After the snow cover disappears with the first days of spring, grass begins to appear, which pleases with a delicate green cover. However, literally after a few weeks all the irregularities and flaws become noticeable, and the weeds begin to rise above the lawn. From this moment the time of struggle for the beauty of the lawn begins. Of course, you can use a regular scythe or sickle to control weeds, but this is time-consuming and labor-intensive, and the cut grass becomes unsightly.

Rice. Class of brush cutters: 1 - household, 2 - semi-professional (farm), 3 - professional (park).

Performance

The choice of petrol mowers, or they are also called by the name of the cutting device - trimmers, should be made based on the volume of work; the larger the area being processed, the more power is needed. For small areas, household trimmers are chosen; for garden plots, middle-class trimmers are suitable - farm trimmers; for mowing a large area, especially if there are thickets of weeds or bushes, you need a powerful professional tool - a park one. This technique has an engine power of more than 2.5 hp. and can work 3-4 hours a day.

Prevention and possible malfunctions of the gearbox

The brush cutter requires first maintenance immediately after purchase, as the manufacturer applies a small amount of oil. If your trimmer is doing a small job, lubricate the unit at the beginning and end of the season. If the hedge trimmer works a lot, then lubricate it after 30-55 hours.

The main disadvantages include the most common options.

- Heatwave. This indicates that the fat has run out. You need to add lubricants and run them in low mode.

- The transmission vibrates or wobbles. This situation indicates mechanical damage.

- There is a knock. Then the bearing fell apart and the trunk was damaged.

- If the 3D knife is stuck, the mechanism must be completely replaced.

How to properly lubricate the transmission brush, see below.

Source

Drive motors

Most mowers are equipped with a gasoline engine (ICE), it can be two-stroke or four-stroke, there is no particular difference between them. The four-stroke is more economical and powerful, but more difficult to maintain and more expensive to repair. The two-stroke is easier to maintain, cheaper, but low-power, consumes more fuel, and has a dirtier and noisier exhaust. There are also combined engines. In addition to gasoline engines, trimmers can be equipped with electric motors that are connected to a 220V household network with a long cable, but, as a rule, these are household devices that are connected to the power supply wires.

Engine starting

Rice.

Starting the engine of a brush cutter ICE domestic mowers are equipped with manual starters. The starter device is simple: a strong cord is wound onto a drum, which is directly or through a gearbox connected to the crankshaft, the start is made by sharply pulling the cord, and the drum unwinds, driving the crankshaft, which in turn starts the engine. More complex models are equipped with an easy-to-start Flash Starter system. This system has a special mainspring, which is twisted through a ratchet by several pulls on the starter cord, accumulating kinetic energy. After which, a special release button is used to release the latch, and the spring unwinds along with the drum and crankshaft. “Easy start” ensures faster start-up and lower energy consumption for the owner. Also, for quick starting, an additional fuel supply to the carburetor is provided with a special button. To supply an additional portion of gasoline, you need to press the button once or twice. The starter gearbox is lubricated with oil intended for lubricating the gearbox.

Rod and drive of the working element

Rice.

The bar of a brush cutter The bar has two very important functions: the first - it forms a rigid frame of the entire structure, the second - a shaft passes inside the hollow metal bar, which connects the working element with the engine. By the appearance of the rod, you can determine the class of the tool; if the rod is curved, this is convenient for work, but in this case the drive is a flexible shaft, which cannot transmit large torque. If the rod is straight, there is a rigid metal rod inside, it is much more reliable and it can transmit more torque. Therefore, professional tools always have straight shafts.

Upper gearbox

Rice.

Upper trimmer gearbox The upper gearbox, or as it is called, the bell, serves to transmit torque from the engine to the shaft through the frictional connection of the gearbox cup with the shaft washer to the lower gearbox. The shaft from the engine is connected to the friction cup using a spline connection. The connection at the end of the motor shaft can be 7, 9 splines or square. Squares can be large or small. Squares are mainly used for powerful trimmers.

In order to disassemble the upper gearbox, it is enough to remove the retaining rings in the special slots of the washer; after the retaining ring is removed from the socket, the clutch plate is removed. You should immediately look at the condition of the damper rubber washer on the body. To press the bearing from the shaft, it is necessary to remove the end retaining ring using standard pullers. Lubrication is required to maintain the splines. What kind of lubricant is used in the gearbox of a lawn mower. To lubricate the splines or square, standard Litol lubricant is used. You can buy lubricant for the gearbox of lawn mowers at specialized dealership centers that sell household appliances or on Internet resources. You can see how to disassemble the “bell” and replace the bearing in the video clip below.

