Repair and maintenance of walk-behind tractors Neva MB-2

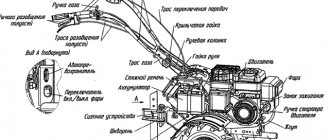

The Neva MB-2 walk-behind tractor is an agricultural unit designed to work on a wide variety of soil types, including previously uncultivated soil.

Available in various modifications with different types of engines:

The main work that can be performed on the Neva MB-2 walk-behind tractor is:

- plowing the soil;

- cultivation, milling;

- watering (pumping station);

- hilling;

- cleaning areas from grass, snow, etc.;

- harvesting potatoes, onions, etc.

Operation and maintenance of Neva MB-2

Changing the engine oil

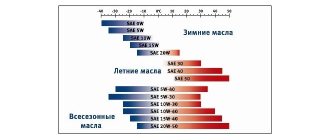

The manufacturer recommends using such well-known brands of motor oil for the walk-behind tractor as LUKOIL - standard SAE 10W30 API SF/CC, as well as RAVENOL SAE 30 API CD/SF.

At temperatures above 4 degrees Celsius, using thickened types of oils (for example, 10W30 brand) will lead to increased consumption of this type of fuel, so in the cold season it is recommended to check the engine oil level more often, preventing its level from dropping below normal.

The oil change is carried out after the walk-behind tractor has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is completely drained from the tank, after which new oil is added until the oil level reaches a special mark. The drain plug is then tightened tightly and wiped dry.

First launch and testing of the Neva MB-2 walk-behind tractor

The first start must be carried out according to the following scheme:

- make sure that the walk-behind tractor is in complete condition (the height of the steering bar and handles must correspond to the user’s height);

- You can start the engine only if the walk-behind tractor is located on a flat surface;

- check the oil and fuel levels in the tank;

- also check the places of threaded connections;

- then you can start the engine by smoothly turning the ignition knob;

- The idle time (without load and movement) should be about 10 minutes, then you can move and operate the walk-behind tractor.

The break-in period is considered to be the first 20 hours of operation of the walk-behind tractor, after which the oil must be changed. During this period it is most important:

- do not operate at full throttle;

- work only on pre-prepared soils (not virgin soil);

- for cultivation, use only the number of cutters that are included in the kit;

- The Neva MB-2 walk-behind tractor can only be loaded at ¾ power during the run-in period;

- gear shifting in the gearbox can only be done when the rotation of the drive pulley has completely stopped;

After the first 20 hours of operation after the first start, the engine oil should be changed.

How to make a replacement

Periodic maintenance of the gearbox and engine includes timely oil changes.

Oil is poured into the cultivator through a special hole; to simplify the procedure, a watering can is required.

In the gearbox

In most cases, any gear oil can be used to lubricate the gearbox. The replacement procedure is carried out as follows:

- The device is located on a horizontal plane and tilted slightly. This simplifies the filling procedure.

- A probe is inserted into the hole on the gearbox. It is required to determine the level of old substance.

To replenish the oil level in the gearbox, new oil is added. About two liters are poured into a completely dry container. Some models are equipped with a special hole to remove old material, which may contain a large amount of impurities.

In the engine

Changing the engine oil is carried out depending on the manufacturer's instructions. Engine oil is changed taking into account the following points:

- The first replacement is carried out after the engine has been broken in. It is carried out exclusively at idle, because Excessive load can cause wear of the main structural elements.

- Some manufacturers recommend replacement at intervals of 40 hours of operation. The lubricant must be replaced after a period of winter operation.

- Before carrying out the actual replacement, it is recommended to warm up the walk-behind tractor. This is required to increase the fluidity of the substance. In this case, the walk-behind tractor is installed in a horizontal plane. There should be a drain tube at the bottom of the structure; after unscrewing the plug, the old substance is removed.

- After draining the old substance, the plug is screwed back on. There is a filler neck in the upper part of the structure; the level is controlled using a dipstick.

After checking the lubricant level, you can tighten the plug and turn on the engine. The first few minutes need to be run-in at idle speed, because... It takes time to lubricate all structural elements.

Do I need to add oil to gasoline?

You can determine whether oil needs to be added to the cultivator’s gasoline by studying the basic parameters of the device. In most cases, dilution is carried out for a two-stroke engine; recommendations regarding proportions are taken into account. The operation of a four-stroke engine is ensured when refueling with pure gasoline.

It is prohibited to mix gasoline with oil to refuel a four-stroke engine. Such a mixture will cause malfunctions within a few hours of operation.

