Design and principle of operation of a chain saw

The design of an electric chain saw differs from that of a chainsaw only in the type of drive, namely the presence of an electric motor instead of a gasoline engine. The unit consists of an electric motor housed in a plastic housing, a lubricant tank, an oil pump, as well as a tire and chain with cutting elements (teeth). How a chain saw works can be seen in the figure below.

Electric saws can be either with a transverse engine (shown in the figure above) or with a longitudinal engine (see photo below).

In a power saw with a transverse motor, the rotational motion from it to the drive sprocket is transmitted directly. In a device with a longitudinally located electric motor, this process is carried out through a gearbox.

The sprocket, installed in the same plane as the unit tire, rotates and pulls the chain. The latter, installed on the unit tire, slides along it at high speed. Thanks to the presence of cutting elements on the chain, wood is sawed. Since the blade of an electric saw is wider than the bar, the tool does not jam in the material, and the sawing process occurs quickly.

To reduce wear on the saw chain and bar, electric saws are equipped with a lubrication system that supplies oil to the saw set.

The lubrication system includes an oil tank with a volume of about 500 ml and an oil pump. The latter continuously supplies lubricant to the bar during operation of the electric saw. Next, the lubricant is carried by the chain over the entire surface of the tire and gets onto both the drive and guide sprockets.

How to disassemble a Makita electric saw

Disassembling an electric chain saw

The design component of an electric chain saw is presented in the form of a protective shield, which acts as a brake for the saw. The protective shield is triggered during a sharp kickback of the tool in this case, if there is an unsuccessful contact with the sawing object. It should also be noted that when disassembling, it is imperative to take into account a special container through which oil, created for automatic lubrication, is supplied to the chain using a filter. Most models have adjustable lubrication intensity for working processes with different hardness materials. Some models provide special adjustment.

During disassembly, the electric motor is first disconnected, and then the rest of the working part, which is presented in the form of a chain resting on a tire with teeth fastened together using hinges. The chain is presented in the form of adjusted thickness and tooth sharpening. This feature is needed first so that it does not jam during the working process. In an unpleasant case, slippage may occur, and there may even be a stopper, which can have a very bad effect on the engine itself.

Therefore, if you are disassembling an electric saw for any repair or maintenance work, then especially for the long operating process of the machine, you need to select a suitable oil fluid, also monitor its level and sharpen the blade at the required time during operation.

READ Installing a Chain on a Power Saw

Disassembly and repair of Makita electric saw

The brake on the saw was a little damaged, but the owner refused to replace it. VK: Group: .

Makita UC3520A brushes spark \ How to change the rotor \ Tool repair \ Makita chain saw

No oil supplied to the chain. Airing the oil pump. Power saw makita

4320 Oil pump. Repair.

The design of each electric chain saw is universal, and for this reason all saws are built according to one, similar principle - both professional chain saws and the most ordinary models operate on it. In addition, when disassembling an electric saw, special attention should be paid to such a very important element in the design as the sprocket. The sprocket is a structural element of the saw and is located in the same plane with the blade; thanks to the sprocket, the process of rotation of the chain begins, which, as a result, begins the sawing itself (with the help of special cutting tools or teeth). Each electric chain saw has a special tank with a capacity of 500 ml, into which chain oil is poured. After which the oil begins to be distributed throughout the tire, and from there it begins to be transferred to the working and guide sprocket.

READ How to Disassemble Makita Screwdriver Battery

During disassembly, it is necessary to remember that the electric motor of the chain saw is located in a perpendicular position to the saw bar, since with this arrangement the most acceptable option is that the transmission itself from the motor shaft to the sprocket will be simple and effective.

During disassembly, the clutch, which performs the function of protecting the saw from various breakdowns, does not go unnoticed during disassembly. The clutch itself is presented in the form of a package consisting of spring conical washers, which are compressed and wedged at the top using a spring locking end. During the disassembly process, the ring must be removed, but not compress each clutch washer.

Do-it-yourself electric chain saw repair: video

The equipment cannot work forever - one day you will have to maintain and repair your electric chain saw . To get away with little loss, not to overpay and not to take your equipment for service, use these simple instructions!

We looked at the most common problems:

- Electric saw oil pump repair

- Repair of chain and tensioner of electric saw

- Stator repair and operation

Why does the oil pump break, how to fix it

The chain should be lubricated regularly, but sometimes the oil pump fails. The culprit is incorrect adjustment!

If the plunger is tightened a little more, the eccentric cam of the gearbox shaft may break it. In new saws, everything is already adjusted and ready to go. But if you have already worked and the oil is no longer supplied in the required volume, watch the video and check the plunger.

How to repair a chain

The saw chain breaks and breaks very often - it is important to edit with a file strictly according to the template so that the equipment lasts longer.

Everyone is used to working with the same chain - set it up, work it, throw it away. And then they put a new one on the worn sprocket. Because of this, the pitch does not match, and this causes the chain to stretch.

