A walk-behind tractor is a small-sized tractor based on a single-axle chassis. The unit is actively used for plowing the land (the so-called motor cultivator) and clearing roads of snow. Like all other tools for agricultural work, the walk-behind tractor requires proper care. A very important aspect in the maintenance process is the selection of oil for walk-behind tractors. Manufacturers warn: motor oil can either improve the performance of equipment, as well as extend the life of the equipment, or damage the equipment.

How to make the right choice?

An instruction manual is included with the purchased device. The brand of engine oil required is indicated there. The manual also contains information regarding the oil change mode. Unfortunately, in most cases, people either do not read this documentation at all, or it mysteriously disappears somewhere.

Before you go shopping for new oil, find out the model of your walk-behind tractor. It is also worth considering the type of engine, because diesel oil will not work for a gasoline engine, and vice versa. Each type of engine has its own special oil. Some walk-behind tractor manufacturers produce branded oil specifically for the equipment being manufactured.

Technical characteristics of Lifan walk-behind tractors

The range of Lifan walk-behind tractors is quite wide. On the market, the company presents the latest generation cultivators, equipped with massive Lifan engines and having beautiful technical properties.

Let's look at the technical properties using the Lifan 1WG1100С walk-behind tractor as an example:

- Power – 6.5 l. With.

- Engine capacity – 270 cc.

- Engine – Lifan.

- Start - manual.

- Walk-behind tractor control mode: manual transmission.

- Number of gears – 3.

- Productivity – 0.3 m/s.

- The width of the processed harrow is 800-1100 mm.

- Harrow depth 150-200 mm additional equipment: cutters, wheels.

- Weight – 110 kg.

READ How to Dilute Gasoline With Trimmer Oil

Fuel supply problems

This is a more common problem that novice walk-behind tractor users may encounter. In most cases, this is not a problem at all.

The method to solve the problem is to fill the tank and open the valve.

If these measures do not help, you need to clean the air valve or fuel tap; it may be clogged. If these measures do not bring results, you may have filled in with bad fuel, which should be changed. If the reason for poor fuel supply is a broken needle valve or carburetor float, repair of these engine parts is necessary.

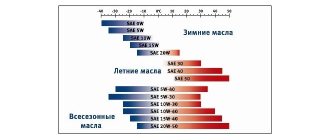

SAE Technical Classification

SAE is one of the most common classifications. It was developed by the American Association of Automotive Engineers (“Society of Automotive Engineers”). In the process of creating the classification, the viscosity and fluidity of the substance in a certain temperature range were taken into account. According to the SAE J300 standard, the following types of oil exist:

- Universal: 5W-30, 5W-50, 5W-50, 15W-30, 20W-30, 10W-50, 10W-30, 10W-40, 15W-50 15W-40, 20W-40;

- For cold climates: SAE 0W, 10W, 15W, 5W,20W;

- For warm climates: 50, 40, 30, 20.

All-season brands are in greatest demand among the population. The great demand for such products is explained by the ability to use them in any climatic conditions. The liquid has optimal performance characteristics all year round in almost any climate zone.

How much to pour the mixture

The amount of liquid that is poured into the mechanism directly depends on a number of factors, namely:

- the volume that is set directly by the manufacturer;

- recommendations regarding the amount of oil;

- design features of the mechanism;

- the amount of liquid drained from the device.

Taking into account all these nuances, you can choose the optimal value at which the device will work best. As a rule, about two liters of transmission fluid are poured into this part of the walk-behind tractor. To determine the reliable amount of this component, you can take a wire 70 centimeters long, and then bend it and insert it into the mechanism. As a result, at least 30 centimeters should be smeared on it (this is considered the norm). If the indicator is less, then you need to add fluid.

Important! If maintenance is performed, it is necessary to fill the liquid to the level, otherwise rapid wear of a part such as the gearbox will be observed.

API Operational Classification

No less popular is the API classification (American Petroleum Institute). It was based on the characteristics of the engine, as well as the type of energy source (gasoline or diesel fuel). According to it, there are 3 main operational categories:

- S – group for gasoline engines. There are the following brands that belong to this group: SA, SB, SC, SD, SE, SF, SG, SH, SJ, SL, SM.

