Chain oil

Almost all chainsaws come with an instruction manual. Such a manual states that in all cases it is necessary to fill in chain oil with a high adhesive effect.

Adhesion is an indicator characterizing the degree of adhesion of the lubricant to the surface of the chain bar.

Adhesive oil is required for chain operation for the following reasons:

- When the device is operating, the chain moves at high speed. If you use oil with a low adhesion index, then during operation it will be scattered due to inertia. You can check this yourself by simply adding a regular lubricant to the surface and adding gas.

- The oil must have high lubricating properties. At a high speed of movement of the tire, it can become very hot, due to which the metal used during manufacturing becomes soft and less wear-resistant.

Lubricating oil in various containers

It is worth considering the fact that when using a chainsaw for a long time, a large amount of oil will be required, since it is quickly wiped off the surface of the tire. A variety of companies are involved in the production of chain lubricants.

Chainsaw Oil Consumption

Content

Oil for chainsaw chains. What oil should I use to lubricate a chainsaw chain?

Chainsaws are a popular tool for those who have to do countless household chores without the help of others. They can be used for various purposes - preparing firewood, cutting dry branches... But in order for the device to last as long as possible, it is necessary to properly care for it, choosing different compositions well. A special role is played by oil for chainsaw chains, which is selected depending on the operating mechanisms of the tool and its features.

What to consider?

Careful attention should be paid to lubricating the saw chain. First, you should choose a special oil that will not harm the oil pump. The consumption of such oil is comparable to that of a chainsaw, which is perfect for lubricating a chain. In addition, this will ensure high-quality operation of the self-lubrication system. The chain also requires proper storage, that is, immersion in oil, and if it wears out, you should not try to revive the old chain - it’s easier to replace it. Which oil to choose for chainsaw chains so that it is safe and meets all requirements?

Types and composition

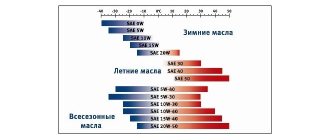

You should choose a specific oil depending on where and how the chainsaw is used. Mineral compositions are suitable for summer and warm seasons. In other cases, it is better to use synthetic or semi-synthetic oils. If it is necessary to lubricate the chain, you should not use used oils, which will lead to clogging of the fuel system, and then to serious damage to the tool.

Chainsaw chain oil must be thoroughly cleaned so that lubrication can be carried out correctly and accurately. If you use low-quality compounds, there will be no contact between the saw elements and the bar, sparks will appear, and subsequently the moving parts of the saw will wear out.

How to choose?

Each chainsaw has a carburetor two-stroke engine and two tanks: one is filled with gasoline, the other with oil. When choosing a lubricant composition, zoning plays an important role - it should be minimal. Another important indicator is resistance to low temperatures: the oil should not solidify at extreme temperatures, which will ensure the quality of operation of the entire tool.

READ Chainsaw Hyundai X 560 Video

For lubrication, it is advisable to use adhesive oil for chainsaw chains , which contains special substances due to which the composition adheres well to the chain. High-quality oil will remain on the chain as it rotates, and the chain itself will be more reliable in operation.

Another important indicator of lubricant is thickness: if the composition is liquid, it will be consumed in greater quantities. To avoid harming the environment when using a chainsaw, it is important to use vegetable-based oil - its waste will decompose in the natural environment.

Which chainsaw oil to choose, since modern manufacturers offer a wide range of options? Among the specialized manufacturers, we can note such brands as Divinol, Bio-Kettenol, Ravenol, VegOil, Mobil, Castrol, Shell. Let's take a closer look at the features of their products.

Divinol

This brand offers high-quality chain lubricant, which has good adhesive and lubricating properties, so that lubrication is carried out efficiently, and chain links and hinges are reliably protected from wear. The optimal combination of viscosity and temperature characteristics ensures that this oil can be used in any season and at any temperature.

Divinol offers different oils for chainsaw chains . Which one should I use? Zweitaktoel FF attracts attention due to its economical consumption, combination with any fuel, prevention of aging of the fuel mixture and excellent corrosion protection. In addition, this oil can be used at any temperature. Divinol Kettenol and Divinol Kettenol Bio can be used to lubricate chainsaw chains and bars. This article will help you decide on the right oil for a chainsaw chain from well-known brands. Using these compounds, you can reliably protect chain links and joints from wear while guaranteeing economical oil consumption. The brand's high-quality organic oils provide excellent lubrication and adhesive properties, making their use not only easy but also environmentally friendly.