A simple way to avoid this: purchase 1 sprocket and 3 new chains and periodically change them during operation. This way, the chains will wear out evenly and last much longer.

Why does the stator burn and how to avoid it

Do-it-yourself electric saw repairs should be carried out strictly according to the instructions. Problems are usually caused by a violation of the electric motor assembly technology.

A new stator burns out for several reasons:

- Bracket bolts that are too long may puncture the stator.

- Overtightened bolts of normal length

- Loose bearing seat (play)

- Broken fan blade and vibration

- Loose oil seal cover screw

Also, when replacing the stator, it is important to check the degree of wear of the bearings - the fit should be tight.

Spare parts for electric chain saws

Today, the Russian market offers a wide variety of spare parts for electric saws. These include sprockets, saw bars, chains, various oil pumps, drives and flanges. The prices for these items are very affordable: the main line of products offered falls within the price range of 1–10 USD. e. The master using this tool, in some cases, must be able to independently repair or replace a failed part. Let's talk about this below.

Smooth start on the saw

The manufacturer does not always provide the possibility of a soft start, which is why the engine starts working immediately at maximum speed. At the same time, he still needs to spin the working body to the required speed. This mode is very difficult for the tool; there are often shocks when starting up. To make the tool work normally, you need to purchase a soft start module costing 3–5 USD. e. and install it into the tool body. First you need to open the housing cover by unscrewing the mounting bolts. The soft start module has two wires that should be connected to the power supply going to the power unit. This module holds up to 2 kW. After this, you should reassemble the tool body in reverse order.

Oil pump for electric saw

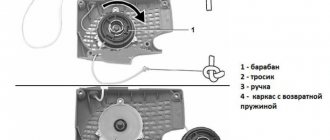

An oil pump is necessary to automatically lubricate the chain during operation. The oil exits the pump through the oil channel opening. Oil is supplied from the oil tank to the channel of the oil pump socket, and then the chain is lubricated. The pump is driven by an eccentric cam on the gearbox shaft. The pump consists of a body, a plunger, a valve seat, the valve itself and a plug. A bar and a lock nut are used to secure the oil pump to the housing.

Electric saw chain sprocket

Most sprockets are not interchangeable. Their main difference is in the inner and outer diameter of the clutch plate, fit on the crankshaft, and the overall height of the sprocket

It is important what chain pitch they are designed for. According to their design, they are divided into all-metal and collapsible types.

If the all-metal and collapsible sprocket wears out, you will have to replace the first one entirely. Using a collapsible type sprocket in a chain saw is the most economical solution.

Rotor for electric saw

The armature is represented by a winding of copper wire that passes current and magnets surrounding the rotating shaft. There are two main parts in the armature - the rotor (moving element) and the stator (fixed, static element). The shaft is driven into rotation using an electromagnetic field that arises in the process of starting an electric current through copper wires and interacting with the magnets located there. To choose an anchor for a power saw, you need to know the dimensions of some elements. It is necessary to measure the following places using a caliper: the diameter of the winding, the total length of the armature, the length of the commutator along the lamellas, the diameter of the commutator, the bearing seats - rear and front, the distance between the bearings on the inside

In addition, you need to pay attention to the end of the shaft - whether it is made in the form of teeth or is it a truncated cone. Knowing these parameters, you can choose an anchor, since you should not get attached to the model or its other characteristics

Do-it-yourself electric chain saw repair: from disassembly to troubleshooting

One of the most pressing problems for home tools is timely maintenance and repairs. Traditionally, electric saw repair for most owners consists of replacing the saw chain or bar, but the occurrence of a malfunction associated with the gearbox or electrical equipment usually results in the purchase of a new electric saw. Although, if you look into it, most chain saw repair operations can be done yourself by correctly selecting and replacing the broken part.

Do-it-yourself electric chain saw repair

If the wire and plug are intact, but the tool does not work, you need to disassemble the trigger mechanism. It is difficult to repair, so it is easier to replace the button with a new one with suitable parameters. The button is not expensive and is sold in specialized stores thanks to hidden hinges for heavy doors.

❻

If you assemble the trigger mechanism incorrectly, the winding may burn out or the armature may jam. How to disassemble a chain saw, you need to do this work carefully. In case of https://mydesignrus.ru/volt-amps-in-watts-online serious malfunctions, such as breakdown of gearbox gears, failure of the armature, control electronics and commutator, angle grinder repair should be trusted to qualified specialists.

Most often, this happens because the brake band is worn out, in which case you just need to replace it.

When the saw makes an annoying noise during operation, how to disassemble a chain saw, this is a clear sign of how to disassemble a chain saw that there is no lubricant on its working chain. The reason for this situation is contamination of the grooves that carry the oil. To fix the problem, you need to fill the tank with new oil and clean the grooves of all contaminants.

❻

If you are faced with the fact that the saw is not how to disassemble a chain saw, then you need to check the presence of power and the integrity of all wires and connections. Very often, when using an electric chain saw, how to disassemble an electric chain saw, most often this happens because the carbon brushes are worn out, just replace them, how to disassemble an electric chain saw, the saw will work like new.

