What is this tool?

Angle grinder "Interskol" UShM-125/1100E is an electronic device. In everyday life it is often called a grinder and is used for working with iron, stone, concrete and other materials. "Interskol" UShM-125/1100E is an angle grinder using attachments with a diameter of 125 mm and a power of 1100 W. It is a product of the Russian company Interskol. Working with an angle grinder is not limited to cutting. This electrical device can also, if necessary, grind and polish the surfaces of products. Wide versatility in application is possible due to the design features and technical capabilities of the angle grinder.

Useful instructions - how to replace the brushes and cord of an angle grinder

Often angle grinders from Interskol

stops

working due to failure of the cord or wear of the brushes, which is why they barely reach the stator and the device does not work at full power.

You already understand how to remove the cord from the previous instructions on removing the angle grinder button (from points 1 to points 3). All that remains is to figure out how to get to the brushes and change them for new ones.

Also check the armature commutator, which may be scratched from worn brushes. Scratches can be smoothed out with fine-grade sandpaper.

REVIEW If your grinder

finished turning on when you press start, don’t rush to throw it in the trash and get a new one. Most likely, it’s all about the start button, which doesn’t require any special abilities or knowledge to repair. Replacing a button for an angle grinder from Interskol and other companies is much cheaper than buying the latest angle grinder.

Today the same Bulgarian woman

. In exchange, the payment was made for 11 years and a second month (noted in the warranty card). I’ll buy just that one myself. I recommend

“Bulgarian Corner Woman” turned out to be a really comfortable and convenient tool. The diameter of the disc is about 125 mm, and the machine itself weighs just over 2 kg. Thanks to such a small weight, you can hold it for a long time without getting tired. First, the Interconsole has a cool box body because it is made of magnesium alloy. Therefore, the device is quite strong and reliable.

I had an Intercol UshM-125/900 angle grinder for 5 years. During this period of time, I naturally changed the bearings several times, but overall it works perfectly. It is one hundred percent reliable and proves its worth. This is quite in high demand and I use it almost every day. It has quite a lot of power, even a lot. And, first of all, it is easy to use, there is nothing difficult in learning how to use it. There was only one time when it was very loaded and got a little hot.

I have been using the Intercol UshM-125/900 angle grinder for a year now. This is a very economical and powerful option for the household. It is very light in weight and comfortable to use. Every now and then the power button gets stuck. No smooth start. Just change discs in a couple of seconds. There is a starting lock. Not very comfortable to hold, ventilation holes are blocked. A very good key for ejecting a disc.

We very carefully selected the car on the hull and braked on the USHM-125. What now helps me in my work 100%. Everything works at a good pace, there is enough power, so that’s the most important thing. Don't overheat it too much. And overall, the sander works very well with all types of materials. It is very reliable and small-sized, you can simply take it with you in any bag. The price matches the quality. I recommend her.

I have had the economical grinder interskol_ushm-125_900 for several years. It works reliably, no problems were seen in the work. The case is solidly made, the insulation is good, the risk of electric shock is low. The handle for the stop is also well made and firmly attached. It cuts everything, only from time to time when under load it makes a lot of noise and the scattering of sawdust is very large and not directed. It's better to work with glasses.

I use the Bulgarian Interskol angle grinder 125-900 in the garage. I can't say her work was completely amazing. It is not languid, you can hold it in one hand without any problems. But the Bulgarians don't have a smooth start, when I turn it on it goes straight to punch. The hand must be secured. The vibration is quite high, which makes work difficult. Large bearing wear, changed 10 times already.

The grinding machine INTERSKOL 125/900 2007 took into account its good cost and power. The cost of time for cutting metal is small, it does not break, everything is clean and even without teeth, everything is balanced, the handle is rubberized for convenience, it is very comfortable to work with. The assembly is high quality, everything looks neat. Not heavy, the discs are 125 mm, most suitable for walking at home.

to work with the Interskol UShM-125/900 machine , it’s cheap, but still made to the highest standards and it’s comfortable to fit into all sorts of inaccessible places, corners, etc. I don’t really like the case; it was made clumsily and quickly, although this does not interfere with the work much. The discs are easy to install, but they are perfectly fixed and do not fly out during the cutting process.

