A screwdriver is one of the most popular tools used by professionals and amateurs. Using corded screwdrivers is not always convenient, especially if you are away from 220 V. With a cordless tool, this problem is solved; you can move freely with it without dragging the cord behind you.

One of the main elements of any cordless tool is the battery, which ensures autonomous operation. But how should you charge the battery correctly so that it lasts as long as possible? Further details in the article.

Types of batteries

In order for the battery to serve for a long time “like a clock,” you must first read the instructions included with the device. It should be noted that screwdrivers differ not only in price, power, manufacturer, but are also divided into professional and semi-professional. Accordingly, batteries will also have different prices, quality and charge capacity. Professional types are equipped with more capacious power supplies, which will cost a level more, but will also work longer than conventional ones. Manufacturers use various batteries in the manufacture of their devices, each of which has certain parameters and features that should be taken into account during charging. Batteries for screwdrivers can be classified into the following types:

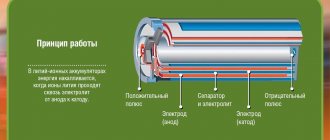

1. Lithium Li-Ion

They are considered the most powerful batteries. They charge fairly quickly, and there is no memory effect at all. Recharging this type of battery is as easy as shelling pears. There is no need to recharge it after it is completely discharged; you can recharge it as needed. The high cost and intolerance to low temperatures discourage many people from purchasing, so they are not in great demand. Batteries should be charged at temperatures between 10 and 40°C. If the battery becomes hot during charging, it must be cooled to avoid further damage.

2. Nickel-cadmium Ni-Cd

The nickel cadmium battery has compact dimensions and large capacity. By following the included instructions, they can be recharged more than 1000 times. There is a memory effect; if you charge it before it is completely discharged, this can reduce the energy capacity. Before first use, you need to charge and discharge the battery at least three times. In the future, it is also recommended to completely discharge and charge the device, this will make it possible to bring the capacity to the required operating condition. The same rule applies when storing the instrument.

3. Nickel metal hydride Ni-MH

They belong to the newest generation of batteries, for this reason, the memory effect is somewhat weaker than the previous type, which is a definite plus. The disadvantage of NMGB is the highest self-discharge current. In order for the battery to function for a long time, it must be kept charged. If the screwdriver is not used for a long time (about a month), it must be completely recharged.

As you can see, each battery is endowed with characteristic features, taking into account which you will be able to charge the screwdriver correctly.

Features of charging of one type or another + (Video)

The initial charging of the screwdriver is considered a very significant factor, since it determines whether the full charge capacity becomes active or not. Any type of battery has its own characteristics of primary charging. The process of recharging a nickel-cadmium battery is somewhat complicated. Initially, it needs to be recharged three times in a row, and so that the charge capacity remains full.

It is recommended to completely discharge the nickel-metal hydride type for the first time, and also fully charge it. The complete charging/discharging cycle is repeated 4-5 times, then you can safely charge and discharge the battery regardless of how full the container is.

There are no special rules for lithium-ion; the capacity remains unchanged for a long time.

Advice! Do not allow the power supply to overheat above 50 degrees.

Storage

If you do not plan to use the battery for a long period of time, then you should pay special attention to how it should be stored. The optimal charge is considered to be 30-60% of the capacity. The battery should be located in a fairly cool room where the air temperature remains around 15 degrees. On the contrary, the battery is stored in a fully charged state, then the next time you turn it on you will find that its capacity has decreased significantly.

When the device is left completely discharged, it is even worse. With a high degree of probability, in six months it will need to be recycled. Lithium-ion batteries should not be stored for long periods of time in deep discharge.

What is the optimal amount of time to charge?

The recharging period is usually indicated in the device instructions. In most cases, the device has a special indicator that helps you understand how long you still need to charge. Once charging is complete, turn it off to avoid damaging the batteries. The average charging time for a screwdriver will be from 30 minutes to seven hours. The longest period is for Ni-Cd with a voltage of 1.2 V, feeding with a current of 250 mA for approximately seven hours.

There are also two types of battery chargers: regular and pulse. Standard charging is most often included with non-professional tools; the charge lasts about 3-7 hours. The pulse device is designed for professional models and is capable of powering the battery in a maximum of 1 hour.