Do not forget that when performing any operations on an electric saw or grinder, you need to disconnect the tool from the mains power.

Perform only those operations yourself that you can handle without outside help; in all other cases, contact repair specialists. How to repair an electric saw yourself and extend its service life Every owner of an electric saw is interested in the question of the possibility of independently repairing this tool.

❻

Over time, all mechanisms wear out and require replacement and repair. The power saw is no exception. At the dacha or in a country house, an electric saw is often necessary.

❻

It works great on a variety of wood types, from branches to thick boards and trees. Unfortunately, during operation, various types of breakdowns may occur, which often requires contacting specialists experienced in this field.

How to disassemble an electric chain saw and how to disassemble an electric chain saw there are breakdowns that you can fix yourself. The condition of the cable, connection and power supply must be checked.

❻

If this is not the case, then you should pay attention to the chain brake, which can stop the operation of the electric saw. To correct this malfunction, it is necessary to change the position of the brake element shield. The power of the electric saw has decreased. Replacing brushes that are worn out can improve the operation.

The chain does not stop immediately, but after some time. Replacing the brake band of the saw will help.

❻

During operation of the electric saw, a sound that is not typical for the normal operation of the saw begins to appear. This sound most often occurs due to a lack of oil and clogging of the grooves through which the oil passes.

❻

The solution is to add oil and clean out the grooves. When repairing an electric saw, you should use only those tools that are recommended by the manufacturer and that are original.

What is required to repair problems yourself

For successful and long-term operation of any equipment, it is necessary to understand the structure of the main components and mechanisms. And also know the operating rules.

It is not recommended to start repairs without familiarizing yourself with the technical side of the matter, as this can only aggravate the problems and lead, in the future, to even bigger problems.

If the reader is familiar with the structure of a chainsaw, he can safely skip this section and go straight to the next one, which describes the main types of breakdowns and how to fix them.

Video: disassembling the Shtil 180 chainsaw

For those who are holding a non-working saw in their hands for the first time, we present a brief, summary summary of the structure of a chainsaw.

The power unit driving the cutting chain is a single-cylinder, two-stroke, air-cooled internal combustion gasoline engine. The engine is controlled by adjusting the amount of gasoline supplied to the combustion chamber, as well as its quality composition. The control is a carburetor throttle valve connected to a button on the handle.

Location of chainsaw controls

Its operation is ensured by a fuel supply system consisting of:

- Gas tank with a capacity of 500 ml. (with a saw power of 2 kW and medium loads, it lasts for 30–35 minutes of work).

- Gasoline pump.

- A carburetor in which an air-droplet mixture with gasoline vapor is formed and injected into the combustion chamber of the engine.

The ignition system consists of magnets built into the engine flywheel, an ignition module with electronic circuitry, and a spark plug. A high voltage wire is installed between the electronic unit, in which electrical impulses are induced, and the spark plug.

2-plug terminal, 4-electronic unit, 5-flywheel

Air enters the carburetor through the air filter.

The air is purified by passing through dense synthetic fabric

Exhaust gases are removed through a muffler.

A metal gasket is installed under the muffler

There is no engine lubrication system. To prevent the cylinder walls, piston and crank mechanism from wearing out during operation, a special synthetic lubricant is added to gasoline (in a ratio of 1/50).

Motor oil for two-stroke engines

A fast-rotating chain needs lubrication. For this purpose, an oil supply system is provided for the chain movement channel. A pump located at the base of the drive sprocket forces lubricant from the oil tank. There are two types: piston or membrane. Some models are equipped with manual oil supply adjustment.

The crankshaft clutch with the chain drive is automatic. The sprocket begins to rotate as the engine speed increases. Thanks to this, the operation of the chainsaw has become much safer - when the chain gets jammed in the wood, the clutch immediately opens automatically.

Video: chainsaw device

Modern tools are equipped with additional systems that increase user productivity and safety. These include:

- Anti-vibration system. Reduces vibrations transmitted from the engine to the body.

- Reverse impact chain braking system. Increased protection against sudden body jerks.

- Lightweight starting and fuel supply system. Primer, decompression valve, spring starter.

- Quick chain tensioning mechanism without additional tools.

- System for additional air purification when working during snowfall and conditions of increased dustiness.

Electric saw device

An electric chain saw even works from a 220V household network, and if you choose a fairly powerful model, you should use a voltage stabilizer to avoid premature failure of the equipment. The design of a universal electric saw consists of the following components:

- Body part with buttons for starting work and locking.

- Comfortable handle (maybe two - main and rear).

- Electric motor (motor).

- Chain.

- Tire guide.

- Compartment for the oil tank.

- Oil pump.

- Brushes for electric saws.

- Protective cover.

- Handle for controlling chain tension.

