What can a boat motor be made from?

The motor can be made in various ways, the main thing is to choose a suitable base and additional parts. An engine from a trimmer or walk-behind tractor, as well as a screwdriver, can be used as a base. A boat motor made from a chainsaw has the best characteristics.

From the trimmer

The trimmer boat motor saves fuel and has a transparent tank. The propeller (homemade propeller) is made of duralumin. The propeller blades are bent up to 10 mm, the edges are carefully sharpened. It is put on in place of the trimmer head. To prevent the propeller blades from damaging the boat during operation, use a ring attachment. The motor shaft and propeller are connected by adapters. The starter is removed from the lawnmower. The motor from the trimmer is made according to a drawing prepared in advance.

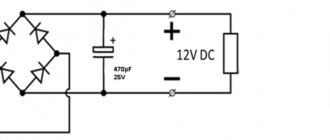

From a screwdriver

If you use a cordless screwdriver, you will get a good homemade engine. For manufacturing, it is better to choose a device with a voltage of 12 V. The process of making an electric motor for a boat with your own hands using a screwdriver:

- The propeller must have a lifting mechanism, so it is attached to the engine transom and secured with frames and plates.

- Clamps are equipped with rings. A tube with a shaft is laid through them. The shaft is made of steel wire or rod.

- Bearings are pressed inside the tube. They will provide the steel shaft with easy sliding.

- To reduce the speed of the electric motor, install a gearbox from an angle grinder. The upper part of the shaft is clamped in the screwdriver chuck.

- The propeller is made of stainless steel, the thickness of the sheet is 2.5-3 mm.

From a walk-behind tractor

From a walk-behind tractor starter you can make a motor for an engine. To assemble a four-stroke model, a simple fuel system is used, but the water pump must be of high quality. The sternwood is removed from the old boat engine. The fuel pump is installed above the carburetor so that it does not come into contact with the rocker arm, and secured with clamps. The crankshaft is mounted above the top gear. A water pump is installed under the deadwood. If you install springs, the lower rod will work freely.

You will find many other interesting homemade products from scrap materials here.

Materials and tools

When selecting equipment, you need to pay attention to two things: power and voltage. These parameters are fundamental, and the quality of operation of the finished electric motor depends on them. The power depends on the selected drill (in this case this tool is taken as the basis), so first of all you need to select this equipment.

When selecting a drill, you need to focus on its power. This figure must exceed one hundred and fifty watts. It is not worth taking a tool with lesser characteristics. In this case, the finished device will not work effectively in moving water (that is, it will not be possible to swim with such a unit on the river). It is best to use a cordless hammer drill.

The hammer drill is equipped with reverse and has several operating modes. This circumstance is important for the motor that will move the watercraft, since it will allow in the future to control the speed of the electric motor.

The second important parameter is voltage. Eighteen volt batteries should not be used. They are difficult to find and expensive. The best choice would be a drill that operates at ten or twelve volts. Such a battery is comparatively cheaper, and, most importantly, it is much easier to find on sale.

After choosing the optimal equipment, you can collect materials. To create an engine you must first acquire:

- An electric drill that will act as a motor.

- Clamps with which the drill will be attached.

- Gearbox. You can use an element from an angle grinder if you intend to install the motor on the transom of the boat.

- Round tubes with a diameter of twenty millimeters.

- Profiled pipes (20*20 millimeters).

- A round metal rod. It will be used to create an electric motor shaft.

- Sheet metal from which the screws will be made.

You will also need some tools:

- scissors for cutting metal;

- welding machine;

- Bulgarian;

- electric drill with a set of drills;

- self-tapping screws with a screwdriver if wood will be used to create the motor.

After all the elements have been collected, you can begin to create an electric boat motor with your own hands. The whole procedure consists of several stages. Work should begin by creating a lifting mechanism for the impeller. In order for the future device to work properly, it is recommended to carefully follow the instructions provided below.

