Design of Makita 2450 and 2470 rotary hammers

The Makita rotary hammer conventionally consists of electrical and mechanical parts. Moreover, the mechanical unit of the hammer drill is located in a black plastic case, and the electrical part of the hammer drill is hidden under the green plastic case.

The procedure for disassembling the mechanical part of the hammer drill

The mechanical unit is designed to transmit the rotational moment of the shaft to the tool, creating not only torque and a translational impact impulse.

The task of the mechanical unit is to transmit rotation from the rotor to the tool, while providing the tool with longitudinal movement.

Disassembling the hammer drill begins with removing the quick-release chuck.

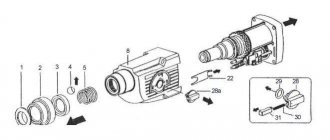

Quick Release Chuck Parts

Having disassembled the cartridge, unscrew the four screws, pos. 10, fastening the gear housing cover, pos. 14, of the mechanical unit and the hammer housing and, pressing on the end of the hammer shaft, remove the black plastic cover.

Removing the cover of the mechanical unit

To remove the mechanical unit from the green stator housing, you must:

- 1. Unscrew the three screws pos. 70, 75, 76 holding the cover pos. 69 in the hammer handle;

- 2. Remove the cover;

- 3. Having released the springs of the brush holders pos. 63, 66, take out the carbon brushes pos. 65.

Now you can remove the mechanical unit from the stator housing.

Type of mechanical block

Having freed the mechanical unit, it is necessary to disconnect the rotor from it. Rotor pos. is attached to the mechanical block due to the friction of the gear teeth and is pulled out by shaking and disconnecting at the same time.

Disassembling the mechanical block of the shock assembly

The mechanical unit is assembled on the inner housing, pos. 49. To remove the intermediate shaft, you need to unscrew two bolts, pos. 43, at the base of the housing. The intermediate shaft is also fixed with the mode switch lever.

Two words about the mode switch

The Makita 2450, 2470 rotary hammers have a lever that provides the tool with three operating modes. A hammer drill can simply drill, simply chisel, and chisel with simultaneous drilling. The switch lever is placed on the axis of the inner housing and is fixed with a compression spring pos. 85, a washer pos. 87 and a retaining ring pos. 86.

It's time to remove the intermediate shaft.

Disassembling the intermediate shaft

To disassemble the intermediate shaft, use the diagram included in this manual.

Photo of the intermediate shaft diagram indicating the disassembly order

Remove from the shaft pos. 40 in order:

- A). bearing pos. 46 and ring pos. 47;

- b). spur gear pos. 42;

- V). rolling bearing pos. 41;

And on the other side of the shaft, remove:

- G). flat washer 12 pos.35;

- d). bearing 606 pos.36;

- e). retaining ring S-7 pos. 37;

- and). compression spring 7 pos. 38;

- h). clutch coupling pos. 39.

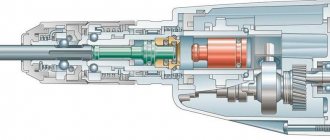

The procedure for disassembling the barrel shaft of the impact mechanism

To disassemble the impact mechanism shaft, it is necessary to pull it out of the inner housing.

It is necessary to remove the cylinder pos. 32, inserted into the internal cavity of the shaft, from the shaft.

The cylinder is very easy to disassemble:

- 1. You need to remove the striker pos. 30 from it;

- 2. The piston hinge pos. 34 is knocked out;

- 3. Remove two flat washers pos. 33, 35.

To disassemble the shaft itself, pos. 21 of the impact mechanism, it is necessary to remove from the side of the cartridge installation shaft:

- — ring spring 28 pos. 16;

- — washer 30 pos. 17;

- — compression spring 31 pos. 18;

- — spur gear 51 position 19;

- — steel ball 7.0 pos.20.

And from the side of the internal cavity of the shaft it is necessary to remove:

- — ring spring 28 pos. 29;

- — rubber ring pos. 28;

- — metal ring pos. 27;

- — rubber ring 15 pos. 26;

- — ring 9 pos.25;

- — flat metal washer 28 pos. 22.

Disassembled barrel shaft

Disassembling the electrical part of the Makita 2450, 2470 rotary hammer

The electrical part of the Makita 2450.2470 rotary hammer includes:

- rotor pos.54;

- stator pos.59;

- switch TG813TLB-1 pos.68;

- carbon brushes SV-419 pos.65;

- brush holder pos. 63,66.

To remove the stator, just tap the end of the plastic green case on the stator side with a wooden mallet or block.