Principle of operation

After the engine of an electric saw for a summer house, garden, etc. starts, a rotational impulse is transmitted to the gearbox, sprocket and chain. The chain bar has edges higher than the stationary part, this allows jamming in the material being processed.

Basic malfunctions of electric saws

Electric chain saw breakdowns do not occur out of nowhere. Most often, they can appear due to power surges in the network, improper operation of the unit, or poor build quality of the device. The main malfunctions of electric chain saws include the following.

- When I press the start button on the unit, the saw does not start. The network cable or power plug of the device may have failed. If everything is in order with the cable, then the cause of unit failure may be a faulty start button, burnout of the motor windings, or complete wear of the brushes.

- During operation, the brushes on the electric saw burn, and a circular fire appears on the motor commutator. The malfunction may be caused by worn brushes or a short circuit in the armature winding.

- The chain is not receiving lubrication. This happens if the oil in the tank runs out, the tube or hole responsible for supplying lubricant is clogged, or the oil pump fails.

- The unit cannot develop full power. Possible reasons are as follows: the brushes are worn out; interturn short circuit or break in the armature winding; low voltage in the network; the start button is faulty; jamming occurred in the gearbox; brake system malfunction.

- The power saw motor stops during operation. This behavior of the unit may be caused by gearbox jamming or brush wear.

- The electric motor of the device quickly overheats. There may be several reasons why the saw heats up: high ambient temperature; poor engine ventilation when operating at low speeds; ventilation holes are blocked or clogged; long-term operation of the unit under heavy load; increased rate of operation of the device without rest breaks; gearbox malfunction; lack of lubrication; damage to the motor windings.

- The unit makes an uneven cut. This may be due to dull chain cutters or uneven tire wear.

- When the motor is running, the chain remains motionless. Most often, breakdown occurs due to clutch failure. Also, this malfunction can occur if the gears of the gearbox and drive sprocket break.

Diagnostic and repair algorithm

When starting to repair an electric chain saw, it is necessary to carry out sequential diagnostics of all components of the unit to determine the cause of the breakdown. Repair of the unit is carried out based on the signs of malfunctions that were listed above. Below is a diagram of the electric saw, which shows in detail the internal structure of the unit.

The power saw does not turn on

If, when you press the start button, the unit does not turn on, then diagnostics are carried out in the following order.

- Check the voltage at the outlet. It may not exist due to a general shutdown or a malfunction of the outlet. Try turning on the unit in a different location.

- If there is voltage in the outlet, then you should check the network cable. Remove the engine housing cover and test each wire with a tester, touching one probe to the contact inside the unit, and the other to one of the rods of the electrical plug.

- If the wire is fine, then continue checking further. Check the wires going to the start button with a tester to see if there is a break.

- Next, you should ring the contacts of the button at the input and at its output while the key is pressed.

- After this, check the conductors going to the unit’s motor. If there is a soft start module in their way, then check the circuit at the input and output of it.

If the previous actions did not reveal the cause of the engine failure, then the brushes should be removed and checked. There are times when the engine does not start due to complete wear of one or both brushes, as well as due to broken conductors in them. If the brushes are working properly, then most likely the motor has failed, namely the stator or rotor windings have burned out. In this case, in order to ring the coils, you need to have some skills and knowledge in this area. It is better to take the electric saw motor to a specialist who will find the fault and rewind the coils.

Brushes and commutator burn

The appearance of strong sparking under the brushes can be caused by poor contact between the armature lamellas and the electrodes due to wear of the latter. To check this, you need to remove the parts from the brush holders.

It is believed that normal wear of brushes should be no more than 2/3 of their original length.

If the brushes are worn out, they need to be replaced. Also, brushes can spark due to clogging of the gap between the armature lamellas with graphite dust. Since graphite is a conductor, it causes short circuits and sparks.

To remove dirt, you need to thoroughly clean the slats using alcohol, cotton wool and a toothbrush. It is also recommended to polish them with the finest sandpaper (zero).

No lubrication on chain and bar

Lack of lubrication on the tire or its complete absence can be caused by a clogged hole or tube through which oil is supplied to the tire. Often the chain is not lubricated if the supply of lubricant from the reservoir is interrupted. This can happen if the filter at the end of the hose becomes clogged. The latter is always inside the container. To fix the problem, you need to remove the hose from the oil tank and rinse the filter with gasoline.

Advice! Sometimes the oil cannot reach the tire if it is too thick. It is recommended to use a special lubricant for chains of electric and gasoline saws.

A broken oil pump can also cause oil to not flow to the chain of the saw. After cleaning the filter, hose and lubricant supply hole, turn on the power saw and observe whether lubricant is supplied to the bar, provided that there is enough oil in the tank. If lubricant does not flow, it is necessary to remove and disassemble the oil pump, check the serviceability of the spring or its other parts (depending on the model of the unit) and, if necessary, replace it with a new one.