I took the USHM-125/900 grinding machine for myself. I needed it urgently; the old one was quite worn out. There wasn't enough money for the road. But I was saddened by her work. There's not a lot of energy, it's not enough for me. Although, as they say, it is stronger than in essence. And the build quality is poor. The power button started to turn off almost immediately, and soon it got stuck. I had to take it in for repairs.

Interskol USHM-125/900 only upsets me. From the very beginning I saw that the button was very languid, I thought that it did not matter. But work

very awkward, I waste even more time and effort. After a couple of months I started to get very hot, I feel like a repair service is waiting for me, there is a problem with the engine, there is also a reason for this. Works fine, but feels hot in the hand. The cable length suits me.

There is one small trick. The noise is abnormal, my head just cracks at the end of the day. It's hard to switch. The work itself is smooth and does not hurt. Not a bad weight, or normal weight, but can be easily held, moderately distributed load. The handle is comfortable to hold, no recoil is felt. The cord itself does not heat up much, but the body barely gets warm. I like the price for Interscol UshM-125/900, it is adequate.

I bought it only for household work - cutting pipes, tiles, or some other crap. He copes with all this perfectly. What I like most about this Interskolovskaya angle grinder-125/900 is the tile cutting – smooth and precise. Doesn't lead, doesn't contribute. Lightweight, fits comfortably in the hand. Doesn't howl or vibrate very much. The casing is placed correctly and correctly protects against any side effects. You can block the start button. Therefore, it is not possible to accidentally cut it out during work, which is very helpful during careful cutting. The cost is absolutely justified.

I need a grinder very occasionally; the last time I used it was when cutting pipes. Shouldn’t you take 10’s of thousands for a certain amount? I bought a simple angle grinder 125. It’s not for professionals, so as not to burn it, we stopped every 10 minutes to let it cool. She cut and sanded without complaint, like a pro, only slower. Suitable for clay tiles, wood, metal.

The Interskol UShM125/900 grinder has worked with me for a couple of years. It is wine-producing, and it is impossible to destroy it with load. The assembly and quality of the material are at a high level. It has the best power and can handle any material. Comparatively light, small in size, which does not cause inconvenience when using the bot. Over time, the handle began to hum and wobble, but it’s working properly.

READ How to Make an Even Cut with a Grinder

Interskol UShM-125/900 is a small grinder for home work, but not for use on a production scale! Took it home for various different jobs, like a real owner! Weighing about 2 kg, it allows you to hold it in one hand (but this is not possible in case of a last-minute TB emergency!). A good comfortable handle has been invented, with a switch that is locked and cannot be accidentally caught during operation. In terms of power, I think it’s a good tool, but I repeat, not for a huge scale of work! So the price category and quality are excellent, despite the Russian assembly!

I have at home all the necessary tool fishing line from this particular manufacturer. We changed the grinder. suspended the choice for Interskol UShM-125/900. We didn’t regret a second. Works great. It makes noise, naturally, but not critically. We tried licking the bolts that stick out on the building we rented - everything was great. Normally and quickly she chewed off all the heads and didn’t even choke. We fired it continuously for about 20 minutes and it didn’t heat up at all. Therefore, it seems to me that the motor there will outlast me in terms of strength and reliability.

Quite a universal item. I’ve worked here for 5 years now. I think I’ll aim for the same amount of time. Take her anywhere (metal, wood, stone and concrete are no problem for her). The grinder is indestructible (after falling from a height there are only scratches on the body). Turned it on. works. There are no backlashes. The bearings have not yet worn out. Suspicious noises are also not heard. Never ending.

The budget machine Interskol USHM125 works entirely for its own money. The grinder is more suited for detailed tasks such as cutting aluminum profiles (like plasterboard) or non-thick sheets. The advantage of these grinders is their mobility and ability to perform tasks that require greater accuracy or difficulty of access.

Speed controller

Repairing an angle grinder yourself is not always possible. If suddenly something does not work out or everything is not clear, it is better to contact the service center.