But first you need to unscrew two self-tapping screws 4x60 mm pos. 57.

When you frequently tap on the housing, the stator spontaneously protrudes beyond the edges of the housing and is then removed by hand.

The remaining elements of the electrical part of the Makita 2450 or 2470 rotary hammer can be easily dismantled, since they are not attached to anything.

Source: domremstroyka.ru

The procedure for disassembling and assembling the tool

Before you start disassembling the hammer drill, you need to stock up on tools that you cannot do without: hexagons, screwdrivers with various cuts (minus, Phillips, figured), special pullers for bearings, a vice.

Always useful:

- lubricant, solvent;

- spare brushes (if replacement is needed);

- copper wire of suitable cross-section.

Disassembly

First you need to remove the quick-release distributor. After dismantling, remove the four screws that secure the “body” of the gearbox of the mechanical part. Next, press the shaft pediment and remove the black cover. Then pull out the mechanized block from the green side; this requires the following manipulations:

- remove the three screws in the handle that hold the cover in place;

- remove the cover;

- Remove the carbon brushes and release the brush holder springs.

After all the actions performed, remove the mechanical stator unit. Release the rotor.

Then you should disassemble the mechanics block of the shock assembly and unscrew the two bolts located in the foundation of the housing.

Now it’s time to remove the intermediate shaft; you will need to remove it in order:

- ring, bearing;

- spur gear;

- friction bearing;

- flat washer;

- 606 bearing;

- S-7 retaining ring;

- compression spiral;

- clutch.

Next, remove the barrel shaft of the chiselling mechanism. It is necessary to remove it from inside the housing, and remove the cylinder from the shaft itself.

Continuing to carry out the disassembly sequence, dismantle it by following the following instructions:

- knock out the piston connector;

- remove flat washers;

- remove the striker.

To expand the shaft itself, you will need to remove the washer, compression and ring springs, steel ball, and spur gear. And from the internal cavity, remove metal and rubber (2 pcs.) rings, an annular spring, a ring, and a flat metal washer.

Observing all the rules for the disassembly sequence, let's move on to dismantling the electrical part, which includes the following parts:

- stator;

- switch;

- rotor;

- carbon brushes;

- brush holder

Then you need to remove the two self-tapping screws.

Assembly

Before returning all the parts that make up the hammer drill to their place, you should apply a new layer of lubricant. Clean the body with gasoline. If necessary, replace all parts that need replacing and varnish the coils. Degrease the collector with a cotton pad soaked in an alcohol solution to avoid dust sticking to the lubricated bearing. Reassemble everything in reverse order.

It may be necessary to repair, service, carry out maintenance or even replace some parts.

Repair of the mechanical part of the Makita 2450 and 2470 rotary hammer

Any tool repair begins with determining the nature of the malfunction and disassembling it.

The Makita 2450 and 2470 rotary hammer can be repaired by a user who has basic plumbing skills and is familiar with electrical safety requirements.

This article discusses the mechanical part of the Makita rotary hammer, the main faults and how to eliminate them.

Disassembling the mechanical part of the Makita 2470 rotary hammer

To get to the mechanical part of the hammer drill, you need to remove or disassemble the cartridge.

Disassembling the quick-release chuck Place the hammer drill on the back cover of the case on a table surface covered with a clean cloth or paper. Using tweezers or a screwdriver, remove the rubber tip 35, item 1.

Carefully release the ring spring pos. 2, coupling casing pos. 3, steel ring pos. 4. You will reach a steel ball with a diameter of 7 mm, pos. 20.

Now you can remove the housing of the mechanical part. It is black. Using a screwdriver, unscrew the four screws at the end of the housing.

Holding the black body with your right hand, press your thumb on the end of the shaft from which the cartridge was disassembled. The plastic case can be easily removed.

Next you need to remove the gearbox shaft.

To disconnect the mechanical part from the electrical part, you must first remove the electric brushes. Remember! The rotor is held in the lower part of the housing by electric brushes, which must be removed.

Mechanical malfunctions of makita 2450 and makita 2470 rotary hammers

Common mechanical malfunctions of Makita rotary hammers include:

- destruction of the quick release chuck;

- bearing failure;

- damage to the impact mechanism;

- wear of the hammer drill barrel;

- wear of the rubber striker and striker;

- gear failure.

Repair of a hammer drill chuck is carried out to replace the boot and rubber ring, as well as a conical spring and a steel ball that clamps the working tool (drill). This is indicated by the fact that the working tool? namely the drill, is poorly held in the chuck.

The main reason is wear of the steel ball 7.0 pos. 20, art. 216022-2. Ball wear occurs from contamination of the cartridge bore due to dust and dirt getting inside.