Basic faults

Belt adjustment and dimensions

For the Neva MB-2 walk-behind tractor, the A-1180 drive belt is used. This model uses one belt that provides forward movement.

In other modifications of the Neva MB-2 model, two drive belts are used. Reverse gearing occurs in the gearbox itself.

Replacing the belt for MB-2 walk-behind tractors is carried out in the following sequence:

- The shield is removed, and then the pulley protective cover.

- The spring from the walk-behind tractor rod is removed to loosen the belt.

- The screws securing the bracket are turned.

- The bracket rotates to a position in which the limiting pins do not prevent the part from being removed from the pulley.

- The pulleys are adjusted, and then a new belt is installed.

- Pull the belt onto the gear shaft pulley, and then onto the motor pulley.

- In reverse order, place the remaining parts in their places.

Replacement of gearbox seals

The oil seals in the Neva MB-2 walk-behind tractor are replaced if an oil leak is detected. This condition is dangerous because the walk-behind tractor gearbox may be left without oil, and this will lead to rapid wear of the unit.

The sequence for replacing oil seals is as follows:

- Remove the cutters from the shaft, cleaning the shaft and covers from dirt and oil residues.

- Unscrew the cover bolts, tap off the oil and debris, and remove the cover from the gearbox.

- The old oil seal is replaced with a new one and wiped dry.

- The cover is returned to its place (if necessary, it is placed on sealant) and fixed with bolts.

Adjusting and tuning the Neva MB-2 carburetor

The functionality and durability of the walk-behind tractor engine depends on the stable operation of the carburetor. This is why its adjustment and tuning are so important. In addition, if the carburetor is incorrectly configured, a gasoline walk-behind tractor may experience increased fuel consumption

The carburetor of the Neva MB-2 walk-behind tractor is adjusted as follows:

- The full throttle and idle screw are turned to the limit.

- Both screws are unscrewed 1-1.5 turns.

- Next comes starting and warming up the engine.

- The throttle control lever is placed in a position in which the engine will operate at minimum speed.

- Set the minimum idle speed until the unit operates stable.

- The idle speed is set to maximum.

- The minimum idle speed is adjusted.

- Steps 6 and 7 are performed until the engine runs smoothly (more smoothly by ear) at idle speed.

For long-term and uninterrupted operation of the walk-behind tractor, it is necessary to regularly perform engine diagnostics, monitor the frequency of oil changes, and also comply with operating conditions and time intervals for scheduled maintenance.

Adjustment of valves

Adjusting the valves is a fairly simple procedure that requires wrenches, screwdrivers and a feeler gauge. The valve adjustment process is needed to establish optimal and technically correct clearances between the valves of a walk-behind tractor engine. Adjusting valves using the example of the Neva MB-23 walk-behind tractor (the principle is the same for everyone)

The adjustment sequence is as follows:

- remove the casing that covers the engine;

- remove the valve box cover;

- make adjustments (see below);

- Reinstall the valve box cover;

- Replace the casing.

The valves are located under the valve cover. The gap size can be checked with a feeler gauge. The intake valve clearance is 0.15 mm, and the exhaust valve clearance is 0.2 mm. The dipstick should fit under the valve with the correct gap size.

To adjust, the valve nuts are loosened, then a feeler gauge is inserted, after which the adjustment itself is made, and the valve nut is tightened.

The manufacturer emphasizes that in Neva MB-2 walk-behind tractors, the gaps between the ends of the valves and the ends of the pushers (0.1÷0.2 mm) are ensured by grinding the ends during the initial assembly of the engine and are not adjusted during operation!

Checking and adjusting the clutch of the Neva MB-2 walk-behind tractor

The main function of the clutch is to connect the gearbox to the engine, disengage it, and also connect other operating devices to the engine. If an overload occurs during operation, the clutch begins to slip - this is how other parts of the walk-behind tractor are protected from damage.

What are the types of walk-behind tractor gearboxes: types and purpose

For the engine used in the Neva, there are two main options. Gasoline and diesel. The electric type is rarely used. The gearbox does not change its direction because of this. The type of mechanisms can be of various options:

- Chain. There is a metal chain with which the sprockets are scrolled. There is a bolted connection. Among the advantages. Convenient operation and reverse function;

- Worm gear is used for vertical crankshaft. Features include high levels of performance and minimal noise levels. Made from various alloys. You can use steel and cast iron;

- The belt version uses a rectangular or V-shaped belt instead of a chain. The tape strip is secured with pulleys in which there are grooves;

- The gear version depends on the design, which can be angular or straight. The gear itself is mounted on shafts and is shaped like a cone or cylinder. This type of gearbox is rarely used because it is difficult to maintain. Most often installed on professional-type equipment, since it has high power.

