How to find out which 18650 batteries are better according to technical characteristics

To determine the optimal 18650 series battery, parameters are calculated in accordance with Ohm's law. To determine the parameters, you need to know the operating voltage U and the resistance of the device R, which is measured by a test device switched to ohmmeter mode.

The ratio of U and R allows you to determine the current strength in the power circuit; based on the analysis of the value, a battery is selected that will operate without overload. When choosing, the capacity and dimensions of the battery, which is located in the tool body, are additionally taken into account.

Ni-MH (nickel metal hydride)

Bottom line: This is a great model for the home if you don't worry too much about costs. Lightweight, compact, durable and reliable, the tool can work for many years without breaking. The capacious battery is enough for about 80 screws. A convenient case allows you to take the screwdriver with you anywhere. As for batteries that contain lithium, it is unlikely that it will be possible to restore their capacity using the popular Imax B6 charger - due to the fact that lithium tends to decompose over time.

Recently, cordless screwdrivers have been gaining popularity, because... they are more mobile and quite functional. Sometimes special color markings can help make the choice easier. Thus, professional tools from Bosch are produced in blue, while green ones are used as household tools. But not all manufacturers do this, so let’s try to figure out what the difference is.

There are also no problems with drilling in hard materials, the main thing is that the power matches the work being performed. Consequently, the first difference between a professional power tool is its high reliability and survivability, which are achieved through better design and high-quality materials. Where a household tool has a bushing or a sliding bearing, a professional tool has a ball or roller bearing, and a sealed one at that.

Batteries such as (Li-Ion) lithium-ion are suitable for professionals who use a screwdriver every day, and perhaps more than once with one charge. For quite a lot of money compared to the cost of batteries of the first type, they will be distinguished by a faster charge of about one hour, a stable powerful charge, without loss of power from undercharging, but the operation and storage of such batteries is possible only under favorable conditions and is adversely affected by frost and heat! Model with lithium battery with a capacity of 1.5 ampere hours. Charging time is only one hour. Torque (maximum) is 30 Newton meters, rotation speed is 1350 rpm. The speed control system is electronic. There is a system for fixing the spindle, as well as reverse. The weight of the device is 1.6 kilograms.

The serviceability of each bank is checked by the value of internal resistance, which should be about 0.06 Ohm. To do this, connect a load to it (a 5-10 Ohm resistor) and at the same time determine the current and voltage. It is convenient to use low-voltage incandescent lamps. Measurements are made with two different resistances, respectively 30% and 70% of the permissible load. The 2nd is subtracted from the 1st voltage, and the 1st from the 2nd current. Then the subtraction results are divided and, in accordance with Ohm's law, we find the internal resistance of the battery.

Screwdriver batteries come in three types: simple, cheap type batteries (Ni-Cd), more advanced and very expensive (Ni-MH) and the same price third type (Li-Ion), I would recommend buying a cordless screwdriver with a set of two batteries of the type (Ni-Cd) nickel-cadmium, because their advantage is that they are relatively inexpensive, the service life is very long (about 5-7 years), there is enough power and the temperature conditions for storage and use are very high, so for the home, when the screwdriver is used from time to time just what you need!

Restoring a screwdriver battery in a similar manner may also not be successful for cadmium batteries.

All of the above can be attributed to the advantages of the series, but as for the disadvantages, these screwdrivers are not suitable for long-term work: the battery cannot withstand heavy loads. You won't be able to use them for drilling large holes either.

Types of lithium-ion batteries

The industry produces several types of 18650 series batteries:

- Lithium-cobalt cell designed for use in devices with reduced energy consumption.

- Lithium-manganese node with increased power and improved stability.

- Lithium-nickel-manganese-cobalt-oxide battery , which has increased power and energy intensity. To further improve performance, the anode is doped with silicon, but the material negatively affects the longevity of the battery. The devices are used to drive electric motors in tools or vehicles.

- Lithium iron phosphate battery, resistant to overdischarge and suitable for installation instead of sulfuric acid batteries in traction drives.

- Lithium-nickel-cobalt-aluminum-oxide element with increased power and extended service life (compared to lithium-cobalt type products). It is better the device for a screwdriver , since the battery retains the main disadvantages of lithium-cobalt batteries.