The general view and design of the Makita hammer drill chuck is shown in the photo below.

Repairing a makita 2450 hammer drill chuck with your own hands is easy. The cartridge must be disassembled, freed from old grease, discarded rubber parts, and replaced defective ones.

More complex faults require knowledge of the mechanical structure of the Makita 2450 rotary hammer.

Having determined the nature of the malfunction of the Makita rotary hammer, proceed to disassembling the mechanical part, called the gearbox.

Disassemble the mechanical part according to the attached video. Free it from old grease. Carefully inspect all parts, their integrity, and level of wear. All rubber products require replacement during any disassembly.

Let's consider repairing a hammer drill barrel. Let's analyze the mechanism completely. Video of disassembling, lubricating and assembling a Makita hammer drill

Repair of parts of the Makita 2450 hammer drill barrel

Remember! The rotor is held in the lower part of the housing by electric brushes, which must be removed.

At the next stage, the rotor must be disconnected from the removed mechanism. The rotor is detached from the mechanism simply by pulling it out, since it is held in place by the friction of two helical gears.

It turned out to be such a dirty knot.

Now we need to separate the impact mechanism shaft.

Most often, the rubber rings and the firing pin, pos. 24, compressor spring pos. 18. and cylinder parts.

This is how barrel parts wear out and break down when the tool is used incorrectly.

Let's consider the most complex malfunction - failure of the impact mechanism. Characteristic signs of failure of the impact mechanism are the absence of impact and the unpleasant noise of the rotary hammer operating in the “Impact” mode.

This malfunction is typical for those rotary hammers that, during operation, were strongly pressed against the surface being processed. Having disassembled the gearbox, we remove debris and pieces of foreign objects. We find the faulty part and clean everything of old grease.

Very often the firing pin, item 24, art. 324396-8, included in the barrel.

metal ring pos. 27. art. 324216-6.

Discard damaged parts, replace with new ones, and cover with a thin layer of lubricant. The parts are ready for assembly. But more on that in the next article.

Source: sdelalremont.ru

Do-it-yourself repair instructions for a Makita 2450 rotary hammer

Hammers. Impact drills designed for drilling and drilling holes in particularly durable materials. The hammer drill implements two ideas: the working tool rotates and simultaneously moves in the longitudinal direction, creating a shock impulse.

READ Rotary Hammer for Concrete Core Drilling

Hammers always work under extreme conditions. Drilling time depends not only on the correct operating conditions, but also on the reliability of the parts included in the product.

But no matter how hard you try, over time the shots begin to fail.

To properly repair a hammer, you need to become familiar with its design. A person who has the skills of a mechanic and knows the basics of electrical engineering can repair a Makita 2470 and 2450 rotary hammer with his own hands.

Remember! When disassembling, take precautions and unplug the power cord.

The Makita 2450 and 2470 rotary hammers are assembled almost identically and from the same parts. Their renovation is no different. For ease of repair, below is an assembly diagram and a parts catalog for the Makita rotary hammer.

The circuit of the Makita 2450 and 2470 rotary hammer consists of a mechanical and electrical part.

The mechanical part transmits torque to the drill, creating a forward movement that creates impact. The mechanical part consists of a rotation drive and an impact mechanism.

The electrical circuit of the Makita rotary hammer converts electrical energy into kinetic energy by rotating the rotor. The electrical part includes an electric motor, a power button with a speed controller, a reversing switch, and connecting wires. The main malfunctions of the Makita rotary hammer The disadvantages of the rotary hammer are divided into electrical and mechanical.

In this article we will look at all the electrical faults of the Makita 2470 and 2450 rotary hammers and how to fix them:

Electrical malfunctions of the Makita 2450 and Makita 2470 rotary hammers Electrical malfunctions manifest themselves in the fact that when the hammer drill is connected to mains voltage, the tool does not turn on. The connection diagram for connecting a Makita rotary hammer to the network is simple.

Electrical diagram of the Makita 2450 rotary hammer. This is a serial connection of the electric motor, start button and wires. The layout of the Makita 2470 rotary hammer is similar.

Through the connecting cord pos. 72, supply voltage 220 V is supplied through the switch pos. 68 and electric brushes through the brush holder pos. 66 to the rotor blades of the electric motor pos. 54, and through the contacts of the reverse switch pos. 60 to the position of the stator winding. The most common problem is missing contacts in connections.