Prevention and possible malfunctions of the gearbox

The brush cutter requires first maintenance immediately after purchase, as the manufacturer applies a small amount of oil. If your trimmer is doing a small job, lubricate the unit at the beginning and end of the season. If the hedge trimmer works a lot, then lubricate it after 30-55 hours.

The main disadvantages include the most common options.

- Heatwave. This indicates that the fat has run out. You need to add lubricants and run them in low mode.

- The transmission vibrates or wobbles. This situation indicates mechanical damage.

- There is a knock. Then the bearing fell apart and the trunk was damaged.

- If the 3D knife is stuck, the mechanism must be completely replaced.

How to properly lubricate the transmission brush, see below.

Lower gearbox

Rice.

Lower gearbox (bevel) On mowers with a drive to a trimmer with working attachments, an adapter bevel gearbox is provided. Torque transmission occurs through bevel gears. This type of gearbox is produced in two types: serviced and maintenance-free. The name serviceable - the gearbox gets its name from the ability to add lubricant to the working cavity to lubricate the gears. If the gearbox is not maintained, then lubricant is supplied by the manufacturer for the entire service life, and the gearbox itself has a sealed housing. According to the developers of the manufacturer, such measures increase the service life of the gearbox, since contamination does not get inside through leaks in the lubrication hole. The gearbox of a lawn mower is the most loaded part, transmitting force with a change in direction, so proper care and proper lubrication are very important for the unit. What kind of lubricant is needed for the gearbox and repair of the bevel gear with replacement of bearings can be seen in the video below.

Stihl lawn mowers are deservedly popular

Rice.

Popular Shtil brushcutter Shtil brushcutters vary in class, engine type and purpose. Designed for caring for small areas to clearing large areas of weeds, shrubs and young trees. In this regard, they are usually divided into classes. The first class includes amateur devices of low power up to 1.2 hp. By design, “Shtil” amateur scythes are produced with a curved rod, which eliminates the lower bevel gearbox from the design, which significantly reduces the cost and maintenance. Brush cutters with a curved bar are designed to work with cutting tools made of fishing line or polymer knives. They are convenient to use in garden plots with small areas.

The second class refers to universal units of average power up to 2.2 hp, intended for field and landscape work. In such designs, a straight rigid shaft is used, which makes it possible to equip this class with steel saw knives for attachments with which you can cut down bushes and small trees. The design provides for a serviceable bevel gearbox. What lubricant to use for the lawnmower gearbox. A special brand name “Shtil” or regular Russian lubricant Litol is used.

Engines from 6.3 to 8 hp are intended for professional use in forestry or gardening. Their name is brush cutters, these are the most powerful brush cutters for working over large areas, cutting down small bushes and trees. The arsenal of working tools includes saw blades for cleaning bushes with a diameter of up to 7 cm. Brush cutters are equipped with an anti-vibration system, which makes working with such a tool more comfortable. What kind of lubricant to lubricate the gearbox of lawn mowers with powerful drive mechanisms? The gearbox of the Shtil lawn mower is lubricated with a special branded or Shtil lubricant or Russian-made Litol 24.

What oil should I use for my trimmer gearbox?

In this case, the mechanical part of the trimmer is loaded with contact forces on the teeth, reaction resistance from the adhesion of grass (sometimes with dirt), dynamic, shock loads due to constantly changing torque. The trimmer's gear oil must fully take these features into account, so the choice of brand must be strictly individual.

The following factors are taken into account:

- Manufacturer's brand. Each brand is unreasonably focused on its own lubricants (we can talk about cheap Chinese products later). This applies to manufacturers such as Husqvarna, Stihl, Huter, Makita and others. An exception is household trimmers: for example, Caliber does not indicate the brand of lubricants in the user manual

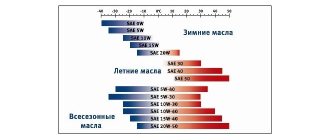

- Oil viscosity. It is known that all lubricants are divided into three groups - high-viscosity (colloidal systems containing various additives), elastic plastic compositions for universal use, and solid lubricants that soften during operation.

- Good adhesion to the surface of transmission parts, as a result of which the oil is not pressed into the gaps or does not collect.

- Gear consumption of lubricants. Here you should rely on your own experience and expert advice, since some trimmer manufacturers, based on their own service centers, usually do not give clear recommendations regarding the life of the gearbox between two lubricants.

Oil consumption also depends on the temperature at which it stores its oil. When the gearbox reaches 40°C, operating conditions are considered satisfactory and lubrication is sufficient.

It is believed that there is no universal trimmer gearbox oil, but this is not entirely true. In fact, a suitable lubricant will be one that contains the following components:

- Anti-wear additives that do not contain toxic lead;

- Hard oils with the presence of graphite or molybdenum disulfide (the latter is preferred because the oil is completely stored for a wide range of shaft speeds);

- Only highly purified mineral (inorganic!) oils.

