Adjusting the chainsaw carburetor

The quality and performance of your chainsaw depends on many factors, but today we will talk about carburetor malfunctions. A lot depends on the operation of this node, including your good mood. You picked up the chainsaw, but it didn’t start, or it started and started sneezing and shooting, while completely losing power. Your day is ruined, and in your head there are thoughts about what is the reason, where to look for a repairman and how much the repair will cost.

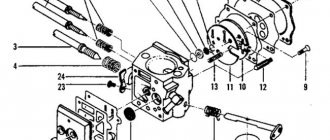

Chainsaw spare parts

However, you shouldn’t despair in advance; most carburetor malfunctions can be corrected with your own hands, or adjustments can be made in a neighbor’s garage.

Features of the Husqvarna chainsaw

Despite the fact that ideal chainsaws have not been created and it is unlikely that anyone will succeed, this Swedish company strives to improve the design and increase the power of its models. The entire line of Husqvarna saws is characterized by pleasant improvements that significantly facilitate the work of its owner.

General view of the husqvarna chainsaw

These positive options include:

- use of the fuel “suction” button (primer) for the convenience of starting the internal combustion engine;

- automatic carburetor adjustment by Auto Tune system;

- chain tension mechanism located on the side;

- environmentally friendly and powerful X-Torg engine;

- vibration reduction system;

- a mechanism for forced lubrication of the chain through a hole in the driven sprocket;

- centrifugal air purification Air Injection, allowing you to change the filter less frequently;

- universal key for maintenance and repair.

Replacing a sprocket on a Husqvarna 137 chainsaw

Often the reason that the Husqvarna 137 chainsaw stalls is the need to replace the clutch sprocket. This procedure is performed in this order:

- First, remove the entire saw set - the bar, chain and nuts should lie to the side;

- Then remove the air filter and unscrew the spark plug;

- Instead of a spark plug, insert a piston stopper;

- Remove the clutch, freeing passage to the internal space;

- Carefully inspect the drum. After this, replace the sprocket, springs and cams;

- Next, use a universal key to tighten the clutch mechanism in a counterclockwise position;

- Then assemble the chainsaw, remove the piston corkscrew and screw the spark plug into its place.

Husqvarna 240 chainsaw device

The main difference between the Husqvarna 240 chainsaw and most market analogues is the excellent quality of its factory assembly. The garden tool is equipped with a durable 2-stroke gasoline engine with a cylinder volume of 38.2 cm3. The engine is equipped with a reliable manual starter, a proprietary Japanese Walbro carburetor, a hand pump for pre-priming fuel, and a fuel tank.

For more convenient operation, the Husqvarna 240 chainsaw is equipped with a modified vibration suppression system. The system includes 6 metal springs, which, when the internal combustion engine is operating at maximum speed, absorb the vibrations of the crankshaft. Thus, vibration on the handles of garden tools is practically not felt.

For continuous connection of the engine with the sawing bodies, the model is equipped with a durable clutch, all spare parts of which are made of metal that is highly resistant to wear and corrosion. A high-quality ignition system consisting of a coil, spark plug and electrical wiring is responsible for igniting the fuel in the internal combustion engine cylinder.

The garden tool saw set includes a steel bar and a chain, which is lubricated by an automatic oil pump. The chain for the Husqvarna 240 chainsaw is tensioned using a side sprocket. To ensure an emergency stop of the headset if it hits a nail or metal wire, the model’s device is equipped with a long-lasting inertial brake, which can be turned on and off using a separate lever.

The Husqvarna chainsaw in the 240th modification is equipped with a reliable body made of impact-resistant plastic. It has separate plates that can be removed if necessary. This simplifies carburetor repair and replacement of chainsaw consumable parts.

Frequent chainsaw problems

Regardless of the power, performance and dimensions of the models, their problems are divided into 2 types:

- Malfunctions of the engine, fuel supply system, cylinder-piston group, muffler;

- Transmission breakdowns (malfunctions of the brake system, tires, chain, clutch, etc.).

Based on many years of experience, most experts confidently claim that the main causes of breakdowns lie in the operation of the internal combustion engine. The most striking manifestations of incorrect operation of a chainsaw motor include:

- difficult starting;

- unstable operation at idle speed;

- does not develop full power;

- Extraneous sounds are heard during operation.