Proper lubrication of a chainsaw chain

How should a chainsaw chain

.

Adjusting the Husqvarna 236 chain oil supply

Unfortunately in a chainsaw

Husqvarna 236 does not provide for adjusting

the oil

for

chain

, so my

READ Launch of Chainsaw Shtil 180

Ravenol

Which oil to lubricate a chainsaw chain? Many people note Ravenol brand compositions. Thus, Ravenol Saegekettenoel S 85 is a special mineral oil created in Germany from high quality base oil with the addition of a number of additives. It is suitable for lubricating saw chains and has good adhesion and lubricating properties. Thanks to special additives, the oil remains on the chain even at high saw speeds, and the chain itself becomes more reliable in operation. Provides oil and reliable protection against corrosion, even if work is carried out in less than favorable conditions. Thanks to the use of this composition you can:

- reduce vibration of the saw chain;

- reliably protect it from corrosion;

- cool the circuit due to good thermal conductivity;

- quickly and cleanly cut any type of wood.

Stihl BioPlus

Probably every user is familiar with Stihl brand products. chainsaw oil "Stil" is effective and is based on plant components. Chain oil is of high quality, which can be appreciated in any climatic conditions. Due to their environmental friendliness, Stihl products have always been popular with customers. Particularly noteworthy is the Stihl BioPlus chain lubricant, which is designed for processing high-speed chains. It is different:

- resistance to oiling;

- excellent adhesion thanks to special additives;

- excellent protection of the cutting set;

- excellent fluidity, which is maintained even at low temperatures;

- oxidation resistance.

The most important thing is that the oil is absolutely safe for the environment, as it decomposes naturally.

Stihl semi-synthetic oil

Stihl chainsaw chain oil is an environmentally friendly lubricant, as it is made from high-quality virgin raffinates. The oil contains no impurities that can pollute the environment. This product can be used in any climatic conditions, and it will behave equally effectively even at low temperatures. Stihl chain oil provides reliable wear protection for saw chains. This composition can be purchased in different quantities. it depends on the characteristics of the chainsaw and the degree of load on it.

Husqvarna

The products of this brand also do not need unnecessary introductions, since they have proven themselves only from the best side. Vegeil Husqvarna chain lubricant oil attracts attention, which is created on a plant basis, has good lubricating properties and is highly environmentally friendly. The oil is economical, biodegradable, and has a low viscosity even when operating at low temperatures. Due to their excellent performance characteristics, oils of this brand are considered one of the best.

READ How to Clean the Carburetor on a Shtil 180 Chainsaw

Oregon

What oil to use to lubricate a chainsaw chain and how to choose one so that it can be used at any time of the year? The Oregon brand offers compounds that are suitable for all types of instruments. Viscosity stability is the key to the fact that the oil is suitable for use at any time of the year. The composition contains refined mineral oils to which additives are added. The peculiarity of Oregon compositions is that they are manufactured on the basis of high-molecular compounds. For lubricating a chainsaw chain, firewood is excellent for chain oil. The distinctive features of the oil include:

- protection of the guide bar and chain from overheating;

- vibration reduction;

- preventing corrosion due to the formation of an oil film.

Thanks to special adhesive additives, this oil acquires greater stickiness and viscosity, so even at high speeds it will not splash and will remain on the chain and tire. Thanks to regular use of oil, you can reduce the load on the cutting set, and, in general, on the entire mechanism of the chainsaw. Special additives reduce saw energy consumption, increasing the efficiency of the sawing process. The main thing is that when using these products, resinous deposits do not form.

Sage-Kettenoil

This oil has such a specific composition that it is completely biodegradable, but remains safe from the point of view of exposure to harmful substances. Thanks to the combination of vegetable oils with high-quality additives, the chain is lubricated more efficiently and is reliably protected from wear under any operating conditions. Due to its good adhesive and lubrication properties, lubrication is carried out as conveniently and optimally as possible, and the composition can be used in frosts of up to 30 degrees.

Source

What parts of a chainsaw need oil?

A modern chainsaw is represented by a complex mechanism, which consists of a large number of different elements. The following elements require lubrication:

- A chain is an element on which blades for sawing wood are attached. It consists of a large number of individual elements movably connected to each other. When using the device, the surface may become very hot. In this case, the metal can rust due to high humidity, which significantly reduces its service life.