- C – this class is used when operating a diesel engine. In the modern world, there are the following brands for diesel engines: CA, CB, CC, CD, CD-II, CE, CF, CF-2, CF-4, CF-II, CG-4, CH-4, CI-4, CI-4 PLUS, CJ-4

- EU – energy saving brands. They contain mixtures of easily flowing and low-viscosity oil fractions. As a result of research, scientists came to the conclusion that this group reduces fuel consumption during operation of a gasoline engine.

- The fourth group includes universal oils. They can be poured into a walk-behind tractor with a gasoline or diesel engine. They are marked with double markings: SA/CE, SD/CF, SF/CB, etc.

Which brand is better according to this classification? This is quite simple to determine: the closer the second character is to the beginning of the Latin alphabet, the lower the quality. For example, SL is much better than SD oil, and CI-4 is better than CD-II.

How to Fix a Motor Oil Leak in Less than 1 Hour

let's start

In most cases, you will need to jack up the car and support it on jack stands to get under the car. Use a flashlight, safety glasses and gloves.

1. Leak from the filler cap

The oil fill cap is used to add oil to the engine and is usually located on the valve cover. If this cap is loose, or the seal is broken or fails to reinstall correctly after adding oil, it will cause leakage. Check for leaks around the cap and tighten, replace or reinstall the cap as necessary.

An oil filter is used to remove carbon and other impurities produced during the combustion process. This filter is subject to oil pressure. is fed by the oil pump and will leak if the filter is loose or the seal from the old oil filter is still on the block, which can pop up after an oil change has been done. Use a flashlight and check the oil filter for leaks. remove or tighten the filter and retest. Wipe the area and check again for leakage after a short time.

Leaking oil pan drain plug

The drain plug is used to remove oil. from the engine. This screw plug uses a sealing washer to tighten flush. against the oil pan and plug. If the drain plug is loose or the sealing washer is missing or worn, it may cause oil leakage. Check to see if oil is dripping from the plug and then check for leaks. If the drain plug is loose and does not tighten the threads on the drain plug, clean and replace or repair the oil pan. It is common for the drain plug to be tightly closed and still leaking due to a faulty seal washer. Replacing the seal washer will require draining the oil.

The oil pressure sensor is used to send feedback data to the PCM (powertrain control module) and the oil pressure sensor or light in the instrument cluster. This sensor is subject to oil pressure in the same way as the oil filter and can leak if it fails. This sensor is usually located next to the oil filter and will have a one or two wire connector.

Valve covers are used to seal the valve train and control oil leakage. This cap is used in conjunction with a gasket that is located between the cap and the cylinder head. Due to the heat of the engine, as this gasket ages, it can become brittle and crack, causing oil leakage. Otherwise, the valve cover can come loose, which can also cause the above leak. Sometimes they can be tightened, but if the cap is already tight, the valve cap gasket will need to be replaced. Fragile valve cover gaskets. a common problem since they are located at the top of the engine.

6. Leakage through the front crankshaft main seal

The front end of the engine uses a seal to seal the crankshaft where it protrudes from the cylinder block and connects to the front balancer. This seal is designed to move against a smoothly rotating shaft while controlling engine oil. When this seal leaks, it typically sprays oil onto the front of the engine. and down into the oil pan. Use a flashlight to confirm the leak and the front main seal needs to be replaced.

Leakage from the timing cover gasket

The timing cover is designed to control the engine oil on the timing chain of type engines. This cover is attached to the engine block with a gasket, which can leak due to age and heat. This type of leak can be difficult to find, so sometimes it's best to clean the engine . This is because the cover is closed close to the front main seal. When replacing the timing cover gasket, it is highly recommended that you also replace the front main seal.

Leakage from rear crankshaft oil seal

The rear crankshaft oil seal does the same job as the front oil seal, but is located at the rear of the engine. When this seal leaks, it will cause engine oil to leak. into the transmission housing and down the oil pan at the rear of the engine . However, this seal is more difficult to replace because the transmission will need to be removed before the rear main seal can be replaced.