Tip: The Interskol screwdriver is distinguished by its versatility; in addition to its main function, it can also be used as a drill.

How long does it take to charge screwdrivers?

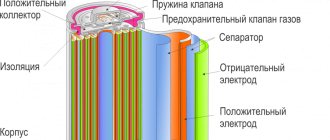

Battery composition.

Important questions regarding charging screwdriver batteries include the time required to fully charge the battery. Many people think that charging a screwdriver battery until it gets hot, but in fact this is a sure way to reduce the charge capacity and performance of the entire unit. It’s worth saying right away that currently there are hundreds of types of screwdrivers and no less number of batteries, so it is very important to read the instructions that come with a specific unit, because in one case 30 minutes will be enough for charging, while in another for a full Charging will take more than 2 hours.

Many types of batteries have an indication system, that is, there are 2 LEDs on the top instrument panel, usually red and green. These LEDs let you know exactly when charging is complete. However, even if there is an indicator, it is necessary to disconnect the batteries from the network in a timely manner, since a long stay in the connected state after recharging can cause damage to the battery.

In addition, when considering the charging duration, you should immediately note that there are 2 main types of chargers, and the exact type included with the screwdriver largely determines how long the charging process will take.

Chargers are divided into pulse and regular ones.

As a rule, cheaper semi-professional devices are equipped with conventional chargers. Pulse chargers are more expensive, but at the same time they allow you to charge the device in less than 1 hour, which is especially important for professional devices.

Should I charge it before long-term storage?

Haven't used your screwdriver battery for a long time? Experts give the following recommendations.

- Before storage, nickel-cadmium For long-term storage, you need to carry out 3-5 full charging/discharging cycles.

- Nickel-metal hydride batteries have a higher self-discharge rate, unlike previous elements. Experts advise keeping them charged, and after a long break, leaving them to recharge for a day. The capacity decreases after 200-300 charge-discharge cycles. Partial discharge is allowed for this type.

- Lithium-ion batteries are distinguished by the complete absence of the “memory effect”. The battery can be charged whenever you want. It is not recommended to completely discharge them, as this may disable the protective circuit. They are equipped with special controllers that, at high temperatures, turn off the element to prevent overload. You can store the cell charged only 50%.

Recommendations for storing batteries

It is recommended to store batteries of any type disconnected from the screwdriver. Each type of battery also has its own characteristics in this regard:

- nickel-cadmium batteries must be discharged before storage to such an extent that the screwdriver does not work at its full power;

- Nickel-metal hydride batteries are recommended to be kept fully charged, but a small discharge is still allowed;

- Before storing a lithium-ion battery, it also needs to be discharged, but only half.

After a long period of storage, nickel-metal hydride batteries, which can withstand 200 to 300 recharge cycles without loss of capacity, must be recharged within 24 hours. Blocks of this type are distinguished by a significant self-discharge parameter.

As mentioned above, lithium-ion power cells do not have a “memory effect”. They have a large capacity and the lowest self-discharge rate. You can replenish their charge at any time, regardless of the degree of discharge.

Li-Ion batteries should not be completely discharged, because this may cause the built-in electronic temperature or voltage protection system to turn off.

To achieve the 50% charge required for proper storage, lithium-ion batteries must be charged from near zero for a period of about 65% of the time it takes to reach full capacity.

Compliance with the simplest recommendations for storing and charging different types of battery packs will allow you to use up the entire lifespan of the batteries included in them by the manufacturers.

What to do if the battery does not charge? + (2 Videos)

The reason may lie in either wear or tear of the device. It often happens that the contacts between the terminals of the charger and the battery are broken. Then you can disassemble the “charging” yourself and bend the terminals.

As you know, all contacts oxidize and become dirty over time, and for a screwdriver with a charger this is no exception. Usually expressed in a significant reduction in charging time, as well as the duration of activity of the power tool. To eliminate the oxide, you need to carefully wipe the contacts with a special substance or, in extreme cases, alcohol.