In order to reduce the labor intensity of diagnostics and subsequent repair of a Husqvarna chainsaw with your own hands, experts advise starting with components and parts that are simpler in terms of maintainability.

Ignition system: possible problems

The first stage of ignition diagnostics is to check the spark plug. It must be unscrewed from the cylinder shaft with a special key or socket head. The gap between the side and central electrodes should vary from 0.7 to 1.5 mm.

Malfunctions of the Husqvarna chainsaw

If this distance is exceeded, an intermittent lack of spark will occur. On the contrary, if the gap is too small, the discharge will not be sufficient to fully ignite the fuel mixture. You can set the recommended clearance parameters using plumbing gauges, which can be purchased at any automotive store.

Read also: Heavy welded reinforcement mesh

If there are traces of gasoline on the surface of the spark plug, then most likely it does not burn completely. There is no need to look for the causes of problems in the Husqvarna ignition system if there is no moisture on the spark plug, since in this case it is necessary to adjust the fuel system, the stages of which are described below.

The most common types of ignition failures include incorrect clearance (more or less 0.2 mm) between the flywheel and the ignition coil. You can also set it yourself using probes.

Fuel system repair

The fuel supply system is one of the most complex in the unit, and therefore it should be taken as seriously as possible and follow certain rules. Gasoline may not enter the carburetor for the following reasons:

— clogged breather (hole in the tank lid);

— The fuel filter is clogged with dirt.

To clean the breather, you need to prepare a regular sewing needle. In the second case, you will need to dismantle the tank and replace the fuel filter.

Do-it-yourself husqvarna carburetor adjustment

Carburetor with adjusting screws

The entire model range of the Swedish manufacturer is equipped with traditional carburetors with three adjustment screws:

- Screw “T” - adjusting the mixture supply at idle;

- Screw “L” - adjustment at low speeds;

- Screw “H” - at maximum speed.

Procedure for setting up the carburetor

First of all, you need to use screw L to “find” the highest speeds when there is no load (idling). Next, turn it counterclockwise a quarter turn.

If in this position the chain on the bar continues to move, you need to stop it using screw T.

Husqvarna chainsaw carburetor

To adjust the Husqvarna carburetor at maximum speed after pressing the accelerator button fully, wait 10-15 seconds. Turn screw “H” clockwise ¼ turn and listen to the operation of the internal combustion engine. If there is an extraneous loud “squeal” when the engine is running, gradually unscrew the bolt until it disappears. On the contrary, if there is excessive smoke emission, it is necessary to lean the mixture by gradually tightening the screw.

After setting the minimum and maximum speeds, we adjust the idle speed of the saw. To do this, tighten the “T” screw clockwise until the chain begins to move along the bar.

Correctly setting the fuel supply system requires a tachometer (a device for measuring revolutions per minute), as well as the owner’s experience.

Chainsaw starter

The internal combustion engine starting system is used to rotate the shaft and, as a result, create a spark and ignite the fuel mixture. Like most models, the Husqvarna kick starter consists of:

Husqvarna chainsaw starter

When pulled by the starter, the drum ratchet engages with the engine shaft, causing the crankshaft to rotate. Despite the condition of the tool, starting the motor the first time is quite problematic. To make starting easier, you need to make several presses of the primer (mixture pumping button). The design of the starter may include a backup spring, which, after compressing the main one, gives a sharp push to the shaft. As such, repair of the starter is not provided and if one of the elements breaks down, it will need to be replaced.

Husqvarna chain features: design, tension

The cutting chain of saws from this manufacturer consists of working teeth, plunge depth limiters, and fixing pins. The most loaded parts during the sawing process are the cutting links made of high-alloy structural steel. By design, they are divided into left- and right-handed. The width of the cut is determined by the distance from the side edges of the left and right links.

DIY Husqvarna chain tension

The main characteristic of a chain for a Husqvarna chainsaw is the pitch, which can be measured from the first to the third rivet, dividing the result by two. Due to the fact that the Western calculation system uses the inch system, manufacturers indicate the pitch in inches (25.4 mm) in tool passports. For medium-power chainsaws, 3/8-inch chains are used, and for heavier-duty chainsaws, 4-inch chains are used.

One of the most important indicators of a chain is the thickness of the shank, which for most models is 1.3 mm. They are often used on specialized and ordinary amateur instruments. The thickness of the links must be consistent with the groove of the bar, since excessive thickness can lead to chain breakage or drop.

