Saw repair price

| Services | Repair cost (from), rub. |

| Inspection, diagnostics, delivery | Free service |

| Consultation, estimate, assistance in selecting spare parts | For free |

| Recommendations for use and spare parts | For free |

| Maintenance (+ cleaning) | 1500 |

| Full maintenance (+ cleaning) | 3000 |

| Minor repairs (without disassembly and assembly) | 900 |

| Working with parsing | 1500 |

| Disassembly, adjustment, assembly | 2500 |

| Metal shoe repair | 150 |

| Repair of brushes, switch | 300 |

| Repair of gearbox housing parts, stator | 900 |

| Replacing the speed controller | 900 |

| Replacing the protective, rubber, movable casing | 1000 |

| Replacing the spindle bearing housing | 800 |

| Replacement of stator, rotor | 3000 |

| Replacing the shaft retainer spring | 500 |

| Changing the shaft lock | 600 |

| Reducer gear change | 900 |

| Repairing brush holder and spindle | 300 |

| Repairing an Electrical Cord | 800 |

| Repairing the saw blade holder | 350 |

| Repair of table, battery | 800 |

| Prevention (blow-out, dust removal) | 500 |

| Armature commutator groove | 1100 |

| Replacing the soft start board and saw body | 2500 |

Circular saws are used for transverse and longitudinal cutting of wood, plywood, chipboard, MDF, fibreboard, PVC, metal, slate, plexiglass. The first household saws were presented by the AEG brand. Modern circulation saws are presented as multifunctional solutions that are used for construction and household work. Leading manufacturers of such tools are Hitachi, Bosch, Makita, Husqvarna, Metabo.

The tool is:

- manual;

- desktop;

- stationary;

- submersible;

- battery-powered

DIY Circular Saw Repair

Content

The design of a circular saw, like many other power tools, is based on a commutator electric motor. The commutator motor tends to spin up to very high speeds. Therefore, even with low motor power, the circular saw has excellent performance properties. For about 30 years, circular saws were made based on asynchronous electric motors. They had worse properties and were more massive. Most of these saws were converted into homemade, stationary circular saws. For this purpose, a table is made for you, or it is also called a bed, and a circular saw is screwed into a comfortable place. A homemade circular saw can be made not so much from an industrial circular saw. To produce a homemade circular saw, it is enough to have an electric motor, a table and a familiar axer.

A frequent cause of failure in the operation of a circular saw is the electric motor. Disadvantages and ways to eliminate them can be found in the section Repair of commutator electric motors.

A special feature of the circular saw is its operation in dusty environments. Since the collector engine is cooled by external air, dust and chips enter and some settle inside the motor. To prevent breakdowns, you need to do technical maintenance from time to time. This includes: cleaning dust and dirt and cleaning the armature commutator from graphite and carbon deposits.

If you liked the article, share the link in your own network. this will be a big thanks for writing it:

Circular (circular) saws are intended for transverse and longitudinal cutting of wood materials, non-ferrous metals and plastic. Thanks to the highest performance of this tool, the ability to make quick and clear straight cuts, it will become your delightful assistant when performing various works with wood: laying floors, designing furniture, roofing, etc. By equipping the tool with a special saw blade, you can easily cut profiles from various non-ferrous metals. Let us not forget that such profiles are now widely used for modern furniture.

Working with such a saw is painfully simple, but at the same time you need to follow safety precautions. The slightest violation of operating rules, negligence in work, of course, will cost you a lot.

Over the long period of use of this device, its design has not changed enough. Perhaps its ergonomics have become more perfect, the weight has changed, and the engine power has increased. The largest configurations touched the saw blade. In the near future, a huge abundance of these disk parts has appeared, made of aluminum, wood, laminated materials, etc.

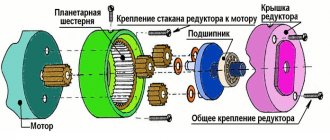

The design of circular saws is quite ordinary. It includes the following elements: gear housing, electronic engine, protective casing, platform, equipped with a guide line.

You, the body of the device is made of heat-resistant, wear-resistant plastic. Quite occasionally, but you may also come across a model with an iron case for sale. The design pays quite a lot of attention to the ventilation and engine cooling systems. Already today, probably, domestic manufacturers, taking into account the fact that a circular saw often has to be worked in the presence of significant dust, have paid attention to the process of removing chips from the working area. At first, this factor has a great effect on the operator’s health, since his lungs are less tormented by dust. All modern models have a chance to connect to a forced dust removal system or to factory vacuum cleaners. For this purpose, special adapters are used.