There may also be homemade options that combine different types.

Experience of owners of operating the Neva MB-2 walk-behind tractor - reviews from forums

Each farmer's experience is unique. The advice of those who use the same walk-behind tractor as you do on their plot of land is especially valuable. Next - some advice from owners of the Neva MB-2 walk-behind tractor regarding maintenance and troubleshooting.

Vitaly, Penza, Russia:

“I bought a Neva mb2 walk-behind tractor and was very pleased. The unit worked normally at first, but a week after the start of operation, white smoke began to emerge from the exhaust pipe. I tried to slow down the engine speed, but it didn't help. It turned out there was water in the float chamber. I drained the gasoline, let it settle, and drained the chamber. After that the walk-behind tractor worked perfectly. If anyone has had a similar problem, I advise you to use my experience!”

Alexey, Rostov-on-Don, Russia:

“I encountered the following problem: in first gear my walk-behind tractor cultivated normally, but when I switched to second gear and worked with the soil, the engine speed did not drop. When I went deeper into the ground, the cutters stopped. Knowledgeable people suggested that the problem might be in towing the belt. I adjusted the tensioner and shortened the chain on the clutch handle and the problem was solved! Now I work with pleasure, I’ve been using my Neva MB2 for two years now.”

Konstantin, Rivne, Ukraine:

“I’m not new to working with a walk-behind tractor; I’ve been using it for 4 years. Recently, if you put a load on it, the engine began to stall, as if it couldn’t pull... I barely drove it into the garage, and there was no popping noise, no smoke. The cause of the malfunction was simple: the air filter was clogged. I had to replace it and now the car runs like a beast.”

You can also help other readers of our site with your reviews on this walk-behind tractor model and its maintenance and main faults.

If you are the owner of this walk-behind tractor model, you can leave a review about its maintenance and operation, or ask any question you are interested in regarding the breakdown or maintenance of this model below in the comments.

How to change the oil in a Neva walk-behind tractor?

Any technical equipment has a complex design, where absolutely everything is interdependent. If you value your own equipment and want it to work as long as possible, then you must not only look after it, but also buy high-quality spare parts, fuel and oils. But if you start using low-quality oil, you will encounter a number of complications in the future and the equipment may need repairs. In this note we will describe which oils (lubricants) are suitable for a particular unit and techniques for changing oils in a walk-behind tractor.

see also

Comments 41

Yesterday I disassembled the gearbox - the chain broke! Corrosion of the gearbox mechanism was discovered; everything that was rusty was in Tad-17 oil, I’m shocked

You can pour any transmission and gearbox, poured Lukoil TM-4 to the top of the filler plug, the one on the gearbox with a hole. Changed the oil every 3 years for 8 years of operation. -flight is normal!

I have the same engine on my motor cultivator, the oil was first filled with Nissan SN 5w30 hydrocrening, now it is filled with IDEMITSU 10w30 mineral water, , . and in the heat you can use 10w40, for example, Helux, ... you can use either 10w30 or 10w40 engine oil or a transmission in the gearbox, you can also use TAD-17.

I always pour nigrol into the gearbox

I filled the gearbox with Lukoil semi-synthetic transmission, and Shell synthetic 5W-30 into the engine.

I change the oil in the spring both in the engine and in the gearbox, although I use it twice a year. spring and autumn!

the Neva walk-behind tractor is almost like in the photo with a 5.5 kW motor, oil Tap 15 nigrol in a Motul synthetic motor

Tad-17 from the factory, if memory serves. Filled for the entire service life, unless of course you plan to drive 100 thousand km on your MB. If the seals do not leak, there is no need to change them.

I always pour oil into the walk-behind tractor, the oil according to the instructions, why bother :)

I'll ask something stupid - did you read the instructions? (I assume the answer is: why, I’ve been using cultivators for a long time and I know everything, and I also had a moped in my childhood, and these instructions are for... well, for those who didn’t have a moped)

It says there - transmission oil gl4 gl5 75-90

There’s a lot written there, but I’m interested in real-life experiences. if you have nothing to share, then don’t bother

I just have something to share and am sharing - transmission oil, class and viscosity of the oil according to the instructions, according to the brand, I think Lukoil for the eyes, I would change it once every couple of years. tad 17 expensive - because Repairing the gearbox will cost a pretty penny.