When the chain relaxes, it must be tightened using a mechanism located on the side of the unit. Having first removed the left side cover (2 bolts), loosen the bar for the Husqvarna chainsaw. Next, we unscrew the longitudinally twisted bolt, thereby moving the guide away from the power unit. When adjusted correctly, the chain should turn easily, but not dangle on the bar.

Husqvarna saw chain brake

An important safety feature in a chainsaw is the chain brake, which blocks the rotation of the cutting edges in the event of a kickback. As a result of the tire rebounding in the direction of the feller and, as a result, his possible injury, the friction mechanism disengages the drive sprocket and the drive shaft.

Husqvarna chainsaw chain bar waste

The brake actuation can be of a contact or inertial design. In the first case, the protection will work as a result of the unit being thrown back. The inertial brake system involves the generation of large inertial forces acting on the drive shaft. Regardless of the features of a particular design, experts recommend purchasing chainsaws equipped with similar mechanisms.

After repairs and adjustments have been made to the Husqvarna chainsaw, you must first check the functionality of the brake unit.

Husqvarna chain lubrication: operating principle

In all presented models of chainsaws, oil is supplied to the tire automatically.

Main components of the husqvarna chain lubrication system

Before starting work, you need to make sure there is lubricant in the tank. The oil pump interacts with the drive sprocket, and when the shaft rotates, the gear supplies lubricant to the working surface of the chain. Due to the constant presence of oil on the cutting edges, the chain is less susceptible to friction and, as a result, loses its properties much more slowly. If the lubrication mechanism of a Husqvarna saw fails, a small chain with a brown tint will be observed. Periodically, the left protective cover of the unit must be removed and the oil hole cleaned with compressed air or a needle. The supply performance of the pump unit directly depends on the number of revolutions of the tool.

Read also: How to put a bit in a screwdriver

A chainsaw is an indispensable assistant for every real owner.

Since the introduction of the instrument, its popularity has grown rapidly.

Thus, the Husqvarna 142 chainsaw has high functionality. It is widely used not only in forestry, but also in household plots.

Choosing a chainsaw is quite easy. So, it is best to pay attention to well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of high quality and functionality. But, unfortunately, even such tools are not immune from breakdowns.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common. The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

To begin repairing the carburetor, they begin by cleaning it from dirt and dust particles and small wood. A brush is used for this. When the surface is completely free of debris, the repairman removes the cover, and then the filter.

The air collector is released after unscrewing the air filter mounts. The user now has access to the accelerator and rods. The accelerator lever is removed as soon as the throttle is lowered by pressing down with your finger.

The carburetor moves away from its seat after the choke lever is removed and closed. Then the wire is removed and pulled towards itself to stop the engine. The plastic lever, which is the place where the wire is attached, is photographed.

It is raised from the left. As a result, the carburetor is freed, which makes it possible to pull it out and clean it. For these purposes, it is convenient to use a compressor. In its absence, the parts are washed in clean gasoline.

Disassembling a Stihl chainsaw – video

Important! When repairing a poorly functioning Stil MS 180, be sure to inspect the condition of the fuel filter. Remove it and blow out the fuel hose

The saw carburetor assembly process is carried out in reverse order. If, after this process, smoke appears from the muffler and the saw engine does not start well, then you need to make sure that there is a spring located under the lever needle.

The spring cuts off the fuel supply. In its absence, a spontaneous “overflow” of fuel into the spark plug occurs.

It is important to ensure that the spring is installed in its place and make sure that the spark plug is working

If a candle is filled with gasoline, it should be dried. To do this, the part is unscrewed and the excess fuel that gets inside is drained through the existing hole. The candle takes more than half an hour to dry. Then it is installed in place, and the chainsaw is brought into working condition.

Insufficient contact between the high-voltage wire and the end of the spark plug can also be one of the reasons for tool failure. Repair of stihl chainsaw parts can be done by replacing problematic parts.

For example, if a spark plug fails, it is replaced with a reliable one. Chains, sprockets, and tires are subject to rapid wear. They solve anti-vibration problems in the chainsaw device, so they are replaced urgently. It is recommended to keep such spare parts in stock.