Some manufacturers, for example, Makita, stuff their products with a stationary device for removing dust and chips. For example, the 1400 W MAKITA 5017 RKB circular saw model has a special container designed to collect sawdust. A similar system removes the bulk of all sawdust generated during operation.

Some of the Russian automobile industry, trying not only to make it easier to work with the device, but also to somehow distinguish their products from the general mass, use rather unusual solutions. For example, the WORX company equipped one of its saw models with a “revolving handle.” There is a start button on the handle and here the angle of the handle itself can of course be changed at sixty degrees. This very solution is quite exciting and useful. After all, now the operator can easily adapt the tool specifically to his anatomical features. I would like to immediately note that this design improvement is available only on WORX brand products.

READ What types of gasoline-powered saws are there by area of application?

It doesn’t matter which circular saw is equipped with a commutator electronic motor. Its power ranges from 500W to 2.7.5kW. It is clear that the power of the motor affects such a fundamental parameter of the tool as the depth of cut. Already today, the speed will depend on the engine power. Nowadays, the number of saw blade revolutions on modern machines has almost doubled. Just 10 years ago, the number of revolutions of units with a power of 4.5.2 kW ranged from 4.5.5 to 3.5 thousand per minute. However, modern models of circular saws with exactly the same motor power already produce about 5 thousand rpm.

It is worth noting separately that now in the tool trade we also come across cordless models of circular saws.

Another exciting option that appears is a laser pointer. During operation, it indicates the direction of the cut. They probably know how awkward it is when, while the disk device is operating, sawdust fills the marked cutting line. Now, having a laser pointer, you will forget about most of the inconveniences in your work.

When choosing a circular saw for yourself, you need to evaluate the quality of its platform. To reduce the price of the product, manufacturers probably use a stamped platform; unfortunately, for professional purposes, you need to select a model equipped with a cast duralumin platform. Only then will the work be carried out very accurately. Even today, such a platform is even less susceptible to various deformations. It’s convenient when the manufacturer places special marks along the platform, allowing you to better control the progress of sawing the material. It turns out to be a typical sight, the means of which produces precise work.

An additional important point when choosing a machine for yourself is the method of changing the saw blade. Nowadays there are products where there is no spindle lock. In other words, the disk here, of course, can only be changed when using two keys. As you know, as you yourself realize, it is both long and awkward.

A circular saw allows you to make long and even cuts.

If, with all this, you want to do this work very accurately, then you should pay attention to such additional tool equipment as a guide rail. Each manufacturer of disk tools produces such tires for their own products. But there is one significant aspect here: the guide bars are, of course, only suitable for tools from the first manufacturer. There is no escape from the laws of competition.

This element of circular saws should be given special attention. Today they produce discs designed for virtually any material. Using a variety of wood discs, it won’t be difficult to quickly unravel the boards. The only thing is that the quality of the cut will be low. Disc elements created for laminate work in such a way that the surface of the sawn material will not require additional processing. This quality of cutting is achieved thanks to the geometry of the teeth on the disk, the frequency of the teeth, and the use of special carbide tips. Recent developments in this area make it possible to saw boards without first removing nails from them. In the process, not only a spectacular spectacle is created, but also an additional opportunity to avoid tool breakdowns and operator injuries.

It would be appropriate to note here that the cost of repairing a circular saw is quite high. Changing an anchor can be compared with the cost of a new product. In general, there are several reasons for wear of the splines on the anchor. Among them are the following:

Excessive pressure on the tool during operation.

Incorrect selection of saw blade.

Insertion of a warped saw blade element (not sharpened, no carbide tips).

READ No Gasoline Flows into Husqvarna Chainsaw Carburetor

Circular saw repair. Repair of a disk saw

If you need this tool for active use, then it is better to choose not a battery model, but one that is powered from an electronic network. This is explained by the fact that cordless saws have a fairly limited range of applications.

Towards the end of the note, it should certainly be noted that the circular apparatus should be used very carefully. During work, be sure to use special safety glasses.

We sincerely wish you a rational choice and measured, safe work.

