Why do you need oil for pneumatic tools?

Oil plays an important role in the longevity of the tool.

Pneumatic tools operate on the energy of compressed air, so various sealing elements are used in the design. These elements are made of special rubber designed to work in friction systems. Where there is friction, additional lubrication is necessary. The oil lubricates the rubber seals and the pneumatic system of the tool operates normally. Before moving on to oil, please note that in order to effectively lubricate the tool, the compressed air must be free of moisture and dirt. Moisture, mixing with oil, turns it into an emulsion, which not only lubricates the tool worse, but also has a destructive effect if it accumulates in the internal parts of the tool. Dirt is an abrasive and greatly reduces the service life of rubber seals. For cleaning and lubrication, we recommend using special air preparation units, which you can read about in this article.

What is a lubricator

A lubricator, or oil sprayer, is a device for creating a suspension of oil droplets in the compressed air supplied to drive pneumatic tools.

Not all compressed air consumers need to supply the oil-air mixture through a hose. It will render them unusable or interfere with normal functioning. For them, on the contrary, it is necessary to pass the air flow through an oil separator, which absorbs droplets of oil that enter it in the cylinders of a piston compressor. These are consumers such as:

- spray guns and other installations for spraying liquids and applying coatings to surfaces;

- sandblasting units;

- devices for inflating wheels and other containers;

- nozzles for cleaning surfaces and blowing out cavities of parts.

But for pneumatic impact wrenches, hammers, scissors, scrapers - all consumers containing moving parts and converting the energy of compressed air into mechanical energy of rotation or reciprocating motion.

Proper lubrication reduces friction between these moving parts, as well as their wear. The absence of the lubrication system’s own oil reservoir as such allows one to reduce the weight, dimensions and cost of pneumatic tools.

Today's pneumatic equipment market offers a large number of lubricator models, both stand-alone, mounted on a hose next to the consumer tool, and centralized, mounted on the wall next to the compressor or air line distribution unit. The devices allow you to control the degree of saturation of the oil-air mixture, selecting the optimal composition for each consumer.

During operation, it is important to monitor the level and quality of oil in the lubricator filling tank. The use of low-quality equipment that does not meet the manufacturer’s conditions or contaminated oil can accelerate the wear of the tool supplied from the station or even cause it to fail.

Repairing pneumatic tools, despite the apparent simplicity of its design, requires highly qualified specialists and special equipment. Self-repair without experience and equipment can permanently damage the instrument.

Choosing oil for pneumatic tools

Oil viscosity table, according to ISO 3448 classification

ISO 3448 viscosity grade

Kinematic viscosity at 40°C [mm 2 /s = cSt (cSt)]

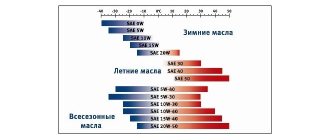

We are only interested in 2 values from this table: 46 and 100. It is these oil viscosity values that are used when servicing pneumatic tools and compressors for them. To lubricate the tool, oil with a viscosity of 46 (ISO 46) is used, and in compressors with an oil system, oil with a viscosity of 100 (ISO 100) is used.

Do not mix oils or use a different type of oil. If you use compressor oil in pneumatic tools, due to its higher viscosity, it will make it difficult for the tool to operate, causing rapid wear of moving parts. Conversely, if you pour oil for pneumatic tools into a compressor, it will not sufficiently lubricate the piston part.

Viscosity is the main criterion in choosing oil for pneumatic tools. All other differences are not significant. It is also not so important which oil manufacturer you will use, since the production of technical oils that comply with the ISO 3448 standard does not contain significant differences in technology.

We recommend Mannol oil. Our 10 years of experience working with these oils suggests that they are excellent for lubricating pneumatic tools and servicing compressors. But you can use any other oil of your choice.

Source: pneumoexpert.ru

How to properly lubricate the impact mechanism of an impact wrench?

Grease Lubricated System:

To properly lubricate the hammer mechanism, it is recommended that you open the tool and carefully apply oil by hand or brush to the critical contact points: the shank (at the hammer contact area) and the inside of the hammer

READ Alvin Straight

Most pneumatic tools have multiple grease fittings, and if the hammer mechanism cannot be lubricated as described above, grease can sometimes be introduced through these holes. If you are not sure where they are, refer to the instruction manual or contact service. Remember to remove old oil before applying new oil!

| Tool operating conditions: | Instrument frequency: low | Tool usage frequency: high |

| Short | About 6 months | About 3 months |

| High | About 3 months | About 1 month |

Oil bath system:

To change the oil, carefully open the tool, drain and dispose of the used oil properly, and then replace it with new oil. Be sure to use an oil that is suitable for impact systems, such as SAE30 oil.