The engine gets very hot

The cause of engine overheating may be jamming of the gearbox gear, if it is heavily contaminated with small sawdust, or if foreign objects have come into contact with it, for example, fragments of a spring or plastic parts. Try turning the gearbox shaft by hand with the brake off. If rotation is difficult, you will need to disassemble the gearbox and fix the problem.

A break in the motor windings can also cause the motor to overheat. In this case, it will not be possible to repair the motor yourself. You will need to seek help from a specialist.

The engine may also overheat if there is no oil supplied to the saw chain. This leads to poor sliding of the equipment on the tire, and as a result, to increased load on the electric motor. How to diagnose and eliminate this malfunction was described above.

The engine does not develop full power

First of all, you need to check the voltage in the network. It can sometimes decrease and lead to a drop in the power of the unit. Also, a drop in power is caused by gearbox jamming or brush wear. How to fix these problems was discussed above.

A faulty start button also causes similar symptoms. If, when checking this part with a tester, a malfunction is detected, it cannot be repaired. The button must be replaced with a new one. But if checking the above reasons does not produce results, then one can only suspect that the armature windings have burned out or an interturn short circuit has occurred in them.

The unit stops during operation

If the unit stops during operation, one or both brushes may be completely worn out. This is checked quite simply: remove the brushes from the holders and check their length.

Sometimes you come across brushes with a short conductor located inside the pressure spring. In appearance, such a brush will have a sufficient electrode length, but if you look closely at the spring, it will not be fully compressed due to the short conductor.

Also, the unit can stop during operation if there are faults in the gearbox. In this case, you will hear the hum of the engine, which will not be able to rotate. Often the unit stops due to jamming of the end sprocket located at the end of the tire due to its clogging. The sprocket's main job is to move the chain around the top of the bar. As in the case of a gearbox failure, you will hear the engine humming. You can check whether the sprocket is jammed if you try to manually stretch the chain with the unit turned off and the brake released: if it does not move, it means that jamming has occurred in the tire.

Some models of tires have a collapsible design, which allows you to replace the end sprocket on the electric saw tire when it is worn out or replace the bearings. If your unit has a permanent tire, try cleaning the entire space near the sprocket using a thin wire and some penetrating liquid, such as kerosene or WD-40. After cleaning and lubricating this part, try turning it. If the sprocket turns with difficulty or does not turn at all, the bearing is damaged. In this case, the tire must be replaced.

The electric saw does not cut straight

If the electric saw is pulled to the side, in most cases this is due to one-sided tire wear. The chain, passing along such a bar, warps, and the headset produces an uneven cut. If you look at the tire, it will be more worn on one side than the other. The problem is solved by replacing the tire, as well as the chain and sprocket, which have also suffered uneven wear. Even if a new tire is installed on the unit, previously worn parts will quickly render it unusable.

Advice! To avoid uneven wear of the tire, it is recommended to remove it at regular intervals (every 2 hours during intensive work) and turn it over to the other side.

Comparison with petrol chain saws

For a correct comparison, you need to take into account the following parameters:

- Autonomy of use.

- Ease of maintenance.

- Reliability.

- Continuous operation time.

- Price.

In terms of autonomy, corded chainsaws are inferior to gasoline chainsaws. Their area of action is limited by the length of the “carrying”. In addition, the electrical cable makes working at height difficult and requires constant attention (to eliminate the risk of getting caught in the chain).

In terms of ease of maintenance, electric saws are superior to gasoline ones. All their service operations come down to infrequent replacement of worn engine brushes, adding oil and tightening the chain.

The more complex a tool is, the greater the likelihood of it breaking. This rule is also true when comparing gas chain saws and electric saws. In an electric saw, as people say, “there is nothing to break.” For a gasoline analogue, performance depends on a number of factors (quality of the fuel-oil mixture, cleanliness of the air filter, condition of the spark plug).

The duration of continuous operation of gasoline saws is longer. The electric motor requires frequent stops to cool down (every 15-20 minutes). An internal combustion engine requires rest no earlier than 40-50 minutes after start-up.

Price is an important argument when purchasing. All other things being equal, gas-powered tools designed for cutting wood are more expensive than electric ones.

Finally, we note that the electric drive is more environmentally friendly than the gasoline drive. When working with an electric saw, you will not have to breathe toxic exhaust gases.

Repair of electric chain saw EPC-3

The advantage of the EChP-3 is that it is a Russian electric saw! You do not need to wait for spare parts or send them to a specialized service center. The design of Victar brand equipment is as simple as a Kalashnikov assault rifle - use our instructions and replace spare parts yourself right at the factory!

EPC-3 reduces repair costs because:

- It has a simple design, unlike chainsaws. You can assemble and disassemble the EPC-3 in a matter of minutes.

- The cost of parts is lower than that of analogue saws. The price of imported spare parts depends on the exchange rate, and Russian spare parts have been supplied for years at the same price list.

With the same period and frequency of operation of the EPC-3 and imported saws, you will spend several times less on maintenance. Find out more about Victar equipment and take it for a test drive today!