Filled with nigrol, lubricant for carriages, more than 15 years in operation.

I have Salyut, I pour TAD-17 into the gearbox

in the transmission - transmission)))) I poured the cheapest 80B90 into the engine, I never bothered with what was left of the Russian tire. For 12 years, I changed it a couple of times, the engine pleases with easy starting and traction. This walk-behind tractor cultivates about 50 acres in cultivator mode. The first 2 years, even loosening 10 acres of virgin soil, the load was enormous.

Look in the manual for SAE parameters and according to API GL-5. it is most suitable for gearboxes. The volume is also written in the manual. no manual - Google to help.

according to the passport - but I pour Lukoil TM-5 80W-90 API GL-5.

Is MAXIGEAR 75W-90 suitable?

suitable, except perhaps more expensive. synthetics. I poured the remains of the Shell Spirax S4 G SAE 75W-90 into the German walk-behind tractor.

Is MAXIGEAR 75W-90 suitable?

I totally use Mobil 75w-90

Walk-behind tractor Salyut 6M I use TNK transmission, the most common one, although it’s a little higher than the level, I don’t use it in winter.

naturally transmission into the gearbox. I pour TAD

I use the Japanese equivalent of Tad 17. They sell it from Kamatsu. And the engine uses 10W40 Eni oil. walk-behind tractor forte 105 e.

Why the hell should I even change the oil in it? From the point of view of the unit, the gearbox is an eternal part. However, the load is not so heavy that you need to bother with types of oil.

It is advisable to change the oil once a year, well, in the gearbox a little less often. in a car at the gearbox - replacement after 70 thousand

Read also: Bumper for VAZ 2107

The NEVA walk-behind tractors, as well as the MK100 and MK200 motor-cultivators, are equipped with mechanical gear-chain reducers housed in aluminum housings. The MK70 motor-cultivator has a mechanical chain gearbox in a steel case. In order for the gearbox to serve for a long time, it is necessary to regularly carry out maintenance of motorcycle equipment. For diagnostics and troubleshooting, please contact authorized service centers.

How to choose gear oil

When choosing gear oil for the gearbox, you should rely on the information specified in the operating manual for the walk-behind tractor or cultivator. The use of oil brands not included in the recommended list will lead to accelerated wear of gearbox parts.

| Vehicle model | Used transmission oils | Filling volume in gearbox |

| Motor cultivator MK70 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | — |

| Motor cultivator MK100 | filled with Litol-24 grease, which does not require replacement during the entire service life of the product | — |

| Motor cultivator MK200 | SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| Motoblock MB2 KS | TSp-15K (80w90), | 2.2 l |

| TEP-15 (-5°С to +35°С) GOST 23652-79 (SAE90 API GI-2), | ||

| TM-5 (-5°С to -25°С) GOST 17479.2-85 (SAE90 API I-5) | ||

| Motoblock MB Compact | SAE85W-90 API GL-5 | 1.15 l |

| TM-5 GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| Motoblock MB2 | TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5ºС to +35ºС) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5ºС to -25ºС) GOST 17479.2-85 (SAE90 API GI-5) | ||

| Motoblock MB23 | TSp-15K (80w90) | 2.2 l |

| TEP-15 (-5ºС to +35ºС) GOST 23652-79 (SAE90 API GI-2) | ||

| TM-5 (-5ºС to -25ºС) GOST 17479.2-85 (SAE90 API GI-5) | ||

| Motoblock MB1 MultiAGRO | SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from -25 to +35) GOST 17479.2-85 | ||

| TSp-15K (80w90) | ||

| Motoblock MB2 MultiAGRO | SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from -25 to +35) GOST 17479.2-85 | ||

| TSp -15K (80w90) | ||

| Motoblock MB23 MultiAGRO | SAE85W-90 API GL-5 | 1.5 l |

| TM-5 (from -25 to +35) GOST 17479.2-85) | ||

| TSp-15K (80w90) |

How to change the oil in a motor cultivator gearbox

Maintenance of the gearbox of the NEVA MK200 motor-cultivator should be performed every 250 hours of operation. It is better to change the oil in the gearbox immediately after operating the equipment, since it is easier to drain the oil during this period.

In order to change the oil in the gearbox of a motor cultivator, you should perform the following steps:

- Place the cultivator in a vertical position

- Place a container of at least 2 liters under the gearbox

- Unscrew the breather plug and clean it of dirt.

