Can I charge a lithium-ion battery without a controller?

Yes, you can.

However, this will require close control of the charging current and voltage. In general, it will not be possible to charge a battery, for example, our 18650, without a charger. You still need to somehow limit the maximum charge current, so at least the most primitive memory will still be required.

The simplest charger for any lithium battery is a resistor connected in series with the battery:

The resistance and power dissipation of the resistor depend on the voltage of the power source that will be used for charging.

As an example, let's calculate a resistor for a 5 Volt power supply. We will charge an 18650 battery with a capacity of 2400 mAh.

So, at the very beginning of charging, the voltage drop across the resistor will be:

Ur = 5 - 2.8 = 2.2 Volts

Let's say our 5V power supply is rated for a maximum current of 1A. The circuit will consume the highest current at the very beginning of the charge, when the voltage on the battery is minimal and amounts to 2.7-2.8 Volts.

Attention: these calculations do not take into account the possibility that the battery may be very deeply discharged and the voltage on it may be much lower, even to zero.

Thus, the resistor resistance required to limit the current at the very beginning of the charge at 1 Ampere should be:

R = U / I = 2.2 / 1 = 2.2 Ohm

Resistor power dissipation:

Pr = I2R = 1*1*2.2 = 2.2 W

At the very end of the battery charge, when the voltage on it approaches 4.2 V, the charge current will be:

Izar = (Uip - 4.2) / R = (5 - 4.2) / 2.2 = 0.3 A

That is, as we see, all values do not go beyond the permissible limits for a given battery: the initial current does not exceed the maximum permissible charging current for a given battery (2.4 A), and the final current exceeds the current at which the battery no longer gains capacity ( 0.24 A).

The main disadvantage of such charging is the need to constantly monitor the voltage on the battery. And manually turn off the charge as soon as the voltage reaches 4.2 Volts. The fact is that lithium batteries tolerate even short-term overvoltage very poorly - the electrode masses begin to quickly degrade, which inevitably leads to loss of capacity. At the same time, all the prerequisites for overheating and depressurization are created.

The protection built into the battery will not allow it to be overcharged under any circumstances. All you have to do is control the charge current so that it does not exceed the permissible values for a given battery (protection boards cannot limit the charge current, unfortunately).

Charging using a laboratory power supply

If you have a power supply with current protection (limitation), then you are saved! Such a power source is already a full-fledged charger that implements the correct charge profile, which we wrote about above (CC/CV).

All you need to do to charge li-ion is set the power supply to 4.2 volts and set the desired current limit. And you can connect the battery.

Initially, when the battery is still discharged, the laboratory power supply will operate in current protection mode (i.e., it will stabilize the output current at a given level). Then, when the voltage on the bank rises to the set 4.2V, the power supply will switch to voltage stabilization mode, and the current will begin to drop.

When the current drops to 0.05-0.1C, the battery can be considered fully charged.

As you can see, the laboratory power supply is an almost ideal charger! The only thing it can’t do automatically is make a decision to fully charge the battery and turn off. But this is a small thing that you shouldn’t even pay attention to.

How can I charge a screwdriver battery without a charger?

- Main classification

- Step-by-step instruction

- Conclusion on the topic

Before charging the screwdriver battery without a charger, you will need to read the instructions. A homemade charger is made taking into account the type of battery.

Types of screwdrivers.

Main classification

Experts distinguish the following categories of screwdrivers:

- domestic;

- semi-professional;

- professional.

Since the battery is designed for a specific job and load, each type of tool requires an appropriate charger. The operating time of the tool depends on the battery power. Experts distinguish the following types of batteries:

Table of characteristics of batteries for a screwdriver.

Type 2 batteries, unlike the others, are compact and have greater energy capacity.

With proper use, the tool can be charged more than 1000 times. The screwdriver battery must be charged if the following rules are observed:

- Battery is fully charged. Otherwise, the energy capacity and operating life of the tool will be reduced.

- Toxicity of nickel-cadmium battery (do not drop).

- The nickel-metal hydride battery is developed using new technology and is environmentally friendly for humans. It can be charged frequently. If the tool is not in use, then the battery is stored in a charged state. If the screwdriver is left idle for a long time, the battery is completely discharged.