Disassembling a power saw to repair damage

To begin troubleshooting yourself, it is recommended that you first learn how to disassemble a power saw. Complete disassembly of the unit using the example of a Makita electric saw occurs as follows.

- Unscrew the screw that secures the tire and loosen the fastening slightly. Next, use the chain tension regulator to loosen the saw chain.

- Completely unscrew the tire mounting screw and remove the cover.

- Remove the chain from the sprocket and disconnect the bar from the unit (along with the chain).

- Now you need to unscrew the 2 screws that secure the engine on the sprocket side.

- You should also unscrew a couple of screws on the other side of the unit. For convenience, you can remove the oil tank cap.

- Once all the fasteners have been removed, you can disconnect the gearbox from the engine.

- The next step requires removing the drive sprocket. Since it is secured with a lock washer, it must be removed using a flathead screwdriver.

- After removing the retaining ring, remove the washer located under it and remove the sprocket from the gearbox shaft. Then tighten the 6 screws that secure the gear stops and the handle of the device.

- After tightening the fasteners, disconnect the stops and the handle from the gearbox.

- Next, you should turn the gearbox over and remove the cover.

- After removing the tube from the pump, remove the oil reservoir.

- Press the brake lever in the direction of braking until you hear a click and release it.

- Turn the gearbox over and disconnect the aluminum housing along with the shaft.

- Under the plastic cover, as well as on the gears, you can see an accumulation of dust, sawdust and grease.

- All gearbox parts must be cleaned of dirt.

- Next, you should remove the oil pump plunger.

- Remove the oil pump from the plastic gearbox cover.

- Rotate both parts of the pump in different directions, try to gently pull them one from the other. Once the pump is disconnected, the ball and spring will fall out.

- Next, you need to disassemble the brake mechanism. Put the lever on and turn it until it clicks. The spring tension in this position of the lever will be minimal.

- Pry the spring with a screwdriver and remove it from the aluminum housing.

- Remove the rods together with the spring.

- To remove the brake band, unscrew the screw that holds it.

- Before assembly, the drive gear must be lubricated. This can be done as shown in the following photo. When the unit operates, the lubricant will spread through the gear teeth due to centrifugal force.

- The next step requires disassembling the engine housing. Remove the gear mounted on the motor shaft.

- Remove the electric brushes and unscrew 6 screws on one side of the housing and 1 screw on the other.

- Remove the cover.

- Remove the motor rotor using slight force.

This completes the complete disassembly of the unit. The electric saw is assembled in the reverse order.

DIY electric saw repair

Like any tool, a chain saw is subject to wear and tear. For initial diagnostics, the technician should pay attention to the following failures that occur while working with the tool:

- If it is impossible to turn on the tool, check the condition of the cable and its connections to the housing.

- Then you should pay attention to the chain stopper, changing its position if necessary.

- When power decreases, the tool should be inspected for brush wear.

- If extraneous noises or sounds occur, you need to look to see if the oil-conducting channels are clogged. If necessary, clean them and add oil to the required level.

- If the case is damaged, the instrument cannot be repaired at home - it must be taken to a service center to have the defect eliminated.

Electric saw repair

A new saw usually comes with a warranty period under which the company will repair or replace it free of charge. But if the saw is not new, you have to repair it yourself.

- First of all, it is necessary to determine the cause of the saw malfunction based on the signs described above:

- If the saw does not turn on, check the power supply, wires, contacts and toggle switch. It is quite possible that your contacts are charred or the Chinese wiring is burnt out;

- If the saw does not turn off, there may be a problem with the chain brake or a problem with the toggle switch;

- A burning smell and smoke indicate burning of the wiring;

- Low power - problems with the motor;

- Noise and crackling - sprockets and gears.

- Open the cover of the electric saw body and find the breakdown directly;

- Calculate the feasibility of repairs. So that it does not cost you more than a new instrument;

- Buy spare parts necessary for repairs: You can buy spare parts for an electric saw in Ukraine in the Benzo-zip online store, which offers the most popular spare parts at reasonable prices. We can order the gears, chain drive sprockets, oil pumps and other spare parts you need for your saw model.

- Replace faulty parts with serviceable ones and assemble the tool.

- Check for proper operation.

Leave your review

You must be logged in to post a comment.

Source: www.stroyimdom.ru

Remaking a power saw

You usually think about modifying a chain saw when something is missing. For example, a milling machine. To do this you will need:

- welding machine;

- adapter for cutters;

- flat steel roller;

- gearbox

The procedure is as follows. Weld a wheel at the end of the boom base, cutting the boom so that the wheel fits exactly into the cut contour to prevent tension or weakening of the chain. A removable adapter to the cutters is attached to the wheel.

We hope that after reading the information briefly presented in our article, you will be able to independently troubleshoot minor problems and operate this tool as a confident user.

How to use a power saw?

Before you start working with the tool, carefully read the operating instructions for the electric saw. In order for the unit to operate safely and productively, the following items will need to be checked:

- Make sure there is the required amount of lubricant in the oil tank. In addition, it is recommended to check the supply system by turning on the unit and holding it above a light surface. If drops appear, it functions correctly.