- Unscrew the oil drain screw and drain the oil from the gearbox

- After draining the oil, screw in the oil drain screw with the gasket and tighten the screw. Dispose of the oil at a waste oil collection point.

- Pour 1.15 liters of fresh transmission oil of the appropriate brand and operating temperature through the hole under the breather plug.

- Screw in the breather plug.

How to change the oil in a walk-behind tractor gearbox

It is recommended to service the gearbox of the NEVA walk-behind tractor after every 100 hours of operation or every season, depending on which stage comes first. It is recommended to use only transmission oil to fill the gearbox.

In order to change the oil in the gearbox of a walk-behind tractor, you should perform the following steps:

- Place the walk-behind tractor in a vertical position

- Place a container under the gearbox: at least 2 liters

- for MB Compact, MB1 MultiAGRO, MB2 MultiAGRO, MB23 MultiAGRO;

not less than 3 liters

- for MB2 KS, MB2, MB23 - Unscrew the breather plug and clean it of dirt.

- Unscrew the oil drain screw and drain the oil from the gearbox

- After draining the oil, screw in the oil drain screw with the gasket and tighten the screw. Dispose of the oil at a waste oil collection point

- Fill through the hole under the breather plug with fresh gear oil of the appropriate brand and operating temperature, volume: 1.15 l

- for MB Compact;

1.5 l

- for MB1 MultiAGRO, MB2 MultiAGRO, MB23 MultiAGRO;

2.2 l

- for MB2 KS, MB2, MB23 - Screw in the breather plug

- Clean the axis of the drive belt tension lever and the bushing from dirt.

- Lubricate the drive belt tension lever shaft and bushing with engine oil.

- Check the functionality of the clutch mechanism, adjust the tension of the drive belt

- Lubricate the clutch cable

Any technical equipment has a complex design, where absolutely everything is interdependent. If you value your own equipment and want it to work as long as possible, then you must not only look after it, but also buy high-quality spare parts, fuel and oils. But if you start using low-quality oil, you will encounter a number of complications in the future and the equipment may need repairs. In this note we will describe which oils (lubricants) are suitable for a particular unit and techniques for changing oils in a walk-behind tractor.

Read also: How to set up a 2nd generation LPG reducer

What type of oil should be poured into the motor cultivator motor

There are many debates about what kind of oil should be poured into the engine of a home motor-cultivator (motor-block). Some are confident that his views are correct, others deny them, but only one thing can resolve such discussions - the manual for the unit created by the product manufacturer. Any manufacturer prescribes a specific volume of oil to be poured, a method for measuring this volume, including the type of oil that can be used.

What all their positions have in common is that the lubricant must be intended specifically for the engine. There are 2 types of oils - oils for 2-stroke engines and oils for 4-stroke engines.

Both samples are used for motor cultivators in accordance with which specific motor is mounted in the model. For the most part, motor cultivators are equipped with 4-stroke engines, however, to determine the type of motor you need to read the manufacturer’s markings.

What lubricant should be poured into the air filter of a walk-behind tractor?

For such purposes, it is recommended to use the same lubricant that is located in the engine sump. According to the generally accepted standard, machine oil for 4-stroke engines is used in the walk-behind tractor engine, as well as in the air filter.

In accordance with the season and ambient temperature, it is allowed to fill the engine with seasonal lubricants of the class 5W-30, 10W-30, 15W-40 or all-weather motor oils with the widest temperature spectrum.

Some simple tips.

- Never use additives or oil additives.

- The lubricant level must be checked when the cultivator is in a level position. You need to wait until the oil has completely drained into the pan.

- If you decide to completely change the lubricant, drain it while the engine is warm.

- Dispose of the lubricant in a way that does not cause harm to the external environment, in other words, do not pour it onto the ground or throw it in the trash. For this purpose, there are specialized collection points for used motor lubricant.

To learn how to change the oil in the Neva walk-behind tractor, see the following video.

Changing the oil in the engine of the Neva walk-behind tractor

First of all, you need to find out whether the lubricant needs to be changed? It is possible that its level is still sufficient for the effective functioning of the motor cultivator. If you still need to change the oil, place the cultivator on a leveled surface and clean the surface around the dipstick plug (plug) for filling lubricant into the engine. This plug is located on the bottom end area of the motor.

How to set the oil level after changing? Quite simple: using a measuring probe (probe). To establish the oil level, you need to wipe the dipstick dry, and then, without tightening the plug, insert it into the oil filler neck. By the oil imprint on the probe, you can determine what spirit level it is at. On a note! The amount of lubricant in the engine should not exceed the limit mark. If there is excess oil in the container, it will begin to flow. This will increase unnecessary costs of lubricants, and, consequently, operating costs.

