then unscrew them about 1 turn;

- Turn on the ignition and warm up the engine;

- Then place the throttle control lever until the engine is turned off (that is, until the speed is at a minimum level);

- Set the minimum idle speed level with the third screw;

- Then set the maximum idle speed with the second screw;

- If necessary, adjust the minimum speed again by adjusting the position of the third screw;

- Carry out the last two steps until stable engine operation is obtained;

- If there are interruptions, tighten the first screw again until it stops and unscrew it one and a half turns.

Clutch, levers, cables

The Neva walk-behind tractor is equipped with several simple elements: levers and cables. The number of engine revolutions depends on the operation of the gearbox lever and all connecting cables. Such a device tends to wear out and fail during operation. Therefore, they should be periodically checked for integrity and replaced if necessary.

Also, don’t forget about the clutch. It fails much less often, but the plug should also be inspected periodically. If necessary, all these parts are freely available in the store.

Some people think about not buying a new cable, but making one from improvised materials. But it’s better not to experiment with this part and buy a new one. Because it cannot be replaced equivalently. The only temporary replacement option is to take it from a car clutch or scooter.

How to start a walk-behind tractor - in detail for beginners and more

Any branded walk-behind tractor consists of a huge number of complex devices that are activated when the built-in unit is started. When the engine is turned on, the components of the agricultural machine are subject to excessive load, therefore the working life of each of the industrial systems of the walk-behind tractor directly depends on the correct start of the standard motor. To reduce the load and extend their service life, the user must learn the correct procedure when starting the engine, taking into account various weather and operating conditions.

Belts for the Neva walk-behind tractor

Basically, Neva walk-behind tractors use V-belt drives. There are a large number of them presented. And for each individual walk-behind tractor, you should know the belt that needs to be used.

Replacing the belt on the Neva walk-behind tractor:

- Remove the shield, unscrew the two bolts (7) and remove the protective casing from the pulleys (6);

- Remove the reverse belt (3) by removing the spring (8), loosening the bolt (2) of the guide pulley;

- Unscrew the screws (5) holding the bracket (a);

- Position the bracket so that the pins allow the front pass belt (10) to be removed from the pulley;

- Put a new belt in its place (first it is put on the gearbox pulley, then on the engine pulley);

- Reassemble everything in reverse order.

Adjust the belt tension! When the clutch levers are released, the belts should sag freely, and the gear pulley should not rotate when the engine is running.

Pulleys are designed to tension transmission belts. There are a large number of them on the Russian market. To replace a pulley, you need to measure its diameter. The following sizes are available: 18, 20 and 25.4 mm.

Walk-behind tractor ignition system

Ignition adjustment

The ignition coil for the Neva walk-behind tractor is adjusted as follows:

- Take a sheet of paper and fold it 4 times;

- Unscrew the bolts that hold the module;

- Place a piece of paper under them and screw the bolts into place;

- In manual mode, turn the flywheel;

- Check for spark.

Video review of adjusting the ignition of a walk-behind tractor engine

One of the main factors for the correct operation of the ignition system is the gap between the starter and the flywheel. It should be in the range from 0.1 to 0.15 mm.

To adjust it on the Neva walk-behind tractor, you need to remove the housing and unscrew the stator bolts. Then place the feeler gauge and set the required gap, tighten the bolts back and check the gap over the entire surface of the flywheel.

Generator, faults, elimination

The generator is an important component of the entire mechanism. It is designed to charge the battery and operate the headlights.

When choosing a generator, you need to pay attention to its power. It must exceed the power of all connected devices to ensure uninterrupted operation. For the Neva walk-behind tractor, it is possible to use an old car generator.

Important! During its installation, you must follow the diagram presented below. Otherwise, the generator may catch fire.

There are 4 wires in total in the generator. Two of which are blue. It is thanks to them that the converter is connected. Red, connects to the headlights and supplies voltage to them.

Electric starter

Many people strive to improve the performance of their walk-behind tractor. During the winter seasons, it has difficulty starting due to the fact that the manual starter does not turn over. To solve this problem, a special electric starter was invented for the Neva walk-behind tractor. This is an autonomous device that, when the ignition is turned on, begins to rotate and gives a spark.

An electric starter is a complex design, and it is not possible to make it at home. You can use any other car electric starter that could be left over from an old car.

Candles

We have already figured out what spark plugs are for and how to change them. Let's look at the brands that are needed for each specific type of Neva engine:

Operating instructions for the Neva walk-behind tractor

Among the large number of universal domestic, Chinese, Japanese motor-units for cultivating land, the Neva 2MB walk-behind tractor stands out for its relatively low price, operational reliability and traditionally difficult maintenance of the device. Previous Neva-1 models often became the target of criticism due to the low quality of the walk-behind tractor engine. Today the situation has changed dramatically. The engine for the Neva-2MB walk-behind tractor is made more or less reliable, or an imported one is installed, but there is still no information on maintenance and clear operating instructions.