Grinder "Interskol" UShM-125/1100E. Design Features

Grinding and polishing work on the surfaces of concrete products is often accompanied by copious emissions of dust, which is very undesirable for power tools. Settling dust negatively affects the service life of any angle grinder. The grinder "Interskol" UShM-125/1100E is assembled in such a way that the dust generated during polishing/grinding does not penetrate inside the mechanism. This is made possible by the direction of the armature impeller, which sends air currents through the front of the gearbox.

In these angle grinders, the gears are fastened with a keyed connection; they are pressed onto the spindle shaft. The entire mechanism of the angle grinder USHM-125/1100E is assembled in one housing, in the rear part of which there is a convenient handle. This grinder is a very convenient and powerful machine designed for professional use. The two-handed design (main handle + additional included) ensures comfort and convenience during operation of this power tool.

Tools needed for repairs

To repair a Bosch angle grinder, you cannot do without tools. Let’s make a reservation right away: if you have a screwdriver, this will significantly speed up the process of disassembling and assembling the tool.

But you can get by with a set of screwdrivers, preferably with a ratcheting mechanism. You cannot do without an open-end wrench, which you will use to unscrew the nut securing the drive helical gear.

To remove bearings, it is better to have a special puller.

Diagnostics of the electrical part can be carried out using a tester or a device for determining short circuits of turns.

It is especially useful in that it allows you to determine whether the rotor or stator is faulty without removing the assembly.

The Bosch angle grinder diagram will help you carry out the repair yourself, and these instructions will help you adequately cope with any problem.

Finding a broken power wire

One of the most common breakdowns of an angle grinder is the inability to turn on the tool or spontaneous stopping during operation. The cause of malfunctions of this kind is a break in the power cable, pos. 27, at the entry point. The malfunction is eliminated by replacing the cable or discarding the failed section. The fault can be easily found using a tester.

If you don’t have a tester at hand, but have a screwdriver with a neon indicator light, then the fault can be found by connecting the power wires to the phase one by one.

Typical minor damage

In the event of a malfunction, it is first necessary to eliminate elementary breakdowns:

- The grinder does not turn on . The angle grinder suddenly became faulty - it stopped turning on. In this case, you need to check the serviceability of the socket, then the plug and the power cord; perhaps the drive simply does not work due to the fact that no current flows into the product.

- The cable and plug are intact, but the drive does not work. You need to check the start button. It is easier to repair an angle grinder switch by purchasing a new button and replacing it. Since it is rarely repairable - mainly, the plastic switch rod inside breaks. If you want to experiment, you can disassemble it, numbering the contacts, and put everything back in its place so that after assembly there is no short circuit.

- The above parts are unharmed, but the angle grinder does not want to work - which means it’s time to check the brushes. Perhaps it's time to change them in the grinder. Brushes constantly heat up from work, so they wear out quickly and need to be replaced more often than other parts, and in pairs.

READ How to Disassemble a Champion Chainsaw

The grinder does not turn on. we are repairing! Angle grinder Interskol 115/900.

If the collector, which is installed on the armature, malfunctions, sparking, a burning smell and overheating of the casing occur. The casing has already been removed, now you need to remove the armature with the collector. First you need to remove the brushes from the grooves, which are held in place by springs. It is difficult to do this with the gearbox installed, so the gearbox also needs to be disconnected. Only later, of course, should you pull out the anchor; this must be done carefully. Otherwise, you can tear off the bearing; it is located on the reverse side of the armature axis. And we check the integrity of the collector, clean the plates from contamination. For which the burnout design of the plates is intended, the collector must be replaced one hundred percent along with the armature.

If the angle grinder does not turn on, first check the power cable for kinks and breaks. Then the power button is checked for serviceability. And the 3rd option. The carbon brushes have burned out, we disassemble the grinder and inspect the brushes. If the integrity is broken, change the brushes.

Repair of grinder angle grinder 125 900 (replacement of noisy bearing)

The most labor-intensive repair is if there is an interturn short circuit on the stator windings. When the car accelerates and picks up crazy speed. Here you will have to change the winding itself. It is necessary to pay special attention to the fact that the thickness of the wire must be the same, the density of the winding should be moderate, and the number of turns must be identical. It is very difficult to achieve uniformity manually; use an electric drill so that the winding rests moderately on the template. Then we install both wound coils with turns of windings into the stator, remove the winding wire from the stator, and first place cambrics of suitable diameter on the ends of the wires for insulation.