Before checking the oil level, the engine must cool down. A recently functioning motor or gearbox will provide incorrect parameters for the amount of oil, and the level will be significantly higher than it actually is. Once the components have cooled, you can measure the level accurately.

How much lubricant is required to be poured into the gearbox?

The question regarding the volume of transmission oil is quite fundamental. Before answering this question, you will need to set the lubricant level. This is extremely easy to do. Place the cultivator on a level platform so that its wings are parallel to it. Take a wire measuring 70 centimeters. It will be used instead of a probe. Bend it into an arc, and then insert it all the way into the filler neck. After that, remove it back. Carefully inspect the wire: if it is 30 cm dirty with lubricant, it means the lubricant level is normal. When there is less than 30 cm of lubricant on it, it needs to be topped up. If the gearbox is completely dry, you will need 2 liters of lubricant.

How to replace the lubricant in the gearbox?

The procedure is as follows.

- Before you start filling in new fluid, you need to drain the old one.

- Place the cultivator on a raised platform. This will make it easier for you to drain the lubricant.

- You will find 2 plugs on the gearbox. One of the plugs is intended for drainage; it is located at the bottom of the unit. The other closes the filler neck. The filler plug is removed first.

- Take any reservoir and place it directly under the oil drain plug.

- Carefully unscrew the oil drain plug. The transmission oil will begin to flow into the container. Wait until absolutely all the oil has drained, after which you can screw the plug into place. Tighten it to the limit using a spanner.

- Insert a funnel into the filler neck. Use the appropriate lubricant.

- Fill it to the required level. Then replace the plug. Now you need to find out the lubricant level. Tighten the plug with the dipstick until it ends. Then unscrew it again and inspect it.

- If there is lubricant at the tip of the probe, no more should be added.

The procedure for changing transmission lubricant will depend on the modification of the walk-behind tractor. But basically, replacement is carried out every 100 hours of operation of the unit. In some cases, more frequent replacement may be necessary: every 50 hours. If the cultivator is new, then the initial replacement of the lubricant after running in the walk-behind tractor must be performed after 25–50 hours.

Systematic replacement of transmission oil is necessary not only because it is recommended by the manufacturer, but also for a number of other reasons. During operation of the motor cultivator, foreign steel particles are formed in the lubricant. They are formed due to friction of the components of the motor cultivator, which are gradually crushed. The oil ultimately becomes thicker, which leads to unstable operation of the walk-behind tractor. In some cases, the gearbox may fail. Filling in fresh lubricant allows you to prevent such unpleasant events and eliminate repairs. Replacing lubricant is several times cheaper than purchasing and installing a new gearbox.

If you want your technical equipment to function properly for a long time, do not ignore timely oil changes. How to maintain and clean the oil filter of a walk-behind tractor. Maintenance of the air filters of the walk-behind tractor motor must be carried out in accordance with the maintenance intervals specified by the manufacturer or as needed if the technical equipment is used in highly dusty conditions. It is advisable to inspect the condition of the air filter every 5–8 hours of operation of the walk-behind tractor. After 20–30 hours of activity, the air filter needs to be cleaned (if damaged, replace it).

Gearbox for walk-behind tractor Neva

For modern gardeners, cultivating a plot of land is no longer as big a problem as it was in the recent past. Such universal equipment as walk-behind tractors has appeared on sale, which make life much easier for agronomists and gardeners.

Neva walk-behind tractors are one of the best units in their line. They are reliable, durable and multifunctional. You will be able to cultivate the land, care for plants, and collect and transport crops and garbage.

Here we will tell you about the gearbox for the Neva walk-behind tractor, its design and repair. This is one of the most significant elements in any car, so if you want it to last a long time and without breakdowns, you must know all the intricacies of its design, as well as the causes of malfunctions and methods for eliminating them.

Gearbox malfunctions and repairs

Like any other equipment, walk-behind tractors can also fail. If the problem lies in the gearbox, you need to disassemble it and repair it. Often the breakdown turns out to be insignificant and you can easily deal with it yourself.

First, you need to thoroughly clean this part from dirt and residual oil, which will also need to be drained. All parts must be inspected and checked for damage. If something fails, it needs to be replaced. Use only new elements that are suitable specifically for your Neva walk-behind tractor model. Also, do not forget to add oil after assembly.