- The engine is the part of the chainsaw through which rotation is transmitted to the bar. Modern engines also need a lubricant that can significantly extend their service life. Different lubricating products are used to lubricate the chain and engine, which is worth considering.

Pouring oil into a chainsaw

The operating instructions also indicate which parts of the chainsaw need lubrication.

When to use special chain oil?

Manufacturers recommend using special oil to lubricate the chain in all cases of using a chainsaw. This recommendation is related to the following points:

- The oil pump may fail. This is due to the special properties of the lubricant.

- The use of waste or other oils for other purposes reduces the tool’s ability to perform at high speeds.

- If the tire is heavily worn, you cannot install a new chain on it. This is due to increased surface wear. It is recommended to purchase at least four chains for frequent work.

- It is strictly forbidden to work without oil poured into the tank. When refueling the chainsaw, the tire must be lubricated.

When using special oil to lubricate the chain, you need to pay attention to its quality, since the composition should not contain various impurities or debris. Otherwise, the oil pump may quickly fail.

Chainsaw chain lubrication

Almost all manufacturers of chainsaws and components produce lubricants. Chainsaw chain oil protects the metal from rapid wear and corrosion. In addition, chain oil stays on the surface for a long time even during long-term operation of the device.

Chainsaw Chain Oil Consumption

Chainsaw. What kind of oil is used to lubricate the chain?

Chainsaws. A popular tool for those who deal with numerous household chores. They can be used for different purposes. collect firewood, trim dry branches. But in order for the device to last as long as possible, it is necessary to take proper care of it by choosing the right different connections. A special role is played by chain saw oil, which is selected depending on the principles of the tool and its characteristics.

Content

What to count?

Proper care should be taken when lubricating chain saws. , you should choose special oil that will not damage the oil pump. In addition, this will ensure high-quality operation of the self-lubricating system. The chain requires proper storage, that is, immersion in oil, and in case of wear, do not try to revive it; it is easier to replace it. What is the best chain oil that is safe and meets all requirements?

Types and composition

Selecting a specific oil

follows depending on where and how the chainsaw works. Mineral compounds are suitable for the summer and warm seasons. In other cases, it is better to use synthetic or semi-synthetic oils. If it is necessary to lubricate the chain, there is no need to use waste oils, which will clog the fuel system and then cause serious damage to the tool.

The chainsaw oil must be thoroughly cleaned to ensure that the lubricant is applied correctly and accurately. If you use poor-quality connections, there will be no contact between the saw elements and the bars, sparks will appear, and then the moving parts of the saw will wear out.

How to choose?

Each chainsaw has a two-stroke carburetor engine and two tanks: one filled with gasoline, the second. oil. When choosing a lubricant composition, zoning plays an important role. it should be minimal. Another important indicator is resistance to low temperatures: the oil should not freeze at extreme temperatures, which will ensure the quality of the entire tool.

READ Adjusting the Carburetor of the Champion 142 Chainsaw

For lubrication, it is recommended to use adhesive chain oil containing special substances that allow the composition to adhere well to the chain. High-quality oil will remain on the chain as it rotates, and the chain itself will be more reliable in operation.

Another important indicator of a lubricant is density: if the composition is liquid, it will be consumed in large quantities. To avoid harm to the environment, it is important to use vegetable oil when using a chainsaw. its waste will decompose in the natural environment.

Which chainsaw oil should you choose because modern manufacturers offer a wide range of options? Among the specialized manufacturers, we can mention such brands as Divinol, Bio-Kettenol, Ravenol, VegOil, Mobil, Castrol, Shell. Let's take a closer look at the features of their products.

Divinol

This brand offers high quality chain lube that has good adhesive and lubrication properties, so that the lubrication is done efficiently and the hinges and chain loops are reliably protected from wear. The optimal combination of viscosity and temperature characteristics guarantees that this oil can be used at any time of the year and at any temperature.

Divinol offers a variety of oils for chainsaws. What's the use of them? Zweitaktoel FF pays attention to economical consumption, connection to any fuel, prevention of aging of the fuel mixture and excellent corrosion protection. In addition, this oil can be used at any temperature. Divinol Kettenol and Divinol Kettenol Bio can be used to lubricate chainsaws and chainsaws. With these connections you can reliably protect chain links and joints from wear, while guaranteeing economical consumption

oils High-quality organic oils of this brand provide excellent lubricating and adhesive properties, so their use is not only simple, but also environmentally friendly.