Note. This oil is different from the oil used to lubricate air.

| Tool operating conditions: | Instrument frequency: low | Tool usage frequency: high |

| Short | About 12 months | About 6 months |

| High | About 6 months | About 2 months |

Note. Regardless of the type of lubricant, use only cleaners and lubricants recommended by the manufacturer. If you are unsure, consult your tool's manual or service provider.

What kind of oil to pour into the lubricator

Pure lubricant without foreign additives or mechanical inclusions is poured inside the device. Some liquid purification models are equipped with additional filters. This approach is necessary due to design features: the spout nozzle, as a rule, is no more than 1 mm in diameter, which allows the smallest particles to easily clog the hole.

The lubricant is selected based on factory recommendations. In 90% of cases, the exact labeling of liquids can be found on the pages of the user manual.

Lubricant for air tools FILL INN

The most popular manufacturers of lubricating oils for pneumatic tools are the following brands:

The presented list of liquids is not a standard. Lubricating oil for pneumatic tools is selected based on the user’s personal preferences and factory recommendations. In this case, it is necessary to pay attention to the viscosity, physical characteristics and biodegradability of the formula.

Source: masladvig.ru

Lubricator for pneumatic tools. A small detail that works correctly

When working with any pneumatic equipment, it is necessary to ensure that purified air, which is enriched with oil particles, is supplied to the system.

A filter copes with the first task, but for the second, a lubricator for pneumatic tools is needed. With this device, the air flow is diluted with oil during the spraying process, and this greatly extends the service life of all equipment and reduces wear rates. This is especially important for those who are forced to regularly resort to the use of pneumatic devices (workshop employees, service stations, construction crews, etc.). Modern lubricators have an autonomous design; their system allows you to calibrate the supply of lubricants during operation; thus, the pneumatic tool receives the required amount of fluid. During operation, you can control the oil level in the refill container. During operation, it is important to use the types of consumables recommended by the manufacturer: the use of low-quality or simply unsuitable oil leads to malfunctions not only of the equipment, but also of the lubricator itself.

Hose selection

The most tensile strength reinforced oil and petrol resistant rubber hoses. These are difficult to damage even with a car wheel, but they also have the highest price. Hybrid-polymer models with good performance characteristics are more accessible.

First of all, you should decide on the cross-section of the hose, which is selected in accordance with the recommendations of the tool manufacturer. In general, it is recommended to choose hoses with a diameter of 10 and 12 mm to avoid bottlenecks later. Two models with the same cross-section may have different strength and operating pressure characteristics, so it is worth checking these parameters for each position separately.

When operating a pneumatic line in a car service center, it is useful to use the most flexible hoses, because the “oak” line will cling to everything, break easier and be difficult to move around the room. The bendability parameter in the product characteristics is responsible for this property.

As for the form, there are three options:

- Twisted pneumatic hoses

made of polyurethane. They have good strength properties and increased flexibility. Thanks to the coils, they can easily be folded into an accordion and put away, and during operation they do not twist or get in the way. You can select the appropriate model in a separate section of the Garage Tools online store; - Straight pneumatic hoses in a coil

made of reinforced rubber, polyvinyl chloride (PVC) or hybrid polymer (HP). Supplied in coils of 50 meters; - In reels

. This is a pneumatic hose wound on a reel in a protective housing. The most convenient and reliable design, but also the most expensive.

Regardless of the shape and material of manufacture, it is not recommended to use hoses longer than 15 m, as this leads to loss of power.

How does a lubricator for pneumatic tools work?

This device is a reservoir, the body of which is made of metal, which is put on the inlet part of the pneumatic equipment and fixed to a threaded connection. When installed, the lubricator is placed after the filter, which is necessary to dry the air flow. After the air gets inside, it is enriched with oil particles and goes further into the tool itself.

It is very important that the distance of the hose between the lubricator and the device itself is no more than 10-12 meters: with a longer length, the distribution of oil with air is not as effective, and condensation begins to form on the walls, reducing productivity. If this length is not enough, it is better to use linear type lubricators, which are installed directly in front of the tool.

