What types of batteries are there for screwdrivers?

Different manufacturing technologies are inherent in batteries for screwdrivers.

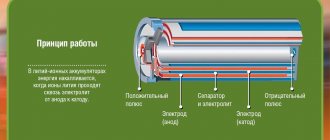

Basically, there are Li-Ion, Ni-Cd or Ni-Mh batteries for devices. Lithium-ion products for screwdrivers are characterized by high electrical accumulation, as well as recharging of the product by a thousand times, or even more. However, they are more susceptible to fire and are much more expensive than other batteries.

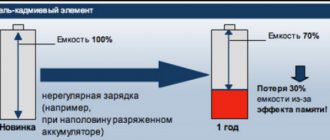

Nickel-cadmium batteries for screwdrivers are much cheaper than previous batteries; the load on such batteries is not a hindrance to them. However, the charge/discharge cycle of such batteries is limited. They also have a large “memory effect”.

Nickel-metal hydride batteries for screwdrivers in terms of performance are between lithium-ion and nickel-cadmium battery models, that is, they rightfully occupy the middle of this product range.

How to store the battery

Any mechanic who pays close attention to a power tool cares about how to properly keep the battery away from the screwdriver. Compliance with maintenance rules applies to all types of batteries.

What to remember:

- If you decide to store your screwdriver, you should discharge and charge the tool several times in advance.

- The optimal positive temperature for battery storage is 10 degrees. Avoid freezing the device.

- It is recommended to collect every six months. This procedure increases battery life.

- It is advisable to disconnect the power source from the screwdriver, while removing all dirt from its surface. Remove oxide from the contacts using a special detergent or alcohol-based liquid.

- Nickel-cadmium batteries should be slightly discharged. This is done due to their rapid self-discharge.

- Avoid direct sunlight and moisture on the housing. High temperatures can melt the plastic housing, damaging it and causing it to malfunction. Water will also damage the battery's internal components.

In such cases, experts recommend overclocking such batteries. To find out the reason for the decrease in efficiency, we disassembled the battery and calculated the problem areas. The cells are then charged again. For charging, a large current is first selected, and after the next discharge, a small current is selected.

If electrolyte has accumulated in the battery (it may evaporate), this procedure will help revive the battery.

How to find out which screwdriver battery is right for you

This definition will not be difficult.

Always pay attention to the letter designation located on the battery housing for screwdrivers. If you don’t find it, then focus on the weight of the product. Light-weight batteries belong mainly to lithium batteries.

If, on the contrary, the battery has a significant weight and the “memory effect” is considerable, then most likely this type of battery belongs to nickel-cadmium batteries.

If your product is of average weight and has a long service life, then it will most likely be a nickel-metal hydride battery. Such batteries are safer for your health, as well as for the environment in general.

Charging a screwdriver without a charger

Restoring a battery without the help of a charger is not difficult, but many people have no idea how. You can charge the screwdriver battery without a charger using any constant voltage power supply. Its value should be equal to or slightly greater than the voltage of the battery being charged. For example, for a 12V battery, you can take a rectifier to charge a car. Using terminal clamps and wires, connect them to each other for about thirty minutes, observing the polarity, while monitoring the temperature of the battery.

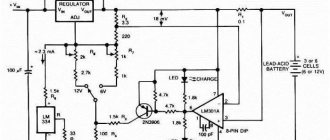

You can also modify power devices with higher voltages using a simple integrated stabilizer. The LM317 chip allows you to control an input signal up to 40 volts. You will need two stabilizers: one is switched on according to the voltage stabilization circuit, and the second - on the current. This scheme can also be used when converting a charger that does not have charging process control units.

The scheme works quite simply. During operation, a voltage drop is formed across resistor R1; it is enough for the LED to light up. As it charges, the current in the circuit drops. After some time, the voltage on the stabilizer will be low and the LED will go out. Resistor Rx sets the highest current. Its power is selected to be at least 0.25 watts. When using this scheme, the battery will not be able to overheat, since the device automatically turns off when the battery is fully charged.

The absence or complete breakdown of a screwdriver's charger stops all planned work. But, using ingenuity and some available tools, the question that has arisen about how to charge a screwdriver battery without a charger can be successfully resolved. There are several ways to resolve this problem.

Selecting a charging unit that matches the characteristics.

The following parameters are indicated on the battery or the screwdriver itself: voltage value (volts), battery capacity (ampere/hour). The same current dimension and identical power should be produced by the charger. A charging module from some other device that has identical indicators can charge the screwdriver battery: you need to expose the wires, connect the battery connectors using alligator clips.

Application of a universal memory

There are universal charging units available for purchase, the output parameters of which are adjusted according to the needs of the user and the individual characteristics of the type of device that needs to be charged. Their package includes an adapter for the most popular connectors, alligator clips; such gadgets are suitable for many types of devices and tools.

Using a charging module for a car battery.

Such a device can damage the screwdriver battery, because its output characteristics are different, so the charging process can only be carried out after they have been leveled. It is safest to use a car charger equipped with a system for adjusting the voltage level. If one is present, it is recommended to set the following parameters: with a battery power of 1.3 ampere/hour, the current value is set to the level of 650 - 130 mA, that is, the current value is 0.5 - 0.1 part of the total battery power.

Making a homemade charging unit

It is possible to fabricate a homemade unit for charging the drive. To do this, the terminals of a failed battery are soldered off, and wires are soldered through the expanded holes according to the polarity. The location of the wires is sealed with some kind of filler, for example, a roll of thick paper/cardboard. The lid is secured with glue to the charging cup. The assembled unit is placed into the battery through an adapter.