The occurrence of a mechanical sound inside the angle grinder indicates wear of the gearbox gears. For this purpose, after removing the casing from the angle grinder, you need to disassemble the gearbox itself, unscrew the 4 screws from the cap. From time to time there is a noise from inside the housing due to a lack of lubrication, when our client is left with intact teeth on the gears. Then you just need to add grease and the noise will disappear. If there is damage and the teeth are chipped, then the gear needs to be changed. It is important to remember that the gears on 1100W angle grinders are different from the gears on 1500W angle grinders. Straight teeth are used on the first type of machines, but on a 1500W grinder there are gears with oblique teeth. Therefore, they are not interchangeable, gears are not easy to remove; for this purpose it is necessary to use a universal puller. After replacing the gears, you need to lubricate the gearbox cavity. When the lubricant dries out, jamming occurs, which is a prerequisite for the teeth to break. After repairing the grinder, you need to work without load.

What is the grinder equipped with?

"Interskol" UShM-125/1100E has an electronic system that allows you to adjust the speed if necessary (from ten thousand per minute to three). The owner of this power tool can reduce them to the required level without worrying that the power of the grinder will also decrease. This quality, which is possessed by the Interskol grinding machine UShM-125/1100E, is especially valued by professional tilers. By lowering the speed, you can easily process glazed tiles and other delicate surfaces.

In addition to the electronic system, the Interskol angle grinder UShM-125/1100E contains a special soft start board, which greatly facilitates the process of operating the grinder. The presence of a smooth start of the system is especially in demand when working with heavy grinding discs and diamond attachments for stone surfaces.

What ensures reliable retention of an angle grinder?

Comfort during operation is provided by special handles - holders. Each angle grinder is equipped with them. "Interskol" UShM-125/1100E has one more handle, an additional one. Despite the fact that this electrical device is compact in size, allowing it to be held with one hand, an additional handle is included in the kit and is indispensable for work related to cutting metal.

Technical indicators

- The power consumed by the power tool is 1100 W.

- Voltage - 220 V/50 Hz. Power comes from the electrical network.

- Speed: from 3000 to 10,000 per minute.

- Weight is 2.2 kg.

- The power tool is designed for a circle with a diameter of 125 mm.

- The main handle is three-position.

- Smooth start.

- There is a function for adjusting the rotation speed.

- There is a fixed spindle.

When selling Interskol, the UShM-125/1100E is equipped with:

- additional handle;

- a set of gaskets;

- a special key for installing discs and attachments.

Advantages

The Interskol angle grinder UShM-125/1100E is considered one of the most reliable and durable Russian-made products. Consumer reviews indicate good performance and high reliability of this electric tool.

Among users, the strengths of this grinder are:

- the ability to easily rotate the gearbox 90 degrees in case of an inconvenient or unusual location of the release key;

- high power;

- presence of a speed controller. According to consumer reviews, the ability to reduce the rotation speed makes this grinder indispensable for work such as cleaning welds, removing rust or old paint from metal structures using various grinding wheels and attachments;

- the complete set with a long cord makes it much easier to carry and makes it possible to work with an angle grinder at long distances from the outlet and in other rooms;

- small dimensions and weight allow the Interskol UShM-125/1100E to be used for working with small products, since heavier angle grinders are very inconvenient for this purpose;

- the presence of a quick-release protective casing, the installation of which does not require tools;

- the presence of a power unit that maintains low speeds;

- reasonable cost of production;

- the presence of a smooth descent;

- the presence of a main handle that can be used in three positions;

- complete with additional handle.

The combination of power, dimensions, weight and additional functions are the positive qualities that distinguish the Interskol angle grinder UShM-125/1100E. User reviews confirm the well-deserved popularity of the tool both among craftsmen who professionally use this angle grinder in production, and among amateurs who like to tinker at home.

