What kind of oil should be poured into the vibrating plate and how to replace it?

The vibration mechanism and the engine are 2 mechanisms in the vibrating plate that require constant monitoring of the presence of oil and lubricant. Before you start working with a vibrating plate, check the engine and vibrator of the vibrating plate

you need to add oil.

If we talk about the vibration mechanism, the oil is filled at the manufacturer’s factory. Each plant uses different types of oils, so there is no specific date for oil changes. Therefore, when changing the oil yourself, you need to use the control for using a vibrating plate .

The gearbox is lubricated separately

The snow blower gearbox also needs regular lubrication, otherwise it will quickly wear out. The period between procedures is 50 operating hours. Lubricant for the snow blower gearbox must be of sufficiently high quality (not salidol). It must be a special gear or graphite. Don’t let the price scare you - it’s better to use a high-quality product and use the unit for a long time than to constantly have some problems with replacing some components due to the use of low-quality consumables.

Regarding gearbox lubrication, I would like to draw your attention to some important nuances.

A dismountable gearbox is also called a serviceable gearbox, because you can easily carry out maintenance at home. Lubricant replacement is carried out through a special bolt. If the gearbox is maintenance-free (there is no bolt), then you need to take the snow blower to a service center. Its maintenance is performed only by specialists.

Honda Engine Maintenance

When replacing a collapsible gearbox at home, we adhere to the following algorithm:

- Unscrew the bolt;

- Apply grease with a syringe to the edge of the internal thread;

- Tighten the lubrication bolt.

READ Motoblock Gearbox MB How Much Oil to Fill

What kind of oil should be poured into the vibrating plate motor?

Before you start working with the vibrating plate, you need to pour oil into its engine. Remember to check the oil level before starting the vibrating plate. Otherwise, your equipment will fail.

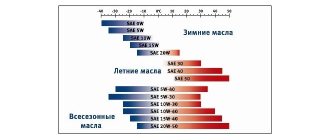

For Honda gx390, gx270, gx200, gx160 gasoline engines, mineral motor oil with a viscosity of sae10w40 or sae10w30 is suitable.

There are also oils of other viscosities, but they may not be suitable due to the characteristics of vibration technology, which can also lead to engine failure. It is best not to carry out any tests, but to use the oil that is recommended according to the instructions for using a vibrating plate.

HOW MUCH OIL IS IN THE ENGINE OF A MAZDA CAR three BL. WHEN TO CHANGE OIL IN MAZDA three BL

The Mazda three BL maintenance schedule provides for replacing the engine oil and oil filter at 5, 15, 30, 45, 60, 75, 90, 105, 120, 135, 150, 165, one hundred eighty thousand km, every fifteen thousand km , at least once every twelve months. In the case when the car has driven less than fifteen thousand km, but the year has expired, it is necessary to update the oil due to a change in its properties. The liquid ages and loses the necessary qualities, which can negatively affect the engine’s service life.

READ How to Properly Sharpen a Garden Hacksaw

The operating instructions also indicate engine oil change intervals every seven thousand five hundred km and six months in the case of heavy-duty vehicles. Such conditions include constant operation of the vehicle in mountainous and hilly areas, very high or low air temperatures, traveling only short distances, when the engine does not have time to warm up to normal operating temperature.

Changing the oil in the vibrating plate

So, first you need to place the equipment on a flat surface. Next, remove the cap from the hole where the oil will be poured. Fill the oil to the indicated mark and close the lid.

Now you need to start the engine for a couple of seconds and immediately turn it off. Check the oil level again. If it remains the same as before start-up, then work can begin.

How often do you need to change the oil in a vibrating plate?

If the engine does not have oil filters, then it is necessary to change the oil regularly, because contamination occurs during operation. It is necessary to change the oil after the first 20 operating hours, and then every 100 hours. Also, if the vibrating plate has not been used for a very long time, it is worth changing the oil.

Starting and stopping the vibrating plate

Quite often, Honda GX series engines are used in light class vibrating plates. Using the example of such a motor, we will look at the starting sequence of a vibrating plate.

- Open the fuel valve by moving the lower lever to the open position.

Move the damper lever to the close position. If the engine is warm or the air temperature is high, then leave the damper open.

Move the throttle lever slightly away from the idle position.

Switch the motor switch to position I

Start the engine with a manual starter. Pull the starter rope until you feel resistance, then sharply pull it to its full length. You may need to pull the cord a couple of times (3-5 times). The number of repetitions may be greater if the engine has not been started for a long time or the temperature outside is below freezing.

After warming up the engine (1-2 minutes), gently move the throttle lever to the open position.

- Move the throttle lever (engine speed level) to close to the maximum position.

- The throttle lever moves to the idle position.

- The engine is turned off by moving the switch to position O.

- The fuel valve is closed.

Stopping the vibration plate occurs as follows:

Pre-launch preparation of the vibrating plate

- Read the annotation. The recommendation is naturally obvious, but your specific equipment may have some feature, ignorance of which can lead to breakdown without ever starting the actual work. Therefore, at least quickly, you should still read the annotation.