Very often, nickel-cadmium batteries lose their capacity, especially when it comes to non-professional models. Experienced users prefer to overclock such batteries. First, the battery pack is disassembled and problem areas are identified. Then they need to be recharged. It is better to immediately use a higher current than expected, and then discharge again. If the electrolyte is still present in the Ni-Cd, the procedure can restore the power supply.

And some experts even use car chargers to recharge the battery.

Source: instrument-blog.ru

Homemade charger for lithium-ion batteries of a screwdriver

In the previous article, I considered the issue of replacing nickel-cadmium (nickel-manganese) NiCd (NiMn) screwdriver batteries with lithium ones. It is necessary to consider several rules for charging batteries.

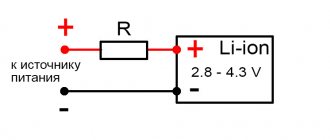

Li-ion batteries of the 18650 size can generally be charged to a voltage of 4.20V per cell with a tolerance of no more than 50mV because increasing the voltage can damage the battery structure. The battery charge current can be 0.1xC to 1xC (here C-capacity). It is better to select these values from the datasheet. I used Samsung INR18650-30Q 3000mAh 15A batteries in remaking the screwdriver. We look at the datasheet - charging current -1.5A.

The most correct way would be to charge lithium batteries in two steps using the CCCV method (constant current, constant voltage).

The first stage must provide a constant charging current. The current value is 0.2-0.5C. I used a battery with a capacity of 3000 mAh, which means the nominal charge current will be 600-1500 mA. After the can is charged at a constant voltage, the current constantly decreases.

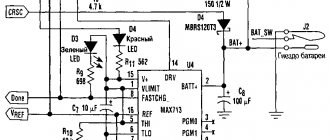

The battery voltage is maintained within 4.15-4.25V. The battery is charged if the current decreases to 0.05-0.01C. Taking into account the above, we use electronic boards from Aliexpress. Step-down CC/CV board with current limiting on the XL4015E1 chip or on the LM2596. The XL4015E1 board is preferable as it is more convenient to configure.

XL4015E1 Specifications. The maximum output current is up to 5 A. Output voltage: 0.8 V-30 V. Input voltage 5 V-32 V. The board on LM2596 has similar parameters, only the current is up to 3 A.

List of tools and materials.

-adapter 22012 V, 3 A - 1 piece; -standard screwdriver charger (or power supply); - CC/CV charge board for XL4015E1 or LM2596 - 1 piece; - connecting wires - soldering iron; -tester; - plastic box for charge board - 1 piece; - minivoltmeter - 1 piece; -variable resistor (potentiometer) for 10-20 kOhm - 1 piece; - power connector for the battery compartment of the screwdriver - 1 pc.

Step one

. Assembling a screwdriver battery charger on an adapter.

We have already chosen the cccv board above. As a power source, you can use any one with the following parameters - output voltage not lower than 18 V (for a 4S circuit), current 3 A. In the first example of making a charger for lithium-ion batteries of a screwdriver, I used a 12 V, 3 A adapter.

First, I checked what current it can produce at the rated load. I connected a car lamp to the output and waited half an hour. It produces 1.9 A freely without overload. I also measured the temperature on the transistor radiator - 40°C. Quite normal mode.

But in this case there is not enough tension. This can be easily fixed using just one cheap radio component - a variable resistor (potentiometer) of 10-20 kOhm. Let's look at a typical adapter circuit.

There is a controlled zener diode TL431 in the diagram; it is located in the feedback circuit. Its task is to maintain a stable output voltage in accordance with the load. Through a divider of two resistors, it is connected to the positive output of the adapter. We need to solder to the resistor (or unsolder it completely and solder it in its place, then the voltage will be regulated downwards) which is connected to pin 1 of the TL431 zener diode and to the negative bus a variable resistor. Rotate the potentiometer axis and set the desired voltage. In my case, I set it to 18 V (small margin from 16.8 V for drop on the CC/CV board). If the voltage indicated on the housings of the electrolytic capacitors located at the output of the circuit is greater than the new voltage, they may explode. Then you need to replace them with a 30% voltage reserve.