Basic faults

If you've ever been interested in the design of a carburetor, you couldn't help but notice that all the holes on the assembly are extremely small. Even minor contamination caused by poor quality fuel can result in improper fuel or air circulation. Yes, there are filters installed on the inlet and outlet ports, but they do not always cope with their task. What does this lead to? Any mechanic will tell you the consequences.

The main malfunctions of a chainsaw due to the carburetor:

- Gasoline consumption has increased, thick black smoke is pouring out of the exhaust pipe, there is a lot of burning and soot around;

- The engine starts, but sneezes and shoots into the carburetor;

- The engine has lost power, the chainsaw no longer “drags”;

- You couldn't start your chainsaw;

- It is impossible to achieve normal operation of the engine: the speed fluctuates all the time;

- The chainsaw stalls immediately after starting, or when you sharply press the accelerator trigger;

As you can see, troubles from a faulty carburetor are guaranteed. Moreover, without disassembling the unit and its subsequent adjustment, they are unlikely to be eliminated. Therefore, it makes sense to take a closer look at the carburetor design.

Why the chainsaw won’t start - reasons and solutions

Each model has its own weaknesses. Some saws require regular carburetor adjustments. The disadvantage of others is the chain lubrication system. Be that as it may, any breakdown can be fixed with your own hands if you figure out what its cause is and what its signs are.

What to do if the chainsaw stalls when you press the gas?

As a rule, owners of chainsaws begin to encounter this breakdown after the first 6 months of intensive use of the tool. There may be several reasons for this malfunction.

Their list includes:

- using a fuel mixture prepared in the wrong proportion. If you regularly pour low-quality gasoline into the tank of a chainsaw, in which too much or too little oil is mixed, the tool will not start. In this case, you will need to drain the fuel and also dry the engine cylinder. To do this, you need to sharply pull the starter cable several times. After this, you need to fill in properly prepared fuel and start the saw engine;

- Filling the spark plug with oil when starting the engine. This problem can be solved by removing, cleaning and drying the candle. After 30 minutes, the candle will dry and you can screw it in. After this you will need to start the chainsaw;

- no spark. This indicates poor contact between the factory high-voltage wire and the spark plug tip. If the contact is not broken, but there is still no spark, then you need to check the electronic unit of the chainsaw’s ignition system. This element cannot be repaired, so it will need to be completely replaced;

- air filter clogged. This element of the saw must be regularly cleaned of debris, small insects and dust. Otherwise, air will not enter the carburetor, where it should enrich the fuel mixture. As a result, the saw will stop starting. To solve the problem, you will need to clean the filter or replace it.

Malfunction of muffler and carburetor

If the chainsaw is used frequently, muffler malfunctions may occur. This is very easy to determine.

If the tool works normally, but when the speed increases, it starts to stall, then the reason is the spark arrester.

Most often, the breakdown of this element is a result of clogging with combustion waste. Disassembling the Husqvarna 365 chainsaw Husqvarna 365 (part 1 disassembly) The saw does not start. You can easily solve this problem with your own hands.

First of all, you need to remove the muffler and disassemble it. It is worth considering here that in some models spark arresters are not disassembled. After this, the muffler is cleaned of carbon deposits. For this purpose, special detergents are used.

When the carbon deposits are removed, the spark arrestor is dried with a hairdryer. At the final stage, the muffler is installed in place.

As for the carburetor, its adjustment and repair can be done at home. But in order to perform such work efficiently, you need to know the structure of the carburetor and the principle of its repair.

Poor repairs can lead to serious damage to the device. Therefore, experts recommend that it be configured and repaired in special workshops.

As you can see, many chainsaw malfunctions can be fixed with your own hands. But to do this, you need to have certain information. If you are not confident in your abilities, then it is better to seek help from specialists.

Watch the video in which a specialist shows in detail the disassembly and assembly process for DIY repair of the Husqvarna 142 chainsaw:

A chainsaw is an indispensable assistant for every real owner.

Since the inception of the instrument, its popularity has grown rapidly.

Thus, the Husqvarna 142 chainsaw has the highest functionality. It is widely used not only in forestry, but also on private plots.

Choosing a chainsaw is quite simple. So, it is best to check well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of the highest quality and functionality. However, unfortunately, even such tools are not immune from breakdowns.

When a chainsaw appeared at home, the owners probably breathed a sigh of relief.

After all, such a tool allows you to solve complex problems quite quickly and simply.