Modern devices may differ in thread size, construction materials and the volume of the storage tank into which oil is poured before use. In addition, devices can be single-point or multi-point, and the choice of equipment is made taking into account the characteristics of future operation. Among other things, devices are divided into two groups according to type of design:

- Lubricator filters, which are mounted on the tool itself between its handle and the hose for air flow.

- Air accessories installed on a compressor or flow distribution system.

Lubricators

This is a small metal reservoir that sprays special oil into the air being passed through to lubricate the working elements of pneumatic tools.

If the lubricator is installed next to the compressor, then for effective lubrication you should not use hoses longer than 15 m. Alternatively, you can select a linear lubricator and install it next to the end instrument. This allows you to use a longer hose, but creates inconvenience when working with impact wrenches. The lubricator is always installed after the filter drier so as not to interfere with its operation and not cause premature clogging.

When choosing a lubricator, you should pay attention to the thread size (1/4″, 3/8″ and 1/2″). Depending on the installation location, it must match the outlet of the compressor or terminal tool.

Advantages of lubricators

The use of such mechanisms is a mandatory requirement for the rational and efficient operation of pneumatic tools. The use of lubricators has many advantages:

- Lubricant in the form of oil is supplied to the structure automatically, which significantly reduces the cost of effort and time for servicing the tool.

- Oil supply significantly reduces wear rates: lubricants reduce friction of key equipment elements and make productivity much higher.

- A lubricator for pneumatic tools can significantly reduce the risk of unplanned downtime that can occur due to equipment breakdown.

- Modern devices are compact and can be installed in the most inaccessible places, while the installation angle also varies.

- The use of multi-point lubricators makes it possible to lubricate up to 8 points simultaneously.

How to choose a lubricator for pneumatic tools?

Such designs should be purchased based on the characteristics of operation and the tasks to be solved. Key features to pay attention to:

- Throughput : the lubricator is selected for equipment that has the appropriate power, and this parameter is important for the most complete provision of air flow with oil particles. If the throughput is low, the pneumatic tool will work less efficiently.

- Working pressure , which determines whether the device can cope with the load.

- Housing materials . This product must be made of high-quality steel: such devices are characterized by increased reliability, durability and minimal maintenance costs.

- Thread size and location : if there is a mismatch, the lubricator simply cannot be used in conjunction with the selected equipment.

If you have doubts when making a choice, it is better to consult with a specialist who can advise which device is most suitable for specific pneumatic equipment. After purchasing a lubricator, it is important to use the required brand of oil, which has the appropriate parameters (viscosity, alkalinity, etc.). It is necessary to check that water does not get inside, which causes corrosion of the housing, and periodically monitor the oil level.

Criterias of choice

When choosing a device, you must be guided, first of all, by what work the equipment is required for and what its volume is. The purchase of equipment must, among other things, also be economically justified.

The following parameters are key:

- Lubricator throughput. It must be no less than the operating flow rate of the connected consumer. It is better to provide a 10-20% reserve for peak loads. Using a device with a lower capacity will lead to a decrease in the consumer’s operating efficiency and deterioration of lubrication conditions.

- Operating pressure. Of course, you cannot install a device designed for less pressure than the load consumes. Such a vessel will simply fail. Too large a pressure reserve will not improve the operating conditions of the equipment, but will lead to an unjustified increase in the cost of the planned purchase.

- Materials used. It is better to choose metal vessels, especially those designed for high pressure. And not just any Chinese ones, but only high-quality alloys produced by global brands. The consequences of a hull rupture will be significantly more expensive.

- Connecting dimensions. The dimensions and type of thread must be suitable for the user. The use of adapters in this case is highly undesirable. Many manufacturers directly indicate the inadmissibility of this approach

If you do not have sufficient skills in handling pneumatic tools and organizing air lines, it is better to engage an experienced expert for consultation.

It is imperative to install a water vapor separator BEFORE the lubricator or distribution unit. Moisture entering the device will significantly reduce its performance. The quality of lubrication of pneumatic tools and its performance will also decrease. Prolonged operation in this mode will lead to breakdown and costly repairs.

During work, you should systematically check the oil level in the reservoir and replenish it in a timely manner. It is better to do this before starting work, so that you do not have to be interrupted in the middle of the working day.

Device price

The cost depends on several factors:

- Material of manufacture (steel, iron, brass, etc.).

