Features and selection of plunge-cut saws

When processing wood using power tools, the problem of accurate cutting often arises. Unfortunately, even modern disk models cannot boast of a perfectly executed job. This is due to the impossibility of proper control over the position of the cutting tool relative to the workpiece. To solve the problem of sawing accuracy, a plunge-cut circular saw was invented and put into production, which immediately gained popularity among woodworking craftsmen and became a sales leader.

What it is?

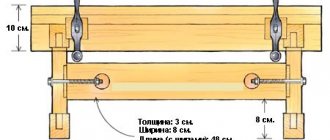

A plunge-cut saw is a type of electric circular saw and is intended for cutting wooden surfaces not only from the edge, but also from the middle of the workpiece. A special feature of the device is the ability to regulate the cutting depth, which is carried out by placing the disk in a given position relative to the base plate.

Thanks to the adjustment mechanism, the cutting depth can be adjusted down to a millimeter, which is impossible to achieve with a conventional tool.

The principle of operation of a plunge-cut saw is quite simple and is as follows: the operator sets the required depth and the desired inclination of the working disk. Then the tool is turned on, released from the lock, inserted into the wood and carefully guided along the marked line. When the engine starts, the working shaft begins to rotate along with the disk mounted on it and cuts the surface. Many modern models of plunge-cut saws are equipped with a speed control function, so the number of revolutions can be changed depending on the type of material being processed.

At the end of the work, when the pressure on the disk weakens, the cutting unit is raised to the upper position by means of a spring and hidden behind the sole. The scope of application of plunge-cut saws is quite wide. The tool is used for making furniture, cutting grooves, cutting shaped openings and gutters in wooden products, as well as for roof repairs and working with laminated materials.

Device

A plunge-cut circular saw is slightly different in structure from a conventional circular saw and is equipped with a specialized unit. Thus, the accuracy of the cut and the absence of play are ensured by a complex precision mechanism, which significantly increases the cost of the tool. Otherwise, the design of the saw is similar to the basic models. The device consists of a durable housing, where an electric motor is located, during which the torque is transmitted to a special shaft. There is a locking device on this shaft that reliably holds the working disk and does not allow it to move relative to the shaft axis.

The saw blade, when in the non-working position, is located under a protective casing and is located in the same plane with the mounting base. This design allows for more precise positioning of the tool on the work surface compared to conventional circular models. All controls are located on one panel, which makes working with the device very convenient and understandable.

Some models of plunge-cut saws are equipped with two discs at once, which allows you to cut a board of any width, making two cuts at once in one pass.

Without exception, all devices are equipped with a spring-loaded lower base, thanks to which, if the cutting disc hits a nail or other third-party element, the operation of the device will be stopped in time. Features of the design of plunge-cut saws include the function of tilting the disk, which is especially convenient when it is necessary to manufacture products of complex configurations.

In addition to the standard design and traditional set of functions, many modern devices often have additional options. They do not have a fundamental effect on the operation of the saw, however, they make its use more convenient and safe. Among them, we can highlight a backlight, a speed controller, rulers of different sizes, and a chip sucker that forcibly removes the cutting products.

Design and types of saws

A circular saw is most often used for longitudinal and transverse cutting of wood and materials created on its basis. However, making changes to the equipment settings and replacing the disks with special ones makes it possible to use it for working with plastics, slate and even aluminum sheets.

1. The circular saw can only cut in a straight line, and is not designed to work with concrete, brick and other similar materials. This is worth considering before purchasing a tool.

2. The design of the plunge-type circular saw allows cutting into the material at any point, so you can easily select grooves and grooves of any size.

| Characteristics | Description |

| Blade tilt function | Used when forming complex shapes |

| Possibility of installing 2 disks | Allows simultaneous pair cuts |

| Spring loaded bottom base | Allows you to adjust the level of pressure on the working part |

| Accessories (not available from all manufacturers) | Temperature sensor; electronic brake; container for transportation; guide rulers; finisher; recoil limiter; rip fence, other accessories |

3. In fact, all plunge-cut saws are available with a connector for connecting a forced dust and chip removal system. This helps prevent them from becoming clogged with cutting waste.

4. The basic design of most of these circular saws is standard and consists of:

- switch with locking switch;

- base plate with protective casing;

- parallel angle and its fasteners;

- bell for ejecting chips;

- depth and angle regulators;

- support handle.