Characteristics of outboard motors

First of all, you should pay attention to the size and power of the engine. To prevent the stern of the boat from sinking under the water, you should not use too heavy devices. Two-stroke models are easy to maintain and lightweight. Four-stroke options are installed on large boats.

Power

A high power engine can capsize the boat during launch. To prevent this from happening, you need to know how much power the device should have. An 8-9 liter motor is installed on a boat up to 7 m in size. With. For a small boat 5 m long, an engine of up to 5 hp will be sufficient.

Motor control and other design options for its creation

Although the electric motor is ready, it is not yet capable of cornering. In order not to turn with the help of oars, it is necessary to make minor modifications to the design. It is enough to attach a bolt to the central part of the mount, onto which you then put a pipe. This will make it possible to make turns by changing the position of the base and, accordingly, the electric motor.

You can weld another handle to the base, connecting it to a regulator responsible for supplying current to the motor. It would be advisable to use a rheostat. However, in this case, you will have to slightly change the drill itself by connecting the motor located in its body to a rheostat. This will allow you to create a more functional design.

Screwdriver as a motor

There are several ways to make an electric motor. Instead of a drill, you can use a screwdriver. In design, it is almost no different from a device with a drill. A distinctive feature of the product is its lower maintenance cost. So, one twelve-volt battery will be enough to operate the device for six hours. However, you will have to sacrifice speed due to less power.

In order for a sailing vessel to move faster, larger pitch propellers can be used. In addition, as in the previous case, the electric motor based on the screwdriver can be equipped with handles that make it easier to control.

Trimer electric motor

A trimer is also perfect for this purpose. Using this device will make the process of creating a motor much easier. The only thing the technician will need to do is shorten the length of the device and attach a screw to it. There is no need to mount the gearbox.

There is also no need to modify the control and system responsible for powering the motor. The only difficulty that may arise along the way is the problem of attaching the device to the boat. Especially for the inflatable one. But it can also be solved.

As an electric motor, you can use the units that power the windshield washers, or a simple electric motor. In the latter case, power supply difficulties may arise, since standard motors operate on an alternating voltage of two hundred and twenty volts. The problem is solved by installing an inverter.

Thus, the owner of the watercraft can create an electric motor for the boat with his own hands. You don't need any special skills for this. You just need to purchase the necessary materials and prepare some tools. It is recommended to use a drill with a power of more than one hundred and fifty watts as a motor. This indicator will allow you to move the boat both in still water and along the river. In addition to a drill, you can use a trimmer or a conventional electric motor. Another option is an electric motor based on a screwdriver. Such a device is cheaper to maintain, but problems may arise with the speed of movement of the craft.

Unlike ancient times, when you could only hope for a fair wind to appear by relying on the forces of nature, today you can move along the surface of the water in any direction without significant physical effort and in complete calm.

Thanks to scientists who obtained electricity for humanity and tamed the fire of the internal combustion engine, any boatman can independently attach some kind of motor to his watercraft.

Making a boat motor with your own hands

You can make a homemade outboard boat motor from a chainsaw with your own hands. It consists of a chainsaw (engine), gearbox and screw mechanism. Step-by-step instruction:

- The propeller is mounted in place of the chain boom, having first removed it.

- The coupling needs to be modified. To do this, grind the cup several sizes smaller and replace the spring.

- Using staples, connect the cup and the coupling cover. The brackets are clamped with a screw and washer.

- The connecting pin between the cup and the shaft is closed with a screw and a bar.

- The shaft and motor are connected by a channel.

- There should be a small gap between the support frame and the front coupling cup.

- A gearbox is mounted on the other side of the shaft.

- A piece of pipe is installed for the rotary motor. It is intended for fastening the guide. The diameter of the rod must match the size of the hexagonal part.

After fastening the screw and shaft, be sure to fill in transmission oil. The lid is mounted on top and secured with sealant.

With gearbox

Assembling a model with a gearbox is difficult, as a high-quality connector is required. For the motor, you can use a four-stroke engine and wide pushrods. The gearbox is installed near the top flange. The wiring is carefully insulated, this will help avoid short circuits. The upper rod and carburetor are sealed with sealant. The motor is equipped with a high-quality water pump.