Procedure for identifying electrical faults

Video: Makita HR 2470 \ 2470 disease: hammer drill stopped turning on \ burnt contacts \ maintenance tool

Determining the electrical integrity of a Makita rotary hammer. To repair a Makita 2450 or Makita 2470 hammer with your own hands, you need to arm yourself with devices and tools. Will make any tester, set of screwdrivers, wrenches, hammer, wooden extension. It's good to have a screwdriver with a built-in phase indicator.

You need to take the tester, connect it to the ends of the hammer drill and press the hammer. If the tester shows some resistance, the power supply circuit of the hammer drill is not damaged. If the tester shows infinity, then the integrity of the circuit is broken, and it is necessary to remove the back cover to control the connecting cable and electric brushes of the hammer drill.

The back cover (usually black) of the punch is easy to remove, you just need to remove three screws using a screwdriver or screwdriver.

Remove the cover and use a screwdriver to disconnect the ends of the wires from the electric brushes. Using a tester or a homemade device, which is popularly called an “arch,” the integrity of the wires and the correct operation of the switch are determined.

A few words about a simple control device called an “arcade”. The device consists of an LED or a flashlight, a AA battery and two pieces of wire. The entire electrical circuit of the control device consists of parts connected in series. Connect the battery from one end of the LED lamp or light bulb, connect the wires to the free ends of the LED and battery. You will receive a universal device for checking the integrity of electrical circuits.

Typical malfunctions of the Makita 2450 and 2470 rotary hammer Frequent malfunctions in the electrical part of the Makita 2450 and Makita 2470 rotary hammer:

- Fracture of the power cable at the entrance to the hammer drill;

- Failure of the switch button TG813TLB-1, art. 650508-0, pos. 68.;

- Wear of electric carbon brushes SV-419, art. 191962-4, item 65;

- Worn rear derailleur contacts;

- Wear of rotor bearings: bearing 609LLU, art. 210060-6, pos. 51; bearing 607LLU, article 211021-9, pos. 56;

- Rotor short circuit 220-240 V, art. 515668-8, art. 54;

- Broken stator winding 220-240 V for HR2450, art. 633488-5, pos. 59.

As a start button. Switch TG813TLB-1, art. 650508-0; position 68.

Repair of the mechanical part of the Makita 2450 and 2470 rotary hammer

Due to the ingress of dust, dirt and moisture, the internal lubricant becomes hard over time and does not fulfill its purpose. The hammer drill starts to work with extraneous noise. When starting to repair the rotary hammer, be sure to read the attached instructions for disassembling, lubricating, and assembling components of the Makita 2450, 2470 rotary hammer. The diagram of the Makita 2450 and 2470 rotary hammer will help you correctly disassemble faulty components and find defective parts. We will also tell you how to disassemble the Makita 2450 rotary hammer.

Disassembling the Makita 2470 hammer drill begins with removing the mode switch knob.

Makita rotary hammer device

Among users, the Makita hammer drill has established itself as a tool with the greatest functionality. It is durable and does not require special skills to use, lightweight and convenient to use.

The design provides a special protective system designed to limit the spread of dust. With timely cleaning, the tool will work effectively throughout its entire service life.

Makita is widely used by people who prefer to do their own renovations. The tool is easy to use, maintenance costs are minimal and inexpensive.

The manufacturer presents the following technical specifications:

- Total weight. 2.04 kg

- The SDS system allows you to mount drills

- You can hammer and drill

- The system has three operating modes

- Maximum number of beats per minute. 4500

- Translation power. 2.7 J

- Power unit. 780 W.

The procedure for disassembling the hammer drill

Place the hammer drill on a clean surface.

When disassembling the mechanical part of a Makita 2450 or Makita 2470 rotary hammer, you should always remove the mode switch handle.

At the beginning of work, the handle is set to the “Impact” mode (far right position clockwise).

Use a screwdriver to pry up the latch on the handle and remove it.

After removing the latch, the handle is moved to the extreme left position, to the “Drilling” mode.

The handle, clamped with your fingers, is removed from the grooves of the body.

Video instructions for disassembling the mode switch handle of a Makita 2450 hammer drill

Procedure for setting the mode knob

To install the mode switch into the case, you need to perform some actions: • insert the switch into the “drilling” position into the mounting socket until it clicks; • move the switch counterclockwise to the “blow” position; • turn the switch counterclockwise with a click to the “drilling” position; • insert the spring and the red button; • insert the cover on top until it locks into place. The mode switch is assembled.

At the second stage, you should disassemble the quick-release chuck and repair the hammer drill chuck with your own hands. By the way, the cartridge requires disassembly only for Makita 2470 models. The design of the cartridge is quite simple, and anyone with a little knowledge of metalworking skills can handle its repair.