What is a Neva 2 walk-behind tractor?

The powerful motor unit produced is equipped with three engine options for the walk-behind tractor:

- Gasoline engine produced by the Kaluga plant, the most often used modification is DM-1, DM-2, with a power of 6 and 7 hp. respectively. The first works on the A-76, the second on the A-95. In this case, the letter “K” is added to the walk-behind tractor index according to the instructions;

- American engines from Briggs & Stratton. The version of the walk-behind tractor with the index “B” is considered the most reliable and easy to maintain, even without any instructions;

- Subarov engines, when equipped with them, the Neva walk-behind tractor is assigned the index “C”. The engines have a similar power of 6-7 horses, but there are also diesel versions with colossal torque. The most capricious in maintenance and operation, all operations, even refueling and starting, must be performed only according to the instructions.

To find out what specific fuel is used for a particular walk-behind tractor model, you need to check the passport and operating instructions. For example, an attempt to fill a Subarov engine with 92-octane gasoline during operation can lead to burnout of the piston system, and walk-behind tractors with American Briggs often experienced serious problems with starting and controlling engine speed due to the large amount of dirt in domestic fuel.

General parameters of the Neva 2MB walk-behind tractor, taken from the operating instructions:

- The mass of the unit when charged reaches 100 kg. This is the average for most walk-behind tractors; Chinese heavy versions can reach 150-180 kg;

- Motor power -6 hp, with a torque of 180 kg?s, for a diesel engine the torque is increased to 220 kg?s;

- The plowing depth according to the instructions, when using a standard plow, on a walk-behind tractor reaches 200 mm, the maximum harrowing width is 170 cm.

The machine can plow, harrow, dig up potatoes planted in beds, clear snow and much more, provided that the standard attachments specified in the operating instructions are used.

Kickback on startup: how to avoid

Many owners have noted this phenomenon when trying to start the equipment. Why does it give in your hand when you start the walk-behind tractor and how to avoid it? This phenomenon usually indicates early ignition. This is a common problem with motorcycles.

Early ignition is a consequence of contact wear during operation. To fix it, you need to reconfigure the starting system.

Another reason for kickback may be poor quality gasoline. You need to drain the fuel and replace it with another, remembering to maintain the proportion with the oil. The tank may need to be flushed additionally. When dust and dirt accumulate in it, the gasoline becomes clogged, which leads to uneven operation of the engine. You can understand for sure that it is the fuel that affects the operation of the equipment and provokes recoil when starting the engine by looking at the spark plugs. Having unscrewed it, you need to examine it for burning and soot. If combustion products are in abundance, then this clearly indicates the low quality of gasoline (provided that the spark plugs are changed regularly).

Important! In any case, the walk-behind tractor, like any equipment, requires maintenance. All basic recommendations are indicated by the manufacturer, so you should carefully read the instructions and follow all measures for servicing the machine.

The main problems of operating the Neva MB walk-behind tractor

The fate of the walk-behind tractor has so happened that each of the components requires regular attention and periodic maintenance, regardless of which engine is installed on the unit. But even Subaru and Briggs engines require periodic washing and adjustment of carburetors during operation, cleaning the needle valve seat from accumulated dirt, and cleaning the spark plug.

Gearbox and V-belt drive

The next most important unit of the walk-behind tractor is the gear-belt reducer. The mechanism consists of two parts - a gear reducer and a V-belt drive. The walk-behind tractor gearbox is assembled in a light alloy housing and filled with oil. According to the instructions, the oil is changed after the first 200 hours of operation. There are no problems with oil, TAD17i is suitable, there are problems with deformation and splitting of the gearbox housing, rapid operation of sealing seals and leakage. The gearbox provides two forward and one reverse gears. Two more gears are obtained by reversing the V-belt drive belt.

Experts recommend changing the oil not according to the instructions, but after the first 40 hours of operation, with mandatory flushing of the crankcase and replacement of rubber seals with imported ones.

According to the instructions, the belt of the Neva-2 walk-behind tractor should be of standard A1180 - A45. This is the most consumed and worn part of the transmission, since instead of the traditional disc clutch, which even the Chinese often install on their Zubrs, the Neva uses a V-belt clutch, which is already more than a hundred years old. It is clear that the service life of such a mechanism is ten times less than the ferrido system.