However, it is worth considering that the chainsaw often burns out. This is due to the fact that it is subjected to enormous loads during its operation. Therefore, it is always necessary to prepare for troubleshooting.

Nowadays there are many workshops that offer their services for repairing chainsaws and other tools. However, this does not mean that if there is a malfunction you need to immediately run to a repair shop.

Read also: How an AVR generator works

Of course, some faults can be fixed at home. For this purpose, you just need to have information about the main reasons for the occurrence of breakdowns and the method for eliminating them.

So, during frequent use of the tool, breakdowns may occur:

- carburetor;

- muffler;

- oil pump;

- allowing accounting (software) of ignition and fuel supply.

Checking the carburetor and signs that it needs adjustment

The rated engine power and savings in fuel consumption depend on the good condition of the carburetor. The carburetor of a chainsaw has no functional difference from a car. It mixes gasoline vapors with air entering through the pipe and delivers them further into the combustion chamber.

Carburetor design

It consists of:

- air duct or tube for air supply;

- fuel line or fuel supply tube for mixing it with air;

- air damper.

A sign that the carburetor needs to be adjusted:

- strong vibrations due to unbalanced screws. An engine with a working carburetor runs smoothly and sounds like a four-stroke stroke;

- damage to the protection cap;

- wear of the piston system, which already requires a different mixture in composition;

- involuntary engine shutdown, inability to restart or initially start;

- an unreasonable increase in gasoline consumption, while engine power may remain the same, but most often decrease;

What to do if the chainsaw refuses to start

- First of all, do not fall into despair and do not start randomly turning the carburetor adjusting screws.

- Set the chainsaw aside for about 15 minutes. It is quite possible that the cause of the problem was a spark plug filled with gasoline.

- Try to start the chainsaw again, following all the instructions in the operating instructions, but without activating the safety saw brake. The fact is that turning on the saw brake makes it much more difficult to start the chainsaw, and if you hold the device securely and correctly in your hands, then you will not need any additional insurance against accidents.

- Unscrew the fasteners, remove the top cover of the chainsaw and remove the container with the air filter from it. This technique also makes starting the chainsaw much easier. At the same time, you can perform preventative maintenance on the filter by removing accumulated dust, dirt and debris.

- If possible, replace the flooded spark plug with a spare one. If there is no spare spark plug, unscrew the old one, heat it in an open flame, replace it and try to start it again without an air filter.

- If you notice the smell of gasoline, unscrew the spark plug and turn the chainsaw over so that excess gasoline flows out through the hole. After this, in an inverted state, pull the ignition cord several times (about 10 times) to provide fresh air to the combustion chamber. Screw in a new spark plug or a fire-heated spark plug, and then try again to start the chainsaw without connecting the air filter.

- Look into the spark plug hole. If the piston is completely dry, then it is possible that the cause of the starting problem is a blockage in the carburetor or water getting inside it, which prevents gasoline from entering the chamber. Fill a medical syringe with some fuel (about 1 cm³) and inject it into the chamber. Screw the spark plug back in and try to start the engine again. If it starts, the cause of the blockage should be swept away by a strong flow.

- Before performing the last two techniques, you must carefully ensure that the spark plug remains dry.

- Then visually check that the spark plug is producing a spark. It also happens that the cause of the breakdown is a failed electronic ignition module. Although, with some malfunctions, the spark may also skip.

- Loosen the chainsaw muffler mounting bolts and separate it from the body, being careful not to damage the gasket between the muffler and the cylinder. Repeating the above operations, try starting the chainsaw without a muffler and air filter. Through the opened hole on the muffler side, you can assess the condition of the piston system by slowly pulling the starter and moving the piston. If you observe the presence of deep burrs, scratches on the surface of the cylinder or piston, or a tightly clamped ring in a groove, it means that the engine will no longer start, since its piston has become unusable.

If the algorithm proposed above does not help, you should seek help from qualified technicians and adjusters from the service center.

Every person who is familiar with gas-powered tools knows that sometimes the equipment works intermittently, or may stall at one point and not start again. There are many reasons why a chainsaw does not start; we will try to consider the most common of them.

IMPORTANT!!!

An experienced electrician leaked the secret of how to pay half as much for electricity, a legal way...

Husqvarna saw disassembly algorithm

The process of disassembling a Husqvarna chainsaw is quite simple. In order to do everything correctly and not break parts of the housing or CPG, it is necessary to disassemble in the following order:

- Top cover.