The procedure for disassembling the Makita hammer drill chuck

Repairing a hammer drill chuck begins with installing the hammer drill vertically on the back cover of the case. The hrmakita rotary hammer diagram will help you perform disassembly work correctly. Is it necessary to replace the chuck of a Makita 2470 hammer drill? The answer can only be obtained after completely disassembling the cartridge with your own hands. Using a screwdriver or puller, the boot is removed, the cartridge is freed from the retaining ring, the coupling casing, and the metal ring 20 pos.4. Next, you need to carefully remove the ball, pos. 20, remove the guide washer, pos. 5, and the conical spring, pos. 6, that supports it. The cartridge is disassembled.

The diagram below shows the design of a hammer drill chuck.

The main malfunctions of the makita 2450 rotary hammer, causing defects in the operation of the chuck, are:

- wear of the protective rubber boot pos. 1;

- relaxation of the locking ring pos. 2 or its partial wear;

- ball wear pos. 20;

- loss of elasticity of the conical spring pos. 6 or its stretching.

Repairing a hammer drill chuck is not a complicated procedure and is usually easy to do by anyone who can hold a screwdriver.

If replacing a rubber boot, retaining ring, or conical spring is not difficult, then replacing a new ball requires attention. The new ball should have a diameter of 7mm ±1 µm. As lubricants, it is recommended to use a special lubricant designed for Makita rotary hammers. The lubricant has the index Makita P-08361, Makita 183477-5 SDS-PLUS 30g for the gearbox. For drill shanks, it is recommended to use Makita 196804-7 lubricant.

When assembling the cartridge, install the conical spring with its narrow side facing the hammer. Do not forget, repairing a hammer drill chuck with your own hands requires attention from the assembler.

Assembly procedure for quick release chuck

Assembly is carried out on a clean surface. The parts are pre-washed, dried and lubricated with a thin layer of recommended lubricant.

Makita rotary hammer: do-it-yourself repair

Diagnostic technology and troubleshooting are identical to other devices. First, you should disassemble the tool by removing the body, and then remove the old grease and contamination.

It is recommended to replace components that have stopped working. After this, all the components of the mechanism are installed in their original position.

For correct operation, it is recommended to carefully study each repair item. To restore the functionality of the 2010 cartridge, mode switch and housing, perform the following steps:

- Remove the cartridge

- Remove the switch

- Eliminate defects in the interior of the case

- Apply lubricant and replace worn parts

How to disassemble a hammer drill and gearbox?

When disassembling the gearbox, it is recommended to adhere to the following instructions:

- Place the hammer drill on a hard surface, lifting its barrel up

- Using forward movements, pull out the shell, pressing the tool against the table. This position will prevent accidental displacement of the constituent elements

Assembling a Makita hammer drill

After the repair is completed, all removed parts should be returned to their original position. It is recommended to apply a fresh coat of lubricant to all necessary parts.

Before assembly, the body is cleaned with kerosene or gasoline. The cleaned shell is returned to its place. The mode switch should not be located in it.

Read also: Starting the Stihl 180 saw

Makita HR 2450 diagram

The Makita-2450 rotary hammer system consists of many complementary components and a list of spare parts. Among the most significant elements, the features of which should be taken into account during repair work, are the following:

- Ring locking device. It is designed to hold the ball element that secures the drill. The washer and spring guide it

- Retaining ring. This is necessary for correct removal of the cartridge cover.

- Four screws connect the gearbox and motor, eliminating vibration. The circuit contains a large number of rubber components. Often they are the cause of a malfunction.

A description of the mentioned components will be sufficient for high-quality repairs.

We disassemble the gearbox

To get to the mechanical part, you will need to remove the plastic housing.

The procedure for disassembling the mechanical part of a Makita rotary hammer: First, remove the black protective plastic case. The case is removed after you unscrew the four screws securing the case from the end. By pressing on the end of the shaft you will press the gearbox out of the housing.

After removing the housing, you need to separate the rotor from the gearbox. The gearbox is the general mechanical part. The rotor is separated from the mechanical part (gearbox) simply. You need to clamp the gearbox with your right hand, and clamp the rotor with your left hand. While rocking, pull both parts in opposite directions. The rotor is held in the gearbox by friction of helical gears. The main malfunctions of the Makita rotary hammer occur in the mechanical part of the tool.

The most typical malfunction for the mechanical part is the failure of the impact mechanism.