- The lithium-ion device does not have a memory effect. The battery has a high energy capacity. Due to exposure to the negative effects of low temperatures, the lithium-ion battery is not used in winter.

To charge the battery for a screwdriver with your own hands, you will need the following materials and tools:

Interpretation of charger indicators.

- charging glass;

- damaged battery;

- 2 wires 15 cm long;

- soldering iron;

- screwdriver;

- drill;

- knife;

- heat gun.

Using a soldering iron, solder the terminals of the damaged battery. Using a marker on the cover of the device, make notes where the minus and plus were. If necessary, the prepared holes are adjusted to the required dimensions. A blade is used for this.

The next step is to route the wire through the holes. The cable is soldered to the glass, taking into account the polarity. To prevent the connector from falling apart, cardboard is inserted into the battery. The bottom cover is attached to the charging cup. The resulting structure is inserted into the adapter and then into the battery.

To charge the device, you can make a charger from a USB source. To do this, use a socket, USB charger, fuse (10 A), connectors, paint, electrical tape and tape. The screwdriver is disassembled into parts. The upper body is cut off from the handle with a knife.

Diagram of a charger for a screwdriver.

A hole is made on the side of the handle for the fuse. The wire is connected to the fuse and mounted in the handle of the unit.

How to use a nickel metal hydride battery (video)

It is quite difficult to say exactly which battery is best for a screwdriver. It all depends on one factor, this is the purpose of purchasing a power tool. For household and infrequent use, nickel-based batteries are suitable. If you are using a professional tool, then it is advisable to use a lithium ion power source.

The memory effect refers to a significant loss of battery power as a result of recharging an incompletely discharged battery.

How to properly charge a new screwdriver battery? This question worries many owners of cordless construction power tools.

How to bypass protection

The socket to which the screwdriver battery is connected contains four terminals. Two of them are negative and positive. The other two terminals go to the relay for protection against short circuits, overheating, and other things. To bypass the protection and not have to deal with the electrical circuit, you can use an unnecessary battery from a drill.

Screwdriver battery disassembled

The screwdriver battery is removed from the housing. The small white plastic box will say that it is a thermal protector. This element, along with the black wires, must be desoldered and soldered to the terminals of the charger. Now the white and black wires are soldered to the protection, observing the polarity.

When connecting a battery or other devices, the indicator should show that charging is working normally. If you just turn on the charger, it will blink, indicating that you need to add a battery. That is, the blinking will disappear and the red light will remain on. When the battery or other device is fully charged, the green light should light up.

An example of a diagram for connecting a screwdriver charging to a car battery

To charge a car battery, a wire is brought out from the side of the case. You need to connect the terminal blocks, and then connect the wire to the power supply. Otherwise, the protection system will work and charging will not start. The positive and negative wires are connected to the corresponding terminals of the car battery. If the charger is working properly, it should not overheat or melt.

Connecting terminals to charging a screwdriver

Safety and Precautions

Basic safety requirements when charging tool power supplies from non-standard charging units:

- Direct current is used to charge the tool's batteries.

- The connection is made using cables with a protective insulator; it is necessary to ensure reliable fixation of the electrical wiring on the battery contact plugs.

- When the capacity of the elements is replenished, heating occurs, accompanied by the release of gases. The battery cells are equipped with emergency valves, but the leaked component is not suitable for further use.

- It is recommended to carry out work in a ventilated area; eyes and hands are protected using personal protective equipment. If the case overheats, smoke or traces of electrolyte appear on the body of the can, charging stops immediately. Reconnection is carried out after determining the causes of the malfunction.

- Connecting power adapters that are not designed to charge the screwdriver battery is a last resort. Due to the mismatch in current parameters, the circuit components are overloaded, which causes increased heating and fire. Continuous use of non-original charging blocks is not recommended.

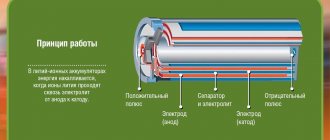

How to properly charge lithium batteries

There are several charging schemes for lithium batteries. Two-stage charging developed by SONY is most often used. Devices using pulse charging and step-by-step charging, as for acid batteries, are not used.