According to the instructions, the clutch works as follows:

- When you press the lever-handle, the force is transmitted through a flexible cable to the tension roller, which tensions the belt and picks up the slack, ensuring traction of the narrow side belt drive with the cheeks of the pulleys;

- When the lever is released, the return coil spring increases the slack and loosens the belt's grip on the pulleys.

But unfortunately, regularly stretching the coil spring to its maximum leads to its weakening, and, as a result, burning of the belt at maximum speed. Therefore, during operation, you have to regularly stop the walk-behind tractor to adjust the belt tension according to the instructions. According to the instructions, the deflection of the belt in the center when pressed with a force of 5 kg should not exceed 9-10 mm.

Motor DM-2

To operate the walk-behind tractor, according to the instructions, use pure unleaded gasoline of the A-92 brand. If you use a clean canister for intermediate storage, and be sure to settle the fuel before starting operation, and do not fill the last 100-150 ml into the tank, but carefully drain it for other purposes, then there should be no problems with the operation of the engine.

The most painful part of a walk-behind tractor engine is its carburetor. Not only is it almost impossible to adjust the operation according to the instructions, but even at the factory settings the needle does not lock and regularly pours fuel into the intake tract. Accordingly, after 20-30 hours the engine oil in the crankcase turns into a stinking slurry.

According to the instructions, M10GI mineral oils are used to fill the engine crankcase; in practice, semi-synthetics and synthetics are used, for example, 10W40 approximately 1.3 liters. For the gearbox, the instructions require filling 2.2 liters.

To start the engine according to the instructions, you need:

- Open the tap, pump fuel into the carburetor and move the pump foot to the starting position;

- Hole a couple of times with the damper open;

- Close the throttle completely and start the engine.

Of course, when the walk-behind tractor engine is hot, it is started with the throttle open.

Plow adjustment

In order to obtain the required plowing depth and blade direction, you need to know how to set up a plow on a walk-behind tractor. According to the instructions, the plow is attached to the hitch using an adjustable bracket and kingpin. Installation and adjustment of the plow is carried out in two stages.

At the first stage of operation, the installation height of the plow is adjusted; for the Neva, the vertical bar must be installed higher and lower in the row of finished holes. The optimal height is 7-9 cm.

After trial operation of the plow, you will need to set the angle of attack of the cutting edge. To do this, according to the instructions, the walk-behind tractor, shod with lugs, is installed on a flat surface. A 15 cm high stand is placed under the left wheel, and by turning the fastening head the inclination of the cutting edge to the coating surface is adjusted.

How to start a Neva walk-behind tractor - Technology Expert

If you have been using the Neva , then there is no point in this article to figure out how to start tractor , but let’s touch on the moment that happens to everyone at one not-so-wonderful moment: the sun is shining, it’s time to plow, but the walk-behind tractor won’t start!

Let’s make a reservation right away that this article will not make you a walk-behind tractor repairman, but will simply make you understand where to find the fault and roughly evaluate the nature and methods of repairing a walk-behind tractor. We would also like to note that you can always contact our service center, where experienced specialists will provide professional assistance and carry out high-quality repairs of the Neva !

Repair of the Neva begins with troubleshooting; first you need to find out what exactly is not working: the engine or the gearbox. If during operation the walk-behind tractor suddenly stops, you should release the clutch lever, turn off the gear and look for the malfunction in the following order:

- If the walk-behind tractor does not start, then it is logical to look for a fault in the engine. First, determine whether the engine is turned by the starter cable. If the engine runs very lightly, the engine turns over effortlessly, then the fault is in the mechanical part of the engine: either the valve group, which is responsible for closing and opening the valves, also includes the pushrod, or a broken connecting rod is to blame. This conclusion can be drawn if, during engine diagnostics, when you crank the starter, you hear extraneous metallic knocks. This repair is quite complicated, so it is advisable to bring the walk-behind tractor engine to a service center, where experienced mechanics will determine the malfunction and name the exact cost of repairing the walk-behind tractor and spare parts for it.

- If the engine does not turn over with the starter, you can judge that the connecting rod-piston group is jammed; in this case, the walk-behind tractor is repaired by overhauling the engine. Our mechanics will do the engine overhaul efficiently and in a very short time. Attention! There is a rare, but very absurd exception to this malfunction: when transporting a walk-behind tractor on its side, the oil that fills the crankcase flows into the combustion chamber (this is a design feature of a four-stroke engine, and the oil is not compressible), so when diagnosing a walk-behind tractor, you need to unscrew the spark plug and try crank the engine again. Perhaps you will be lucky and this will not be a malfunction, but just a misunderstanding.