Proper lubrication of a chainsaw chain

How should a chainsaw chain

.

Which chainsaw chain oil is best to use, choosing chain oil for chainsaws and chainsaws

What kind of oil

select and use to

lubricate chainsaws

/chainsaws.

READ How many teeth are on the chainsaw Shtil 180

Ravenol

Which chain lubrication oil should you choose? Many people note Ravenol brand compositions. Thus, Ravenol Saegekettenoel S 85 is a special mineral oil created in Germany from high quality base oil with the addition of various additives. It is suitable for saw chain lubrication and has good adhesive and lubricating properties. Thanks to special additives, the oil remains on the chain even at high saw speeds, and the chain itself becomes more reliable in operation. Provides oil and reliable corrosion protection even when operating under the most favorable conditions. By using this composition you can:

- reduce vibration of the saw chain;

- reliably protect it from corrosion;

- cool the circuit due to good thermal conductivity;

- quickly and cleanly cut all types of trees.

Stihl BioPlus

Probably every user listens to Stihl brand products. The eco-friendly chainsaw oil is calm, effective and based on plant components. Chain oil is of high quality, which can be appreciated in any climatic conditions. Stihl's eco-friendly products have always been popular among customers. Of particular note is chain lubrication

Stihl BioPlus, which is designed to work with high-speed chains. This is different:

- grease resistance;

- excellent adhesion thanks to special additives;

- excellent protection of the cutting set;

- excellent fluidity, which is maintained even at low temperatures;

- oxidation resistance.

The most important thing is that the oil is absolutely safe for the environment, as it decomposes naturally.

Stihl semi-synthetic oil

Stihl chain saw oil is an environmentally friendly lubricant as it is made from high quality virgin raffinates. The oil does not contain impurities that can pollute the environment. This tool can be used in any climatic conditions, and it will be equally effective even at low temperatures. Stihl chain oil provides reliable wear protection for saw chains. You can buy this composition in different volumes. it depends on the characteristics of the chainsaw and the degree of load on it.

Husqvarna

The products of this brand also do not need unnecessary ideas, since it has shown itself only from its best side. Attention is drawn to chain oil. Vegeil Husqvarna, created at the factory, has good lubricating properties and high environmental friendliness. The oil is economical, biodegradable, and has low viscosity even at low temperatures. Thanks to its excellent characteristics, this brand of oil is considered one of the best.

READ How to Remove the Clutch on a Chinese Chainsaw

Oregon

What kind of oil is used to lubricate chains and how to choose one so that it can be used at any time of the year? The Oregon brand offers connections that are suitable for all types of tools. Viscosity stability guarantees that the oil is suitable for use at any time of the year. The composition includes purified mineral oils to which additives are added. The peculiarity of Oregon compounds is that they are made on the basis of high molecular weight compounds. The distinctive features of the oil are:

- protection of the guide bar and chain from overheating;

- vibration reduction;

- preventing corrosion due to the formation of an oil film.

Thanks to special adhesive additives, this oil acquires greater viscosity and viscosity, so even at high speeds it will not splash and remain on the chain and bar. Regular use of oil can reduce the load on the cutting set and, in general, the entire mechanism of the chainsaw. Special additives can reduce the energy consumption of the saw, which increases the efficiency of the sawing process. The main thing is that when using these tools, deposited deposits are not formed.

Sage-Kettenoil

This oil has such a specific composition that it is completely biodegradable, but remains safe from the point of view of exposure to harmful substances. Thanks to the combination of vegetable oils with high-quality additives, the chain is lubricated more efficiently and is reliably protected from wear under any operating conditions. Thanks to its good adhesive and lubricity, lubrication is carried out as conveniently and optimally as possible, and the composition can work in frosts of up to 30 degrees.

A little about lubrication of a chainsaw chain by working off

Used oil is oil that has already served its useful life in an engine or gearbox. It is often used to save money, including when servicing the chainsaw.

It is worth considering that working out can lead to rapid wear of the structure.

This can be associated with the following points:

- Often the breakdown is associated with a large amount of metal shavings in the composition. It gets there during the operation of the engine and gearbox, then accumulates in the pan.

- When metal shavings come into contact with a tire, they become like an abrasive. Due to this, the process of surface wear is significantly accelerated. The sprocket and bearing are worn out.

- Mining also has a negative impact on the connection points of the moving elements of the chain. Due to severe wear, the likelihood of its breakage during operation increases.