Charging any type of lithium ion or lithium polymer battery requires strict adherence to voltage. One cell of a charged lithium battery should have no more than 4.2 V. The nominal voltage for them is considered to be 3.7 V.

Can lithium batteries be charged quickly, but not fully? Yes. They can always be recharged. Operating the battery at 40-80% capacity extends the battery's shelf life.

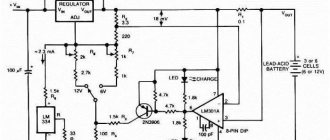

Two-stage lithium battery charging circuit

The principle of the CC/CV circuit is constant charging current/constant voltage. How to charge a lithium battery using this scheme?

The diagram before stage 1 of charging shows the pre-stage for restoring a deeply dead lithium battery, with a voltage at the terminals of at least 2.0 V. The first stage should restore 70-80% of the capacity. The charging current is selected at 0.2-0.5 C. You can quickly charge with a current of 0.5-1.0 C. (C is the capacity of lithium batteries, digital value). What should the charging voltage be at the first stage? Stable, 5 V. When the voltage at the battery terminals is 4.2, this is a signal to move to the second stage.

Now the charger maintains a stable voltage at the terminals, and the charging current decreases as the capacity rises. When its value decreases to 0.05-0.01 C, charging will end and the device will turn off, preventing recharging. The total capacity recovery time for a lithium battery does not exceed 3 hours.

If the lithium-ion battery is discharged below 3.0V, a “jump” will be required. This consists of charging with a low current until there is 3.1 V at the terminals. Then the usual circuit is used.

How to control charging parameters

Since lithium batteries operate in a narrow range of voltage changes at the terminals, they cannot be recharged above 4.2 V and discharged below 3 V. The charge controller is installed in the charger. But each battery or battery has its own breakers, PCB board or PCM protection modules. The batteries are equipped with protection against one or another factor. If the parameter is violated, it must turn off the jar and break the circuit.

A controller is a device that must implement control functions - switch CC/CV modes, control the amount of energy in the banks, turn off charging. At the same time, the assembly works and heats up.

Homemade charging circuits used for lithium batteries

- LM317 – circuit of a simple charger with a charge indicator. It is not powered from the USB port.

- MAX1555, MAX1551 - specially for Li batteries, installed in the power adapter from the phone to USB. There is a pre-charge function.

- The LP2951 stabilizer limits the current and generates a stable voltage of 4.08-4.26V.

- MCP73831 is one of the simplest circuits, suitable for charging ionic and polymer devices.

If the battery consists of several cells, they are not always discharged evenly. When charging, a balancer is needed to distribute the charge and ensure uniform charging of all the cells in the battery. The balancer can be separate or built into the battery connection circuit. The battery protection device is called BMS. Knowing how to charge devices and understanding the circuits, you can assemble a protective device circuit for a lithium battery with your own hands.

How to properly charge a screwdriver battery

Proper charging performance differs from one device to another and depends on specific factors:

- residual amount of energy (for some models it is recommended to wait for complete discharge or, conversely, not to bring it to the limit);

- the chemical composition of the battery, that is, the characteristics of certain metals included in it (metal ions are extremely sensitive to heat, and prolonged, uncontrolled exposure to energy can negatively affect the properties of conductors/semiconductors, which will lead to rapid failure of the battery);

- type of charger (pulse/regular).

How to charge a screwdriver battery without a charger?

The situation when the screwdriver charger is inaccessible or has failed cannot be called normal, so there is no easy solution to this problem. The best way out of this situation is to find and purchase a charger suitable for your model, since only it can safely and efficiently charge the batteries of your particular tool. If this is not possible, there are fallback options:

- charge the battery with a car charger;

- purchase a universal charger;

- convert a power tool to be powered by an external battery.

Using a car charger

The main danger when using this method is overcharging the battery. The batteries used in power tools differ in their characteristics from car lead batteries. A charger equipped with electronic current and voltage regulation is suitable.

The charging current is selected at the rate of 0.5 to 0.1 of the battery capacity in Ah. So, with a capacity of 1.3 Ah, the charging current is set from 650 to 130 mA. Chargers for lead batteries are designed to operate with high currents, and the required value may be outside their operating range. In this case, to limit the current, a ballast resistor is used, connected in series with the battery. A car lamp can be used as resistance.