READ What kind of oil can be poured into a walk-behind tractor

The next stage of repair of the Neva : the engine cranks with normal effort, there is compression, but there are no flashes in the cylinder. Determine whether the fuel mixture is flowing: remove the spark plug, it should be wet. If this is not the case, then there is a malfunction in the fuel system of the walk-behind tractor.

Motoblock Neva MB-2 review, starting

Repairing the fuel system involves checking the flow of fuel from the gas tank through the gas tap into the carburetor. If fuel flows, carburetor repair is necessary.

Agree that it is better to repair the carburetor of a walk-behind tractor in a specialized service center, and not in a garden plot.

The spark plug turned out to be wet, which means fuel is entering the cylinder and then there is a problem with starting the walk-behind tractor in the absence of a spark. First, try to replace the spark plug; maybe an insulation breakdown has caused it to fail.

the main malfunctions of the Neva and now let's turn to the next stage of walk-behind tractor malfunctions: the engine is running, but the walk-behind tractor does not move.

- First, check the clutch belt - it often happens that such a belt fails, because torque is transmitted through it from the engine to the gearbox.

- Now about repairing the gearbox of the Neva : the belt has been checked and it transmits rotation. This means the malfunction is much more complex than we would like.

Motor DM-2

To operate the walk-behind tractor, according to the instructions, use pure unleaded gasoline of the A-92 brand. If you use a clean canister for intermediate storage, and be sure to settle the fuel before starting operation, and do not fill the last 100-150 ml into the tank, but carefully drain it for other purposes, then there should be no problems with the operation of the engine.

The most painful part of a walk-behind tractor engine is its carburetor. Not only is it almost impossible to adjust the operation according to the instructions, but even at the factory settings the needle does not lock and regularly pours fuel into the intake tract. Accordingly, after 20-30 hours the engine oil in the crankcase turns into a stinking slurry.

According to the instructions, M10GI mineral oils are used to fill the engine crankcase; in practice, semi-synthetics and synthetics are used, for example, 10W40 approximately 1.3 liters. For the gearbox, the instructions require filling 2.2 liters.

Advice! If it is not possible to adjust the needle hang and gasoline regularly gets into the crankcase, then it is better to buy inexpensive mineral water and change it every 50 hours of driving.

To start the engine according to the instructions, you need:

- Open the tap, pump fuel into the carburetor and move the pump foot to the starting position;

- Hole a couple of times with the damper open;

- Close the throttle completely and start the engine.

Of course, when the walk-behind tractor engine is hot, it is started with the throttle open.

Is it necessary to drain gasoline from a walk-behind tractor for the winter?

The operating instructions clearly state that the fuel must be drained from the walk-behind tractor before winter storage. But owners have differing opinions on this matter. Some say that it is best to drain the gasoline and let the tank dry thoroughly. Others advise filling the tank to the top to prevent corrosion.

There will be no corrosion of the tank either in the first or in the second case. But following fire safety precautions, there is no need to leave the walk-behind tractor with a full tank of gasoline. Also, gasoline may become waterlogged during inactivity.

Our advice is that before winter storage, be sure to drain the gasoline, exhaust any remaining fuel in the system, and let the tank dry. After such actions, there will be no problems with the fuel system of the walk-behind tractor in the spring.

READ DIY hydraulics for a walk-behind tractor

Main characteristics

The Neva walk-behind tractor is used for secondary tillage. The design includes a shank that pierces the soil, grips it and turns it over. When viewed from a design point of view, the technique refers to machines that use the rotational movement of disks or teeth. The rotary cultivator of this line is a perfect example.

Walk-behind tractors are used before sowing or after the crop has begun to grow to remove weeds . Thus, operator-controlled disturbance of the soil layer near the plants kills unnecessary plants and uproots them. Neva gear-type products are often similar in shape to chisel plows, but they have different purposes. The technique works close to the surface, while the plow is deep below the surface.

All the company's units can be described as compact equipment with a low center of gravity.

Thanks to this design, it is more convenient to work on a walk-behind tractor; there is no risk that the equipment may lose balance and roll over.

All models have an engine from Subaru , and along with it an electronic switching system is installed. All units have a front wheel for moving, and the compact dimensions allow the walk-behind tractor to be transported in the trunk of a car.

Power may vary depending on model. This figure is in the range from 4.5 to 7.5 horsepower. The working width is from 15 to 95 cm, the immersion depth of the cutters is up to 32 cm, most often the fuel tank volume is 3.6 liters, but on some models it reaches 4.5 liters.

The gearbox installed in the Neva walk-behind tractors is three-speed and V-belt. This equipment runs on AI-95 or 92 gasoline ; other fuel cannot be used.