Checking the battery condition with a multimeter

Not always, when the battery runs out quickly or does not function at all, it is necessary to buy a new one or take the unit to the service center specialists. In many cases, even an inexperienced electrician can independently find the cause of the malfunction after familiarizing himself with the search algorithm. To do this, you will need to use a multimeter or similar measuring devices. In addition to this device, you will also need the following tools:

- screwdriver;

- soldering iron with soldering kit;

- knife;

- pliers.

To accurately determine the cause of battery problems, it is necessary to determine the performance of each individual power element. But first it is recommended to check the charger. Using a multimeter this is done this way:

- turn on the device;

- set the switch of the measured values of the multimeter to constant voltage;

- install the probes into the corresponding sockets of the multimeter and touch them to the contacts (“+” and “-”) of the charger;

- compare the value displayed on the device display with the output voltage of the charger indicated in the operating instructions or on the case;

- if the values do not match, then repair the adapter or buy a new one.

Whenever possible, select the measurement range on the device used that is closest to the output voltage indicated on the charger.

To check the battery of a screwdriver with a multimeter, perform the following steps:

- fully charge the battery pack;

- check the output voltage of the battery with a multimeter, setting the device switch to its constant value, and touching the plus and minus with probes;

- if it is determined that the measured parameter does not correspond to the value specified in the operating instructions, then disassemble the battery pack and remove all the batteries;

- when there are no damaged banks (leaking or swollen), then check the voltage at the terminals of each battery with a multimeter, having previously soldered the circuit using a soldering iron;

- a load is connected to the batteries in turn for the same amount of time (for example, a light bulb of the appropriate voltage);

- Whichever battery experienced the greatest drawdown is the one that is damaged.

To check, nickel-metal hydride and nickel-cadmium energy storage devices are completely discharged - this is done to avoid the “memory effect”.

When checking batteries, it should be taken into account that for nickel-cadmium and nickel-metal hydride types of batteries, the output voltage should be in the range from 1.2 to 1.4 V, and for lithium batteries - from 3.6 to 3.8 V.

Having found a defective battery, you can replace it with a new one or try to temporarily restore it. You can also measure the current strength with a multimeter: if it grows and exceeds 1 A in the first hour, then the battery is considered operational.

If there is no voltage at the battery output, then there is a high probability of a violation of the integrity of the circuit inside the unit. At the same time, they also disassemble the block and first look for the break point visually and then using a multimeter.

Tools

Among power tools, both household and professional, a screwdriver is one of the most popular. With its help you can not only unscrew and screw in self-tapping screws, but also drill holes. Tools powered by the mains cannot be used always and everywhere, and the cord always interferes with the work. Cordless screwdrivers are free from these disadvantages. You can move freely with them and not depend on the presence of an outlet in the room.

An important element of every cordless tool is the battery, which allows you to work with it autonomously. This is very convenient, but sooner or later every owner of such a power tool faces the question of how to charge the screwdriver battery.

Content

Types of batteries used to operate a screwdriver

Before purchasing new batteries for a screwdriver, you must carefully study the instructions for the device. The tools needed for work can be professional, household and semi-professional. The batteries for them differ from each other in capacity, quality and price.

Certain types of cordless tools are designed for certain jobs, designed for different loads, and therefore they require different batteries. The higher the battery power rating, the longer it can last. For convenience, it is better to have two batteries so that you can recharge the second while working with one. Often a second battery is already included when the tool is sold.

Screwdrivers can use different types of batteries. The most commonly used are nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH), and more recently also lithium-ion (Li-Ion).

The most common of them are nickel-cadmium batteries, characterized by their compact size, high capacity and reasonable price. These batteries can be effectively charged more than a thousand times, depending on their design, purity of materials, operating conditions, including correct charging. However, these devices have a so-called memory effect, and if they are charged without waiting for complete discharge, the battery capacity will gradually decrease. In addition, the production of such elements is so toxic that the European Union has abandoned it on its territory.

In second place in terms of frequency of use are nickel-metal hydride batteries, which represent a new generation of such devices. From an environmental point of view, both the production and disposal of these batteries are practically safe. The advantages of batteries of this type include the fact that they have a less pronounced memory effect, and the disadvantages are a high self-discharge current. These batteries must be kept charged and must be fully recharged when not in use for more than a month.