- Checking the oil level. Any engines of vibrating plates and vibrating rammers (except electronic ones) use motor oils. If the oil level in the engine crankcase is insufficient, you, at a minimum, cannot start the engine (if an oil level sensor is installed), or you risk destroying the piston block. Before checking the oil level, place the vibrating plate in a horizontal position.

Checking the fuel level. Here you should pay attention only to the compliance of what you pour into the tank with what is stated by the manufacturer. After refueling, be sure to wipe off all fuel spills, as... they may be unsafely close to hot parts.

Checking the air filter. Because vibrating plates

Often work in an environment with a huge amount of dust, it is necessary to monitor the cleanliness of the air filter very often. If necessary, it must be cleaned using an air compressor.

Transportation of the vibrating plate

Here are a few requirements that must be observed when transporting vibrating plates:

- Be sure to check that the fuel valve is closed!

- Be sure to provide for the availability of lifting equipment during loading and unloading. The load capacity must be at least 50 kg more than the mass of the vibrating plate.

- Lifting the vibrating plate is allowed only by using a special eye located in the central part of the frame.

- Vibrating plates are transported in a vertical position to avoid oil leakage.

- During transportation, the vibrating plate must be firmly secured with straps to the frame at more than 4 points.

READ Gasoline To Oil Ratio For Lawn Mower

Application

Before filling or replacing, you should check the oil level in the equipment. To begin with, the equipment is placed on a flat surface. Next, remove the lid from the hole into which the liquid is poured. They begin to pour the mixture there up to the indicated mark, but do not pour a larger volume. When the oil is poured into the hole, turn on the engine for a few seconds and then turn it off. Then check the fluid level again. If it remains unchanged, then you can start working with the equipment.

Remember that if the vibrating plate does not have special filter elements, then the oil will have to be changed quite often, because severe contamination will form during use. After the first use, the fluid will need to be changed after 20 hours of operation. Subsequently, filling is carried out every 100 working hours.

If you have not used such equipment for a long time, then you should also change the oil before starting work to avoid further breakdowns.

The following video will tell you about the intricacies of starting a vibrating plate and oil filling technology.

How to choose oil for a vibrating plate?

Any vibrating plate has two internal mechanisms that require repeated monitoring of the oil level. This is a vibration mechanism and engine. Before starting work, you should make sure that there is a sufficient level of lubrication in these two systems. If necessary, it is worth adding working water, but, in principle, do not overdo it. If you rent a vibrating plate, you can be sure of the oil level, because the rental company technician constantly monitors the lubricant level.

If you are concerned about this issue as the owner of a vibrating plate, you should know that a fair amount of oil is poured into the vibration system at the factory. Each manufacturer uses their own oils, so you can only navigate the timing of changing this water using the attached annotation. It is advisable to carry out such an operation with the role of service center professionals.

When renting a vibrating plate, you should not try to change any liquids on your own - these characteristics are controlled by specialists of the rental company. All that remains for you is to replenish the fuel level. The need to add oil to the engine can be discussed immediately when registering for equipment rental.

Despite the fact that Honda engines of the GX160 - GX390 models run on gasoline, only petrol-free mineral lubricants with a viscosity of SAE 10W30-40 are suitable for them. Other viscosity characteristics, presence of additives, etc. – all this can lead to serious damage to your own or rental vibrating plate.

The thing is that this type of engine is not equipped with oil filters. This fact makes repeated changes of oil that mixes evenly with contaminants one of the important rules for long-term successful operation of the engine. In a new unit, the lubricant is changed after the first 20 hours of operation, and then every 100.

Cheap rental of massive vibrating plates

The Budprokat company offers rental of vibrating plates on the most profitable criteria and at the lowest prices. The technical condition and fluid levels of the equipment are constantly checked by our specialists, so you do not have to select consumables for the units without the help of others. When ordering a vibrating plate rental from us, you will certainly receive advice on its operation.

Changing the oil in the vibrating plate

So, first you need to place the equipment on a flat surface. Next, remove the cap from the hole where the oil will be poured. Fill the oil to the indicated mark and close the lid.

Now you need to start the engine for a couple of seconds and immediately turn it off. Check the oil level again. If it remains the same as before start-up, then work can begin.

will allow you not to worry about changing the oil: they will do it for you!

Vibrating plate oil: description and application

Currently, various types of vibrating plates are widely used. This unit is used during construction and road work. In order for the plates to last for a long time without breakdowns, the oil should be changed in a timely manner. Today we will talk about its main features and what types of oil there are.

The following types of oil are used for vibrating plates:

- mineral;

- synthetic;

- semi-synthetic.

What kind of oil should be poured into the vibrating plate and how to replace it?

The vibration mechanism and the engine are 2 mechanisms in the vibrating plate that require constant monitoring of the presence of oil and lubricant. Before you start working with a vibrating plate, you need to fill the engine and vibrator of the vibrating plate with oil.

If we talk about the vibration mechanism, the oil is filled at the manufacturer’s factory. Each plant uses different types of oils, so there is no specific date for oil changes. Therefore, when changing the oil yourself, you need to use the control for using a vibrating plate.