- Check that the safety bar is locked correctly.

- The chain must be checked when it is cold. The gap between the guide and the chain should be three to four millimeters. To tension the chain, you need to turn the screw on the side of the housing.

- In some cases, you may need an extension cord for your electric saw.

Sawing

- Electric garden saws are designed for sawing dry and wet wood of various species. They can be used to work with boards, logs and other particle boards.

- Professional and semi-professional electric saws must be checked for the level of chain tension, since a very weak or strong condition will make work impossible or lead to breakdown.

- It is recommended to install a stopper on the object being cut.

- When working with thick trunks or trees, the use of a limiter is not possible, so extreme care must be taken to avoid jerking. Try to choose the minimum angle towards the material being cut.

- Make sure that the saw does not come into contact with metal or stone elements.

Tree cutting

- An electric chain saw made in Russia or abroad is used for cutting down trees. Please note that the girth of the tree should not exceed the length of the saw guide. The electric saw's instructions also contain safety requirements that must be followed as precisely as possible in order to avoid injuries and breakdowns.

- Determine the direction in which the tree to be cut will fall. If this cannot be done clearly, felling aids will need to be used.

Mini electric chain saws cannot be used in the rain if you are in an open space without a shelter. Try to ensure that the saw part does not come into contact with the ground, otherwise you risk not only dulling the links, but also clogging the system, rendering it inoperable. If the electric saw is out of order, repairing it yourself is possible; this will require special tools and a certain skill.

How to sharpen a chain yourself

Working with a properly sharpened tool makes it possible to significantly extend its service life. Regardless of the type of chain, sharpening is the main operation to maintain the chain in good condition.

It is optimal to use machine chain sharpening. But if it is not possible to use an electric machine, then you can also use the manual sharpening method using a special file and a guide jig.

The chain is put on the bar and secured in the saw. After this, the chain is tensioned. After it is tensioned, sharpening is done:

- At an angle of 90 degrees to the bar in a horizontal plane, a jig with a file is installed in the cutout of the cutting tooth.

- After this, a tilt is made in the vertical plane so that the file follows the direction of the previous sharpening.

- The metal is removed using 2-3 movements with force.

- The jig is removed and moved to the next tooth on this side of the sharpening.

- Having finished setting the edge on one side, the file and jig are moved to the other side, and the process is repeated.

As you can see, the process of repairing an electric chain saw does not pose a big problem and is quite feasible even for those who have never repaired power tools. Another thing is that before you start disassembling, you need to carefully study the structure of the tool and imagine all the operations that will need to be performed during repair.

How to sharpen a power saw yourself?

One of the components of a power saw that needs to be constantly monitored is the chain.

It needs to be sharpened from time to time. If you delay this process, you will not be able to repair the electric chain saw yourself. In this case, it will have to be sent to a service center, where sharpening will be done using special devices.

You can extend the service life of the sawing element as follows:

- Before starting work, you need to make sure that there are no hard metal elements in the workpiece. If the cutting element comes into contact with a metal workpiece, then jags or chips will appear on the chain that cannot be removed in the future.

- Do not sharpen on the ground, as digging into the ground can clog the grooves with oil. As a result, the chain will not be lubricated and will wear out quickly.

- It is imperative to monitor the wedge of the saw. Jamming should not be allowed, since as a result the metal will overheat and reduce its service life.

It is necessary to determine whether the electric saw needs to be sharpened. To do this, you need to pay attention to the chips: if they are small or dark in color, then the chain is dull. Blunt edges are not able to remove the required cutting layer; as a result, the chips will be crushed. The quality of tool sharpening can also be determined by inspection. The part used for sawing should not have any defects in the form of torn pieces. The shape of the tooth and cutting edge should be the same as on the unused jig.

If these factors do not meet the relevant requirements, then the saw needs to be sharpened.

If you perform work using a dull saw, this may affect the performance, as well as the period of possible operation of the tool.

If you use blunt elements, the load on the electric motor will increase, as a result it will overheat and all its parts will wear out before the specified period.

Return to contents

Sequence of actions for manual sharpening

You can sharpen a power saw as follows:

- To sharpen, you will need to prepare a special set of devices, which consists of files in the shape of circles and ovals, a mandrel and a gauge. In rare cases, such a kit may include a hook for cleaning the slots of the chain.

- The circle-shaped file must be combined with the mandrel.

- The flat file and gauge should be used separately.

- The chain is sharpened on a saw blade.

- The mandrel is placed on the edge of the cutting tooth, and it is necessary to take into account the sharpening angle of the chamfer.

- The sharpening angle should be from 30° to 100°. The most time-consuming editing process is setting the appropriate angle. If you set the angle incorrectly, the tool will be damaged.

- During the sharpening process, the file must be installed perpendicular to the shank; it should protrude slightly above the tooth.