- Fault localization

- Disassembly and its features

- Mechanical problems

- Armature and stator faults

The benefits of any home tool can only be fully appreciated when it breaks down. This theorem is known to every home handyman. The presence of most devices in the arsenal has led to the fact that the majority of the population simply has no idea how to perform this other operation in their absence.

A circular saw is used for smooth cutting of various materials.

For which the design with a circular saw is intended, this is especially important. It is known that it is irreplaceable for longitudinal sawing of wood; it has no worthy analogue among hand tools. This cannot be done with a regular hand saw. Therefore, when the circular machine refuses to work for some reason, all work stops. Something needs to be decided urgently. But don’t rush to take it to the workshop; you can repair the circular saw yourself.

In the beginning you try to find what is broken. The cause is not a specific node, but the nature of the damage. You will like it better than the mechanical one, as it is also called, which appears in the electronic part of the saw. In other words, if smoke comes out of it, this is one thing, but when there is extraneous noise or whistle #8211 this is completely different. These two aspects are the main ones when localizing a fault. There are, however, a third case, when the saw makes no sounds at all. Let's start with it.

Circular saw device.

No matter how strange it may seem, the fact that the saw is silent is a good sign. Here it would be useful to mention those defects that are usually printed on the last page of the instruction manual. At first they seem funny, alas, show a little respect there. Check to see if there is voltage at the outlet and if the power cord is working properly. If our client remains fine, then there is only one chance left to avoid operational disassembly #8211 check the brushes.

On the vast majority of circular saws, to be able to reach the brushes, you need to unscrew two bolts. Such a unit is essentially two carbon elements that rest against the collector. Because it is constantly spinning, the brushes are subject to wear and over the years they “hang”, i.e. can't reach him. To do this, you need to pay attention initially. Today, carbon brushes are connected to the stator terminals. In this area, contact is lost from time to time. Check it. If our client remains fine, a showdown cannot be avoided.

The operation itself is quite difficult; some workshops charge money for it regardless of the result of the repair. Any saw has its own device, and it is impossible to give clear advice. There is an option to deal with this without the help of others. But let’s take a closer look at what to sort out initially.

Replacing the armature and brushes on a circular saw

A very common problem, regardless of brand, is a faulty switch button.

The device of a circular saw with a separate engine.

In all models it is located in the handle, which, when untwisted, splits into two parts.

You can’t completely halve it, it will stick to other parts, but you can already get to the button, but it will be a little awkward. Despite this, you need to use the tester probes to check the functionality of the switch.

If it turns out to be faulty, the repair is complete. But in order to put a new one at its destination, the saw will have to be completely disassembled. If the button is working properly, you will have to do this too.

READ Hooter Chainsaw No Gasoline Supply

Remove the disc. There is an opportunity to remove the protection, which is what you do. There are 4 long bolts under it, unscrew them. The sequence and quantity of parts will be a few principles, but ultimately the engine with the gearbox, handle and electronic cord should remain in the palm of your hand. When you disconnect the gearbox, in this matter it’s time to remember how the malfunction manifested itself.

Symptoms of such defects, of course, manifest themselves in different ways, but almost always the work is accompanied by extraneous noise. This may be a whistling, grinding or clicking noise. At this point, while the engine and gearbox are still assembled, it is necessary to establish what is faulty among them. Try to rotate the engine by the shaft. It should spin quite hard, but moderately, i.e. should not jam.

The layout of a circular electric saw.

If the motor shaft does not spin or spins jerkily, the motor is faulty. Take it apart and look at the bearings. The first one is located in the motor housing, the other is on its rotor. It is certain that one of them will be to blame. The first one would be nice, changing it is quite easy.

If the bearing on the motor armature becomes faulty, you can safely take it in for repairs. It is essentially impossible to remove it without the help of others without a special device. Today, our client's attempts to do this result in damage to the anchor. You will not have to carry the entire saw to the workshop, but only the rotor. It's easier and cheaper.

The main gearbox malfunction is wear of the gear teeth. In this case, it must be replaced. Also pay attention to the armature splines. They are also not usually damaged.

These faults are the most common. During operation, a strong spark suddenly appears in the brush area. There will be smoke and a burning smell. Such damage is sometimes impossible to diagnose. Let's start with the most common and expensive option.

Scheme for testing the functionality of a circular saw.