Operation and maintenance of vibrating plate MS 50

Commissioning and technical service of the Masalta MS50 vibrating plate. Dealers required:.

Next, unscrew the drain plug. This is also a bolt located on the lower surface of the motor, in the rear part.

Do not confuse this bolt with the oil drain plug from the crankcase. This plug is huge and can be unscrewed with a 17 or 19 wrench. The bolt that suits us is small. Usually there is a rubber gasket installed underneath it. In general, it won’t be difficult to find him. To unscrew the bolts, we use heads of suitable sizes; open-end wrenches can be used to destroy the bolts. On new scooters they are quite tight. Before unscrewing the drain plug, place an oil container under it.

So butter

We drained it, to be sure, you can tilt the scooter to drain the remainder.

Now we wipe the drain hole and drain bolt dry and screw it into place. It will be useful to apply a thread sealant (oil- and petrol-resistant) to the threads. We place the scooter on its side (on the right) to make it easier to fill the oil. The filler hole is very small in diameter, so finding a suitable funnel can be problematic. You can use a large syringe to add oil. Typically, transmission oil cans already have a tube through which oil is poured, but its diameter is larger than the diameter of the filler hole. So, pour in 110 ml of oil. Next, we put the roller in the usual position to control the oil level, which should be level with the bottom edge of the filler hole. If, with all this, oil flows from the filler hole (which means we filled in a little more than necessary), then this is not terrible - only excess will flow out.

If we haven’t filled in enough oil, we add it, checking the level at the filler hole. Naturally, when checking the oil level, the scooter should be in an upright position, on the center stand. The appropriate level has been reached, then wipe the filler hole and bolt dry, then tighten the bolt. After changing the oil, we check the tightness of the connections.

Some scooter riders advise flushing the gearbox housing when changing the oil. Some of them use diesel fuel, others use transmission oil. On a new scooter, the need to flush the gearbox housing is not so great (provided that there are no metal particles in the housing), so it is possible to do without it.

READ How Much Oil to Put in a Patriot Lawn Mower

Vibrating plate maintenance

The frequency of maintenance of components and assemblies of the vibrating plate is presented in the table:

IntervalDetailAction

| Before each start | Air filter | Check for external damage and tighten fasteners. Clean or replace the air filter cartridge as necessary |

| Fuel tank | Check the tightness of the tank lid and change the gasket as necessary. | |

| Engine oil | Check the oil level and add as necessary. Check the tightness of the caps. | |

| Pathogen | Check for smooth operation. | |

| After 20 hours of production | Engine oil | 1st oil change. |

| Every month | Ignition system | Check the spark plug and its gap |

| Control hydraulics | Check the reliability of the threaded fasteners. Check the oil level and add as necessary. | |

| Drive belt | Check the belt tension and add more as needed. | |

| Protective frame | Check the security of the threaded fastenings of the protective frame and the central suspension. | |

| After 150 hours | Pathogen | Check the oil level and add as necessary. |

| After 250 hours | Engine oil | Change the oil |

| Exhaust manifold | Remove combustion residue from the spark arrester. | |

| Pathogen | Change the oil | |

| After 300 hours | Valve clearance | Check and set to 0.15mm for the intake valve and 0.20mm for the exhaust valve. |

Why do you change the oil?

The rear axle gearbox is a mechanism that is subjected to a number of different loads. Through these loads, destructive actions occur. To avoid accelerated wear of gearbox parts, it is necessary to use a special lubricant. This lubricant is an oil that, during the operation of the gears of the mechanism, envelops them, eliminating accelerated wear and overheating, and also cleans the teeth from chips and metal dust.

to change the oil in the rear axle gearbox for the simple reason that over time it loses its primary properties. When the gears rub against each other, thermal energy is released, the value of which is reduced with the help of a lubricating fluid. In addition, when the gears rub, the teeth wear out, resulting in the formation of chips and metal dust. If you do not change the lubricant in the gearbox for a long time, the amount of metal shavings and dust will only increase, which will lead to accelerated wear of the rubbing parts.

Features of lubricant selection

the gearbox of the VAZ 2107 with semi-synthetic gear oil. It should have viscosity parameters 75W-90. This is a universal lubricant option, which is usually poured into the gearbox.

Special gear oil in the gearbox improves the quality of parts and also reduces their wear. Not every G7 owner knows how much oil needs to be poured The lubricant volume for the gearbox is 1.35 liters. It is poured through a special filler hole (on the side), using a technical syringe. You must first drain the old lubricating fluid, for which there is a special drain plug at the bottom.

Oil change step by step

The procedure for changing the oil in the gearbox is by warming up the old fluid; for this you need to drive the car for 10-15 minutes. After this, you need to go to the inspection hole, take the necessary tools and materials, and go down. The replacement procedure involves performing the following manipulations:

At the top of the bridge there is a breather. After adding oil, you should check its movement characteristics. It should move easily and without jamming. If the breather does not function, then when the lubricant in the gearbox heats up, it will begin to leak through the seals.