Universal chargers

The purchase of such a device is justified if, in addition to a screwdriver, there are other battery-powered equipment at home. Laboratory power supplies or model chargers can act in this capacity. The advantage of this type of device is its versatility and many adjustments, with which you can set the required charging mode.

Using an external power source

This is not the most convenient option from an operational point of view. In the case when the tool is already old, and purchasing additional equipment for it is too expensive, it can be used. A battery with the appropriate voltage is suitable for this upgrade. When using a powerful battery, protection of the electric motor should be provided. The simplest option is a 10 A fuse installed in the power circuit. Do not forget that the wires, when using low voltage, must have a larger cross-section than when powered from a 220 V network.

When using non-standard equipment to charge a screwdriver, make sure that the devices are connected correctly, that the charging mode complies with the technical characteristics of the battery, and ensure the safety of the process.

Methods for charging a screwdriver without a charger

The electric cordless tool is equipped with a factory charger that allows you to replenish the battery capacity. If the unit is lost or broken, the owner has a question about how to charge the screwdriver without a charger. In addition to purchasing an original unit, there are several methods for recharging a power source from household or automotive equipment.

Using a car charger

Using a charger designed to service a 12-volt vehicle battery may permanently damage the power source for the power tool.

Before connecting devices, it is necessary to bring the charging operating parameters to the necessary requirements.

If the equipment is equipped with stepless voltage and current regulators, then it is necessary to set parameters identical to the standard unit. To reduce the current load, a ballast resistor is used (for example, a car parking light lamp).

If information about the operating parameters of standard charging is unknown, then for a nickel-cadmium battery with a capacity of 1.3 Ah, the charging current is set within 50-100% of the nominal capacity. The voltage is set to the minimum level. Then the polarity of the battery bank is determined (according to the factory markings), the location of the minus and plus is, if necessary, clarified with a test device.

To take measurements, you need to drill through the plastic casing of the can and install a sensor inside (for example, from a household test device). Depending on the current parameters, charging lasts from 30 minutes to 2 hours; when the threshold temperature is reached, the external unit turns off.

universal memory

Universal battery charging equipment supports stepwise or continuous adjustment of voltage and current in the output circuit. The unit is equipped with instruments and indicators that allow you to monitor the charging progress.

READ What Can Be Made From a Non-Working Screwdriver

If the device design includes a battery type switch, then you must select the appropriate value. Universal charging equipment is recommended for servicing worn-out elements.

Via USB

To replenish the capacity, it is possible to connect an external charging unit via a self-installed USB port. It is recommended to use adapters rated for a current of 5-7 A. It is not recommended to use computers or laptops to supply current, since the increased current in the circuit overheats the controller and disables the unit.

Algorithm for equipping a screwdriver battery with a USB connector:

- Remove the battery bank, and then separate the sections of the case (the elements are held on by screws and additional plastic clips).

- Cut a hole in the housing section to install a USB connector. The port installation location should not interfere with the placement of the power source in the tool handle or in a standard charging station. The channel configuration depends on the appearance of the prepared plug. The block is installed in the resulting socket and fixed using special hot-melt adhesive.

- Place a 10 A fuse in the circuit connecting the standard charging controller and the USB connector. Hot-melt adhesive is used to secure the protective element and electrical wiring. The cables are connected by soldering with lead-tin solder, the fixation points are protected with insulating materials.

- Connect the body sections using standard screws. If a permanent structure was cut, the joint line is covered with a strip of fabric or masking tape coated with liquid epoxy resin. After the material hardens, the surface is sanded and painted to match the color of the battery can body.

- Carry out test charging of the DC source. Since the voltage in the charging circuit is 5 V, replenishing the capacity takes up to 6-8 hours for batteries with a capacity of 1-2 Ah.

How to charge a screwdriver battery without a charger: ensuring safety

Before using any charging method other than the native charger, you should remember that:

- The process must be closely monitored; after filling the battery, it is recommended to stop the procedure, because if overfilled, the electrolytic elements of the battery can boil, the temperature will rise sharply, and the slightest spark will explode the entire structure;

- Non-native, homemade chargers threaten to completely ruin the battery, excluding the possibility of its subsequent restoration;

- It is necessary to ensure the correct inclusion of all elements of the circuit, strict consideration of the technical parameters of the battery when installing the circuit, the safety of the procedure, and compliance with polarity;

- If the characteristics of the modules differ slightly (for example, 10 and 13 volts), then the battery cannot be charged for a long time.