Creation of an electric motor

As mentioned earlier, you need to start making an electric motor with your own hands by creating a lifting mechanism for the impeller. It will allow you to lift this element above the water. To create it, you need to weld a metal tube to pre-prepared clamps.

You must first attach a base to this tube (a frame shaped like a pyramid, with its smaller base pointing in the direction of the water). A frame is attached to a large base, and another tube is welded to the lower edge. A bearing is installed on the frame. The shaft must be passed through it and the tube welded at the bottom.

You can use a tube or wire as a shaft. However, the first option is more successful:

- firstly, bearings can be attached to the tube (at both ends), which will reduce the friction force;

- secondly, it is desirable that this shaft be thin but strong. In the case of wire, you will have to use a large diameter product.

After all actions are completed, you can move on to the next stage. The next step is to install the gearbox and propellers.

Gearbox/propeller

It is recommended to attach gearboxes to the sides of the shaft. It is advisable to first create them yourself, focusing on the parameters of the electric motor. However, this process can take a very long time. Therefore, you can buy a device or use gearboxes installed on an angle grinder.

Depending on the specific engine, one or two gearboxes may be needed. When choosing a device, you need to focus on one basic rule - it is desirable that the transmitting number be small. It is optimal if the gearbox is capable of reducing the speed by 5 times. This will ensure the normal running of the boat.

The lower gearbox is necessary for horizontal mounting of the screw. If you use a gearbox from a tool such as an angle grinder, it will be enough to clamp it in a drill chuck. Elements of other devices can also be used as a propeller. If there is none, you can make a homemade screw. To do this you need:

- Cut a square (the length of one side is thirty centimeters).

- Drill a hole in its center.

- Make slits diagonally (the distance between the slits should be at least five centimeters).

- The resulting blades must be given a rounded appearance. It is important that the size of the blades is the same, otherwise third-party vibrations may occur.

Read also: Uzo and automatic, what is the difference

The propeller can be secured to the shaft using a bolt and nut. It was for this purpose that a hole was made in the center of the metal sheet.

Latest improvements

Next, you need to connect the gearbox to the motor, that is, to the drill. This is easy to do - just clamp the gearbox in the drill chuck, as mentioned earlier. If the base does not match the size of the drill, you must use an additional tube.

The tube must be placed tightly onto the shaft. To prevent the latter from rotating in it, reliable fixation is needed. This can be achieved by making a through hole in the tube and shaft. Next, both elements must be secured with a pin. This fixation will prevent rotational movements of the shaft.

After the device is ready, the homemade boat electric motor must be checked. It is enough to fill the bathtub with water and start the electric motor in it. If pressure is felt by hand, the engine is operating normally. You can attach it to a boat and test it in a body of water.

Boat mounts

The mounting location for the outboard motor is called the transom. This part must be durable and reliable. In order to correctly design the part, they carefully study the technical characteristics of the boat and the motor, since the transom creates additional load. The transom for an inflatable boat consists of:

The edges of waterproof plywood are treated with sandpaper. Loops for metal staples are installed on the plate. The fastening arcs are bent using a machine; you can do it manually. Eyes are made of plastic or bought in a store.

Gearbox and its influence on operation

The use of a gearbox for a boat motor allows you to change the direction of axial rotation. The gearbox changes the shaft rotation speed several times, which has a positive effect on the operating life of the engine. When equipping a gearbox with a boat motor, you should stick to the golden mean and not install a device with a large gear ratio. Failure to comply with this rule leads to excessive fuel consumption, low boat speed and engine overheating. The most reliable way to install a gearbox with the optimal gear ratio for a given engine is to test several different devices. If during operation there is no feeling of excessive load, which manifests itself in the impossibility of quickly accelerating to high speeds and the speed of the craft is quite high, then this gear ratio can be considered optimal for a given engine.