READ How Much Oil Should You Add to Your Trimmer

At this point, the process of changing the oil in the rear axle can be considered complete. If during a trip you hear a hum or howl from the rear of the car, then it is recommended to carry out repairs before changing the oil, but that’s a completely different story.

Characteristics of vibrating plates based on their mass

The weight of the plate is the most important indicator when choosing the right model or when purchasing parts for assembling a vibrating plate at home. Weight determines 70 percent of a unit's productivity and suitability for the job you need. Models are divided into four types based on weight:

- light – weighing up to 70 kilograms;

- universal – with a weight from 71 to 90 kilograms;

- medium-heavy – with a weight from 91 to 140 kilograms;

- heavy - with a mass of 141 kilograms.

The light type is normally suitable for landscaping work in the local area; the maximum soil depth should not exceed 15 cm. This type is also used for work related to laying paving slabs and laying damping mats made of polyurethane on paths.

The middle type is used for partial repair of the road surface with the introduction of asphalt and laying tiles on the sidewalk. The greatest depth of the soil should not exceed 25 cm.

The medium-heavy and heavy type also copes well with more severe work, for example, laying road surfaces in several layers. Using units of this type, trenches after backfilling and the perimeter of the foundation of a small house are compacted. The largest layer of soil for this type is 60 cm. The weight limit when laying asphalt is 100 kilograms.

When choosing a good vibrator mass, you need to pay attention to the motor power. A weak motor mounted on a bulky slab can frustrate you during the execution of your work plan. Such a unit will sink into a layer of earth and will require unnecessary efforts from the person doing the work. This discrepancy is especially critical in models of types 3 and 4.

When purchasing or manufacturing a vibrating plate , you need to calculate this ratio. An example of an irrational relationship is a stove weighing 140 - 175 kilograms and a 6 hp engine installed on it. An example of the correct ratio is 5 hp per 100 kilograms. motor.

Model range of vibrating plates VS SPLITSTONE

| Vibrating plate VS-104 | Vibrating plate VS-134 | Vibrating plate VS-244 | Vibrating plate VS-245 E8 | Vibrating plate VS-245 E10-2 | Vibrating plate VS-246 E12 | |

| Compaction modes | ||||||

| Crushed stone | Invalid | Invalid | Acceptable | Acceptable | Acceptable | Acceptable |

| Soils (mixed soil, loams) | Acceptable | Acceptable | Acceptable | Acceptable | Recommended | Recommended |

| Sand | Acceptable | Acceptable | Acceptable | Acceptable | Acceptable | Acceptable |

| Paving slabs, paving stones (using a damping mat) | Acceptable | Acceptable | Recommended | Recommended | Recommended | Invalid |

| Asphalt, asphalt concrete | Acceptable | Acceptable | Recommended | Recommended | Acceptable | Acceptable |

| Specifications | ||||||

| Width of the slab working area, m | 0.29 | 0.29 | 0.41 | 0.41 | 0.50 | 0.43 |

| Dimensions (LxWxH), mm | 995x320x835 | 1040x320x1000 | 1055x450x975 | 1170x450x955 | 1270x450x1030 | 1340x500x900 |

| Operating weight, kg (without water / with water) | 55 | 70 /80 | 89 /99 | 111 /121 | 128 /138 | 141 /151 |

| Depth of compaction of bulk materials in 4 passes up to 95%, mm | 100 | 100 | 200 | 210 | 200 | 250 |

| Driving centrifugal force, kN | 11 | 11 | 13.5 | 18.4 | 21.3 | 23.1 |

| Vibration frequency, Hz | 100 | 100 | 93 | 93 | 93 | 80 |

| Movement speed for bulk materials, m/min | 20-25 | 20 | 20-25 | 20-25 | 20-25 | 20-25 |

| HONDA engine, model | GX 160 | GX 160 | GX 160 | GX 160 | GX 160 | GX 160 |

| Engine power, kW (hp) | 3.6 (4.8) | 3.6 (4.8) | 3.6 (4.8) | 3.6 (4.8) | 3.6 (4.8) | 3.6 (4.8) |

| Gas tank volume, l | 3 | 3 | 3 | 3 | 3 | 3 |

| Fuel consumption, l/h | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

| Productivity, sq.m/hour | 100 | 100 | 140 | 140 | 170 | 150 |

| Productivity, cubic meters/hour | 10 | 10 | 25 | 28 | 36 | 40 |

READ Cutting Tempered Glass at Home

| Vibrating plate VS-245 E10 | Vibrating plate VS-246 E20 | Vibrating plate VS-309 | |

| Compaction modes | |||

| Crushed stone | Acceptable | Acceptable | Recommended |

| Soils (mixed soil, loams) | Acceptable | Recommended | Recommended |

| Sand | Acceptable | Recommended | Recommended |

| Paving slabs, paving stones (using a damping mat) | Recommended | Acceptable | Invalid |

| Asphalt, asphalt concrete | Acceptable | Invalid | Invalid |

| Specifications | |||

| Width of the slab working area, m | 0.41 | 0.43 | 0.50 |

| Dimensions (LxWxH), mm | 980x450x1010 | 1020x450x1040 | 1340x500x900 |

| Operating weight, kg (without water/with water) | 128 /138 | 159 /169 | 300 |

| Depth of compaction of bulk materials in 4 passes up to 97%, mm | 220 | 300 | 400 |