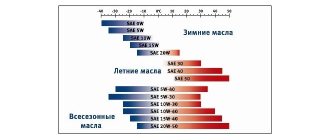

The type of oil depends on the conditions in which the walk-behind tractor is operated. This could be SAE30 or SAE10W3.

Some walk-behind tractors have an engine with a cast-iron sleeve; simpler vehicles have one speed forward and the same speed backward. There are multi-speed units that can be switched between three speeds. Most walk-behind tractors can replace a small tractor ; they can not only cultivate the soil, but also transport various loads. Such equipment is capable of accelerating from 1.8 to 12 kilometers per hour; accordingly, the models have different motors.

On average, a semi-professional engine is designed to operate without breakdown for up to 5 thousand hours. The housing, made of aluminum, protects against moisture and dust.

Design and principle of operation

The design of the Neva walk-behind tractors is classical.

The main components include the following:

- candles;

- hub;

- water pump;

- air filter;

- generator;

- tension roller;

- throttle handle, engine;

- gearbox;

- wheels;

- pump;

- starter;

- frame;

- clutch cable;

- axle extensions;

- starter.

This is approximately what the detailed design diagram of the described walk-behind tractors looks like.

Often, to make the structure heavier, a load is additionally used, through which the cutters are better immersed in the ground, thereby ensuring high-quality operation of the equipment. The shaft diameter in modern models is on average 19 mm.

The design of the device may vary depending on the needs of the user, in this case we are talking about the use of attachments. Gardeners and gardeners most often use a walk-behind tractor when preparing a plot of land for planting.

This is an effective tool that helps perform many agricultural tasks. Its tines can go deep into the soil to extract weed roots. Walk-behind tractors are equipped with pneumatic wheels that help guide the device during use.

Gear wheels, or lugs, are used for cultivation, and pneumatic wheels are used for transportation along the highway . The lugs are oriented parallel to each other in a metal frame, usually made of steel.

Starting a walk-behind tractor

Motoblocks today have become an almost integral part of agriculture.

Many farmers have transferred all the most difficult and exhausting work to this technique. Now she prepares the land for planting crops, waters the plants, digs up potatoes, transports goods, and even cares for the territory of her personal plot. However, like any other equipment, walk-behind tractors require careful treatment from the moment they are first started. If you want them to serve you as long as possible, you must know all the nuances of starting a walk-behind tractor.

In this article we will talk about how to start a walk-behind tractor correctly and how to do it after storage during the winter. After all, if you start it incorrectly, you may have serious problems that will require repair of the unit.

Step-by-step instructions for starting a walk-behind tractor

After all the checks, you are convinced that the oil is filled in in sufficient quantities, gasoline or diesel fuel matches the model of your walk-behind tractor, and all fasteners and systems are in correct and working condition. Now we will tell you how to start a walk-behind tractor :

- gasoline walk-behind tractor. You need to open the gasoline tap, and the choke lever should be in the “Start” position, and also turn off the ignition. After this, you need to pump the recoil starter a couple of times, turn on the ignition, and pull the starter again. In this state, the walk-behind tractor will start, and you must move the choke lever to the “Work” position. If your vehicle model has an electric starter, you can immediately turn on the ignition and start it;

- diesel walk-behind tractor. Diesel walk-behind tractors are known to be a little more difficult to start. Moreover, if you plan to work on it in winter, then you should be aware that diesel fuel tends to freeze. Therefore, you first need to warm up the equipment, and only then apply loads. So, if the unit is new, then its entire system is aired. To pump it up, you need to work with the starter. If the starter is manual, you can, of course, pull it yourself, or you can do the following procedure. Unscrew the fuel supply valve and unscrew each supply connection from it. In this case, you need to Unscrew it, wait until the fuel flows and tighten it again. Keep doing this until you reach the injector. To manually start, open all valves and set the gas to the middle position. Hold the decompressor with your finger, squeeze it out and pump it several times. After this, release it and pull until it returns to its original position. Now press the decompressor again, and without supporting it, press the starter. The walk-behind tractor should start.

READ What kind of oil to pour into a walk-behind tractor engine

How to start a Patriot walk-behind tractor?

To extend the service life of Patriot brand walk-behind tractors, you need to fill them only with pure 92-grade gasoline. It is not recommended to use 95 fuel, since its quality at many gas stations is much lower than AI-92 gasoline. Synthetic motor oil for 4-stroke internal combustion engines is poured into the engine crankcase.

In addition, Patriot brand walk-behind tractors are equipped with a container for pouring oil directly into the air filter of agricultural implements. There are marks on the container where you need to fill the lubricant. The manufacturer does NOT recommend pouring lubricant above the “bath” provided in the container, since the heated liquid will gradually begin to flow into the engine carburetor.