- Lithium-titanium assembly equipped with a lithium titanate crystal anode. The cathode is made of graphite, the voltage at the terminals is 2.4 V. The device supports accelerated charging modes and allows operation at low temperatures. The drop in capacity when cooled to 30°C does not exceed 20%. The product is not subject to thermal breakdown, but low energy intensity and increased cost are holding back the proliferation of lithium-titanium cells.

Li-ion battery capacity

To indicate battery capacity, the measurement unit Ah (ampere per hour) or mAh (milliampere per hour) is used; the digital value is printed on a label on the battery case. The parameter determines the duration of operation of the battery at standard load before the capacity decreases to zero. The batteries are characterized by a reduced manifestation of the “memory effect,” which consists of a reversible drop in capacity (observed when the charge of a partially dead battery is restored).

Standard Li-Ion devices do not allow deep discharge, which irreversibly destroys the anode and cathode material. The longevity of operation is affected by charging modes; with increased voltage in the power circuit, batteries degrade with a simultaneous drop in capacity. Exceeding the voltage by 4% leads to a decrease in capacity by 50%, and upon subsequent charging in violation of the parameters, the capacity will again decrease by 2 times.

Current efficiency of lithium-ion batteries

Current output is an additional parameter characterizing the battery; the value is printed on the battery case and measured in A (amps) or mA (milliamps). Batteries with an increased parameter are called high-current (High drain marking) and have a reduced capacity. When choosing a battery, it is necessary to take into account the characteristics of the electric drive; increased load on the battery leads to overheating of the structure and premature failure of the unit.

READ Which Tile Cutter Is Better: Manual Or Electric?

Mechanical protection of lithium-ion batteries

To prevent explosion of Li-Ion batteries, 2 additional protection methods are used:

- A mechanical toggle switch that breaks the power circuit when the temperature of the battery case rises. The device prevents further heating of the element, leading to deformation of the housing, rupture of the shell and fire.

- A safety valve used to relieve excess gas generated during battery operation. Along with the gaseous products, part of the liquid electrolyte is also released, which destroys the contact pads and electronic components of the equipment. It is recommended to replace a battery with a tripped safety valve.

Battery Bleeding

This repair method applies to lithium-ion battery cells. During the period of operation, they overheat, as a result of which the electrolyte evaporates from some batteries. Because of this, gases accumulate inside the battery, causing swelling, accompanied by bending of the plate. After this, you have to restore the screwdriver battery.

The solution to this problem is carried out in the following order:

- Disassembling the battery and finding a faulty battery using a multimeter. Usually there is no voltage in such elements.

- After this, the battery is removed and gas is released from it. In the first case, you will need some kind of flat tool, curved at the end. It is brought under the positive contact and the swollen plate is gently pressed down. The gas finds its way on its own, making a hole and exiting. In this case, you restore functionality only for a short time, since the electrolyte will evaporate completely through the hole and the battery will stop working again.

- In the second case, the positive contact is disconnected using wire cutters, after which it is slightly bent, but not completely cut off. After this, an awl is inserted under the curved plate and gradually pushed inward. That is, the plate is disconnected from the edge of the battery and the gas comes out. After this, it is inserted into its place, and the hole is sealed in the most convenient way. All that remains is to solder the contact that was disconnected at the very beginning.

Source: electric-220.ru

pros and 5 cons of alterations for a screwdriver

- The energy density of the elements will be better than nickel-cadmium. This means that the screwdriver will retain its original weight, even be somewhat lighter, while the output voltage will remain within normal limits.

- Lithium batteries charge much faster than other batteries. It only takes one hour to charge them safely.

- Lithium-ion batteries do not have a memory effect. From this we can conclude that there is no need to completely discharge them before installing them on the charger.

- If you install lithium battery, you will have to carefully monitor it: when charging, it cannot be charged above 4.2 Volts, and it cannot be discharged by less than 2.7 Volts. Otherwise, the battery will simply fail.

- 18650 cans are used as lithium cells. They are different in size from nickel-cadmium ones. In addition, you will have to find a place for the charge-discharge controller of the wires. And all this should somehow fit into the body of the screwdriver.

- Chargers for cadmium batteries may not be suitable for conversion. You may have to additionally look for a universal charger.