| Driving centrifugal force, kN | 21.3 | 26.6 | 40 |

| Vibration frequency, Hz | 93 | 80 | 72 |

| Movement speed for bulk materials, m/min | 20-25 | 20-25 | 20-25 |

| HONDA engine, model | GX 160 | GX 200 | GX 270 |

| Engine power, kW (hp) | 3.6 (4.8) | 4.1 (5.5) | 6 (8) |

| Gas tank volume, l | 3 | 3 | 5.3 |

| Fuel consumption, l/h | 1.4 | 1.4 | 2.5 |

| Productivity, sq.m/hour | 140 | 160 | 180 |

| Productivity, cubic meters/hour | 32 | 50 | 72 |

Now our vibrating plates are equipped with a new folding folding handle with increased vibration resistance!

The design features of our vibrating plates are:

Scope of application of vibrating plates

The main scope of application of vibrating plates is construction and repair of various levels of complexity, laying sidewalks and roads, arranging sports grounds and much more. They are used both for industrial purposes and for private homes. The uniqueness of this mechanism lies in its relatively small size and ability to cope in conditions in which a conventional bulldozer would not be able to fulfill its purpose. For example, laying a sidewalk or garden path in a private house.

Using a vibrating plate, concrete, asphalt, sand, gravel and ordinary soil are compacted on the lawn. This machine is indispensable for laying roads and sidewalks. The vibrating plate works even in trenches and narrow pits. Since this configuration of the mechanism allows it to move in reverse, this greatly simplifies work in a small area where there is a need for frequent turns or overcoming obstacles.

General characteristics of vibrating plates by weight

The plate mass indicator is the most important when choosing a suitable model or when selecting parts for making a vibrating plate with your own hands. This indicator determines 70% of the productivity of the device and its compliance with the work performed. Models of vibrating plates according to this indicator are divided into 4 classes:

Lightweight models are optimally suited for work on landscaping adjacent areas; the maximum soil layer for these models is 15 cm. These models are also used for laying paving slabs and laying damping polyurethane mats on paths.

Medium models are used for partial repair of asphalt road surfaces, laying tiles on the sidewalk, and repair of the road surface after replacing the underlying communications. The maximum soil layer for these models is 25 cm.

Medium-heavy and heavy models also cope well with more serious tasks, for example, laying layers of road surfaces. Vibrating machines of this category are used to compact the backfill of trenches and the perimeter of the foundation of a low-rise building. The maximum soil layer for these models is 60 cm. The weight limit of the vibrator for laying asphalt is 100 kg.

When selecting the optimal weight of the vibrating machine, special attention should be paid to the engine power. A weak motor on a heavy stove will not provide the expected productivity at work. Such a mechanism will sink into the soil layer and require additional effort from the person performing the work. This discrepancy is especially acute in models from categories 3 and 4. When making or purchasing a vibrating plate, you should calculate this ratio. An example of a discrepancy is a stove weighing 150-170 kg and an engine with a power of 5-6 hp. An example of an ideal ratio is 5 hp per 100 kg.

Operating principle of vibrating plates

To better understand the operating principle of a vibrating plate, you should consider its general structure. This unit consists of 4 main parts:

- steel or cast iron plate;

- vibrator;

- engine;

- frame.

The basis of the mechanism is a massive plate lying at its base. In the center of this plate there is a vibrator, with a motor on top. The engine communicates with the vibrator using a coupling and a V-belt transmission, through which it supplies rotational movements. Already directly in the vibrator, these movements are converted into oscillatory ones. Vibrations are transmitted from the vibrator to the slab, and from the slab to the ground. Thanks to its mass and this vibration, the mechanism does the work - it compacts bulk materials of different thicknesses and densities.

Vibrating plates are equipped with a base made of cast iron or steel; the engines are powered by electricity, gasoline or diesel fuel. Different models have different weight, vibration torque, and engine power. All this is discussed below.

- Operating principle of vibrating plates

- Scope of application of vibrating plates

- General characteristics of vibrating plates by weight

- General characteristics of vibrating plates according to other criteria

- Useful functional additions for vibrating plates

- Instructions: make the vibrating plate yourself

- Rules for operating a homemade vibrating plate with a gasoline engine

Useful functional additions for vibrating plates

In addition to the main indicators, there are some additions to the mechanisms that facilitate the use of the vibrating plate. One of these useful additions is the presence of wheels for transportation and a folding handle. These functions are useless in management and use, but when transporting the mechanism they greatly facilitate the task.

- One of the important additions, without which it is difficult to compact asphalt with a vibrating plate, is the presence of an irrigation system. Without this function, the car will stick to the asphalt and create a lot of inconvenience.

- An addition that will extend the service life of the vibrating plate is the presence of a casing for the belt and coupling. It must cover these parts of the mechanism completely to protect them from soil and parts of the compacted surface.