Leak in oil cooler adapter

Some engines are designed with an engine oil cooler or adapter that can leak due to poor seals preventing oil from leaking between the block and the O-ring. This seal or gasket will deteriorate due to engine heat and vibration, which can cause oil to leak. Use a flashlight and look above the oil filter to confirm a leak, which will leak from the oil filter and may fool you into thinking it is the oil filter that is leaking.

In some vehicles, the oil level sensor is used to provide feedback data to the PCM and illuminate the oil level warning light to inform the driver that the engine oil level is low. This two-wire sensor is located on the side. oil pan and immersed in engine oil. Attached to the oil pan with an O-ring, this unit can harden and leak, in which case the oil must be drained. and the o-ring and sender were replaced.

READ How much oil to add to gasoline for a chainsaw

The oil pan is located at the bottom of the engine and is bolted to the block. using many bolts and sealed with a gasket. This oil pan is designed to collect oil in a centralized area, allowing the oil pump to recirculate it back to the engine . If the pan is damaged or the gasket fails, oil may leak. around the pan itself. In any case, the oil pan must be removed and replaced. if it leaks along with the gasket. Depending on the design of the car, this job can be difficult or quite easy.

Oil leak in intake manifold

On most V6, V8 and V10 cylinder engines, the intake manifold stretches between the cylinder head while sealing the cylinder block against oil leaks at the front and the rear manifold at the top of the engine. Over time, gaskets and seals age, causing them to wear out and leak engine oil. Unfortunately there is no easy solution to this problem and the Intake Manifold will need to be removed and the seals and gasket replaced.

Oil leak from head gasket

Overhead cam engines have pressurized oil passages in the engine. oil supply unit to the camshaft and lifters. The head gasket is responsible for the oil pressure seal between the engine block and the cylinder cover. A leak like this can be difficult to find due to engine accessories, mainly the exhaust and intake manifolds, that are in the way. This problem is not easy to solve and the cylinder head will need to be repaired. Removed and replaced the gasket.

An engine equipped with an ignition distributor uses an O-ring seal. located on the outside of the distributor housing, which controls the oil between the cylinder block housing. When this seal hardens and cracks, oil will leak. from the distributor base. This problem is not difficult to detect and is usually attached to the cylinder head on the top of the engine. To correct this problem, remove the distributor and replace the seal, then reinstall the unit.

How to change the oil in a walk-behind tractor

Experts strongly advise pouring new oil into the walk-behind tractor every 100-150 hours of operation of the device. Replacement is a simple process, so no specific skills are required. The main thing is to know the algorithm of actions and strictly follow it:

- Place the unit body horizontally.

- Use a strong screwdriver to remove the plug from the drain tank.

- Pour the contents of the tank into a pre-prepared container with a volume of more than 2 liters. On average this process takes 15 minutes.

- Using the same screwdriver, tightly tighten the drain tank plug.

- Carefully pour the petroleum product into the walk-behind tractor. If there is a gearbox, first fill the gearbox. If there is no gearbox, the fluid must be poured directly into the gearbox. Remember that the poured solution should not flow down the edges. Important: it is highly not recommended to exceed the mark set in the box.

- Do not forget to close the hole intended for pouring oil into the walk-behind tractor.

What happens if you put too much oil in your car?

Don't be judgmental about too much oil in your car or too much engine oil in your car. Sometimes the user does not pay attention to this small detail (or maybe ignores it). If this happens for a long time, the gasket gap will be larger, causing more oil to leak out. The operation of the engine will be affected by oil leakage, engine parts that are not lubricated enough will be broken for a long time, the consequences of this are extremely severe. For more details, we will discuss this situation and the reasons that cause too much oil in the car.

There is too much oil in the car. Badly?

Never treat an engine oil overflow situation casually. This can cause a lot of equipment breakdowns and even cost you thousands of dollars. When you overfill the crankshaft, the oil becomes vented due to the strong rotation of the crankshaft. Foamed oil cannot lubricate the vehicle and may even stop the oil from being distributed to other parts. As a result, the engine began to lock up due to receiving enough oil for combustion. In addition, overheating causes a loss of air pressure. So this is what happens if you put too much oil in your car?

What are the consequences of putting too much oil in a car?