Waste oil

The above information indicates that in all cases you need to use a special product that is designed for this purpose. Processing that was previously used in the engine or gearbox is not suitable for a chainsaw.

How should a chain oil lubrication system work?

To ensure reliable operation of the chainsaw, a special chain oil lubrication system is installed. An example is the following information:

- Fuel tanks are selected by volume, taking into account that when the fuel is completely used up, some oil should remain. In addition, it is important to correctly set the carburetor so that fuel is not quickly produced.

- With a slow decrease in oil at the time of use of the saw, the lubrication efficiency decreases several times, and the conductivity of the channels also decreases. Over time, a malfunction may appear that will be quite difficult to fix.

- It is recommended to check the condition of the oil pump from time to time. If necessary, you can adjust the performance using a special screw.

- You can check the correct operation of the pump yourself. To do this, the tire is brought to an illuminated surface. If oil splashes appear on it, then the design is working correctly. Lubricant consumption is adjusted depending on the specific situation.

Saw chain lubrication system

A sign that an insufficient amount of lubricant is getting into the cutting zone is strong heating and the appearance of smoke and an unpleasant odor when cutting wood. When heated strongly, the metal expands, causing the chain to become pinched in the groove. The effectiveness of the lubrication rate decreases when the tire gets into the ground. That is why, if the saw is not used carefully, it will quickly wear out. When chain oil comes into contact with the ground, it collects various substances, due to which the heating of the metal accelerates.

Electric saw chain lubrication system: operating principle

Modern models of electric saws are most often equipped with special systems that automatically supply oil to the cutting tool. Old versions of such units required manual lubrication. For this purpose, you need to use oil that has certain technical characteristics and viscosity index.

Oil is poured into a special tank, from which after a certain time it is pushed out by an oil pump. The feed mechanism must provide enough lubrication to the saw's chain to prevent increased friction, which causes overheating.

When the engine speed increases, the oil pump starts working. The gear is driven on the main shaft. The pressure in the system increases. The oil begins to move towards the tire until it comes into contact with the saw housing. There is a groove there. It is towards this that the channel supplying oil is directed. This longitudinal groove is necessary so that lubricant can be supplied to the tire regardless of the voltage level of the mechanism. The position of the tire during operation does not matter; lubricant, thanks to the presence of a groove, will flow to it constantly and evenly. The links of the chain itself have a hole or their own groove, from where the lubricant is distributed along its entire length. If the motor increases the speed of rotation, then the pumping of lubricant material also occurs faster. Therefore, you only need to fill the electric saw with lubricant when the engine is turned off.

Universality problems

Universal oil for lubricating chainsaw chains has relatively unattractive performance properties. It is worth considering that even lubricant manufacturers do not indicate their 100% versatility.

An incorrect choice leads to the fact that the wear of the structure increases by approximately 10% and the working life of the saw set is reduced.

The information above indicates that there are no universal options for oils. That is why when choosing, you need to pay attention to operational properties, in particular, temperature conditions.

Why do you need to lubricate the chain of an electric saw?

Lubricating your chain saw helps reduce friction. When parts of the tool come into contact with each other, they do not experience unnecessary heating. The friction force is equalized. A means for lubricating the chain of an electric saw prevents failure of both the chain itself and the bar.

Sometimes when working with an electric saw, there is a need for extra effort during cutting. This indicates that low-quality lubricant was used, or the quantity was not enough. Then you need to immediately check the oil level in the tank. You can also lubricate the saw chain itself to complete the job.

If you use the proper quality chain saw oil and apply it on time, it will be easier to work with the electric saw. This also contributes to the safety of the instrument. Lubrication of the unit prevents breakdowns and failure.

Performance properties

When producing branded and standard oils, standards related to viscosity or density, as well as the concentration of foreign impurities, are taken into account. Among the features we note the following points:

- Organic and mineral compositions practically do not differ in their performance qualities. This is due to the fact that the lubricant flies off the surface of the tire quite quickly. There is no point in overpaying significantly for the purchase of expensive lubricants, since the difference is insignificant.

- The protective properties of mineral compositions are significantly higher than those of natural ones. That is why it is recommended to use such oils for one-time work.

- If there are only a few days between jobs, then it is recommended to use organic compounds. They are much cheaper than mineral ones and are characterized by high efficiency in use.