- Reversible vibrating plates are machines with the ability to move in reverse. This addition also does not have to be present, but it will greatly facilitate the work, especially when it comes to compacting on narrow or small surfaces - trenches, pits, small courtyards or narrow sidewalks.

Instructions: make the vibrating plate yourself

One of the most important reasons for making a vibrating plate with your own hands is significant cost savings. The most inexpensive but reliable Chinese model will cost about 550 EUR, and the cost of a homemade machine will not exceed 250 EUR. In addition, it is always nice to work with your head and your hands to improve your own home.

The process of independently designing and manufacturing a vibrating plate is quite simple, since this mechanism itself is not very complex in its design.

Vibrating plate, spare parts for its assembly:

- engine - chosen at your discretion, for example, it could be an IV-98E platform vibrator, powered by a 220 V network, a gasoline version - three-stroke with one cylinder. Preferred model. Honda;

- the base for the platform is sheet metal, 8 mm thick and 45x80 in size;

- channel – 2 pcs.;

- soft elastic cushions are necessary to secure the handle to the vibrating plate. 2 pcs.;

- M10 bolts for an electric motor or M12 for a gasoline motor;

- plastic wheels – 2 pcs.;

- pipe section;

- hollow pipe about 1.2 m long.

Having collected everything you need, they begin to work, and there is no need to make drawings of the vibrating plate:

- Working with the engine. The cover is removed from it in order to be able to adjust the vibration strength - only relevant for an electric motor.

- An incision is made on the metal sheet with a grinder. The distance from the edge is 10 cm, the depth is about 5 mm. The cuts are made in the amount of two pieces on both sides symmetrically.

- Bend the edges along the cuts using a hammer, the bend angle is 20-30o. This is done to prevent the machine from digging in during operation.

- The places of the cuts are welded and the position of the ends is fixed. This work is not pointless, since without pre-made cuts, bending the metal to the desired angle will be very problematic.

- The vibrator is mounted on the plate using two channels. They are adjusted so that the edges do not protrude beyond the line of the working surface. Welding is required again at this point. The channels are welded very well, the optimal position of the welding mowing line is across. The distance is 7-10 cm from each other relative to the central point of the plate and taking into account the position of the mounting holes on the engine.

- M10 or M12 bolts secure the vibrator to the metal. Measure the distance between the motor mounting holes, drill holes on the channels at the same distance, and fasten the motor to the base with bolts.

- Elastic pads and a pipe are needed to make the vibrating plate handle. The handle is attached to the base through these pads to dampen vibration when the machine is operating. This is very important, because if you do not dampen the vibration, the plate will begin to tear from your hands, and the vibrations will have a negative impact on the joints of the upper limbs.

- To facilitate transportation of the slab, a piece of pipe is welded to it, onto which the wheels are attached. The weight of the finished car will be about 60 kg, so this measure will not be superfluous. The wheels are attached so that they can be easily mounted and dismantled.

READ What Oil to Fill in a Pneumatic Impact Wrench

Helpful operating tip: to dampen vibrations during operation, wrap the handle with rope and make a loop out of it. When performing tamping work, hold not the handle itself, but this loop, so as not to feel vibrations from the mechanism.

General characteristics of vibrating plates according to other criteria

Additional data indicators include:

- vibration force;

- working surface size;

- engine power and the type of fuel it consumes.

These parameters determine the compaction density that the mechanism will ultimately produce, as well as ease of operation and control. Now in more detail:

Honda Engine Maintenance

- Vibration force - the level of vibration power of the base of the mechanism. For dense soils and coatings, this indicator is selected as high as possible. Since weak shocks do not compact hard soil to the required density.

- Working surface size - this indicator determines the pressure of the plate per unit of the surface being processed. On a surface with a small area this figure will be lower. This figure should not exceed 0.3. Conclusion - the smaller the working surface, the higher the efficiency of the vibrating plate. Models with a cast iron base have the highest rates; for steel bases this figure is lower.

- Based on the type of fuel consumed, vibrating plates are divided into electric, gasoline and diesel. The gasoline vibrating plate is recognized by practicing specialists as the most convenient and in demand. The engine for this mechanism has a lower price when compared with a diesel engine, and such a machine works in any conditions. An electric vibrating plate has a lower cost than a gasoline or diesel one, while the power and performance are at the same level. The disadvantage is the need to access electrical networks. As for diesel engines, these mechanisms are the most expensive, but the fuel for them is cheaper than for models with a gasoline engine. The disadvantage of a diesel stove is the high noise level.

- The engine power determines the ability of the vibrating plate to move on a viscous surface and on an incline. The higher this indicator, the easier the machine moves on the surface. The powerful motor itself pulls the slab forward and does not require additional effort from the worker controlling the compaction. At low power levels, the slab buries itself in the ground, and working downhill is especially problematic. The exception is models from the first weight class, in which the motor power and the weight of the plate correspond to each other.

Making a vibrating plate with your own hands

The process of making a vibrating plate with your own hands and designing it yourself is quite simple, because the mechanism by its own design is not complicated.