Additional useful information

Rechargeable batteries are available in different versions: lithium, nickel-metal hydride, and cadmium. Charging powerful lithium blocks is the easiest; replenishing the charge of the other two types has some peculiarities. The charging time for different batteries also varies - from 0.5 hours to 7 hours. Cadmium modules take the longest to fill (7 hours).

The considered methods for solving such a problem as charging a screwdriver battery without a charger are not acceptable for every type of power tool. Before you start experimenting, you need to take into account all the technical features of the devices and materials used, so as not to damage the power tool itself, your health, property or real estate.

A screwdriver equipped with a battery makes it possible to fully work where there is no possibility to connect to an electrical outlet. This simplifies construction and repair.

The screwdriver itself is in excellent condition, but the charger is lost, and it turns out to be impossible to find the same one.

How to charge a screwdriver battery without a charger?

If you understand the basics of electromechanics, you will find the voltage and battery capacity on the battery or screwdriver, and the polarity on the battery or screwdriver body - this is the main thing!

You need a charger; we determine its characteristics from the data, for example, an 18V battery and a capacity of 2 A/hour - this means you need a charger capable of delivering a charging current of 18V and a power of approximately 200 mA/hour, since it takes a longer time to charge, but it is sufficiently charged with less power take 8-10 times less, adjust it on the charger, or purchase it with exactly these characteristics.

To supply charging current to the battery, use small alligator clips simply by hanging them on the current distributing plates of the battery connector.

A regular rectifier for car batteries

It is extremely important not to confuse the polarity of the connection because not all batteries for screwdrivers have a + designation - like Makita, for example. It is better to have a tester on hand

A current of 1 ampere is quite enough and the charging duration should not be more than half an hour, under constant supervision.

Although this method can save the situation once or twice, there is no need to use it constantly. To match the battery life as stated by the manufacturer, you must use only original chargers that provide the required voltage and charging current.

Can be charged with a car charger (C/U).

On the device itself we set the minimum voltage.

We remove the battery of the screwdriver, determine exactly where we have a plus and where we have a minus (although the batteries are different, there may be nuances).

Sometimes it is not possible to connect the terminals from the charger directly to the battery of the screwdriver; you need to slightly improve this unit, using, for example, paper clips or plates.

In general, that’s it, turn on the charger so as not to risk the screwdriver’s battery, control the charging duration, 15, 20 minutes will be enough to begin with, as soon as the screwdriver’s battery becomes warm, turn off the charger.

Here is a video on the topic,

a person used an Orion PW-260 charger to charge the battery of a Hyundai screwdriver.

And it’s even better, of course, to buy a native (or at least similar) charger; you can find almost any one in the markets, even for an old model of a screwdriver.

How to charge a screwdriver without a charger: 12 and 18 volts, precautions

A screwdriver is an indispensable tool that is often used in the household. It's no secret that most of these devices are powered by a battery, which has to be recharged periodically.

There are situations when the charger fails and because of this it is not possible to use the tool.

However, if you know how to charge a screwdriver without a charger, even a broken charger will not interfere with the planned work.

A screwdriver is a tool that is often used during repair or construction work.

Safety and Precautions

Before you charge anything, you need to familiarize yourself with safety precautions. This will help prevent possible problems that may arise while recharging the tool's battery.

The following recommendations must be followed:

- The process must be constantly monitored. As soon as the battery charging is completed, the procedure must be completely stopped. The fact is that as a result of overfilling, lithium components can boil. Their temperature increases sharply, which can lead to an explosion.

- It is necessary to ensure that all network elements are correctly turned on. Particular attention should be paid to the polarity used and the battery specifications.

- If the characteristics of the modules are different from each other, the battery cannot be charged for too long.

Additional Information! The duration of recharging depends largely on the type of battery. On average, the procedure lasts about 3-4 hours. However, some batteries may take 7 hours to charge.