- The volume of the container into which oil is poured for further distribution.

- Type of instalation.

- The number of points that the device can lubricate at a time.

- Capacity and maximum pressure.

- Manufacturer (domestic devices are 10-20% cheaper than their foreign counterparts).

As a rule, the least expensive option is to purchase a lubricator through an online store, where products for air tools are offered at discounted prices. In ordinary construction stores you can find the most popular devices that are used in conjunction with equipment for garages, workshops, construction compressor equipment, and are used for industrial and domestic purposes.

Source: proinstrumentinfo.ru

Video text

Greetings! Today in the video we will talk about lubrication and care of pneumatic tools, or more precisely:

— how to lubricate it correctly; — what oil to use for this; — how to choose a lubricator and what types there are; — how to prepare air for a pneumatic tool; — how to eliminate problems with the operation of the tool;

And many other topics will be discussed. I will try to explain in detail and clearly the questions that interest many, to give a theory of what is important to take into account in order for your tool to work as expected!;)

More details in the video itself, link to it:

I recommend watching my friends video:

Beautiful and positive films

Business on the Internet and development on YouTube

Useful tips for: auto and motorcycle repairs, home and cottages

There is also a video on the topic of anticorrosion on my channel:

Other video topics on the channel:

Good online stores - goods and services at an affordable price:

High-quality furniture from "Mr.Doors": https://goo.gl/cfqmXs Useful products - online store "Gearbest": https://goo.gl/riFbzo Necessary and useful - online store - "Aliexpress": https:/ /goo.gl/242qIr Many necessary products - online store - "Banggood": https://goo.gl/U7l3Kp Knife store - "Knives": https://goo.gl/pPjgRj

Earn money from your video with affiliate programs:

Source: www.youtube.com

Oils for pneumatic tools

| All products Select store | |

| Sort by: | Show by: products |

| Products found: 10 |

Air tool oil will help protect the air motor, pistons and other internal parts from wear, corrosion and burning. It forms a protective film on the surface of the elements, which increases the service life of moving and rubbing parts. It is made from mineral oils with the addition of anti-corrosion, adhesive and anti-wear additives and is subjected to deep cleaning during the production process.

Each tool operating on compressed air must have a special air preparation unit. It consists of an oil and moisture separator, a pressure regulator and a lubricator (oil sprayer). It is into the lubricator that the oil is poured. If there is no such block, then lubricating fluid can be poured directly into the lubrication hole approximately every 30 minutes of operation. You can buy oil for pneumatic tools in our online store by calling 8-800-333-83-28 or through your personal account.

© 2006 — 2021. VseInstruments.ru

Email Tel. (from 07:00 to 22:00) 8 (from 07:00 to 22:00) The call is free

All information on the site is the property of the online store Vseinstrumenti.ru. Publishing information from the website vseinstrumenti.ru without permission is prohibited. All rights reserved.

The information on the website www.vseinstrumenti.ru is not a public offer. The indicated prices are valid only when placing an order through the online store www.vseinstrumenti.ru.

Prices at delivery points and retail stores of VseInstrumenty.ru may differ from those indicated on the website.

You accept the terms of the privacy policy and user agreement every time you leave your data in any feedback form on the VseInstrumenty.ru website.

Source: www.vseinstrumenti.ru

Article rating:

Save to:

What kind of oil to pour into a lubricator for pneumatic tools Link to main publication

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

A modern tire changing machine, despite its apparent simplicity, is a rather complex device. It uses electromechanical, pneumatic, electronic and hydraulic components (mainly in truck tire changing machines) and elements. Moreover, the machines are designed for constant and long-term use.

Let's take, as an example, the issue of the intensity of operation of a tire machine during the so-called high season. As a rule, at this time tire shops work 12–14 hours a day, and some around the clock. Typically, one specialist works at one tire station (one tire changer and one balancing machine). Depending on the qualifications of the employee, servicing a car takes from 40 minutes to one hour. During this time, it is necessary to remove 4 wheels, change the tires, balance the newly assembled wheels and install them on the car. That is, it takes from 10 to 15 minutes to service one wheel. This means that if a service point operates 12 hours a day, then about 50 wheels are disassembled and assembled on one tire machine. At the same time, during the work process, all components and mechanisms of this machine are intensively exploited.