READ How to Clean Carburetor Trimmer

Lithium oils Gear Grease OREGON or Champion EP-0, domestic formulations Oleo-Mas, Litol.24 or Azmol 158, as well as those recommended by the manufacturer of a specific trimmer model fully comply with these requirements.

Lubricant for the gearbox of popular brands of trimmers

Rice.

Types of gear lubricants Well-known companies produce their own lubricants:

- For gearboxes, the lawn mower recommends using Stihl Superlub FS gear lubricant, available in tubes from 250 g to 80 with a special pointed tip for ease of application, has a silver-orange color;

- The manufacturer recommends that the gearboxes of Patriot lawn mowers be serviced with a self-produced lubricant based on lithium components called Arsenal AR-417;

- The Huter company offers Rezoil and CIATIM plastic universal lubricants for its products; all of the above lubricants can also be used;

- In all cases, it is necessary to monitor the condition of the gear unit, lubricating it at least once a month. At the same time as lubricating the gears, the drive shaft itself can be lubricated.

You can learn how to lubricate a maintenance-free gearbox by watching the video below.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by mail or call now: tel: +7 (495) 128 22 34 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

How to lubricate a lawn mower gearbox

Purchase of any equipment. This is a kind of lottery, but a lot depends on the gardener. In caring hands, Chinese samples will last a long time and will not let their owners down at the most inopportune moment. And if you forget to lubricate the gearbox on time, do not clean the filters, and do not use cheap, low-quality gasoline, then garden equipment from the most famous brands will become a headache.

Gear lubrication. One of the most important maintenance elements of a gas trimmer, which must be performed directly by the user.

Time and procedure for gearbox maintenance

I recommend immediately after purchase that you carry out maintenance on a new gas trimmer by adding oil to the gearbox. Despite the high cost of gardening equipment, some manufacturers save money and use oil only at least during a breakdown.

How often to lubricate the gearbox of a brush cutter

Often a routine transmission oil check is performed once a year at the beginning or end of the season. If you do not use a gas trimmer in professional quantities, this is enough.

For large mowing volumes, it is necessary to lubricate the gearbox with a brush every 20-50 hours of operation. If the operating conditions of garden equipment are difficult, for example, a large field is immediately mowed and the brush cutter does not have time to cool down, or cheap oils are used, the oil should be checked and added every 20 hours. Operations.

Indirect evidence that the gearbox needs to be lubricated may be overheating or increased noise of the unit.

Also, when doing a complete oil change, disassembling and washing the unit, I recommend buying a gasoline trimmer.

Lubricant for the gearbox of a gasoline trimmer

Range of lubricants for garden equipment

According to the instructions, a special transmission fluid must be used to lubricate the bevel gear. As a rule, manufacturers of garden equipment produce and recommend their brand chemicals as the most suitable for their devices.

At the same time, in order to reduce the cost of garden equipment and increase the attractiveness of the brand of auto chemicals, lubricants for garden equipment are usually produced as multifunctional ones. It is designed not only to lubricate the gearbox of gasoline trimmers, but also to treat hoses, gears and gearboxes of any garden equipment and mechanical devices operating under heavy loads.

This lubricant is sold in tubes that are easy to use and store.

Even if a special gear lubricant has been almost completely developed during operation, the additives still create an effective lubricating protective film on the surface of the gears.

It should be noted that many mower owners in the former CIS countries use conventional lithium-24 or lithium-based oil to lubricate the gearbox. It is convenient to fill the gearbox with a 5 cubic meter medical syringe.

The undoubted advantage of using Litol and lithium-based lubricants for refueling a brush cutter is a cheaper operation. But there are nuances that make spears break on gardening forums on the Internet. I think what you can lubricate with lithium based oil and what you can't, read the article "Litol as a Gearbox Lubricant".

How to lubricate the gearbox of a brush cutter or gasoline trimmer

17 side bolts on gas trimmer gearbox

For safety reasons, to avoid accidental starting, all braid maintenance work must be performed with the electrical cover/plug removed from the spark plug. Do not turn the trimmer over to avoid gas leakage.

Unscrew the side screw on the gears. Depending on the garden tool manufacturer, you may be able to use a socket head bolt instead of a hex head bolt, usually up to 17. The threads are normal, unscrew them counterclockwise. Be careful not to lose the sealing washer.

Add specialized lubricant

If no fat is visible on the inner end of the screw, add 3-4 grams. Turn the gear by hand, reversing the direction of rotation to distribute the grease throughout the gears.

Then replace the screw, tightening it securely.