Via USB

Some types of screwdrivers are initially equipped with a USB input for charging

If you urgently need to replenish the battery capacity, you can use an external charger that connects via a USB port. It is necessary to use devices that are designed for a current of 5-7 A. However, before doing this, you must independently equip the screwdriver with a USB connector. This is done as follows:

- Remove the battery and separate the housing sections.

- Cut a special hole in the case to install a USB port.

- Insert a 10 A fuse into the circuit that connects the USB connector and the standard charging controller. It is attached with hot-melt adhesive.

- Carry out test charging.

To get a full charge from the installed USB port, you will need to wait at least 12 hours.

Important! You only need to install USB in a screwdriver yourself if you have good knowledge in the field of electronics.

Using a car charger

Car charger - a device that can be used to charge tools

Some people try to use car chargers and connect a screwdriver to them. However, you shouldn’t do this right away.

The fact is that such chargers are designed to service car batteries with a voltage of 12 Volts. If you connect them to a screwdriver, the tool may break.

Therefore, it is necessary to ensure that the charging parameters meet all requirements in advance.

If the device has a stepless current regulator, it must be used to set parameters that correspond to the standard unit. To reduce the load, you can use ballast resistance.

There are situations when it is not possible to find out accurate information about the optimal parameters. In this case, it is necessary to set the current to 50% of the nominal values. The voltage level is kept to a minimum. It is also necessary to determine the polarity of the battery. This can be done using a test device.

Additional Information! On average, charging a Li Ion battery takes about 3-4 hours.

Universal chargers

Universal charger ideal for recharging screwdrivers and other frequently used tools

The most common way to quickly recharge a screwdriver is to use a universal charger. Such devices are equipped with special step regulators, with which you can adjust the current and voltage at the output.

Also, many such memory devices are equipped with indicators to monitor the process. With their help, it is possible to understand how much the battery has been charged.

Additional Information! If the universal charger model you are using allows you to change the type of battery, you must select the appropriate type. This will greatly speed up the process of recharging a dead screwdriver.

How long does it take to charge a screwdriver battery?

Many people are interested in how long it will take to recharge a screwdriver. The duration of this procedure largely depends on the type of charging used. For example, if the instrument is connected to a pulse device, the process lasts only an hour. During this time, the screwdriver will be able to fully charge.

Some people use regular, non-pulse chargers. In such cases, the tool will take many times longer to charge. Recharging will finish within 5-8 hours.

Additional Information! The duration of a full charge also depends on the model of screwdriver used.

Each such tool is sold with instructions. Before you charge the screwdriver battery, you need to familiarize yourself with it. Please refer to the instructions for more precise information about how long charging should take.

Is it possible to charge a lithium-ion battery without a controller?

Lithium-ion battery is used in most screwdriver models

Many people are interested in whether it is possible to recharge a lithium-ion battery without using a controller. It's actually possible.

However, you will have to carefully monitor the voltage and charging current indicators. They must not be allowed to be too large.

The fact is that increased values can lead to the battery failing and then it will not be possible to use it.

To protect your screwdriver with a lithium-ion battery, you will have to independently limit the maximum charging current. Only in this case will it be possible to recharge without using a controller.

Additional Information! This charging method is used extremely rarely, since many people do not want to constantly monitor the voltage. It is better to use universal chargers. With their help, charging a dead screwdriver is much easier.

Some people do not know how to charge a screwdriver without a charger and immediately buy a new charger. However, you don't actually have to do this. There are several effective ways that allow you to recharge a tool at home, even without using a proprietary charger.

How long does it take to charge a screwdriver battery?

Each power tool is always accompanied by an instruction manual, which specifies exactly how long to charge the screwdriver battery. As already mentioned, the vast majority of modern chargers have charge level indicators, which makes them much easier to use. When the indicator lights up green or another color, indicating that the screwdriver’s battery charging time is coming to an end, you need to disconnect the battery in time.

The average time it takes for the battery to be fully charged is 7 hours. And if the battery just needs to be recharged, it can be left on charge for 30 minutes. Although, in the case of Ni Cd batteries that have a “memory effect”, frequent and short recharging is not recommended.