5. The class of plunge-cut circular saws includes not only hand-held, but also stationary devices. There are certain differences between this and classic equipment.

| Nuances | A circular saw | |

| Regular | Submersible | |

| Protective cover | Located on top of the cutting element, protrudes along with the cutting element | The disc is located inside, as close as possible to the sole. Completely hidden, visible only during operation |

| Base plate | Classic look. | The cutting element is located inside the sole. |

| Sawing materials | Works on the surface of the operating table and suspended | Can only be used on a workbench or other stable structure |

| Adjustable cutting angle and depth | Available for all types of circular saws. Some models have a speed controller with soft start | |

| Working with the tire | Option not available for all models | Specially adapted for this function, the sole has mounting grooves |

6. The exact location of the circular on the surface of the part is achieved due to design nuances:

- when not in use, the cutting elements are hidden in the mounting base;

- the disk is lowered using the cutting level coordination unit;

- the cutting depth is set with a special regulator;

- The immersion speed and the degree of departure are controlled manually.

7. The use of a tire allows you to improve the result. The parallel arrangement of this element during cutting is achieved by adjusting the eccentrics.

Before performing an operation on the plunge-cut type, you must first set the cutting parameters. The limiter will not allow you to exceed them. Upon completion of the work, it is enough to release the pressure on the tool and the cutting unit, with the help of a spring, itself enters the casing.

Advantages and disadvantages

Plunge saws are in demand both in industrial furniture production and in home workshops. According to reviews from experts, the positive side of this equipment is its versatility.

| Scroll | Advantages | Flaws |

| Curly cuts | Allowed when using additional devices | Not all manufacturers produce the required blocks |

| Parts processing | High degree of accuracy due to correct installation of the circular disk | The dimensions of the part are limited by the parameters of the supporting part |

| Labor intensity of operations | The technically correct arrangement of elements allows the weight of equipment to be evenly distributed throughout the entire structure | Due to the structural complexity of the unit that regulates the position of the cutting element relative to the workpiece, this type of saw has prices higher than the cost for which you can purchase a regular circular saw |

| Perform different types of cutting | You can make longitudinal, transverse and even radial | Small-diameter rounding cuts are not provided |

| Speed control mechanism | Can set the operation mode according to the selected material | Often the location of this node does not allow switching directly while the circular machine is operating |

1. The main difference between this type of device and its disk counterparts is the presence of a unit for adjusting the immersion of the cutting device into the material. The simpler the setup system, the faster the processing process will occur.

2. The main parameters are:

- maximum and minimum sections;

- fit, disc thickness.

In addition, it is worth considering:

| Properties | Peculiarities |

| Sawing (max depth) | Depends on the angle of inclination (45°-90°); modifications of the feed unit, section of the disk cutter |

| Drive shaft | Gear transmission is used |

| Connector for removing waste products | Section, method of fastening |

| Mandatory values | Distance from the edge of the support pad to the blade; cutting speed; circular power |

3. The performance characteristics of the equipment depend on the design of the specific model. Therefore, there are minor differences between circulars from different manufacturers that cannot be ignored.

Before buying a saw, you need to pay attention to the power of the electric motor, as well as what voltage it needs to operate. Most professional and semi-professional tools of this type operate at 220 W. However, there are circular machines that require 380 W.

Tips for choosing what to consider before purchasing

The range of equipment on the market makes it possible to select a model with optimal parameters.

- It is important that the master feels comfortable working with the tool, so it is worth not just visually examining the equipment, but also performing several actions with it.

- A big plus would be the presence of an emergency shutdown unit. This allows you to avoid overloading the engine and increase the service life of the circular saw.

| Indicators | Action |

| Electric motor power and speed | Affects operating efficiency and the level of permissible loads |

| Cutting blade rotation speed | Constant speed holding device under load |

| Weight (for portable tool) | The more powerful the plunge-cut saw, the greater its weight |

| Protective units | Affect the safety of operations |

| Manufacturing company | The brand price is higher than the cost of a little-known manufacturer. Even if the technical capabilities of the instruments are identical. Appearance does not matter when working |

| Additional accessories included with the plunge-cut saw. | Not always needed when working, but can significantly affect the price. In addition, tires and a number of other materials are easy to buy |

| Number of options for customization and adjustment. | The more functions a tool can customize, the more convenient it is to work with. |

| Voltage type | A must for all types of power tools. Industrial devices operate from 380 W, and household devices from 220 W |

| Smooth start | Guarantees smooth, jerk-free movement during operations |

| Cutting depth | Mandatory value for plunge-cut saws |

- When choosing, you should pay attention to the presence and distance of service centers, as well as the availability of basic components and spare parts for free sale.