- Chain and saw brake cover.

- Starter.

- Flywheel and clutch.

- Front handle.

- Carburetor.

- Oil pump.

- Engine.

Depending on the Husqvarna model, the disassembly procedure may vary slightly.

Important: before you start disassembling the chainsaw, you need to clean it. When working with a saw, a lot of chips and wood dust are generated, which during disassembly can get into the internal parts of the Husqvarna chainsaw

Removing the side cover and saw set

The side cover, or also called the saw chain brake cover, is held in place with two thirteen nuts.

After unscrewing the nuts, the cover is removed from the guide pins, after which you can remove the bar and chain from the chainsaw. Some models of Husqvarna saws have a special mechanism installed that allows you to dismantle the cover and saw set without the help of special tools.

Starter

The starter is located on the right side of the Husqvarna and is held in place by several screws. By unscrewing them, you can easily remove the starter and thereby gain access to the flywheel and ignition coil.

Removing the flywheel and clutch

In order to unscrew the flywheel nut, you need to unscrew the spark plug and install a piston stopper in its place.

Once the piston stopper is installed in the cylinder, the flywheel nut can be loosened. After the nut is unscrewed, it is necessary to use a hammer and a drift made of soft material to apply one sharp blow, installing the drift on the flywheel mounting shaft. This is necessary to remove the flywheel from the shaft, since the design provides for the installation and tightening of this element with great force.

You can learn more about how to properly remove the flywheel from a Husqvarna chainsaw, as well as how to completely disassemble the saw by watching the video. The wizard explains the entire process step by step and demonstrates all the necessary tools:

In order to unscrew the clutch you will need a special key. If there is no key, then it can be made from an old twenty-two head, grinding it in a certain way using emery.

Do not try to unscrew the clutch with a hammer and chisel, as some craftsmen advise. Using these tools, you risk breaking the clutch housing and increasing repair costs. It can also damage the crankshaft bearings.

Removing the Husqvarna front handle is quite simple, as it is attached to the shock absorbers with screws.

Air filter and carburetor

To remove the carburetor, it is necessary to disconnect the fuel hose and damper rods from it; this can be done conveniently after the air filter is removed, which is installed immediately behind the carburetor and held in place with two 10mm nuts. After the air filter is removed, the fuel hose and the rods are disconnected, just pull the carburetor towards you and remove it from the studs.

Oil pump

On Husqvarna, the oil pump is installed on the right side of the chainsaw. It can only be removed after the clutch has been released. Removal does not require a special tool, because... The fastening screws are made for a regular Phillips screwdriver. After the screws are unscrewed, it is necessary to lift the pump and disconnect the oil hoses from it.

Engine

To remove the engine on a Husqvarna chainsaw, after the carburetor, clutch, flywheel and muffler have been removed, you will need to unscrew the four screws securing it to the body.

After the engine is removed, you can unscrew the ignition coil from it, remembering to first disconnect the wires leading from it to the ignition switch. The coil can also be removed immediately after the starter is removed.

Assembling the Husqvarna chainsaw should be carried out in the reverse order, and the flywheel nut and clutch must be tightened with the force specified in the chainsaw operating instructions.

Chainsaw won't start

Why doesn't the chainsaw start, even if everything is done correctly, in accordance with the operating instructions? The working mixture is prepared in the required ratio, according to the requirements of the manufacturer, and poured into the tank. The air damper is closed to obtain a rich working mixture. Fuel was pumped up with a hand pump. The ignition is turned on with the corresponding button. Several vigorous jerks were made with the starter handle.

I would like to draw the attention of beginners to the process of starting a chainsaw. If everything is done correctly, then when starting the engine, at the moment fuel enters the cylinder, additional resistance will be felt on the starter handle

It arises because when moving upward, before igniting the spark plug, the piston pre-compresses the working mixture, and the resistance increases sharply. Based on this, we can already say that:

- Fuel enters the cylinder.

- The piston group is still alive and has some compression, the exact value of which we can only judge by measuring it with a compression meter.

Based on these conclusions, we can make the assumption that if there is fuel in the cylinder and the engine does not start, then the reason is probably the spark plug.