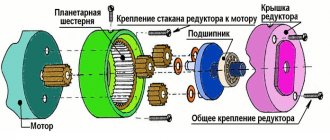

Disassembling the impact mechanism The impact mechanism is assembled on the inner housing and consists of a gearbox shaft and an intermediate shaft. The rotational motion is transmitted through helical gears to the intermediate shaft.

The gearbox shaft is a hollow shaft in which the cylinder moves freely.

A small spur gear mounted on the intermediate shaft transmits rotation to the large spur gear of the gearbox shaft, in which the impact mechanism is mounted. And translational movements are simultaneously transmitted to the gearbox shaft of the impact mechanism due to transmission from the rolling bearing of the intermediate shaft to the cylinder moving in the gearbox barrel.

Let's move on to disassembling the intermediate shaft.

Disassembling the intermediate shaft

Mounted on the shaft pos.40 is a helical gear pos.42, to which rotation is transmitted from the rotor gear, a rolling bearing 608zz pos.41, which transmits translational motion to the hinge pos.34 of the piston pos.32. On the other side of the shaft, a clutch coupling is installed, pos. 39, spur gear 10, pos. 80, compression spring, pos. 38, retaining ring S-7, pos. 37, bearing 606zz, pos. 36. Particular attention should be paid to the condition of the rolling bearings. The hammer drill has imported bearings. Installation of domestic bearings is allowed. Bearing 606zz can be replaced with 80016, bearing 609zz can be replaced with 80019.

Let's move on to disassembling the impact mechanic shaft

Dismantling the impact shaft

Disassembling the barrel of a Makita 2470 hammer drill is a simple process if you use the Makita hammer drill design diagram. The shaft is a barrel, pos. 21, in which the impact mechanism is assembled. A gear, pos. 19, is attached to the barrel, which is pressed by a spring, pos. 18, through a washer, pos. 17, and secured with a retaining ring, pos. 16. The cylinder pos. 32 moves in the barrel, acting on the firing pin pos. 24. On the reverse side of the striker there is a metal ring, position 27, which transmits the blow to the drill. When is it necessary to replace the hammer drill barrel?

Most often the metal ring fails.

Striker

Cylinder with striker

We've sorted out the disassembly. We replace the parts with serviceable ones and get ready to assemble. Learn more about lubrication and assembly of the hammer drill.

Video of quick disassembly of a Makita rotary hammer

Source: sdelalremont.ru

How to lubricate and assemble the Makita 2450 and 2470 hammer drill correctly

The assembly of any mechanism must begin after careful preparation. It is necessary to prepare not only the parts, but also the tools, space, and oil.

Tools are not complete without pliers, screwdrivers, hammers, and brushes for applying oil.

But what is the assembly diagram for the Makita 2450 and 2470 rotary hammer?

Self-assembly of a Makita rotary hammer can only be carried out with the accompanying instructions.

Build process task. Replace faulty parts with suitable parts and ensure that the tool is interchangeable and in good working order.

Assembly procedure for the Makita 2450 rotary hammer

Impact mechanism assembly

How to assemble the impact mechanism of a Makita rotary hammer? The impact mechanism is assembled from two components: a shaft with a screw gear and an intermediate shaft with a rolling bearing.

AND). Gear drive pos. 19 is located on the barrel, pos. 21 and pressed by the compression spring pos. 18. To fix the spring, it is pressed with washer 30 pos. 17 and fixed with ring 28 pos. 16.

B) To assemble the striker, put on the ring 9 pos. 25 on the shock shaft, tighten the rubber ring pos. 26, press the metal ring pos. 27.

Now move to the opposite side of the trunk. On the other hand, the inner surface of the barrel must be lubricated and inserted into the assembled drummer position 24.

Intermediate shaft and piston assembly

Assembling the intermediate shaft assembly

A rolling bearing must be installed to assemble the intermediate shaft. 41 on the shaft pos. 40 teeth to the shaft slots, install the coupling pos. 39 there are slots on the shaft.

Forward movement

On the opposite side of the shaft there is a helical gear 26 pos. 42., Flat washer 8 pos. 45, bearing 608zz pos. 46 and retaining ring 8 pos. 47 put on. Intermediate shaft assembly.

Assembly of the gearbox assembly

The gearbox is installed on the inner housing, pos. 49.

By the way, there are cases when the axles fall out of the internal aluminum housing. Both axes are pressed to the body.

The assembled intermediate shaft is inserted into the housing pos. 49, the roller bearing handle should fit into the hole in the cylinder hinge.

In this case, the rolling bearing pos. 41 of the intermediate shaft should fall into the hinge pos. 32, and the lower bearing of the intermediate shaft in a seat in the housing. This procedure is usually performed by rocking the structure until the parts are completely in place.