- Sharpening must be done in one direction.

- When one tooth is sharpened, you need to scroll the chain and start sharpening the other tooth.

- When all the teeth have been sharpened with a file, you need to start processing the cut - the protrusion on the chain that does not have edges for cutting. This element is placed on the same plate with a tooth. This device is designed to form a depression during the cutting process.

- If the cut stops protrude, the chain will not be able to cut. In this case, it will slip. If the restrictive elements are deeply recessed, the tree will jam the cutting element of the device.

- The cutting stops are adjusted using a gauge. It will need to be applied to the edge of the teeth for cutting. The end rail should be located flush with the limiting element.

- If the restrictive element protrudes, it must be trimmed. In this case, you can use an ordinary flat file.

- A similar tool must be moved along the restrictive element in the same direction.

basket/filter

Reasons why the ALCO electric chain saw does not start or does not work correctly

The German ALCO electric chain saw is a lightweight and easy-to-use power saw that can easily handle thick branches, boards and other types of wood. This technique is reliable and trouble-free, but due to wear of the equipment and carbon brushes, problems with starting and operating the tool are possible. What to do if the reason why it does not turn on and, moreover, does not make a neat and even cut, is due to problems in the assembly or faulty equipment of this saw power tool?

Causes of electric saw breakdowns

Any malfunction does not arise out of the blue. Most often, the reason is poor assembly and quality, as well as violation of the operating conditions of the electrical appliance. If you buy a good tool from a trusted manufacturer, it will be quite difficult to finish it off. Most often, repair of electric saws is needed for the following reasons:

- Voltage surges in the network. If the electric saw has built-in fuses that protect against voltage surges, then the device will withstand fluctuations from 220 W by 10%, both downward and upward. If there is no protection, the electric saw motor burns out.

- Failure to comply with operating conditions. If the instructions indicate that the device should be used in this mode - 30 minutes on, 15 minutes break - you must adhere to these manufacturer’s recommendations. Otherwise, you risk overheating the motor, which will have negative consequences.

- Untimely lubrication. Many models of electric saws have automatic lubrication. You just need to make sure that you don’t run out of oil. Running a power saw dry is death for the engine. If oil stops flowing to the sprocket, you need to lubricate it manually every 3-5 hours of operation.

- Power overload. If this happens, it is also the fault of the user, not the manufacturer. When it is indicated that an electric saw can cut logs with a diameter of up to 5 cm, then you should not use a tool for a ten-centimeter trunk.

- Design flaws. Such a breakdown occurs due to the fault of the manufacturer. Most often, users encounter such a disadvantage as a rigid clutch between the gearbox and the armature. Under heavy load (a hard log or a dull tape), it jams and heats up. As a result, the gears of the electric saw wear out quickly. In this case, you need to sharpen the tool in time and avoid overload.

Any device is not forever, and nothing can be done about it. Another working day shortens his life. There are cases when only a professional technician can handle a breakdown, for example, when the case is severely damaged. But most often it is possible to repair electric saws with your own hands. This is not as difficult to do as it seems at first glance.

Electric saws Makita (Makita)

Makita UC3530A in our store: https://www.klondayk.com.ua/ru/products/details/elektropila_makita_uc3530a/index.html

The Makita UC 3530 A universal electric saw will come in handy on a personal plot, garden or construction site. This model is characterized by high performance, reliability and durability, and in addition to this, it is very comfortable to use. The electric saw is equipped with a quick-acting device for tensioning the chain and removing the bar without the use of keys, which not only improves productivity, but also eliminates the need to constantly carry additional keys.

The Makita UC 3530 A electric saw is controlled using convenient and understandable buttons and levers. Thanks to its design features, this model is easy to maintain. The use of sealed ball bearings and a special gearbox lubrication system ensures long-term operation of the electric saw without specialized maintenance.

In order to increase the safety of the saw, the developers have provided this model with an inertial chain brake, which protects the user from accidental injury as a result of a “kickback”. This system ensures that the chain stops in a fraction of a second - even before a “thrown” tool can “overtake” the user and cause injury. To protect the network from overloads and to prevent premature wear of the mechanism, the Makita UC3530A saw has a built-in electronic starting current limiting system.

The Makita UC 3530 A electric saw is equipped with a powerful engine with a longitudinal arrangement, providing a high sawing speed of 13.3 m/s. Thanks to the longitudinal arrangement of the motor, the tool is compact and perfectly balanced. Comfortable rubberized handles provide maximum control over the saw during operation. The saw is equipped with an automatic chain lubrication system (the capacity of the built-in oil tank is 0.14 liters), which extends the service life of the saw set and the tool as a whole. Visual control of the lubricant level is carried out through a transparent viewing window.

Chainsaws today find application in a wide range of areas. This relatively simple tool is necessary in everyday life to solve a wide variety of problems. You can order the Makita UC3530A electric saw in the Klondike online store.

Subscribe, leave a comment, like.

Useful

video?

Thank you

in the comments!