Checking the spark on the spark plug and the gap between the coil and the magneto

The spark plug is the most important part that is responsible for igniting the fuel mixture supplied to the cylinder chamber. If the spark plug has served its purpose, it will produce a weak spark or not produce one at all. You can check this in the following way:

- Unscrew the spark plug

- Place it on the cylinder, connecting it to the candlestick

- Turn on the ignition

- Pull the starter handle

If a spark occurs constantly, then this indicates the serviceability of the spark plug. Moreover, not only the spark plug is in working order, but also the ignition system - the coil and the high-voltage wire. If a spark appears on the spark plug, but intermittently (intermittently), then such a part must be replaced. First you need to check the gap between the contacts. The gap size should be from 0.5 to 1 mm.

For each chainsaw model, manufacturers indicate the recommended gap value, so you need to use a reference book. You can measure the gap with a special feeler gauge or a sheet of paper folded several times.

The absence of a spark on the spark plug indicates a malfunction of the ignition system, so before replacing the part, you should make sure that the ignition coil and high-voltage wire are in good condition.

The chainsaw may not start due to clogged spark plug electrodes. The presence of black carbon deposits on the spark plug or wet electrodes - all this may indicate the following malfunctions:

- Black carbon deposits - the chainsaw carburetor is not adjusted correctly

. The mixture entering the cylinder contains a lot of fuel and little air. The malfunction can be eliminated by cleaning the carbon deposits on the spark plug electrodes and then adjusting the carburetor - If the spark plug is wet (it floods), then this may indicate the following - either the ignition system is faulty (including the spark plug itself), or an excess amount of fuel enters the cylinder, thereby flooding the spark plug.

First you need to make sure that the spark plug gives a good spark, and only then adjust the carburetor. It is not recommended to dry a wet candle using the calcination method, so it should be wiped dry and then allowed to dry in the sun - If the spark plug has red or pink carbon deposits on the electrodes, this indicates that the gasoline used contains a large amount of additives.

Typically, this effect is achieved by gasoline grade AI-95 and higher, an increase in the octane number of which is achieved by adding additives

When the spark plug is brown (brick), this indicates not only that the chainsaw carburetor is correctly adjusted, but also that the ignition system is working properly. If you are using a new spark plug and when tested it produces a weak spark (or no spark at all), this is a sign of a faulty ignition coil. The coil must be replaced along with the high-voltage wire.

This is interesting!

It is necessary to check the size of the gap between the ignition coil and the magnet. Different manufacturers of chainsaws indicate the recommended gap value (usually the value is 0.25 mm); if this value is higher than the norm, then it should be adjusted using a feeler gauge.

Operating instructions

It is necessary to have instructions included with the power tool. The manual answers all the saw user's questions, allowing him to independently assemble (disassemble) the tool, make repairs, adjust the carburetor, and learn how to operate the tool.

The instructions consist of the following sections:

- The device of the Husqvarna 365 XP petrol saw.

- Step-by-step assembly of the saw, shown in detail in the diagrams, described in the accompanying texts. You can download the instructions here.

- Product specifications.

- Security measures.

- What's included in the kit.

- Working methods.

- Preparing the tool for work.

- Run-in.

- Saw maintenance.

- Malfunctions.

Equipment

- chain;

- petrol tools;

- tire;

- container with oil intended to lubricate the chain mechanism.

Preparatory stages

Long-term operation of the Husqvarna 365 xp professional chainsaw is achieved by the following actions:

- Properly assemble gas powered tools.

- Correctly install the bar, put on and tension the chain.

- The chainsaw is filled with a flammable mixture (for 1 liter of AI 90-93 gasoline, take 100 ml of Husqvarna oil for two-stroke engines, ratio 50/1).

- The oil tank is filled with original chain lubrication oil; if it is not commercially available, you can use ER 90 transmission oil instead of the original one.

- The chainsaw starts.

- Idle speed, brake operation and lubrication supply to the chain are checked.

Run-in

Break-in time is 10 hours. During this period, the Husqvarna chainsaw is used with minimal loads; this is necessary for grinding in the moving parts of the engine, including the piston.

Read also: Intercom and calling panel connection diagram

Service

The main maintenance steps are as follows:

- monitor the fullness of fuel and lubricant tanks;

- check the condition of the saw bar;

- sharpen the chain in a timely manner;

- cleaning the filter;

- spark plug maintenance;

- replacing a worn sprocket;

- cleaning petrol tools after each use;

- cleaning oil channels;

- carburetor adjustment;

- debugging the brake system.