Installing the mode switch lever

The mode switch is designed to move the coupling pos. 39 to different positions and transmit the translational motion of the impact mechanism shaft through the rolling bearing pos. 41 to the cylinder pos. 32.

Makita 2450 Punch Mode Switch Lever Assembly

Install the mode switch lever on the axis of the inner housing. 82, compressed spring, pos. 88 from above, and press the flat washer pos. 87. Set pos. 86. And close. The snap ring must be carefully secured. When turning the intermediate shaft, it is necessary to carefully check the correct operation and free movement of the cylinder in the housing. This should be done now so that at the end of the meeting it does not become clear that the collection was assembled incorrectly.

Impact shaft assembly

First lubricate the inner surface of the cylinder pos. 32 and insert drummer pos. 30, in it.

All that remains is to put the greased barrel in position. 49 in the inner building, village. 21, putting it on the lubricated cylinder in pos. 32. It is recommended to use a special lubricant designed for Makita rotary hammers as a lubricant.

Lubricants are available in several types: Makita P-08361 and Makita 183477-5 SDS-PLUS.

Makita 183477-5 SDS-PLUS oil is recommended for gearboxes. Makita 196804-7 oil is used for drill shanks.

Lubricants vary in color, but have exactly the same characteristics. What lubricants are used in the Makita 2450 and 2470 rotary hammer?

And here is the assembled mechanical unit.

Video of general disassembly and assembly of the Makita 2450 rotary hammer

Check its effectiveness by rotating the counter shaft and monitoring the movement of the piston in the impact mechanism. All!

Now lubricate all parts of the mechanical unit with the recommended oil. Here is an example of proper lubrication on rotating surfaces. Here is another example of generous lubrication of a mechanical unit.

Don't spoil the porridge with oil

Therefore, it is also allowed to use oil. Don't spoil the porridge with oil!

The lubricated mechanical unit must be covered with a plastic housing, pos. 14, black. With the housing on top of the assembly, push down on the housing until the assembly is fully seated. Delay, insert four screws, pos. 10, into the body and tighten.

Now it's time to join the mechanical part of the engine rotor. Rotor installation

The rotor helical gear train is tightly inserted into the mechanical assembly housing and pressed together.

It remains to insert four screws m4 × 60 pos. 57. And screw them into the body of the electrical unit.

READ Installing the Ignition on a Subaru Ex21 Motoblock

Installation of electric brushes

Remove dirt from the brush holder grooves and reinstall the brushes, securing them with the clips.

Now is the time to test the impact. Insert the hammer drill into the socket, turn on the hammer drill for a while in the “drilling” mode. Once you are sure that the tool is working, turn it off. Set the mode switch to the "impact" position. Do not insert the tool. Check the operation of the hammer drill in this position. At the same time, you checked the operation of the mode switch.

All that remains is to check the installation of the speed control button, make sure that the contact connections are secure, and you can begin installing the cover.

The cover is secured with three M×4 self-tapping screws of different lengths.

Connect the hammer drill to a 220Β network and check all modes. The Makita 2450 or 2470 rotary hammer is assembled and working correctly!

How to repair a Makita HR 2450 rotary hammer if the shock mode has disappeared

Makita power tools have long established themselves as professional, reliable and easy to maintain. In addition, it has good maintainability and a relatively low price.

Of all the lines of rotary hammers, I would like to focus on the Makita HR 2450 . The tool is very easy to use, has three operating modes and can withstand very long loads. The author of these lines worked faithfully and faithfully for more than six years without any breakdowns. Moreover, it was used under intense loads. But one fine moment...

Makita rotary hammer device

Among users, the Makita hammer drill has established itself as a tool with the greatest functionality. It is durable and does not require special skills to use, lightweight and convenient to use.

The design provides a special protective system designed to limit the spread of dust. With timely cleaning, the tool will work effectively throughout its entire service life.

Makita is widely used by people who prefer to do their own renovations. The tool is easy to use, maintenance costs are minimal and inexpensive.

The manufacturer presents the following technical specifications:

- Total weight. 2.04 kg

- The SDS system allows you to mount drills

- You can hammer and drill

- The system has three operating modes

- Maximum number of beats per minute. 4500

- Translation power. 2.7 J

- Power unit. 780 W.

The hammer blow has disappeared - what to do?

As you know, nothing lasts forever. And reliable equipment breaks down. Somehow, in the midst of work, he stopped hammering. The machine was working in rotation mode, but the shock suddenly disappeared.