An average gear ratio that will work well with many internal combustion engines used as a boat motor is 1/5.

Electric motors can be used as propulsion for boats without a gearbox. The traction force of such devices is sufficient to operate stably in the mode of direct transmission of torque to the propeller. An excellent engineering solution is to use an electric motor underwater. With this arrangement, the screw is fixed directly to the motor shaft.

Homemade boat motor from a trimmer

A gas trimmer is a very successful tool for converting into a boat motor.

.

See for yourself - it has almost everything you need - an internal combustion engine, a rod with a shaft transmitting torsion and an angular gearbox. All that remains is to equip the trimmer with a suspension on the transom, change the throttle control handle and install the water propeller.

The petrol trimmer is equipped with a centrifugal clutch, so the screw will not rotate at low speeds.

Here's a video

testing such a modification.

As you can see, a homemade boat motor from a gas mower does its job perfectly.

Boat motor from a screwdriver

New videos

about fishing only with us.

As you can see, it is assembled from very simple parts - pins, boards, ties, the only rarely used part is an angular gearbox for changing vertical rotation from a screwdriver

into a horizontal screw.

Watch the video of testing such a boat propulsion unit.

The speed is, of course, less than that of a boat motor from a gas trimmer, but operating an electric motor is several orders of magnitude cheaper.

Firstly, you can connect a small 12 Volt battery from a motorcycle, this will give you an energy reserve for 6-8 hours of engine operation.

Secondly, the cost of electricity is very low compared to gasoline. Let's remember the Tesla electric car - its range of 250 kilometers costs the owner 150 rubles spent on charging the batteries, but how much gasoline does a sports car with the same speed characteristics consume?

Features and benefits of the device

The name “electric motor” contains the essence of the device it denotes. An electric motor for boats means a unit that drives a boat due to the movement of the blades. Its action is based on physical laws. A special feature of electric motors is the resource they consume to perform their functions.

Today, fuel-powered boat engines are common throughout the world. An electric motor for a boat, unlike similar units, operates by consuming electricity rather than gasoline. There is a widespread belief among some boat owners that such devices are ineffective. However, it is wrong. When properly designed, an electric motor can provide sufficient traction to propel a boat through the water at normal speed.

In addition, a homemade engine has a number of advantages, for example:

- The final costs of creating such a device will be significantly lower than the market value of factory gasoline engines and electric motors.

- The country's environmental legislation strictly regulates the use of electric motors for boats. These rules do not apply to homemade units.

- The device operates with virtually no noise. This feature will be especially useful for fishermen, because any loud sounds can scare off a potential catch.

- Electricity is cheaper than fuel materials. In addition, devices equipped with internal combustion engines consume incomparably more resources than homemade electric motors.

- The boat owner has the opportunity to independently select the power of the unit that is suitable for him. The basis of a homemade motor is a drill or other devices. The characteristics of the future engine depend on their power. Which device the master chooses, these will be the performance of the electric motor.

Creating a homemade electric motor is quite simple. It is enough to strictly follow the instructions. However, you will need certain materials and tools. There shouldn't be any problems accessing them. Most of the necessary tools are already available to any owner. All materials can be found freely available in retail outlets. It is easy to find the drawings necessary for the work.

Related Posts

Restore Screwdriver Battery Video

A comfortable owner, better than anyone else, understands how comfortable and effective a self-contained hand-held power tool is in use. A professional builder who deals mostly with finishing work is completely unable to do without a screwdriver. However, a battery, no matter what type, loses its energy potential after a certain time. Purchasing a new battery is an expensive pleasure. Who said […]

Replacing Batteries in a Screwdriver Battery

Screwdriver battery repair. Diagnostics and replacement of elements Any equipment breaks down constantly. This also happens often with screwdrivers. No one will want to take up an ordinary screwdriver once they have appreciated the advantages of this type of device. Batteries become unusable. It is harmful to rush to throw away a faulty battery. Repairing screwdriver batteries is not difficult if you follow the instructions […]