When developing and producing CORGHI tire fitting equipment, the company's engineers pay priority attention to the issues of its reliability and durability. This approach is one of the fundamental methods of CORGHI's work in the global market, where it is rightfully among the industry leaders. Many years of experience working with CORGHI equipment in Russia have shown that tire machines of this brand can operate for 10–12, and sometimes more, years. It’s not so rare that our specialists come across equipment at car repair shops and tire shops , which was produced in the 90s. And these machines do not lie dead weight, but have been successfully performing their functions and tasks for many years.

The service life of tire fitting equipment, of course, is determined by a number of factors, among which the quality of its manufacture plays an important role. However, another important factor is the attitude of service station specialists towards the equipment. After all, it’s no secret that a tire changing machine requires timely and correct maintenance. And usually, reputable manufacturers of auto service equipment indicate requirements and recommendations for the operation and maintenance of their tire changers in the operating instructions. Such “manuals” are supplied with the equipment. However, these instructions are often lost during long periods of work. Given the importance of the issue under consideration, we decided to once again remind everyone that the service life of a tire changing machine depends on the people who operate it.

There are a number of activities that need to be carried out with established regularity - daily, weekly, monthly and annually. They are the key to the long service life of the tire changing machine.

The tire service area must be cleaned daily. Using a scraper and brush, it is necessary to clean the turntable every day, removing dirt, dust and other deposits from it. It is also necessary to wipe the cylinder rods from dust and dirt. To carry out this work, do not use compressed air, water jets or strong solvents.

The issue of cleaning a tire changing machine from dirt accumulated during a shift is very important. Modern tire changing machines include a lot of moving elements (clamping jaws, columns with tire changing heads, rods of various cylinders, etc.). The sand and other solid particles found in this mud are an abrasive material and contribute to increased wear of these components and mechanisms.

In addition, we recommend using only mild solvents for cleaning, since the use of strong solvents for cleaning, as well as dirt and sand, leads to increased mechanical wear of the treated elements. It is also important to check the proper operation of the movable bolts, mounting head rollers and bid breaker. The accumulation of dirt on these components reduces their performance and can lead to damage to the machine.

And finally, one more recommendation that is often neglected at car service centers. At the end of the working day, it is necessary to turn off, that is, disconnect the machine from the air line.

The weekly maintenance schedule for a tire changer involves checking the oil level in the hydraulic system (for truck tire changers), checking for the presence of condensation in the water separator cup (if the level is exceeded, you must drain the condensate manually), as well as checking the oil level in the lubricator (if necessary, it must be topped up). The importance of the oil level criterion in hydraulic systems is obvious. It's like the oil level in car engines. There is no need to talk about the consequences of insufficient oil in engines. An important issue is the presence of oil in lubricators of pneumatic systems. This oil is designed to create an “oil mist” that reduces friction of the moving elements of these systems, which means that wear on the system as a whole is reduced. Condensate, but in reality it is water, on the contrary, negatively affects the operation of pneumatic systems. Special glasses are used to collect condensate, from which this condensate must simply be drained in a timely manner.

Monthly service for tire changing machines also involves a number of operations. In particular, once a month it is necessary to lubricate the moving parts of the mounting head rods, guide movable arms, rollers, and also check for play and gaps in the guide rollers, fixing mechanisms of vertical and horizontal rods. If any play or gaps are detected, adjustments must be made. In addition, it is necessary to check the rate of oil flow through the dropper. The normal rate is 1 drop of oil for every 4 bead lift cycles. If necessary, you will need to make adjustments, which are done using the adjusting screw.

And finally, monthly maintenance operations must be carried out annually, as well as a complete oil change in the hydraulic system (for truck tire changers).

Any pneumatic tool requires regular checking of the oil level. It is very important to monitor this: if there is not enough lubrication, the friction of moving parts of the equipment increases, and this, in turn, leads to accelerated wear of the entire system.

The oil level in the lubricator of the tire changer should be checked daily. If necessary, you need to add or change the technical fluid. To do this:

In addition, do not forget to check the oil supply setting. The machines have special regulators that allow you to adjust the operation of the dispenser in accordance with the manufacturer’s recommendations.

Another important point is the timely removal of condensate. Water negatively affects the operation of the tire changer, so it should be drained from the filter regulator regularly.

When servicing pneumatic equipment, do not forget to clean and lubricate all moving parts, tighten loose fasteners, and check the condition of the drive belt.