- The size of the power cord and the presence of additional disks do not affect the operation of the saw, so they may not be taken into account.

Full information about the characteristics is available in the instructions supplied with the equipment. It also provides recommendations for operation, compatibility with additional devices and other guidelines.

Advantages and disadvantages

High consumer demand for plunge-cut saws and positive reviews from professionals are due to a number of important advantages of this equipment.

- The ability to perform longitudinal and transverse cuts significantly expands the scope of use of such models and allows you to perform complex shaped cuts. The only limitation when cutting out non-standard shapes is the radius of curvature. For plunge-cut saws it should not be too small.

- Thanks to the most accurate positioning of the cutting disc relative to the working surface, cutting the material is carried out with pinpoint precision, which no other type of saw can do.

- Due to the peculiarities of the location of the working disk, a plunge-cut saw can be used to work directly near the wall, which is something simple circular saws cannot boast of.

- By equipping all submersible models with a finishing disc, the edges of the cuts are absolutely smooth and neat. The formation of burrs, roughness and small cracks is excluded.

- Thanks to the equipment of many models with a guide rail, the geometry of the cut being formed is not disturbed and the wood is cut as accurately as possible. In addition, to prevent lateral play of the saw blade, the design of the tool provides for the presence of special eccentrics.

- The cleanliness of the workplace when working with a plunge-cut saw is due to the presence of a chip sucker, which instantly draws in the resulting sawdust and fine wood dust.

- High power of 1000 W and above allows you to saw wood pieces 6 or more centimeters thick. In addition, using a submersible model, it is possible to saw plastic and plexiglass, although the main specialization of the tool is woodworking.

- Many models are equipped with stepless adjustment of the cutting angle, which is carried out using a screw mechanism. This allows you to quickly and accurately measure the desired angle and cut it no less accurately.

- The high safety of using the devices is due to the fact that most models are equipped with double protective insulation, electronic motor protection against overloads and a function for stabilizing the number of revolutions at high loads.

However, like any other electric tool, submersible models also have disadvantages. The disadvantages include the cost being too high compared to conventional circular saws and the difficulty of cross-cutting too narrow workpieces if their width does not exceed the supporting part of the saw.

Specifications

If you have realized the need to purchase this equipment, then you should carefully familiarize yourself with the main technical characteristics of plunge-cut saws. They may differ slightly in their design and performance properties.

When choosing a saw to solve your problems , the main attention, first of all, needs to be paid to the power of the installed electric motor. In most models that are available on the market, the power unit present in the design of plunge-cut saws is designed to operate on a 220 V network. This makes it possible for even a home craftsman to use this tool. When choosing equipment, you should also take into account the fact that the speed at which the workpieces will be processed depends on the power of the electric motor with which the saw is equipped. Additionally, the hardness of the parts, relative humidity, and the depth of cut should be taken into account.

The main technical characteristics present in the saws are the following:

- maximum depth of cut. This parameter largely depends on the feed unit, the diameter of the saw blade, as well as the angle of inclination of the cut. For plunge-cut saws it can vary from 45 to 90 degrees;

- power of the installed electric motor;

- distance from the blade to the edge of the support pad;

- saw parameters. The maximum and minimum diameters should be taken into account, taking into account the seat size and thickness;

- drive shaft rotation speed. In order to reduce weight, manufacturers use gear transmissions of torque from the engine to the cutting tool in the design of such tools;

- diameter of the pipe for connecting the chip vacuum cleaner;

- weight of the structure.

As an additional characteristic when choosing equipment, cutting speed should be taken into account. This parameter depends mainly on the density of the workpiece, as well as the parameters inherent to the saw blade.

In order for the processing of wooden workpieces using a plunge-cut saw to occur quickly, and the final result to be of high quality, it is necessary to choose the right tool. To do this, you should know the main types of tools, as well as be able to understand the symbols on the saw blade.

What are they?

Submersible models are classified according to several criteria, the main one of which is the method of powering the device. According to this criterion, devices are divided into two types: mains-powered and battery-powered. Networked models operate from an electrical power source and have higher power and performance. The advantages of such models include the absence of the need for regular battery charging and low weight. The disadvantages include the inability to use the tool in the field, as well as in any other places where there is no electricity or access to an outlet is difficult. The rotation speed in network models varies between 4-5 thousand rpm, and the average power is about 2 kW.