After this, you can proceed directly to starting the engine. To do this you will need:

- Set the cold start lever to the left position;

- Turn the fuel supply valve to the “On” position;

- Set the ignition switch to the “Start” position;

- Slowly pull the starter cable towards you until resistance appears;

- Pull the starter cable sharply towards you - as a result, the engine should start;

- Give the engine time to warm up;

- Move the throttle control lever to the mid-turn position;

- Set the cold start lever to the right position.

It is important to remember that after turning on the Patriot walk-behind tractor for the first time, it must be run in, which is done under loads. There is no need to let the engine exhaust the first tank at idle speed, since its design includes a piston with rather thin walls. When idling for a long time, the part heats up and fails.

Motoblocks today have become almost an integral part of agriculture. Many farmers have transferred all the most difficult and exhausting work to this equipment. Now she prepares the land for planting crops, waters the plants, digs up potatoes, transports goods, and even looks after the territory of her personal plot.

However, like any other equipment, walk-behind tractors require careful treatment from the moment they are first started. If you want them to serve you as long as possible, you must know all the nuances of starting a walk-behind tractor.

In this article we will talk about how to start a walk-behind tractor correctly and how to do it after storage during the winter. After all, if you start it incorrectly, you may have serious problems that will require repair of the unit.

How to start a walk-behind tractor correctly?

After you have bought your walk-behind tractor, you should not start it right away, even if the consultants assure you that the equipment is completely ready for use.

You need to start with the preparatory work. To do this, you first need to check the engine oil level. There should be a sufficient amount of it. If this is not the case, the oil needs to be added. If you start the engine without oil, it will immediately fail. On sale you can find walk-behind tractors, such as Caiman, that have an oil level sensor. If there is little or no lubricant, the engine simply will not start. This is very convenient and significantly extends the life of your equipment.

After this, you need to add fuel. When purchasing, check with your consultant or in the operating instructions for the type of gasoline that is suitable for your model of walk-behind tractor. If the unit has a two-stroke engine, then the fuel must be diluted with oil in a certain ratio. Never use low-quality fuel or fuel that is not suitable for your walk-behind tractor.

The final stage of preparing the machine for launch is checking all connections and fastenings. All moving elements should not be tightly tightened - their operation should be elastic, but smooth.

Starting a diesel and gasoline walk-behind tractor is slightly different. The gasoline unit starts like this:

- open the gasoline tap;

- the choke lever must be in the “start” position;

- the ignition must be turned off;

- pump with a mechanical starter a couple of times;

- now you need to turn on the ignition;

- pull the starter again.

If you have an electric starter, then you can immediately turn on the ignition. The starter will quickly pump fuel into the carburetor.

With a diesel walk-behind tractor, things are a little more complicated. The new unit is completely airless, unless, of course, no one started it. To bleed it, you need to turn the starter. The process will take longer than when starting a gasoline car, but eventually the walk-behind tractor will start.

If you have a manual starter, you can pull it, but you can also start the walk-behind tractor in another way. To do this, you need to open the fuel tap, and from there, unscrew each connection all the way to the injector. You unscrew the connection, wait for the fuel to flow, and tighten it, moving on to the next one.

When starting mechanically, you need to open all the valves and put the gas in the middle position. After squeezing the decompressor, pump it a couple of times, holding it with your finger. After this, lower the decompressor and pull it to its original position. Press it again and do not hold it, but immediately pull the starter. The walk-behind tractor should work.

How to start a walk-behind tractor without a starter?

In some cases, operation of the walk-behind tractor becomes impossible due to a breakdown of the trigger mechanism. It can fail anywhere, including in a field, far from home. To solve the problem and start the walk-behind tractor, you don’t always need to take it back to the garage.

Sometimes the design of agricultural units makes it possible to start their power unit without using a starter.

- Unscrew the screws and remove the trigger mechanism;

- Clean the area under the standard starter, remove dirt and moisture from it;

- Under the starter there is a crown necessary for permanent connection of the engine crankshaft with the starter drum. You will need to wind any cable around the rim of this crown, making 4-5 complete windings around the element;

- Lightly pull the free end of the cord towards you against resistance - this means that the piston has risen up;

- Turn off the decompressor, move its lever to the zero position;

- Pull the cable sharply towards you.

Motoblock Neva - how to start it yourself?

Before directly starting the engine, you need to check the oil level in its crankcase. To do this, you need to unscrew the filler cap located in the front part of the power unit. At the end of the plug there is a threaded probe. If the oil slick reaches this thread, then there is enough lubrication to operate the engine.