After opening the motor, it turns out that there are traces of burning on the rotor and stator. Here, what remains to be done is clear to our client. Both this and that need to be changed. The option is expensive, but the possibility of error is excluded. It’s worse when the stator is smoked, but the armature is like new. At first it seems simple #8211 the stator needs to be replaced. Completely optional. You will also like the rotor to be faulty, but to be “in a break”. In addition, it could serve as a prerequisite for a more severe breakdown. Finding its malfunction in this case is quite easy.

- Disconnect the stator terminals from the brushes. Attach the tester probes in their place; it should show a tiny resistance.

- Slowly turn the motor shaft; if at some point the resistance increases, it means the armature is faulty.

And the last, most difficult case is when our client’s vision remains intact. If you use the method described a little higher, this will not guarantee that the rotor is working. But if the device shows a break, then there is an option to try and change it. Basically, then it is better to contact a specialist. You won’t be able to do this without special devices.

Often a circular saw is purchased for a specific purpose. With all this, the person does not even think whether she is suitable for this purpose for you. There are professional circular machines designed for long-term work, and there are those that, of course, only work for 3 hours during the day, and then only with breaks.

Why do the circulars burn? / Circular saw Hitachi C7SS /HiKOKI – Our New Brand

Therefore, while you are using the circular saw intensively, read the instructions and consult with the experts. The same applies to the operation of chainsaws and other tools. You will like it, then there is no need for repairs. Fortune!

Source

How to prevent electric saw breakdown?

To prevent tool failure, follow these rules:

- use the device for its intended purpose;

- do not put strong pressure on the electric saw;

- when working with a dull saw for a long time, the motor overloads, so work intermittently;

- do not allow the saw blade to be sharpened poorly;

- Avoid mechanical damage, such as falling to the floor.

A circular saw breaks over time. In this case, it is better not to try to restore it yourself, but to contact a service center where there are tools and equipment that allow you to quickly repair miter saws in Moscow.

How to saw a board evenly lengthwise and crosswise

Due to the differences in the design of hand and stationary saws, the methods of sawing wood differ significantly.

Working on a circular saw

If you need to saw a board along the grain, for example, an unedged board, then this is done as follows:

draw a straight line on the workpiece using a ruler;

then, along this line, with maximum precision, make the first cut to cut off the bark;

Next, you should install a parallel stop (guide) and spread the workpiece into smaller boards;

If the length of the circular table does not allow you to unravel long boards, then for these purposes you can make a simple device, shown in the following figure.

Using this carriage, you can trim boards and bars both at a straight line and at any angle.

Cutting boards with a hand-held circular saw

Many owners of hand-held circular saws are faced with the problem of trimming boards along a line. At the very beginning of sawing, the line is visible, but then it is blocked by the casing of the unit. Since the markings are not visible, the cut is uneven.

To cut the board smoothly and get the perfect cut, you need to position the tool so that the saw blade is opposite the marking. On the other side of the unit, attach a square to the board and move it to the base of the unit. Secure the square with a clamp. You will receive a guide installed at a right angle. Trim the board. The result is a perfect 90° cut.

For longitudinal cutting of boards, a guide rail is used. It may have longitudinal grooves into which a hand-held power saw is installed. You can also make a tire in the form of a simple long guide yourself. In the second case, one of the sides of the unit’s sole during sawing will go along the tire (ruler) attached to the workpiece. As a result, you will get an even longitudinal cut.

The following pictures show homemade guides, the width of which depends on the size of the hand saw sole.

Typical faults

Any type of modern electric saw is a reliable, durable tool that can last for years if used carefully. However, intensive loads during work lead to the need for service. The causes of breakdowns are different, failure of a mechanical or electrical part. Repair of a circular saw will be required if there are such breakdowns:

- problems with the mechanical part manifest themselves in extraneous sounds, knocks, vibrations;

- breakdowns of electrical components manifest themselves in the form of smoke, the smell of burnt wires;

- if the tool simply does not turn on, then the problem may lie in worn brushes of the electric motor.

These and other problems can be easily fixed. When restoring saws, you must follow the manufacturer’s instructions and use branded spare parts - this guarantees the preservation of the life of the electric saw.

Cutting teeth on a circular saw

The teeth are cut using a file if they are broken. Before cutting the old teeth, you should grind down to the defect line, then joint. If it is necessary to cut small teeth up to 5 mm high, they are planed to half the height of the tooth, then the tooth is cut in half with a file. This is a rather labor-intensive process that requires significant man-hours. In addition, the process of cutting one blade itself requires a set of files. To speed up cutting, a device shaped like a wire cutter is used. They use it to chop metal until teeth are formed.