Battery equipment with USB connector

To be able to replenish the screwdriver’s battery via a USB charging unit, it is equipped with such a connector using a fuse. The contact points are soldered, the fuse is fixed with glue, the assembled case is secured with adhesive insulating tape.

Charging through external sources of electricity.

If the power tool is very worn out, it is possible to purchase a universal charger for a screwdriver, or a unit that corresponds specifically to your model of tool. You will find a huge selection of power supplies for screwdrivers at MegaBattery.ru

Continuing the topic, you can connect the device to any source of electricity. This is usually done using an old battery of adequate parameters. A 10A fuse is integrated into the circuit. The wiring must have a larger cross-section.

Storing Nickel-Cadmium Batteries

This type of battery can be stored either fully charged or when the battery is completely discharged.

Unlike lithium-ion, they are more resistant to long-term storage. If you fully charge this product before storing it, the charge will not last long due to electrical leakage.

Ni-Cd batteries must be stored at temperatures ranging from ten to twelve degrees Celsius. Cold storage is contraindicated for them.

If the screwdriver in which this type of battery is installed will not be used for a long time, then before storing the battery, be sure to carry out several charge/discharge cycles of the battery.

Storing lithium-ion electric vehicle batteries in winter

Winter has already arrived - and the question always arises: how to properly store lithium-ion batteries for a long period without use. This is an important topic, because every owner wants to preserve the properties of the battery as much as possible.

There is a clear recommendation regarding storage temperature. The most favorable temperature is around 0°C, but not below zero. In such cool conditions, the properties of the electrolyte are preserved as long as possible, so you can wrap the battery in a sealed bag and store it in the refrigerator (but not in the freezer). But it’s okay if you don’t have the right conditions. Batteries can also be stored up to +20°C. It is possible higher, but this is less favorable.

But there is controversy regarding the level to which the battery should be charged.

The well-known website batteryuniversity.com, which is referenced in one way or another by the authors of almost all articles about storing lithium-ion batteries, recommends storing batteries at a charge level of 40%. That is, if we talk about Li-Ion, this is approximately 3.5 V per element. The site claims that in this way the recoverable residual capacity of the battery is preserved as much as possible. For example, if a battery charged to 40% is stored at +25°C, after a year the recoverable capacity will be 96%, and if a battery charged to 100% is stored, then the recoverable capacity will be 80%.

Where they got these numbers from, how and what research was carried out - the site is silent.

However, I have serious doubts about the data provided. The thing is, I always keep all my batteries 100% charged. And for several years. And they are stored perfectly. I didn't notice any significant loss of capacity. Of course, after some period of operation they fail one way or another. But not after 5 years of simple storage.

Therefore, although I cannot refute the exact figure of 40% (most likely, at this level of charge the battery will certainly not deteriorate) - I still prefer to read the operating manuals for the equipment.

Let's look at the manufacturer's recommendations. Here, for example, is the instruction plate on the battery of the Airwheel Z3 scooter.

Translated it means: “Fully charge the battery before storage and after use. This will extend battery life."

And here are the instructions on the battery from the QiCYCLE bicycle.

Let's use a Chinese translator.

And we get such a translation.

And it's the same here. The manufacturer recommends storing the battery in a cool, dry place and recharging it every two months for two hours. That is, we are again talking about a full battery charge.

So, we have two opposing opinions: some sources advocate for a 40% charge level, others for 100%. And there is no concrete evidence in favor of one version or another. Therefore, I cannot name the only correct option. As I said above, I decided for myself to act according to the manufacturer’s recommendations, that is, to fully charge the battery before storage. And by the way, when the battery is turned off, there is practically no self-discharge. Over the course of a month, only a few percent are lost, so there’s no point in recharging the battery; it’s enough to just check the charge occasionally.

Please note: This article and the images in it are subject to copyright. Partial or complete reproduction on other resources without permission is prohibited

Storing Nickel Metal Hydride Batteries for Screwdrivers

Preservation of this type of battery is recommended at a temperature not lower than plus ten degrees Celsius. Despite their considerable capacity and excellent performance, it is recommended to comply with this requirement for storing batteries.

In order to maximize the effect of storing a rechargeable battery, it is necessary to fully charge a product of this type of power supply from time to time (for example, once every six months). It should also be noted that, unlike lithium-ion batteries, nickel-metal hydride batteries require 100% charging during storage.

What is the best way to store batteries. Charged or discharged?

If the battery is nickel-cadmium or nickel-metal hydride, it should be left fully charged if you plan to store it for less than 30 days, and at 30-50% of its maximum capacity if you plan to store it for more than 30 days. ,

According to DeWalt, lithium-ion batteries must be fully charged. Although this is a strange rule, because of everything I've learned about this type of battery, I know that lithium-ion batteries charge very slowly (they lose about 4% per year). Apparently, DeWalt simply decided not to take risks in this case, since the user can leave the battery completely in place. Many people probably know that lithium-ion batteries have electronics that cut off power when the charge level reaches a certain minimum. For the user it will be zero, but in fact there is still a charge. And if such a battery is left in storage without pre-charging, it may simply reach true zero even at low discharge rates. And for lithium-ion batteries. This is death. They can't be completely drained, so the electronics are worth it. Here at DeWalt I played it safe. Well, I think so.

READ Magneto clearance of Stihl 180 chainsaw