- It will not be possible to work outside in winter, since the lithium battery does not tolerate negative temperatures well.

- A lithium-ion battery costs more than a cadmium battery.

How to store the battery

Any craftsman who takes care of power tools is concerned about how to properly store the battery from a screwdriver. Compliance with maintenance rules applies to all types of batteries.

Things to remember:

- If you decide to send the screwdriver for storage, then before doing so you should discharge and charge the tool several times.

- The optimal positive temperature for storing the battery is 10 degrees. Avoid freezing the device.

- It is recommended to recharge every six months. This procedure increases battery life.

- It is advisable to disconnect the current source from the screwdriver, while removing all contaminants from its surface. Remove oxide from contacts with a special cleaning agent or alcohol-based liquid.

- Nickel-cadmium batteries should be slightly discharged. This is done due to their rapid self-discharge.

- Avoid exposing the housing to direct sunlight and moisture. High temperatures can melt the plastic housing, causing damage and loss of efficiency. Getting water inside will also damage the condition of the internal battery cells.

In such cases, experts recommend overclocking such batteries. To find out what is the reason for the decrease in operating efficiency, the battery is disassembled and problem areas are calculated. The cells are then charged again. For charging, a high current is first selected, then, after another discharge, a low current is selected.

If electrolyte is retained in the batteries (it may evaporate), this procedure will help to revive the battery.

It is also important to know 3 nuances before starting work

Answers:

- b) It is advisable to take Chinese KEEPPOWER batteries. Samsung does not produce models with protection.

- a) The correct output indicators are 5 Volts and the current is from 0.5 to 1 of the nominal capacity of the battery itself.

- a) 10 – 25 – ideal indicators. Do not place the battery in other conditions.

- a) Two stages - first with a voltage of 0.2-1A, and then with a high constant.

- a) Only one. High voltage is immediately applied to the element. The remaining stages are missing.

The problem with a nickel-cadmium battery installed in a screwdriver is that it needs to be used constantly. If the battery is completely discharged or is not used for a long time, the crystallization process will begin in it, and the battery will soon fail completely.

You will have to spend a lot of money to replace the battery, since batteries suitable for a screwdriver are not cheap.

For these reasons, screwdriver owners modify the battery slightly to accommodate lithium cells. But before starting such work, you need to think about whether such a modification is necessary and whether it is advisable at all.

READ How to restore the battery of a Hitachi screwdriver yourself

Definition: An 18650 battery is a battery that produces 3.7V power.

HOW TO CHOOSE li-ion 18650 BATTERIES AND WHERE TO BUY THEM

How can you replace the “original” battery in a screwdriver?

If the batteries in your screwdriver have exhausted their service life, they can be easily replaced. There is such a thing as battery interchangeability. For example, the PowerPlant brand produces batteries that are compatible with most popular brands of power tools. They cost much less than “native” batteries and are quite functional.

But if this option does not suit you, then the batteries themselves in the unit can be replaced with new ones. To do this, you will have to disassemble the battery pack and remove its constituent elements.

Replacing batteries with similar ones

On some blocks you can see mounting screws that need to be unscrewed. But on most battery packs there are no self-tapping screws, since the body is glued together. To open such a block, you will need to carefully insert a screwdriver into the gluing area (shown with an arrow in the photo) and press lightly so that the walls of the housing are detached. The same actions need to be done around the entire perimeter.

After opening the unit, you will see the batteries contained in it.

Next, you should look at the markings on the elements, write them down and choose the same ones in the online store. When you have new batteries, you need to solder them and install them back into the case. To solder batteries, you will need a soldering iron and flux (alcohol rosin or soldering acid), as well as tin. It is necessary to take into account several nuances during soldering.

- You need to solder quickly, not allowing the battery to heat up, as it may become unusable.

- For connections, you need to use “original” plates, unsoldering them from old batteries (they have the required cross-section and resistance).

- It is important to correctly connect the plus and minus of the battery. The elements must be connected in series: the negative of the previous battery must be connected to the positive of the new one, and the negative of the new battery must be connected to the positive contact of the next battery.