The vibrating plate consists of the following parts:

- motor - selected at your discretion, for example, you can use the IV-98E on-site unit, which operates on a 220-volt network, or a single-cylinder gasoline unit. Preferably manufactured by Honda;

- base platform – sheet metal, 45 by 80 in size and 8 mm wide;

- channel - two pieces;

- elastic soft cushions, which are necessary for attaching the handle to the vibrating plate - 2 pieces;

- M12 bolts for fastening a gasoline or M10 for an electronic motor;

- plastic wheels to facilitate construction - 2 pieces;

- pipe;

- The pipe is hollow, approximately 1.2 meters long.

Having purchased the necessary materials, proceed to assembly; however, the drawing will not be useful to you.

- Remove the cover on the electric motor to adjust the vibration strength.

- Make a cut on a sheet of metal with a grinder. From the edge of the sheet - 100 mm, depth - approximately 5 mm. It is necessary to make two symmetrical cuts on both sides.

- Using a hammer, bend the edges along the cuts, the bend angle is approximately 25 degrees. This is necessary to ensure that the unit does not bury itself during operation.

- The places where the cuts are made need to be welded and the position of the ends fixed.

- A

do-it-yourself vibrator is mounted on the stove using two channels. They need to be adjusted in such a way that the edges do not extend beyond the edge of the working surface. The channels are painstakingly welded. - The vibrator itself is secured to the metal with M12 or M10 bolts . You need to measure the distance between the motor mounting holes, drill holes in the channels at the same distance, and strengthen the engine to the base by hand using prepared bolts.

- A pipe and elastic pads are needed to dampen vibration and produce the handle of the unit itself.

Scope of use of vibrating plates

The scope of use of the unit is repair and construction, laying roads and sidewalks, beautifying various sites and other work. It is used both on an industrial scale and for home use. The uniqueness of this mechanism lies in its comparatively small dimensions and the ability to work in conditions for which massive devices are not suitable. For example, laying a garden path or sidewalk in a private home.

READ How to cut a hole in metal for a pipe

Using the unit, asphalt, concrete, sand, ordinary soil on the lawn and gravel are compacted. Such a device is indispensable when laying sidewalks and roads. It works even in narrow pits and trenches. The advantage of equipping the mechanism is that it can move in reverse; this greatly simplifies work in small areas, where you often need to turn around or overcome obstacles.

General characteristics of vibrators

Additional indicators when choosing units include:

- Working surface area.

- Vibration force.

- Engine power and type of fuel consumed.

Working surface area - this feature determines the pressure of your slab per unit of surface area of the soil being processed. For a surface with a small area, this value will be less. This parameter should not exceed 0.3. Models with a metal base demonstrate a higher performance; for bases made from other materials this figure is lower.

Vibration force is an indicator of the vibration power of the base mechanism. For dense coatings and soils, this line should be very high. Because with weak shocks, hard soil is not compacted to the required density.

Depending on the type of fuel used, engines can be gasoline, electronic and diesel. A vibrating plate with the use of a gasoline engine is the most necessary and comfortable for professionals. A unit with an internal combustion engine has a lower cost when compared to a diesel unit, and it operates in all weather and production conditions.

A vibrating plate with an electronic drive has a lower price than a diesel or gasoline one, while its performance and power are at the same level. The disadvantage is that not everywhere there is access to the electronic network.

A diesel-powered unit is the most expensive, but its fuel is cheaper compared to a gasoline unit. The disadvantage of this type of drive is the high noise level.

The drive power determines the ability of the vibrating plate to move downhill and on a viscous surface. The higher this line, the easier the unit moves on the surface. The most powerful engine moves forward on its own and does not require additional effort from the employee. With a low power rating, the slab will bury itself in the ground, this will be especially noticeable when working on a slope. The exception is models from the first type in terms of weight, in which the weight of the plate and the motor power correspond to each other.

How much oil should be poured into the engine

It is impossible to give a definite answer to this question. Cars from different manufacturers and brands have their own lubrication system. In addition to the crankcase, oil fluid is found in the pipeline, filter, crankshaft and other components. How many liters of oil to pour into your own engine can be found in the operating instructions. This is important when you need to add lubricant for the first time. The correct filling indicator is indicated by the manufacturer if the power unit is hollow, assembled only.

After draining the oil solution from the system, part of it remains not drained. This is 300-500 grams of lubricant. You can determine how many liters of oil to pour into a car engine by following the recommendations developed for this. In engines of domestic cars with a volume of 1.8 to 2.4 liters, you can add from 3.5 to 4.0 liters of oil. The same imported power units will include from 4.0 to 4.3 liters of lubricant. To determine how much oil is in the engine, you need to use the dipstick and follow several steps:

- First fill the filler neck with 3.5-3.8 liters of lubricant.

- Wait 2-3 minutes and check the lubricant level with a dipstick.

- If the value is insufficient, then add 100-200 grams and check the fill level again.

The procedure must be repeated until the desired filling level is achieved. When adding grease, remember that it is better to add a little more than to immediately overflow. Pumping lubricant out of the system is a very problematic task. If too much grease gets in, it will flood the engine parts and components near it. This will cause the oil to foam and the power unit to work hard. If the filling rate is less than normal, friction units and parts will quickly wear out.