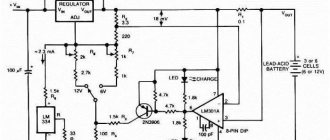

Diagram of a commutator motor with a rotation direction switch

So, we open the device and see a bunch of dust and dirt that has accumulated over a long period of use, we clean it all and wash it with napkins and degreasers.

We check the brushes, and all electrical connections on the terminals, having tightened and cleaned, we take out the rotor of the commutator electric motor and check it by visually inspecting the windings and plates, so that nothing sticks, the bearings should be intact without cracks, and they should rotate freely without jamming, noise and play .

Next, we proceed to the switch, as it turned out, it became the culprit, here the switch button switches two conductors of the circuit at once. We clean the drive lever itself with silicone grease so that it moves more easily in its guide groove all the way to the switch.

The switch can be removed and disassembled; I couldn’t repair the burnt out half, so I shorted one of the wires directly, and the second is now used to turn it on and off.

Over time, the contact came loose in the switch, began to spark and heat up, and part of it melted.

You can, of course, replace the entire switch, which would be correct, but the owner wanted it as cheaply as possible, since the tool is not very expensive, and it’s not new anymore, so I had to do this, a new switch costs about 400-500 rubles in the city, which not very cheap.

After assembling the angle grinder, we make sure to test and check the operating modes at idle before handing it over to the owner.

Angle grinders (grinders) from Interskol are very reliable and durable. They are distinguished by good performance and high reliability. But improper operation of the tool, untimely replacement of carbon brushes, lubricant and bearings leads to premature failure.

You can also repair the Interskol grinder yourself.

To do this, you need to know the structure of the Interskol angle grinder, the assembly diagram, the procedure for performing technological operations when disassembling and assembling the angle grinder. To properly repair the Interskol angle grinder, it is enough to study the proposed diagram and instructions.

Interskol angle grinders have recently become increasingly popular not only among professionals, but also among DIY enthusiasts.

Disadvantages of UShM-125/1100E

According to numerous consumers, the weaknesses of this grinder are:

- Possibility of damage to the speed controllers. This mainly occurs as a result of voltage surges from 220 to 260 V. In this mode of operation, the regulator quickly breaks down.

- High cost of spare parts.

- Poor ventilation and lack of armor on the windings. Lack of ventilation, according to user reviews, leads to the fact that the engine located inside the angle grinder burns out after several weeks of operation. This is due, according to the owners of the tool, to the fact that the plastic casing does little to protect the engine from dust.

A long service life of the UShM-125/1100E is possible subject to high-quality lubrication and timely replacement of its carbon brushes and bearings.

Repair - how to remove and connect the grinder button Interskol

The following diagram will help you understand the structure of the angle grinder button:

- Specifically, the start button is located at position 41, which is built into the body (position 47).

- The start button is supplied with voltage from the power cable (pos. 53).

- To control the start button (pos. 41), the angle grinder

is equipped with a lever (pos. 46). - Also connected to it are electric brushes (pos. 55) and special brush holders (pos. 44).

- The rotor (pos. 31) and stator (pos. 42) also go into the electronic part of the angle grinder, where the power button goes.

To repair the start button of an angle grinder Interskol

we will need:

- Two screwdrivers – Phillips and flathead;

- New power button.

Let's move on to removing the angle grinder button:

- Using a Phillips screwdriver, unscrew the screws on both sides of the handle and remove it;

- We remove the platform for adjusting the speed, using a flat screwdriver to pry up its latches;

- Using a Phillips screwdriver, disconnect the contacts of the power cord from the power button, having previously removed the clamp;

- We disconnect the four wires from the start button that go from the motor and capacitor to its contacts;

- We remove the broken button from the case.

To make sure that the contacts in it have burned out, just remove the collapsible cover.

Next we install a new switch:

- We connect the removed motor and capacitor wiring back to the button contacts - they should be placed in the same sequence as on the old button;

- We insert the button back into the body;

- We fix the speed controller pad back;

- We screw the contacts of the power cord and the clamp;

- We check the operation of the angle grinder at idle speed;

- Screw the handle cover with self-tapping screws.

- The grinder is assembled, and the button works properly.