READ What kind of oil to pour into the gearbox of the Neva walk-behind tractor

start correctly , you must:

- Turn the ignition switch to the “On” position;

- Open the fuel supply valve;

- Close the standard throttle valve;

- Set the accelerator lever to approximately 3/4 of the maximum permissible speed;

- Pull the starter cable towards you until resistance appears;

- Pull the starter cable sharply towards you - as a result, the engine should start and stall instantly;

- Slowly open the throttle valve;

- Pull the starter cable a few more times until the engine starts and starts idling.

Starting a walk-behind tractor without a starter

In walk-behind tractors, certain elements often fail. Starters are one of the first to break. However, this does not in any way affect the operation of the unit, or even its startup. It is only important to know some secrets:

- Remove the damaged part;

- You will need a strong rope, approximately 1 meter long;

- In place of the former starter there is a round element, on the wall of which you can see a hole into which you need to stretch the rope and securely fasten it;

- The rope needs to be wrapped around this round piece several times. As a result, you should be left with a cable about 40 cm long.

To start the engine, you need to pull the rope hard. If nothing works the first time, you will have to repeat all the steps again, since the rope does not remain on the part.

Starting a walk-behind tractor after winter

Owners of walk-behind tractors often encounter this problem when the equipment does not want to start after wintering.

This is due to storage conditions. If the car was in a cold room with high humidity, then you may end up with a number of serious breakdowns. Before the first start in the spring, you must completely change the oil and fuel. Ensuring that liquids are at ambient temperature is extremely important.

You may encounter that the walk-behind tractor refuses to start immediately. And this is quite normal. Let the equipment warm up a little. It should warm up even after starting the engine.

If the start of the walk-behind tractor still fails, you need to perform the following steps:

- Bleed the fuel system. There could be residues from gasoline or diesel in it;

- check the spark plug. The contact can even be cleaned a little with sandpaper;

- Check all wiring to ensure there are no breaks or damage.

Starting a walk-behind tractor correctly after winter

Before starting the walk-behind tractor after a long winter period of inactivity, it is necessary to carefully prepare it. The first step is to remove the equipment from the garage and inspect it. There should be no pockets of corrosion on the metal surfaces of the agricultural implement, the appearance of which may be caused by high humidity. In case of corrosion, it will need to be removed, the problem areas treated with a special rust converter and areas of paint.

After this you will need:

- Drain the old fuel from the tank and remove the old lubrication gear. The latter must be thoroughly washed and dried. Next you will need to add fresh fuel and new transmission oil;

- Wash the fuel pipes, make sure they are not leaking and there are no cracks in the walls;

- Remove all filter elements provided by the design, wash them thoroughly with clean gasoline, dry and reinstall. Damaged filters must be replaced;

- Remove and disassemble the carburetor, blow it with compressed air or wash it with gasoline. After this, the completely dried parts of the fuel block must be reassembled and replaced;

- Check the drive belts. Cracks may appear on their surface due to high humidity. In this case, the elements must be replaced immediately;

- Disassemble and inspect the CIS power supply. If burrs or traces of rust appear on the walls of the assembly, they will need to be removed;

- Unscrew and check the spark plug. There should be no traces of scale or deposits on it. Otherwise, the candle must be cleaned and dried. After this, it is necessary to ventilate the engine by sharply pulling the starter cable several times;

- Check the ignition system clearance and install it again if it was broken;

- Inspect the controls and ensure that the gas cables and brakes are as tight as required for operation;

- Remove, charge and reinstall the battery, if provided for by the design of the walk-behind tractor. At the same stage, it is necessary to check the wiring terminals and contacts. There should be no traces of oxidation on them;

- Check the tire pressure and inflate them according to the walk-behind tractor instructions;

- Inspect the chassis of the walk-behind tractor and tighten the mounting bolts;

- Check the connection mechanism for attachments and trailers.

READ Which walk-behind tractor is better for the garden

Only after all the above steps can you start the walk-behind tractor.

To start an agricultural unit with a gasoline engine, you must:

- Open the gas valve fully. In this case, the fuel suction lever should be in the “Start” position and the clutch lever. In the "Disabled" position;

- Perform manual bleeding of the starter by sharply pulling the cable several times;

- Turn the ignition lever to the "On" position and pull the starter rope a few more times;

- As soon as the engine of the used walk-behind tractor starts, you will need to quickly move the fuel suction lever to the “Work” position.

If the gasoline walk-behind tractor has an electric starter, the operator just needs to turn on the ignition and press the engine start button.

Getting a diesel walk-behind tractor is a little more difficult.