Read also: Do-it-yourself adjustment of the carburetor of the Shtil 660 chainsaw

After connecting all the elements, you need to equalize the potentials on all batteries, since they are different . Carry out one charge-discharge cycle: connect the charger to the battery overnight, then let it cool for 24 hours and measure the output voltage on all cells in turn. If everything went well, then the indicator on all batteries will be the same - within 1.3 V.

Now the battery needs to be discharged by inserting it into a screwdriver and loading the latter to the maximum. The main thing is not to overheat the engine of the tool. Give him a little rest. Bring the battery to full discharge. This procedure should be repeated 2 more times (full charge and full discharge).

Replacement with lithium batteries

Replacing NiCd elements with Li-Ion is also not difficult. It is known from the school course that if the batteries are connected in series, then their voltage ratings will be summed up. For example, your screwdriver runs on a battery with a voltage of 14.4 V, which means it can be replaced with four 3.3 V AA batteries. This voltage will be sufficient, because lithium batteries do not “sag” too much when starting the device.

It is recommended to buy batteries from well-known manufacturers, for example, Sistem A123. The LiFePO4 battery of this company has a capacity of 2400 mAh, sufficient for the normal functioning of the screwdriver. If you buy batteries online, they will cost you less - around 900 rubles for 3 pieces.

When purchasing batteries, pay attention to whether there are copper strips on their contacts. If they are, then the soldering process is much easier.

You will also need to purchase soldering acid instead of alcohol flux. In this case, overheating of the batteries will be minimized. The soldering iron must have a power within 65 W.

You can learn more about how batteries are replaced with lithium batteries by watching this video.

What are the best 18650 batteries for flashlights and screwdrivers?

Review of 18650 for different devices, converting the battery to a screwdriver, the best batteries from AliExpress

- When purchasing 18650 for a security flashlight, which manufacturer is preferable?

- What indicators should chargers give for 18650?

a) The output is 5 Volts and the current is from 0.5 to 1 from the nominal capacity of the battery itself. b) The output is 10 Volts and the current is from 1 to 3 of the nominal capacity of the battery itself.

Test of Li-Ion batteries for a screwdriver. Which ones to choose.

- In what temperature range is it desirable to store the battery?

a) 10 – 25 – ideal indicators. The battery does not tolerate extremely cold or hot rooms. b) At a temperature of 20 - 45 degrees.

- How many stages does a lithium battery take to charge?

How does a screwdriver battery work?

A rechargeable battery is a chemical power source used to operate cordless types of power tools. The accumulation of electricity occurs due to the electrolysis occurring in the battery. This process creates a constant voltage at the required level.

Voltage and capacitance values are the main parameters in the drive. The unit of measurement for voltage is volt.

The voltage in the battery occurs due to the potential difference between the cathode and anode. The unit of capacity is ampere-hour. This value shows the amount of current that is supplied by the battery per hour.

The design of the battery pack does not depend on the type of screwdriver model.

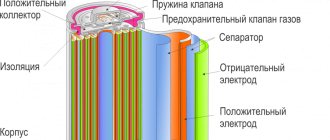

It includes the following structural elements:

- the housing on which the contacts are located;

- series-connected power elements (batteries);

- a thermistor that protects the battery pack from overheating.

Not all models have thermistors. The tool body, consisting of two parts, is made of plastic. It houses a dozen energy storage devices (in some cases there are more). The batteries are connected to each other in a single series circuit.

The outer terminals are connected to contacts located outside the housing. Using these contacts, the tool is connected to the charger. The output voltage of the battery pack is the sum of the voltages of the batteries connected in the chain.

There are four contacts outside the battery case:

- two power contacts (positive and negative), the purpose of which is to charge and discharge the battery;

- contact located at the top to control the thermistor;

- a contact capable of charging and equalizing the charge sizes of each storage unit included in the unit using a special station.

There are the following types of batteries:

- Nickel metal hydride (or Ni-MN). Their output voltage is 1.2 V. Manufacturers of such batteries position them as environmentally friendly. This applies to both production and further disposal. Despite their small dimensions compared to other types of batteries, they have a greater capacity. Another advantage of this type of drive is its performance at low temperatures. The disadvantages of Ni-MH batteries include high cost, limited service life and increased self-discharge. It is not recommended to discharge them completely during operation.