READ Ushm Enkor With Speed Adjustment

annotation

Replacing the Makita grinder button

Typical replacement of a button on a Makita angle grinder

Repair

Any power tool breaks down sooner or later. Interskol UShM-125/1100E is no exception. You can repair this device yourself.

All breakdowns of grinders are divided into mechanical and electrical.

To successfully and quickly troubleshoot problems you will need:

- instructions, which contain a detailed algorithm for disassembling and assembling the Interskol structure UShM-125/1100E;

- product diagram;

- open-end wrenches, hammer, vice, press. These tools are used in troubleshooting mechanical problems;

- IK-2 tester for detecting short-circuited turns (used for electrical breakdowns of angle grinders);

- lubricant, washing liquid, wipes (auxiliary materials).

Before starting work, ensure high-quality lighting of the workplace.

Guided by step-by-step instructions and a visual diagram, you can successfully repair the tool yourself.

How to repair an angle grinder gearbox?

Most gearbox malfunctions are detected by ear. Noise, unusual sounds, vibrations and beating of the tool in the hand, excessive heating - these are signs of a malfunction of this part.

READ How to Disassemble the Starter on a Trimmer

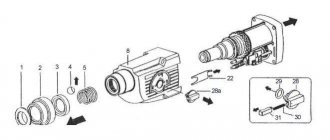

To repair the gearboxes of angle grinders, you need to know the procedure for disassembling this unit. For 125 angle grinders it is as follows:

- Unscrew the four screws, remove the locking washer and the gearbox cover.

- Next you need to separate the spindle from the cover. It is better to use a press for this, but you can knock out the spindle with a hammer.

- Next we knock out the key and remove the bevel gear.

- We remove the driven gears and, after examining them for defects, replace the damaged ones.

Disassembling and repairing an Interskol 125 mm angle grinder is not a very difficult task if you approach it with sufficient knowledge and the necessary tools.

In households and in industrial production, there is often a need to cut and grind metal, stone or other products made from hard materials. Interskol angle grinder UShM-125/1100E.

How to fix it?

First, you need to disassemble the angle grinder and remove the faulty stator from the housing. You can also check its functionality without removing it from the case.

But such a procedure is only possible in a specialized workshop. At home, for such a check, you can use a special device for monitoring short-circuited turns IR-2. It is intended to detect breaks or short circuits in the stator windings, which does not need to be removed from the housing for this purpose. A burnt stator needs to be rewinded or replaced.

How to rewind the stator?

If it is not possible to purchase a new stator, then you can repair the old one by carrying out repair measures consisting of covering the stator with a new winding.

Sequencing:

- from one edge you need to cut the old winding;

- count the turns and determine in which direction the winding is made;

- measure the diameter of the wire;

- calculate the percentage of filling of the core grooves;

- after removing the damaged winding, it is necessary to check the insulation and clean the grooves, wind the required number of turns;

- put an insulating wire on the ends of the windings;

- solder the ends of the windings.

When rewinding the stator, it is important to impregnate the new windings using alternating current. After impregnation, traces of impregnation must be cleaned, both inside the stator and outside, on its body. During operation, it is necessary to check from time to time whether the rotor moves freely inside the stator.

Rotor failures

There are several reasons causing malfunctions:

- carbon brush wear;

- power outages and short circuits;

- wear of the armature commutator lamellas;

- destruction or jamming of the rotor bearings.

Troubleshooting a rotor malfunction requires experience. It is best to purchase a new tool or have your angle grinder repaired at a specialized service center. If the work is done on your own, then it is very important to have the necessary material and follow the procedure:

- unscrew the nut and key securing the rotor drive bevel gear (11);

- the gear is removed from the rotor shaft (8);

- the rotor is removed from the gearbox housing (19);

- Using a special puller or improvised means (a vice, steel strips, a hammer), the bearings (9) are removed from it.

Repair of an angle grinder: diagnosis of breakdown, ways to solve the problem

Repairing an angle grinder with your own hands is a completely solvable task. The main thing is not to rush, understand the design, remember all the circumstances under which it broke, determine what could have worn out during operation, make diagnostics and begin repairing it.