Rechargeable models operate on battery power and are slightly inferior in power to mains-powered models. One battery charge lasts about 50 minutes, which forces you to interrupt the process and waste time on charging. A way out of the situation can be a replaceable battery, which allows you to continue working for some time. The battery voltage is usually 36 V and the engine speed ranges from 2500 to 6300 rpm depending on the model. The cutting depth of such devices varies from 38 to 60 mm.

Another difference criterion is the size and weight of the models. According to this feature, mini-saws, middle-class models and heavy units are distinguished. Weight indicators directly depend on the engine power and the type of power supply of the device. The more powerful the product, the more it weighs.

Review of the sp6000set plunge-cut circular saw

A good option for purchasing for a home workshop is the sp6000set plunge-cut circular saw. This saw is a professional tool. Ergonomics and efficiency have been tested by time and craftsmen. The tool will help you cope with cuts in wood in given planes. The rotation speed is regulated by a switch ranging from 2000 – 5200 rpm.

Advantages of this model:

- Sawdust removal;

- Choice of cutting speed;

- Overload blocking allows you to turn off the engine;

- Setting parameters before operation;

- Ergonomics and efficiency in the process of work;

- Robust support platform;

- The handle allows you to control the saw;

- High performance.

This model is considered only by professionals engaged in qualified carpentry work. Since the tool is not affordable for the average user. That's basically all I wanted to tell you at the moment.

Andrey Noak was with you. Visit my blog and stay updated on all events. Subscribe to updates and invite your friends to check out my tips and materials. Thank you for your attention, good luck and see you again!

Source: andreynoak.ru

How is it different from circular?

The main difference between a plunge-cut saw and a traditional one is the location of the blade. It immediately catches the eye and does not allow you to confuse the models. If in a regular saw it is covered at the top with a protective casing, it is still clearly visible from below, then in plunge-cut models it is located above the level of the sole and is completely covered by the casing. The horizontal position of the disk relative to the sole also differs: in plunge-cut saws it is maximally shifted to the edge, while in conventional saws it is located almost in the middle.

The next difference is the principle of work execution. So, if when using traditional models, sawing begins from the edge of the workpiece, then with submersible models it can be started from any place. To do this, you just need to set the required cutting depth parameters, unlock the “head” equipped with a spring mechanism, and place the device exactly in the place where you need to go deeper into the wood. After the disk is immersed in the material, it is necessary to smoothly guide the device along the outlined line.

Another distinctive feature of plunge-cut saws is the presence of a tire. This allows for even cutting of edges on long boards, which cannot be achieved with a conventional circular saw, despite the presence of a parallel stop.

It should be noted that the plunge-cut saws have an anti-splinter insert and “clean cut” discs, thanks to which it is possible to form an absolutely smooth cut surface and completely eliminate the formation of chips.

A circular saw

A circular or circular saw is an equipment that has an unlimited number of teeth for cutting (cutting) hard materials, such as wood or plastic.

This device has the highest performance. For circular saws, you can change the depth and angle of the cut. A circular saw is something between a regular jigsaw and a powerful chainsaw. Using a circular saw, they make a straight, clear and sharp cut in wood of various thicknesses.

Circular saws for wood have a fairly simple design. The main components and parts of this tool are:

- housing containing the engine, gearbox, control electronics and a pipe for removing sawdust

- spindle having a saw blade mount

- base plate. There is a cutout, a folding guard, a rip fence and a riving knife.

- two handles - main and additional

- power cable.

Additional details available:

- laser cut line indicator.

There are models with a dot indicator or a linear one

- backlight

- permanent electronics and/or soft start circuit

- slip clutch or electrodynamic brake

- mount for stationary device

- There is a charge level scale on the battery tool.

The body in most cases is made of plastic. There is a collector unit, which rotates the spindle using a gearbox for attaching the saw blade. The gearbox and spindle can be broken by a slip clutch, which is triggered when the torque is unsafely exceeded, for example, if the disk is jammed. The majority of circular saw models have a body designed for right-handed people.

But there are also options for left-handers.

Cooling of the motor is carried out through the holes; immediately the motor axis has an impeller, which creates air pressure. The air flow is also used to blow away sawdust from the cutting area, which is directed into the outlet pipe.