The required grease filling rate can be specified in the AL-KO cheat table.

| Power plant volume, l | Engine oil volume, l | |

| Internal units | Foreign units | |

| 1.6 | 3,3-4,0 | 3.5-4.2 |

| 1,8 | 3,6-4,1 | 3.8-4.3 |

| 2.0 | 3,9–4,4 | 4,0-4,5 |

| 2.2 | 4,0-5,5 | 4,2-5,6 |

| 2,5 | 4,0-5,7 | 4,2-5,8 |

| 3.0 | 4,5-7,5 | 4,6-7,7 |

| 4.0 | 7,0-8,5 | 7.2-8.7 |

| 4.4 | 7,5-9,5 | 7,7-9,7 |

| 5.5 | 8,0-10,0 | 8.2-10.2 |

To be sure and find out exactly how much lubricant is needed for your car, you can contact specialists at a service station.

Useful additions when choosing a vibrating plate

In addition to the main features, there are necessary additions to the mechanisms that simplify the use of the vibrating plate. One of these additions is the presence of a folding handle and wheels for transportation. These functions are not necessary for use and control, but they help significantly when transporting the unit.

A good multifunctional addition is an irrigation system, which simply compacts the asphalt with the unit. If you create asphalt compaction without an irrigation system, the vibratory rammer will stick to the asphalt surface.

The inclusion of a clutch cover and belt will extend the life of your unit. The casing is needed to protect the mechanism from pieces of soil or compacted surfaces during operation.

Possibility of moving the vibrating rammer in reverse. This addition will significantly speed up and facilitate the operation of the unit in inaccessible and oversized areas.

DIY vibrating plate with an electric motor

A vibrating plate is a functional construction tool that can be used to perfectly compact surfaces of large and small soil, sand or asphalt. A vibrating plate, as a tool, is irreplaceable when laying tiles on sidewalks and preparing the base during the formation of the foundation.

The advantage of a vibrating plate in a small-sized version, at home, is its size; it allows you to create work in the most awkward areas, the size of which does not make it possible to use an industrial roller. A successful and small-sized unit can be purchased or rented. But, if you have a large amount of work and plan to use a vibrating plate often, making a vibrating plate with your own hands is a very good option.

Operating principle of vibrating plate

To understand the principle of operation of a vibrating plate

, you need to look at its structure. This tool consists of 4 main parts:

- engine;

- metal or iron plate;

- vibrator

; - frame.

The basis of the unit is an iron plate, which is located at its foot. The vibrator is located in the central part of the plate, with a motor on top. The engine drives the vibrator through a clutch and V-belt drive. Then, in the vibrator, radial movements are converted into oscillatory ones.

From the vibrator, oscillatory movements are transmitted to the slab, and from the slab directly to the ground. Thanks to this vibration and its own weight, the unit does the job - it compacts soil of varying densities and thicknesses.

The base of the vibrating plates is made of steel or cast iron, the engines are powered by gasoline, electricity or diesel fuel. Due to different configurations, models have different motor power, weight, and vibration torque.

Rules for operating your vibrating plate with a gasoline engine installed

In order to increase the service life of your vibrating plate with an installed gasoline engine, you need to follow a number of rules:

- Before starting work, the mechanism must be carefully inspected for damage and the tightness of all fastenings must be checked.

- It is often necessary to check the oil level in the engine and, if necessary, according to the manufacturer’s regulations, change the oil and filters. You need to change the oil on a warm engine.

- The spark plugs in the engine must be cleaned from time to time and visually inspected.

- The engine air filter requires constant cleaning.

- Refuel a gasoline engine only with the engine turned off.

- Do not use the device on hard surfaces – hardened asphalt or concrete.

Sources:

https://metlon.ru/stati/kakoe-maslo-lit-v-vibroplitu.html https://stanok.guru/oborudovanie/press/samodelnaya-vibroplita-s-elektrodvigatelem-svoimi-rukami.html https:// splitstone.ru/technika/vibroplity https://plitavibro.ru/vibroplita-maslo/

The need for replacement according to engine hours

Initial data. stable average speed of the car in the city, manufacturer's recommendations for changing the lubricant. Let's say the speed in the city is forty km/h, and the factory recommendations for replacement are fifteen thousand km.

To calculate engine hours, the distance must be divided by the speed limit. In this situation, 15000/40 = three hundred seventy-five m3 / h. The resulting value means that after three hundred seventy-five hours of operation of the power plant it is necessary to change the oil.

According to the international API standard, a summary table for replacing oils has been developed depending on their type and operating time.

READ How to Correctly Cut Corners of Baseboards

| Type of oil solution | Opening hours |

| Mineral | 130–150 |

| Synthetic API SJ / SHAPI SL / SM Polyalphaolefins Esters | 230-250 320-350 370-400 430-450 |

| Semi-synthetic | 230–250 |

Let's say an SL/SM oil solution with a service life of three hundred and thirty hours is poured into a car engine. To determine the mileage, you need to multiply three hundred and thirty m/h by the average traffic of forty km/h. As a result, we get a mileage of thirteen thousand two hundred km until the next lubricant change.