Sometimes you check and see that there is too much oil in the car or engine, or maybe sometimes you accidentally add too much oil while servicing the engine? You think that more oil will help the engine run smoother. But in reality everything is different. Let's figure out the problem.

What's going wrong?

As an engine ages, its gaskets and seals become hard and crack due to high temperatures. This will allow the oil to flow to the ground or into the exhaust system, where it is burned. creating smoke from under the hood. Such oil leaks can be found from the air conditioner or heater vents. If the oil filter seal or housing fails, the oil pressure sensor will force oil under pressure out of the engine while it is running. Such leaks can cause the engine to leak in a short time. time.

2.Motor overload

As explained above, too much oil will cause the pressure in the cacti to increase, which can cause oil to flow through the exhaust pipe. The role of this exhaust pipe is to help remove oil vapor from the cactus and reduce the pressure created by the up and down movement of the piston. Instead of releasing polluting oil, it releases oil vapors back into the combustion chamber through the air intake. If there is too much oil in the cactus, the oil can flow back down the pipe, entering the combustion chamber through the intake neck. As a result, the suction hose becomes clogged with oil soot.

READ Heavy diesel walk-behind tractors in operation

What kind of oil to fill in a centaur diesel walk-behind tractor

In our time, 6 Centaur models have been developed.:

- KM170F (FA);

- KM170FS (FAS);

- KM178F (FA);

- KM178FS (FAS);

- KM186F (FA);

- KM178FS (FAS).

All of the above models are equipped with a four-stroke vertical diesel engine. According to the operating manual, it is recommended to fill the crankcase of the Centaur diesel engine with all-season oil 15W-40, 15W-50. According to the API, the brand must be better than CC (CD, CD-II, CE...CJ-4 are suitable). Based on the fact that all models have the same motor, the solution will be suitable for all brands of Centaur.

Features of the gearbox design

This structural element includes many individual parts. Here we need to consider some of the nuances of the design of this working unit, namely:

- Since the composition contains a large number of different elements, for their reliable operation they require a lubricant, which is oil.

- This working mechanism also requires timely maintenance (replacement of consumables).

- The performance of the entire walk-behind tractor directly depends on the condition of the gearbox, since torque is transmitted through it to the drive axle.

- If you do not change the oil in the gearbox in a timely manner, the working elements will quickly become unusable.

- There are metal gears that are constantly in contact with each other, forming friction.

- This operating mechanism can be replaced if necessary, but it is expensive.

In this video you will learn about the walk-behind tractor gearbox:

Salyut walk-behind tractor must also be replaced in a timely manner , since this element is responsible for the tightness of the entire structural component. If this device fails, oil gradually disappears, which is extremely important for the operation of the entire mechanism.

Important! Despite its design feature, this element is not a complex mechanism and, if necessary, anyone can cope with its overhaul or repair independently.

Briggs&Stratton walk-behind tractor

The unit of the same name is equipped with a gasoline engine, which is cooled by air (so-called convection cooling). Due to this feature, engineers recommend:

- Use synthetic oil ILSAC GF-2 “SJ/CF ENERGY CONVERSING”. It is suitable in any temperature range.

- If the above brand is not available, and the device is forced to operate in subzero temperatures, you need to use Briggs&Stratton 10W-30 branded oil.

- Operating class according to API: SF, SG, SH and higher.

Note: when using grade 5W-30 or higher in warm climates, oil consumption will increase several times. That is why manufacturers need to check its level much more often to avoid unwanted problems.

Replacing oil seals

If maintenance is performed, then this element will also have to be replaced. Let us consider in detail how this procedure is performed:

- first of all, you need to remove the cutters from the device;

- Next, you need to unscrew the holding bolts;

- after this, the corresponding cover is removed;

- the old structural element is removed;

- a new oil seal is placed in its place;

- sealant must be applied on top.

READ What Oil Can You Put in a Four-Stroke Lawn Mower

After this, the lid is closed, the bolts are screwed in, and the removed cutters are installed in place.

It is worth noting that this procedure is recommended to be carried out in conjunction with replacing the fluid, which is carried out once every 100 hours of using special equipment.