If you are using lubricant for the first time, you should hold the saw at medium speed for several minutes and check whether it is suitable for your specific model. Such oils are also characterized by the temperature at which they can maintain their performance characteristics.

Can I use regular motor oil?

Many novice craftsmen wonder whether regular motor oil is suitable for lubricating an electric saw chain. It is almost always available in any workshop, but not every user has a special lubricant.

It is permissible to use transmission and motor compositions, but it is undesirable to use mineral ones. Although there are some models for which it is suitable. The technical documentation of the unit provides such information. If it is not there, then it is unacceptable to lubricate the saw chain mechanism with motor oil, so as not to spoil it.

Regular vegetable oil is also not suitable for this purpose. It does not have sufficient viscosity, so the lubricating effect will not last long and the tool will not be protected during operation. It is not recommended to use mining, since it is of low quality and will not be able to provide the necessary protection.

Choosing engine oil

Saw chain oil is not always used as an all-purpose option. Often, the option for the engine from which the tire receives rotation is also filled. When choosing it, the following points are taken into account:

- You should give preference exclusively to the options recommended by the saw manufacturer.

- Mineral lubricants are more popular, as they are more effective in use.

- Products from well-known manufacturers are characterized by higher performance characteristics.

- The recommended temperature regime must also be taken into account. Some versions cannot be operated at too low a temperature, as this leads to an increase in viscosity. Too high a viscosity causes structural damage when operating at high speeds.

Various brands of chainsaw oils

If you do not add lubricant to the engine in a timely manner, it can quickly wear out or even fail.

Self-selection criteria

Problems often arise due to the fact that it is impossible to find a suitable branded oil. Many experts recommend choosing an analogue from well-known manufacturers that will ensure long-term operation of the device. Among the features of choosing a chain lubricant, we note the following points:

- There are budget and expensive analogues on sale. The price may depend on a variety of parameters, for example, resistance to heat.

- The constant use of products from one brand allows you to open up all the possibilities of a lubricant. Having selected a high-quality product from a well-known manufacturer, you can purchase it regularly.

- You cannot purchase lubricant with bright sediment and fractional separation. Moreover, such an offer is often much cheaper than branded options.

- If a product of a little-known brand is purchased, then consumer reviews are studied before doing so. On the Internet you can find quite a large number of different blogs and services where you can find reviews. Of course, not everyone needs to be believed, as some will be placed as part of an advertising campaign. Do not forget that good oil will not be cheap.

- It is forbidden to mix mineral and organic oil, as their performance characteristics are significantly reduced. Therefore, it is recommended to drain the old substance, after which only a new one can be poured.

The operation of the lubrication system must be monitored in a timely manner. If you choose the wrong oil, the service life of the saw is reduced several times.

When and how to fill

It’s clear where to add chain oil. There is a separate container for this. In most chainsaws, the size of this container is calculated taking into account the volume of the saw's gas tank. When both tanks are filled to capacity, they empty at approximately the same time. Therefore, it is recommended to fill the full volume of the oil tank at the same time as filling the fuel tank. Then you won’t have to be distracted by topping up twice.

Before starting work, it is useful to check whether oil will flow to the chain. To do this, just point the end of the tire onto a flat surface. Some of the grease will fly off the edge of the tire. Droplets falling on the surface indicate normal operation of the system.

At high negative temperatures, summer oil thickens and its lubricity deteriorates. Therefore, it is worth using brands designed for winter conditions. If this is not possible, then it is worth spending time diluting the existing oil to reduce its thickness. It is best to dilute with kerosene in a ratio of 1 to 4.

Some models provide adjustment of the feed rate in the lubrication system. It is useful for adjustments in case of changing the type of lubricant.

Note! You cannot fill the tank with a mixture of oils of different types - mineral and synthetic.

If you run out of oil from one manufacturer, and the same type is available, but from another company, then mixing them is allowed, subject to immediate use. You should not leave such a mixture for a long time.

Adjusting oil density to external temperature factors

The performance characteristics of the lubricant decrease when it is used when the ambient temperature drops to -20 degrees Celsius and below. Also, at low temperatures, the pump responsible for supplying oil does not work properly. The solution to this problem is often mixing the thickened composition with kerosene. Such an additive provides the required density of the substance, but it is still recommended to reduce the applied load. If the ambient temperature is too low, you need to monitor the effectiveness of lubrication of the main elements. This recommendation can also be attributed to the fact that the liquid in the wood begins to freeze, increasing the hardness and reducing the degree of workability. Too high a load causes rapid wear. An increase in viscosity makes engine operation more difficult. This is why many manufacturers indicate the conditions under which a chainsaw can be used.