Device and principle of operation

The design of a circular saw is quite simple. The device can be manual, or there are also combined stationary models.

Regardless of the type of equipment, it consists of a saw and a base plate. The last element is made of durable steel sheets or aluminum alloys. The main purpose of a circular saw is accurate and high-quality longitudinal sawing of wood.

A circular saw

Cutting boards and woolen stones is carried out by rotating discs, which have special covers that serve as protection against injury during the working process. The cutting part is driven by a trigger. Circular equipment allows you to process large volumes of wood.

Cleaning saws from carbon deposits

Basic principles of sharpening

When sawing massive workpieces, the side edges are also subject to rapid wear.

The saw should not be allowed to become too dull. The rounding radius of the cutting edge should not exceed 0.1-0.2 mm. In addition to the fact that when working with a very dull saw, productivity drops sharply, sharpening it takes several times longer than sharpening a saw with a normal dullness. The degree of dullness can be determined both by the teeth themselves and by the type of cut they leave.

READ Idle Speed Adjustment on Husqvarna 137 Chainsaw

Proper sharpening of circular saws consists in simultaneously ensuring the proper sharpness of the cutting edge, providing the maximum number of sharpenings, which in the optimal case can reach 25-30 times. For this purpose, it is recommended to sharpen the carbide tooth along the front and back planes. In essence, the teeth can be sharpened along one front plane, but the number of possible sharpenings is almost two times less than when sharpening along two planes. The picture below clearly demonstrates why this happens.

The last pass when sharpening saw blades is recommended to be made along the back plane of the tooth. The standard metal removal rate is 0.05-0.15 mm.

Before sharpening, it is necessary to clean the saw from contaminants, such as resin, and check the sharpening angles. On some saws they are written on the blade.

Mechanical problems

Symptoms of such malfunctions can manifest themselves in different ways, but almost always the operation is accompanied by extraneous noise. This may be a whistling, grinding or clicking sound. Now, while the engine and gearbox are still assembled, it is necessary to determine which of them is faulty. Try turning the motor by the shaft. It should rotate quite hard, but evenly, i.e. should not jam.

The layout of a circular electric saw.

If the motor shaft does not rotate or rotates jerkily, the motor is faulty. Take it apart and look at the bearings. The first is located in the engine housing, the other on its rotor. We can assume with complete confidence that one of them is to blame. The first one would be good, it's quite easy to change.

If the bearing on the engine armature is at fault, you can safely take it in for repairs. It is almost impossible to remove it yourself without a special device. In addition, any attempts to do this may result in damage to the anchor. You will not have to carry the entire saw to the workshop, but only the rotor. It's easier and cheaper.

The main gearbox malfunction is wear of the gear teeth. In this case, it must be replaced. You should also pay attention to the armature splines. They should also not be damaged.

Repair scheme

repair your electric saw yourself. This is quite easy to do. To do this you need the following set of tools:

- several small files of different sizes;

- a hook that cleans the slots from chips;

- flat files.

It is best to sharpen the chain on the tool bar itself. Editing is done along the edge of the cutting tooth, taking into account the sharpening angle (from 30 degrees). This operation must be done carefully: if the angle is set incorrectly, this will affect the quality of work and performance of the tool.

READ Chainsaw Clutch Repair Ural

During operation, the file is placed perpendicularly (90 degrees relative to the bar). The whole process occurs in one vector, translational oscillations are performed, no rotational movements can be made. After processing the tooth, the chain moves, then another element is ground. After processing all the elements, the “polishing” of the fixing cut begins. If the cut clamps protrude too much, the chain will not “reach” the material - the work process will not occur. And vice versa: if the clamps are too deep, the saw will get stuck in the wood. The limiter is straightened using a gauge, which is placed on the edge of the cutting teeth. It is important that the bar is located at the same level as the clamp.

If the stopper protrudes too much, it is trimmed with a flat file. Movements are performed in one direction at an angle of 90 degrees.

Materials for the circular table

To make the circular table I used 3 mm sheet steel. I cut two squares measuring 45x50 cm. I marked a window for a saw blade with protection measuring 26x200 mm and cut it out with a grinder, trimming the edges with a file.

At the base of the circular saw I drilled 4 holes with a diameter of 6 mm to attach the saw to the table.