- Lithium-ion (or Li-ion). The voltage of this type of battery is directly proportional to the number of storage devices included in the battery. The range is from 1.2 to 3.6 V. Li-ion batteries have a control board and a special controller that monitors all power supplies included in the unit. The advantage of lithium batteries is the absence of a “memory effect”, large capacity, and low weight. The absence of a “memory effect” allows you to charge the battery as needed. It is advisable to charge it well before prolonged use. The charge can be stored for a long time if the battery is at least half charged. The disadvantages of this type of battery include their high price, short service life, and inability to operate at low temperatures. Batteries of this type are the most common - most construction tools are equipped with them.

- Nickel-cadmium (or Ni-Cd). They represent the battery standard for all cordless power tools. The advantages of Ni-Cd batteries lie in their: low price, fast charging function, maximum load current transfer function, the ability to maintain high capacity at temperatures below twenty degrees, the ability to perform a charge-discharge cycle up to a thousand times.

How to avoid 4 mistakes when assembling a 18650 charger

To correctly connect lithium cells to the battery, you will need to follow the instructions exactly:

- We disassemble the battery housing. In the 14.4 Volt model you can find 12 1.2 Volt nickel-cadmium batteries. We immediately get rid of this coupling - we bite it off with wire cutters. The result is only a connector with a plus and a minus.

Frame

- We also get rid of the temperature sensor. Instead, we use a controller with a thermocouple, which will turn off the battery when it overheats.

- All elements are connected in series. We solder the controller to the assembly. We connect the balancing points to a special connector on the chip.

- When the battery is assembled, solder the terminals to the “minus” and “plus”. We put everything in the case.

Chargers for 18650 batteries

For the 18650 battery you will have to use the correct charger. At the output it will produce 5 Volts and a current from 0.5 to 1 of the rated capacity of the battery itself. If lithium cells support 2600 mAh, then a current of 1.3-2.6 amperes should be used to charge it.

The device for lithium batteries charges the battery in several stages:

If the charger has a pulse mode, this will significantly speed up the charging time.

If the battery contains graphite, the voltage should not exceed 4.3 Volts per cell. If you exceed this figure, the energy density will increase and the oxidation process will begin.

There are lithium batteries that charge in less than an hour. They do not provide for the second stage - the current is immediately supplied to 80% and after that it is put into operation. This is normal for a lithium battery.

Sources:

https://elektro220v.ru/akkumulyatory/kakie-luchshe-akkumulyatory.html

Storage process

Proper storage of the battery before use is an important condition for its correct and long-term operation. Therefore, the storage process should begin not from the moment of purchase, but immediately after production.

When purchasing a product equipped with a battery, you should look at the packaging date. It must be remembered that the deterioration of the battery quality depends not only on how actively it was used, but also on the storage time.

The shelf life of a lithium-ion battery is on average 5 years under normal load conditions. But if a screwdriver (another tool) has been lying on the counter for a long time, the battery loses 10 - 20% of its life.

Batteries should be stored at temperatures from 0C to +20C. The maximum permissible storage temperature should not exceed +35C. At the same time, the cooler, the better for the battery, but if the temperature is not below zero. Given this feature of the battery, some users store it on the refrigerator shelf. In principle, this is possible provided that the battery is in a sealed, waterproof package. If there is no confidence in the quality of the packaging, it would be more correct if the batteries of the screwdriver (other device) are stored in another cool place.

Properly charging the battery also affects how long it lasts. To prevent its case from overheating when connected to the network, it is better if this occurs at a low ambient temperature. In this case, the power supply must be “native”. Otherwise, the manufacturer does not guarantee normal battery life.

The average time to fully charge a modern lithium-ion battery is 6–7 hours. More precise characteristics of a particular product are indicated in its technical documentation. But even without instructions, you can intuitively understand when the battery is fully charged. In most cases, it has LED indicators (red – charging, green – charging complete). In addition, when the battery is fully charged, the voltage supply automatically stops and the power supply stops heating. But even such a measure does not guarantee complete safety of the battery life. Therefore, it is not recommended to leave it connected to the charger for a long time after it is fully charged.

For lithium batteries, complete charging and discharging is not fundamentally important. They, unlike nickel-cadmium ones, for example, do not have “charge level memory”

This means that the level of the battery’s operating capacity does not reflect the degree of its charge during subsequent recharging.