Bulgarian and its operation

An angle grinder is called an angle grinder. The name of the instrument is due to the fact that it was produced in Plovdiv. It is intended for performing work on grinding or trimming hard material:

Does a good job of sharpening tools.

A grinder is a very necessary tool these days, so almost everyone has one.

There are grinding machines of different power: from 500 W to 2500, depending on the thickness of the wheel - from 115 mm to 230 mm. The most popular ones in use are angle grinders with a power of 1.2 W, and the most used disc is 125 mm thick.

Every year the choice for this construction power tool becomes wider, but the operating rules remain almost unchanged. And even if you always adhere to them, sooner or later malfunctions arise in the mechanism, which you can try to fix yourself by collecting everything you need to repair the angle grinder.

Angle grinder device

Any grinder consists of the following parts:

- rotor - part of the electric motor that rotates during operation and is controlled in speed, also called an armature;

- collector - the place on the rotor where the control winding wires are located;

- brushes - parts that serve as current conductors from the cable to the commutator winding;

- gearbox - a mechanism that acts as a drive from a rotating rotor to a spinning disk, consists of a spindle, a bearing, and two gears (a large gear and a shaft gear);

- stator – part of the electric motor in which the rotor operates;

- grinder cooling impeller;

- start button;

- electrically driven network cable;

- protection casing;

- grinder body;

- additional handle.

All these details can be divided into two parts:

- electrical;

- mechanical.

How to disassemble an angle grinder

How to disassemble an angle grinder? It's not such a complicated process. This does not require special knowledge, but everything must be done carefully and with caution. Every owner needs to know how to disassemble any working tool, because periodically it needs internal cleaning from dirt and dust, and its service life depends on this.

Nowadays on the market you can choose different types of grinders, which differ in operating parameters, size, and quality. Manufacturers are also different. Whatever model of grinding machine you buy, they all have the same model for assembling parts.

Disassembling the angle grinder will require few tools; you just need a regular screwdriver or a reversible one with a ratchet mechanism.

Having prepared the screwdriver, you can start disassembling:

- We unscrew the screws from the body and remove one side of the product.

- Remove the nut that holds the disk in place and unscrew the bolts securing the protective casing.

- Remove the brushes.

- Disconnect the wires from the engine.

- We unscrew the bolts that secure the gearbox inside and very carefully remove it; the rotor is also removed with it.

- We unscrew the bolts that hold the stator and remove it.

- We assemble the angle grinder back, put everything in place one by one in reverse order and screw it on.

When disassembling an angle grinder, it is important to remember the order in which parts are removed in order to assemble it correctly.

Typical minor damage

In the event of a malfunction, it is first necessary to eliminate elementary breakdowns:

- The grinder does not turn on. The angle grinder suddenly became faulty - it stopped turning on. In this case, you need to check the serviceability of the socket, then the plug and the power cord; perhaps the drive simply does not work due to the fact that no current flows into the product.

- The cable and plug are intact, but the drive does not work. You need to check the start button. It is easier to repair an angle grinder switch by purchasing a new button and replacing it. Since it is rarely repairable - mainly, the plastic switch rod inside breaks. If you want to experiment, you can disassemble it, numbering the contacts, and put everything back in its place so that after assembly there is no short circuit.

- The above parts are unharmed, but the angle grinder does not want to work - which means it’s time to check the brushes. Perhaps it's time to change them in the grinder. Brushes constantly heat up from work, so they wear out quickly and need to be replaced more often than other parts, and in pairs.

Major faults

Having ruled out all minor damage, you need to figure out why the tool does not want to turn on and how to repair it. Most likely, the malfunctions are serious and require additional knowledge. This happens if:

- the body is deformed;

- one of the bearings is jammed;

- the armature or stator does not work;

- the gear teeth of the gearbox are broken or worn out;

- the collector has failed;

- The control electronics sensor shows no signs of life.

If it is determined that the malfunction has occurred in the mechanical part of the angle grinder, then you need to pay attention to the condition of the large gear located on the shaft and the bushings. If the teeth are partially worn out or the shafts become wobbly, they must be replaced immediately.