Some common gearbox failures:

- the spring or clamps are broken. They need to be replaced with new ones and then adjusted;

- The settings in the switching system have gone wrong. You need to loosen the screws, engage first gear, tighten the screws back;

- Oil is oozing through the shaft. Most likely the reason is the cuff, which is worn out. It needs to be replaced with a new one. How to replace oil seals? It is enough to remove the old ones by prying them off with a screwdriver or other object and install new ones;

- jamming appeared. This may be due to an open circuit. It needs to be replaced with a new one;

- you can't record the transfer. The reason is that the fork brush is worn out, so it needs to be replaced.

These are the main and most common gearbox failures. It is very important - if you cannot fix the breakdown yourself, then you should seek help from professionals.

Gearbox device

The gearbox for the walk-behind tractor allows the use of additional equipment that receives speed from this mechanism. The device itself and the principle of operation are similar to elements of other models.

Important! When assembling the gearbox of the Neva walk-behind tractor, the design features and device must be taken into account first of all, since if the arrangement is incorrect, the mechanism will not work.

The device is responsible for the rotational transmission that goes from the engine to the wheel system and additional attachments. It turns out that without a mechanism there will be no movement, since it is a control tool for the rotational number, speed and direction of movement.

READ Replacing fishing line on a stavr trimmer

The design of the mechanism has an element for changing gears. It is located in the upper body part. The lever includes 5 positions in its location. When it is pressed using the fork, the clutch is released from the clutch. If the lever is released, the fork reverses back.

In this video you will learn how to change the oil:

To slow down the equipment, the drive is connected to the right-hand axis. Torque is produced from a sprocket located near the input shaft. If the lever is pressed, the left sprocket engages, which leads to a lower gear. For top gear, the knob is set to the limit.

You need to know all the design features when correcting breakdowns and malfunctions.

Oil for walk-behind tractor "Neva"

Any technology has a complex structure where everything is interconnected. If you value your equipment and want it to last as long as possible, then you should not only take care of it, but also purchase high-quality parts, fuel and oil.

Today, almost every farmer already knows about such equipment as walk-behind tractors. They are produced by different companies all over the world. At the same time, it is a mistake to believe that Chinese products are worse than, for example, European ones. Often, very high quality components are used in China, but the price remains low. Motoblocks "Neva" MB are produced in Russia and are in great demand due to their excellent quality, reliability, efficiency and a huge selection of attachments.

However, if you use low-quality oil poured into the gearbox or engine in the Neva walk-behind tractor, then you may end up encountering a number of problems and you will even need to have your equipment repaired. In this article we will look at which oils are suitable for this unit, as well as the rules for changing the oil in a walk-behind tractor.

What kind of oil to fill

It is necessary to fill in oil together with the lubrication of all parts, as well as with changing the oil in the engines.

Important! Different types of oil are poured into the engine and gearbox. Transmission oil is poured into the Neva gearbox.

What oil to pour into the walk-behind tractor gearbox and how much depends on various nuances, including the season of operation.

The engines are filled with motor oil, which cannot be poured into the gearbox.

The choice of oil depends both on the season in which the work is carried out and on the data specified in the operating instructions.

For walk-behind tractor models, transmission oil is distributed according to GOST:

This is a standard that is prescribed according to the relevant GOST 23652-79.

The oil for the Neva walk-behind tractor must be of high quality and from a good manufacturer - this is a prerequisite.

It is worth considering that each oil is used only during the allotted period. For example, TEP-15 is used in the summer. The minimum temperature limit is -5 degrees. If the temperature is lower, then you will have to use TM-5, which has a minimum of 25 degrees below zero. These oils are also used in various modifications.

Oil for the Neva walk-behind tractor in the gearbox

The gearbox is one of the most important components of any mechanism, including walk-behind tractors.

What type of oil to fill, how often to change, how to check its quantity - every owner of such equipment should know the answers to all these questions. Before purchasing oil, read the operating instructions for the unit. There the manufacturer gives his recommendations, which are the most accurate and recommended. Type of oil for different models of walk-behind tractors:

- The following oil is suitable for the Neva walk-behind tractor MB 1: transmission TEP-15 according to GOST 23652-79, TM-5 according to GOST 17479.2-85. You need to fill in a volume of 2.2 liters;

- for the Neva unit, MB 2 is suitable according to GOST 23652-79, such as TAP-15V or TAD-17I.