There are several types of chargers for screwdrivers, depending on their scope of application. An ordinary charger is usually included in the package of household power tools. The battery charging time with its help varies from three to seven hours. There are also powerful pulse-type chargers that come with professional tools. How long does it take to charge a screwdriver battery with such a device? “Impulse” devices can fully charge the battery within an hour, which is their undeniable advantage. However, the cost of such a tool is, of course, much higher.

Screwdriver battery device

The battery is a chemical source of current for screwdrivers independent of the mains, in which the energy of a chemical reaction is repeatedly converted into electricity. Due to this, the battery is able to store electrical energy and store it for a long time. During charging, the battery accumulates electricity, and during discharging it transfers it to the consumer.

Main components of the device:

- A housing on which contacts are located for connecting to a charger or power tools.

- “Banks” that are connected to each other by a chain.

- Temperature sensor that helps protect the device from overheating.

Screwdriver battery characteristics:

- Voltage. This is a parameter that characterizes the capabilities of the device. It will determine how complex the task you can perform. The voltage value is not constant: the highest value is when the battery is 100% charged, and it gradually decreases during its discharge. Therefore, it is better to perform complex work with a high battery charge level.

- Energy intensity. It indicates the amount of energy accumulated by the device. Affects the duration of operation of the device. But you need to know that the operating time of the product depends on the complexity of the work performed, so a device with one battery can operate for different times.

- Weight and dimensions. These parameters affect the usability of the device. A tool with a large and at the same time heavy battery will not be able to be kept suspended for a long time, which will affect the efficiency of the work.

- Charge indicator. It indicates the charge level and helps you know when to charge the battery. The nuances of charging batteries of various types

There are different types of batteries in screwdrivers - nickel-metal hydride, nickel-cadmium and lithium ion. Each type has its own nuances, so recharging must be done taking into account the recommendations for a specific type.

- Nickel-cadmium. The most common type of battery, its advantages are small size, price and significant energy consumption. In addition, this type can withstand a large number of charge and discharge cycles, about 1000. But this battery has one drawback - the memory effect. Therefore, if you do not completely discharge or charge the ni-cd battery, its energy capacity will gradually decrease. In addition, the production of nickel-cadmium batteries has a very bad impact on the environment due to toxic emissions, for this reason some countries have abandoned the use of this type of battery.

- Nickel metal hydride. This type of battery also has a memory effect, but it manifests itself to a lesser extent compared to the previous type. For new batteries, you need to complete a full charge and discharge cycle 5 times. And in the future, charging is carried out as necessary. The main advantage of this type is that their production is environmentally friendly.

- Lithium ion. Batteries of this type are much better than their predecessors. They charge quickly and have no memory effect. Such batteries do not need to be fully discharged, and can be connected to a charger as needed. The disadvantages of the battery include the high price and poor tolerance of low temperatures. Lithium ion batteries from a screwdriver need to be recharged at temperatures from 10˚C to 40˚C.

In addition to the types, you also need to know how much time to charge the battery. As a rule, the duration of recharging the screwdriver battery is noted in the instructions for the device. You must study it carefully and adhere to all recommendations. Usually the charger has a charge indicator, which allows you to know how the charging process is going. Using this element, it will not be difficult to determine how much time it takes to recharge. As a rule, the charger charges the battery from 1.5 hours to 7 hours.

But it is necessary to take into account that there are 2 types of battery chargers - regular and pulse. A conventional charger is used in a non-professional device; it recharges the battery in 3-7 hours. The pulse charger is used in professional tools. With this type, capacity restoration occurs in one hour.

How long to charge, and what does this time depend on?

It will take at least 2-3 hours, in this case the charge will be enough to start the car engine. You can charge the battery completely, but it will take 8-14 hours. When the device is completely discharged, it takes a minimum of 15 hours to fully charge before it is fully restored. If you use a low voltage charger, it will take longer to charge. To get more accurate numbers, you need to take into account the battery capacity.

In about 2 hours the battery should reach its starting capacity. You can check whether the charge level has changed by measuring the voltage. The numbers on the multimeter screen need to be compared with the readings in a discharged state. If it was about 16 V, and it became 1-2 Volts more, then everything is working fine.

After carrying out the manipulations, check the charge level again. To do this, connect the load plug or simply connect the battery to the on-board network. If the starter spins, then the operation was successful.