Recently, more powerful lithium-ion batteries have been used for cordless tools. They also do not have the disadvantage of a memory effect, which requires periodic discharge cycles to restore capacity. However, these batteries do not tolerate low temperatures well, and it is not advisable to work with them in frosty conditions. Despite the fast charge and high capacity, they are not yet very popular, since their price is quite high.

Features of battery charging

How to properly charge a screwdriver battery so that it lasts as long as possible?

Batteries must be charged before first use as they will discharge during storage. To ensure that the battery capacity of the screwdriver reaches the maximum possible for a nickel-cadmium cell, it is recommended to charge it three times and then discharge it. Thus, since the new battery does not have full capacity, it must be brought to its working full capacity. After this, the batteries will need to be charged as soon as their power reaches a minimum. Lithium-ion batteries are easier to use. They do not have a memory effect, so you don’t have to let them fully discharge and charge them when it’s convenient.

When charging, you need to take into account the optimal temperature conditions of the process. It is better that the ambient temperature is above ten degrees and does not exceed forty. During charging, batteries sometimes get warm, but this should not happen, since overheating negatively affects their performance and they need to be cooled. It is not advisable to leave batteries in the charger. And it’s better to store them by disconnecting them from the screwdriver, separately from the tool itself. If the batteries are not used for a long time, they should be recharged once a month.

It is better to buy batteries at specialized sales points. Proper operation will help increase their service life. It is not advisable to completely discharge the elements during operation until the engine stops. The fact that they need charging will be indicated by their noticeably reduced performance.

How to charge for the first time

Some people, who would not dream of it, remember how what remains to be done, our client was told that the new battery must be brought to a full discharge, and then fully charged, well, what to do three times. Although such a process of first charging occurs, it is really necessary, alas, for Ni-Cd batteries not Ni-MH. Such batteries were installed in quite ancient telephones, which are now practically not produced.

Not everyone knows how to properly charge a lithium-ion battery at first, and does not begin to carry out the procedure for the working version of discharging. Batteries of this type are designed differently; it is not the process of deep discharge that significantly harms them. It is for this mistake that such devices are sold with a charge of 5/3 of the capacity, and not for the purpose of a person being able to check a phone or other device.

Unfortunately, quite often consumers, before first charging a lithium-ion battery, remembering the old days, begin to completely discharge it, thereby almost immediately taking away half of their service life. Therefore, be careful not to make common mistakes that lead to battery failure.

Dazdranargon › Blog › Converting a screwdriver to lithium batteries (from Ni-Cd to Li-Ion)

The inevitable has come - the batteries in my old Hitachi DS 12DVF3 have finally died. They became disgusting to hold a charge for a very long time, but the existing capacity was enough for small household needs, so I never thought about solving this problem. Until the moment when I needed to drill a hole in a stainless steel kitchen sink, which took me about forty minutes! One hole! One battery could not be pumped up at all, but the other one just worked, spinning for twenty seconds, charging for about ten minutes. That’s when I realized that it was time to give new life to my favorite instrument. It is clear that first I needed to familiarize myself a little with the theory in order to understand what I had to do. Of course, this topic is not new at all, and everyone is involved in converting screwdrivers to lithium. But everyone does it in their own way, depending on their education, amount of laziness and concept of beauty. I needed everything to be done absolutely correctly from the technical side, so that it didn’t look scary from the outside and so that the batteries could be used comfortably. After re-reading and reviewing a huge amount of material, I took the project from AlexGyver as a basis.

Having decided on the necessary elements, I went to Ali to spend money. I ordered lithium batteries with already welded nickel plates, so as not to torment either myself or them with soldering. It turned out that the batteries took a really long time to be delivered, and while I was waiting for some from China, I bought others from a local store, but without plates, because I have two cases for conversion. A month and a half after ordering, I finally received my parcels and it was already possible to get to work. To begin with, I disassemble one old case and get acquainted with its contents.

Here you need to carefully break off the upper contact pad; it will be needed later. You will also need nickel jumpers to solder the second block to the batteries, so I’m moving this trash to the side for now. Next, I try on new components to understand the scope of the upcoming work.

Source: www.drive2.ru