This will require:

- We unscrew the valve intended for supplying fuel, gradually unscrewing each standard connection from it;

- As soon as the fuel reaches the nozzle, you need to open all the valves in the structure and set the gas lever to the middle position;

- Press and hold the decompressor until fuel is pumped into the cylinder;

- Release the decompressor and begin to gently pull it out until it is in its original position;

- Press the decompressor again and at the same time quickly pull the starter cable towards you.

Features of launching some models of walk-behind tractors

Different models of walk-behind tractors start in different ways. In order not to encounter difficulties, you should carefully read the instructions, where everything will be described in detail.

So, to start the Neva walk-behind tractor, you need to turn the ignition switch to the “on” position. After this, you open the gasoline valve and close the choke valve. The throttle should be at approximately ¾ of the maximum setting. Pull the starter and then open the choke. If you start the walk-behind tractor in the cold season, then you need to open the damper gradually.

The Ural walk-behind tractor starts up quite simply too. The gear shift knob should be in neutral and the gas tank should be open. Then close the throttle and choke, and then start the engine.

The Patriot unit starts up in this way. The throttle should be in the maximum position. You need to pull the cord a couple of times to purge, and then a few more times, but sharply and briefly, to start the motor. Rotate the throttle to adjust it.

How to launch walk-behind tractors of popular brands?

Depending on the design features and manufacturer, agricultural units can be launched in one way or another. It is important to remember this because an incorrect algorithm can gradually lead to serious damage to the equipment.

Motoblock Neva. How do you think we should start?

Before starting the engine directly, it is necessary to check the oil level in the crankcase. To do this, unscrew the filler cap located in front of the power source. There is a threaded probe at the end of the plug. If the oil slick reaches this thread, it means there is enough oil to run the engine.

READ Walk-behind tractor produces black smoke and does not pull

To properly start the Neva walk-behind tractor, you must:

- Turn the ignition key to the “on” position;

- Open the fuel supply valve;

- Close the standard butterfly valve;

- Set the accelerator lever to approximately 3/4 of the maximum permissible speed;

- Pull the starter rope towards you until resistance appears;

- Pull the starter rope sharply towards you. As a result, the engine should start and stop immediately;

- Open the throttle slowly;

- Pull the starter rope a few more times until the engine starts and idles.

The engine of the Neva walk-behind tractor can only be turned off at idle, otherwise the risk of failure of a conventional magnet will increase.

How to start the Ural walk-behind tractor?

Before starting the Ural walk-behind tractor, you must make sure that its air filter is completely clean. It is also necessary to inspect the spark plug. agricultural machinery of this brand. This is a common leak of engine oil from a separate tank into the engine cylinder.

Replacing the seals will solve this problem in a short time, but they last about 20 hours.

To start the Ural walk-behind tractor you need:

- Move the throttle control lever to the “closed” position:

- Set the accelerator to minimum speed;

- Turn on the fuel supply valve;

- Slowly pull the starter cable until resistance is felt;

- Pull the starter rope sharply towards you. As a result, the engine should start;

- Open the throttle and let the engine warm up.

After this, you can start operating the walk-behind tractor on the website.

How to start the Patriot walk-behind tractor?

To extend the life of Patriot walk-behind tractors, it is necessary to fill them only with pure 92-octane gasoline. It is not recommended to use 95 fuel, since its quality at many gas stations is much lower than that of AI-92 gasoline. Synthetic motor oil for 4-stroke internal combustion engines is poured into the crankcase.

In addition, Patriot walk-behind tractors are equipped with a reservoir for filling oil directly into the air filter of agricultural units. There are marks on the tank where you can add oil. The manufacturer does not recommend pouring oil through the “bath” provided in the tank, since the heated liquid will gradually begin to flow into the engine carburetor.

Then you can proceed directly to starting the engine. This will require:

- Set the cold start lever to the left position;

- Turn the fuel supply valve to the “On” position;

- Set the ignition button to the “Start” position;

- Slowly pull the starter cord until resistance is felt;

- Pull the starter rope sharply towards you. As a result, the engine should start;

- Let the engine warm up;

- Move the throttle control to the mid-angle position;

- Install the cold start lever on the right.

It is important to remember that after the first activation of the Patriot walk-behind tractor, it must be started, which is done under load. There is no need to allow the engine to generate the first tank at idle, since its device has a piston with rather thin walls. When idling for a long time, the part heats up and fails.

Source

Motoblocks. This is quite a serious and expensive gardening equipment. If you want it to fully perform its functions, work for a long time and reliably, you need to take careful care of it and follow all the recommendations for use prescribed by the manufacturer.

READ Adjusting the Speed of a Walk-Behind Diesel Engine

When buying a car, it is important to know how to start a walk-behind tractor. There is a certain sequence of actions, which consists of preparing the equipment for start-up and its immediate start-up.