The danger of using counterfeit oil

Cheap lubricants are inferior in properties to branded products. At the same time, manufacturers of expensive versions indicate that the saw should be used with the least load. In addition, you should consider:

- Counterfeiters accelerate the wear and tear of the material. Moreover, if the structure is severely worn, it cannot be repaired under warranty, since non-recommended oil was poured during operation.

- Rapid wear can cause the engine or tire to fail quickly. A fuel-powered engine is a combination of various moving elements. In order to reduce their wear, a certain amount of a special lubricant is added to the design, which also provides the required cooling. During operation, due to heating and slow wear of the metal, the properties of the oil change significantly. That is why from time to time it is necessary to completely replace it.

In order to eliminate the possibility of counterfeiters, it is recommended to purchase lubricant for chainsaws in specialized stores. Only in this case can you count on the fact that the information on the packaging will correspond to the real one.

Oil Consumption Rate for a Shtil Chainsaw

Content

Which Shtil oil to choose for a chainsaw

Any two-stroke chainsaw engine runs on a mixture of gasoline and oil, so how long it will last depends on the properties and correct consistency of these components. Also in chainsaws you need to lubricate the bar and chain, and the quality of the lubrication is not the last factor influencing the duration of use of these parts of the chainsaw. In this article we will talk about the oils that Shtil produces and recommends for use not only on chainsaws of its own production.

IMPORTANT. An experienced electrician leaked to the network the secret of how to pay half for electricity, a legal way. Read more

Stihl lubricant for two-stroke engines

Stihl engineers develop oils that are suitable for all two-stroke engines installed on Stihl chainsaws and trimmers and more. The Stihl line of lubricants for two-stroke engines contains several product options:

- Stihl HP;

- Stihl HP Ultra;

- Stihl HP S

Stihl HP review

Shtil HP is a chainsaw lubricant designed to meet high performance requirements and is designed to lubricate the internal parts of the engine during operation. It is made on a mineral base and has good combustion performance (has a low level of release of harmful substances during combustion).

The original Stihl HP is reddish in color and comes in original Stihl packaging.

It comes in several packaging options, the most popular of which is a one-liter with an integrated dispenser. You can also find Stihl HP in canisters of 5, 10 and 50 5 liters.

The smallest packaging of Stihl HP, which is convenient to use in cases where you need to prepare only one liter of fuel mixture, is a twenty-gram plastic bottle.

READ Sharpening for intertool chainsaw chain

The company also produces 100 gram Stihl HP bottles, which can be used to make 5 liters. fuel consistency.

According to the manufacturer's advice, Stihl HP can be used to make a consistency for all two-stroke engines.

The shelf life, if stored in a closed container, is 4 years.

Stihl HP Ultra review

Unlike regular Shtil HP oil, HP Ultra is designed for the highest engine loads during operation and is recommended for use on professional chainsaws. This oil synthetic. To ensure that consumers do not confuse diluted fuel, it has a greenish color; accordingly, the ready-made mixture of gasoline with Stihl HP Ultra also has a green color.

There are only two packages of this oil. This is Stihl HP Ultra 100 ml and 1 liter with dispenser.

The price of the Stihl HP Ultra is actually twice the price of the Stihl HP and for this reason it is the least popular in our country.

The Stihl HP Ultra has a shelf life of four years.

HP Super

Created for high-performance engines and four-stroke engines manufactured using 2-MIX technology. The properties are a little worse than those of HP Ultra, which is why HP Super is not currently available at Shtil dealers.

Proportions for preparing the fuel mixture

Very often people ask the question how much oil per liter of gasoline is considered normal. It’s easy to answer, because in the instructions for any Shtil chainsaw, it is also indicated on the packaging of the additive that when using unique Shtil products, the proportions of oil and gasoline should be 1:50. This means that for one liter of fuel, you need to add 20 ml of additive.

Refilling Stihl MS180 chainsaws, gasoline and oil.

Chainsaw Stihl

MS180 A couple of points about what liquids need to be poured into

a chainsaw

. Always keep an eye on.

Chainsaw Stihl MS180 oil dispenser. Let's make a mixture. Secrets and tricks. Lifehack

Chainsaw Stihl MS180 oil dispenser. Let's make a mixture. Life hack Often you have to make a mixture for a chainsaw and a skein.