A construction vacuum cleaner is connected to this pipe. The main handle, located at the back of the device, is armed with a push-button switch, which in the Russian automotive industry is often combined with a permanent electronics board and a soft start circuit.

Test comparison of Crown circular and plunge-cut saws

To avoid early wear of the power cord, a movable ball joint or a long and elastic input sleeve is often used. For more comfortable use of the saw, the front of the body has a second handle, which is smaller in size.

The support sole is hingedly attached to the bottom of the body, the saw blade passes through its longitudinal hole. By changing the angle of rotation of the sole in the longitudinal plane of the device, you can adjust the highest cutting depth. When turning in the transverse direction, it is possible to adjust the cut at an angle from 45 to 90° to the plane of the workpiece. The sole is made by stamping from steel or cast from a duralumin alloy. Duralumin alloy has higher rigidity. The sole has a side stop that simplifies the cutting process.

READ How to Cut a Timber Along a Chainsaw

Additionally, buy a guide rail, its length ranges from 800 to 2100 mm. It is designed to make a careful and clear cut through the workpiece.

How to choose?

Before you go to the store for a plunge-cut saw, you need to once again make sure that it is necessary. This equipment is more intended for professional use, so when choosing a model for home, as well as in case of rare use, it is better to opt for classic circular products.

If the decision to purchase a plunge-cut saw has already been made, then when choosing it, it is recommended to take into account a number of important factors.

- You need to decide on the type of power supply for the model. So, if a device is purchased for building a house on a site where there is no electricity, then you should choose a battery model. Despite the lower performance characteristics compared to network models, the tool copes with its task quite well and cuts wood no worse than its electric counterpart.

- The next selection criterion should be the power of the device. So, for home use you can limit yourself to models with a power of up to one kilowatt, while for professional equipment it is better to choose a 2.5 kilowatt motor. It is also necessary to pay attention to the presence of an emergency shutdown mechanism, which will prevent engine overheating due to a sharply increased load.

It would be useful to check the convenience of the control and configuration mechanisms, as well as make sure that there are service centers and the availability of spare parts for a particular model.

- Another parameter that you need to pay special attention to is the ergonomics of the model. And despite the fact that most devices are equipped with a comfortable non-slip handle, it is better to hold the tool in your hands and try it out.

- It is necessary to familiarize yourself with an overview of the technical characteristics of different models and the popularity rating. It would also be useful to read reviews about the chosen model, as well as compare the cost of devices in different stores. The last recommendation is due to the fact that the price of the instrument is already considerable, and taking into account dealer markups, it can increase even more.

For a review of the Makita SP 6000 plunge-cut saw, watch the following video.

How to choose the right one and what characteristics to pay attention to

When purchasing a plunge-cut circular saw, you need to pay special attention to the following characteristics:

- Electric motor power . The depth of the saw and the rotation speed of the working element depend on this indicator. Moreover, you need to take into account the following: the more powerful the power tool, the heavier it is.

- Convenience of the tool . A plunge-cut circular saw must be very comfortable, since you often have to work continuously with the tool for a long time. To check the convenience of a plunge-cut saw, you need to hold it in your hands and then make several cuts with it.

- Number of revolutions per minute and the possibility of their adjustment. The faster the disk rotates, the easier it is to work with the saw:

- hard wood is easier to saw;

the cutting line is cleaner;

- A fast rotating disk is less likely to jam.

- Diameter of cutting discs. The depth of the saw depends on the outer diameter of the blade. You also need to take into account that using larger saw blades will result in a wider saw blade.

- Smooth start. Thanks to this option, the saw blade begins to gradually pick up after starting, rather than immediately spinning at maximum speed. This will help protect the electric motor and also prevent the saw from jerking in your hands after starting.

- Difficulty in setting immersion depth. The easier it is to adjust, the faster the work can be done.

- Weight of the power tool . The weight of the saw will determine how long it can work continuously.

- Price and equipment . The functionality of the power tool and the possibility of independent maintenance depend on the configuration.

True, at high speed of the disk, the temperature at the cutting point increases. Many plunge-cut saws have the ability to adjust the motor speed, but they are more expensive. By changing the speed, it is possible to select the optimal operating mode of the saw for any wood.

Attention! All these characteristics need to be taken into account when purchasing a plunge-cut saw in order to buy a model with the required power and functionality.