The gearbox was disassembled and the cause of the breakdown was identified. The bushing in the barrel body, in which the firing pin directly carries out the impact work, was broken. As a result, the striker became jammed in the fragments of the collapsed bushing.

The service center advised to replace the barrel completely. It turned out that the bushing is pressed into the barrel at the manufacturer and is not supplied separately. I had to buy a whole new barrel.

In this article we will tell you how to put the hammer drill into working condition yourself after this, in general, simple breakdown. If you have the skills to repair power tools and the desire not to pay someone your hard-earned money, then we take the tool and start disassembling the machine.

Tools

You will need two ordinary flathead screwdrivers and one Phillips head screwdriver. One of the flat-head screwdrivers should be thin and narrow, no more than 4 mm wide. You will also need a wire hook to remove the retaining ring. It can be made from a bicycle spoke, the main thing is that the wire is rigid and does not bend easily. You will also need a rubber mallet or wooden mallet.

Work process

Disassembling the hammer drill should begin by removing the protective rubber cap - boot. It can be easily removed, just grab it with your fingers and pull it off the barrel.

Removing the boot

Then, by pressing on the plastic cover and squeezing the spring of the SDS + mechanism, remove the retaining ring with a screwdriver.

Using a screwdriver, remove the stopper

The cover is removed from the barrel, and behind it, compressing the spring again, we pull out the retaining ball along with the spring and the figured washer.

Remove the cover

Disassembling the SDS mechanism

After which the operating mode switch is disassembled. Under the cover that holds the red locking button, there is a special slot for a screwdriver. By inserting a screwdriver into this groove and prying the cover slightly, first from one edge and then from the other, carefully remove it. You should not apply significant effort here; the lid is still plastic and may break. The red button along with the spring is removed from the switch body, and it is moved to the left all the way, just beyond the drilling mode. It is from this position that it is removed from the gearbox. For this operation, the switch must be lightly picked up with thin screwdrivers on both sides and removed along with the rubber o-ring.

Removing the rotary hammer mode switch

Now the gear box is removed. Using a Phillips screwdriver, unscrew the four bolts connecting the box to the stator housing. Then, holding it with your hand, you need to lightly hit the end of the barrel with a mallet so that the box comes off the gearbox.

Removing the gearbox

After removing the box, remove the barrel from the gearbox. It comes off easily.

Pull the barrel out of the gearbox

Use a rag to remove old grease, wash the barrel with gasoline or kerosene and wipe dry.

Basic malfunctions of rotary hammers

- If the hammer drill does not turn on or when the device operates, unusual grinding, noise appears, its operation is accompanied by jerking, or an unpleasant odor emanates from inside the housing, then this indicates a malfunction of the mechanical or electrical parts.

- Most often, the switch between different operating modes, located on the device body, breaks down, which leads to the hammer simply not hammering. The cause of this problem in the vast majority of cases is that the fingers of this switch are worn out .

- Due to significant loads, heavy dust, improper operation and for a number of other reasons, even barrel hammer drills with a long service life may experience failure of the impact mechanism. Repair of barrel perforators in this case begins with removing the cartridge. Having reached the mechanical part of the hammer drill, remove the housing, after which you should remove the gearbox shaft. Next, remove the brushes and disconnect the rotor from the mechanical part of the device. The result will be a mountain of different parts. Finally, we replace the defective parts with new ones and assemble the mechanism.

- As already noted, the operation of a hammer drill is accompanied by a significant amount of dust, most of the flow of which settles on the device cartridge. In this case, the quick-release chuck requires more and more force when clamping the tool. To restore its normal operation, you should simply wash it in gasoline. The SDS cartridge must be repaired by blowing it with compressed air.

- What to do if the hammer barrel breaks as a result of heavy load? The best option would be to replace it, although some people restore the barrel by welding.

- If we talk about electrical malfunctions of the rotary hammer, they are often caused by worn motor commutator brushes, which simply need to be replaced. However, if the brushes are normal, and the electric motor does not “give” the required speed, then take sandpaper and remove dirt and carbon deposits from the surface of the commutator.

- It happens that when you press the switch button, the engine does not rotate and hums, and you can smell a burning smell. The problem in this case is a malfunction of the stator winding or armature of the electric motor .

Hammer repair cost

Our workshop specialists, who have extensive experience, will carry out warranty and post-warranty repairs of Makita rotary hammers. As for its price, it is determined by the category of complexity of the work, which depends on the nature of the malfunction, the power of the tool and the cost of spare parts. By the way, we use exclusively original spare parts. Our specialists can also repair Makita angle grinders of any complexity.

If you have any questions regarding instrument repair, please call ext: 120.

Source: servismakita.ru