During the break-in period of a new chainsaw, it is allowed to slightly increase the amount of oil per liter of gasoline. For example, you can dilute one liter with 25 ml of oil, this will reduce the load on the rubbing parts and extend the life of the chainsaw.

READ Chainsaw Oil Pump Echo 325 Pump Replacement

Which oil to choose

If you are a regular chainsaw user and do not use it every day for 6-8 hours, and only work in the summer, then you can use a regular Stihl HP to prepare the fuel mixture for your chainsaw. The optimal ratio of price and quality of lubricant has made it popular among millions of users of power tools.

Stihl HP can be used to mix any two-stroke engine, including moped and boat engines.

Shtil chain oil (oil review)

The Stihl line of oils for chain lubrication includes three types of products:

When working, it is necessary to use the type of lubricant that best suits the conditions and duration of work. Let's take a closer look at each of the oils for the Stihl chain.

ForestPlus

mineral oil is a high-quality product that creates a reliable film on the tire surface and chain links that holds well even at maximum chain rotation speeds.

Packaged in three types of containers, a liter bottle and canisters of five and twenty liters.

ForestPlus has the shortest shelf life among the oils in the Stihl line, which is only three years if storage conditions are met.

BioPlus chain oil review

BioPlus is made on a plant basis, which allows it to decompose when released into the soil in the shortest possible time. It is this property that is marked with the European environmental safety mark. According to the information available on the manufacturer’s website and is official, BioPlus has been tested in accordance with OECD 301 B.

For maximum convenience of consumers, it is packaged in 4 types of containers, these are:

- Liter bottle.

- Canister with a capacity of three liters.

- Five liter canister.

- A twenty-liter plastic canister for those who use a chainsaw every day and use a large amount of lubricants.

The price of BioPlus may vary depending on the region of sale.

BioPlus has a shelf life of four years. Brown color.

SynthPlus

SynthPlus is a semi-synthetic oil that retains its properties even under the most severe conditions. It is capable of maintaining performance characteristics at temperatures of minus 25 degrees. SynthPlus mixes well with BioPlus, making it easy to switch from one type of oil to another.

SynthPlus has a high shelf life, which, if stored properly, reaches seven years. SynthPlus oil color, brown.

READ Chainsaw Patriot 52 20

Calm SynthPlus is packaged in containers of the same capacity as BioPlus.

Which oil to choose for the chain

The best option for chain lubrication is BioPlus and it is worth choosing for those who cut with a chainsaw from time to time. The optimal price and quality of BioPlus have made it the most popular chain oil from the Stihl line.

It is also worth remembering that BioPlus does not harm the environment, because it is made on a plant basis and decomposes in the shortest possible time, which is also important when working with a chainsaw on your own site.

How to distinguish fake Shtil oil

Criminals do not miss the opportunity to make money by selling counterfeit products from a well-known brand. oil is no exception. Most often you can find fake Shtil HP, because its sales volumes are the highest of the entire line of Shtil lubricants.

In order to distinguish a fake from the original, the Shtil company released a special brochure, which recorded all the main differences between the original and the fake.

We also invite you to watch a video that shows, using a specific example, what a package of high-quality Shtil oil should look like and how to distinguish a fake.

Conclusion

We reviewed all the oils in the Stihl line, and found that the most popular lubricant for 2-stroke engines is Stihl HP. It is this that should be used under normal conditions, because in this case you will not have to overpay, and the engine will be reliably protected.

The saw chain, for ordinary users, must be lubricated with BioPlus, since the other options are intended for harsh conditions or work in winter. Also, we figured out that the correct ratio of gasoline to oil is 1:50, but during the break-in period it can be slightly changed and the mixture can be made in a ratio of 1:40, i.e. 25 ml per 1 liter of gasoline. We learned how to distinguish a fake Shtil BioPlus from the original.

Storage Features

It is recommended to store new and used chains in oil baths. This recommendation is due to the fact that prolonged exposure to humidity may cause severe corrosion on the surface. You can also use waste or motor oils for storage, since in this case it is important to protect the metal from corrosion.

Used oil storage

In conclusion, we note that only if the basic recommendations are followed, long-term operation of the structure can be ensured. The cost of a tire or chain, as well as the engine, is very high; if improperly lubricated, they can become completely unusable in just a few hours of operation. Therefore, you can save a lot by purchasing the right lubricant for the chain and engine.