For the normal operation of the gearbox, not only the choice of a reputable oil manufacturer is of great importance, but also replacing it in a timely manner. It needs to be replaced regularly, at certain intervals. This will extend the life of the gearbox. We offer you some tips on how to replace it:

- The walk-behind tractor must be strictly vertical;

- Place a large container (at least 3 liters) under the product;

- Unscrew the breather and clean it;

- Unscrew the screw and drain all the oil;

- Tighten the screw into place;

- Fill in new clean oil with the required amount;

- Close the breather;

- Check the functionality of the equipment.

There are still some points that you should know before you start working on the walk-behind tractor. As you know, the unit needs to be run in for some time. After approximately 30-35 hours of break-in, you should replace the oil with new oil. After this, the oil should be changed every 150-200 hours of operation, and if you do not use the equipment, then every 1-2 years.

Many consumers ignore these recommendations, and the oil itself tends to age. Consequently, breakdowns may eventually occur. If you value your equipment, do not ignore the manufacturer's recommendations.

Repair of the Neva walk-behind tractor: how to do everything correctly without the help of specialists

Firstly, it should be noted that among the many models of these manufacturers, MB1 and MB2 are considered the most famous and widespread. Using their example, we will deal with common problems.

- If the owner of the walk-behind tractor notices an oil leak on the output shaft, he must immediately remove the bridge cover and replace the cuff;

- When the gearbox is stuck, disassemble the mechanism and replace the unusable chain;

- If the gearbox does not have a kinematic connection, do not hesitate to update the sprocket in the block;

- Gear problems can result from a broken shatter switch or through a cut off portion of the shift knob. To get rid of problems, it is necessary to replace damaged parts;

- When the revs start to pile up, it becomes obvious. Remove the starter, remove the clutch and grind the grooves into balls. Adding some good quality oil can reduce clutch and shaft friction.

The focus was on the most common problems. Thanks to the instruction manual, you can easily understand the features and make repairs yourself.

- If the owner of the unit cannot separate the axle shafts, he must check the drive adjustment and change the cable tension;

- Shifting gears is often the result of a malfunction, such as a failure of the shift control system. Then reduce the tension of the screws holding the board, engage 1st gear and tighten the screws again;

- If the transmission does not have a kinematic connection, the shift plug must be replaced.

Other solutions and additional information on using the motor unit can be found in the specialized manuals for new and old devices.

Engine oil

Oil plays the most important role in an engine, ensuring its normal and efficient operation. The operating instructions that come with the unit itself will help you decide which oil to prefer.

The oil is selected according to its operational category and viscosity type. Based on the viscosity of oils, there are winter (low-viscosity), summer (high-viscosity) and all-season (universal).

In order to know what oil to fill, you must check the brand of the engine itself:

- Honda. Both in winter and summer you can fill in SAE 10W-30 oil. If you prefer to use oil seasonally, then choose it based on the temperature conditions of the area where you live. Operational class - SG, SF;

- Robin Subaru. In summer it is recommended to use SAE 10W-30 oil, in winter - SAE 5W-30. Operational type - motor oil for cars of SE, SG, SH, SJ classes;

- Lifan. In summer - SAE 30, in winter - SAE 10W-30, which is universal;

- Briggs & Stratton. If you plan to work in winter, then use synthetic oil or non-synthetic Briggs & Stratton 10W-30 with article number 998208. As is known, an air-cooled engine warms up much faster, hence the consumption of non-synthetic oil, such as 10W-30 , 5W-30, will be increased. Therefore, you will need to check its level more often and top it up on time.

How often do you need to change oil in different engines:

- Robin Subaru. Every time you get ready for work, you should first measure the oil level and, if necessary, fill it to the maximum level. The first time you need to change the oil is after about 20 hours of operation, and then every 100 hours of operation;

- Honda and Lifan. Always check the oil level before work. Replacement - after the first 20 hours of operation, and after that - every six months;

- Briggs & Stratton. After you first work for 5 hours. Check the oil level regularly, namely every time before work or every 8 hours of work. Change the oil completely either every season or every 50 hours of operation.

What kind of oil to fill in a MTZ walk-behind tractor with a Honda engine

MTZ walk-behind tractors have established themselves as high-quality agricultural equipment; coupled with the world-famous Honda engine, they have good performance properties.

For proper operation of the entire device, it is necessary to carry out timely technical inspection, including checking the oil level. What oil should I fill? For Belorus 08H-09H walk-behind tractors with Honda GX 240, 270, three hundred 40 and three hundred ninety engines, oil with a systematization of at least SG and SF is suitable; rich grade oil

SAE 10W-30, but under certain temperature conditions it is necessary to select a special oil.

READ How to Install a Generator on a Forza Motoblock