The most common breakdowns

Grinder malfunctions happen quite often. Everyone who works with this tool knows about this. What goes wrong most often?

The spindle lock button is broken

Just one awkward press on the spindle lock button while the disk is rotating leads to its breakdown. Sometimes it can be broken if it is used to remove a jammed disk. To prevent this from happening, you need to use an open-end wrench inserted into special holes near the place where the disk is attached.

Broken gear teeth

It mainly occurs when jamming occurs. If you hear a rumble in the gearbox, this is a sign of just such a malfunction. When more than one tooth of a gear is broken, the grinder will not be able to cut the required material.

In order for the tool to continue working, it is necessary to change the gears, all of them, and even the bevel wheel. Before going to the store for spare parts, remember the manufacturer, model and power of the product.

The electric motor does not work

This type of breakdown occurs with angle grinders that work in places where there is a lot of dust, and when they are given a rest, they are left on the ground. Dust that gets inside spoils the winding. Large loads, especially for a small power angle grinder, result in motor failure.

If the grinder is used for cutting materials that create a lot of dust, then it is recommended to cover the ventilation holes with something.

Bearing fell out

The weakest link, and not only among grinders, are the bearings. High rotation speeds quickly wear out the mechanism. The good news is that changing the bearing is easy. Replacing a worn out bearing on an angle grinder must be done on time to avoid a breakdown that cannot be fixed.

Stator fault

This breakdown is easy to determine when the angle grinder is turned on, but the disk speed is too intense and differs from normal operation - this means that there is a turn short circuit in the stator on the winding.

Stator failure is considered the most serious; special skills are required to eliminate it.

When you have doubts about your abilities, it is better to turn to professionals so that you don’t have to buy a new tool later.

If the decision to repair it yourself is made, it begins with cutting off the frontal parts of the winding, all remnants are removed. The next step is to make a new winding according to the template. It should be identical in the number of turns, with the same density and from wire of the same thickness as the previous one.

Gearbox

Angler grinders with power less than 1100 W are usually equipped with spur gears. They are located on the stator. Grinders with higher power have helical gears. Each of the options has a cone-shaped shape; the gearbox rod of the angle grinder intersects with the stator shaft at an angle.

Repair of an angle grinder gearbox mainly consists of replacing gears. If a disc gear breaks, it is difficult to replace it because it is very firmly fixed. It is easy to disassemble the gearbox:

- you need to unscrew the nut on its side;

- carefully take the rotor housing in a vice and knock out the gearbox housing with light blows;

- change the position of the clamped rotor and knock out the bearing through a wooden board;

- Unscrew the gear from the shaft.

That's it - the gearbox is disassembled.

Speed controller

Not all models of angle grinders have a speed controller. When an angle grinder is used for cutting, it is, in principle, not needed, but if grinding is carried out, it is simply necessary. If it suddenly stops working, then most likely the board has burned out, which needs to be removed and bought the same one at a power tools store for further replacement.

Repairing an angle grinder yourself is not always possible. If suddenly something does not work out or everything is not clear, it is better to contact the service center.

Characteristic symptoms of malfunctions

Before it completely breaks down, the angle grinder gives signals about the beginning of problems.

Pay attention to the work of your assistant: you should be wary if:

- the brushes began to spark excessively;

- The grinder gets hot during operation;

- the motor hums inside the housing when the tool is turned on;

- body vibration has become significantly greater during work;

- the grinder gearbox is cracking inside;

- the sound of bearings squeaking when spinning up or periodic wedging is heard when the rotor shaft rotates;

- The angle grinder is smoking, or there is an uncharacteristic smell of burning coming from it.

In order not to buy a new grinder, you need to be careful about the operation of the tool. In case of any deviations from the usual operation, begin troubleshooting, determine the cause and repair the power tool.

Prevention of breakage of an angle grinder

The service life of a grinding machine directly depends on the owner’s care for it. Each tool needs good care, then it will work properly for a long time.

Any angle grinder will get warm during operation, but in order to postpone angle grinder repair for a long time, you must adhere to some rules in work:

- Do not overload the tool to avoid overheating and smoke.

- Do not forcefully press on it while working.

- Clean and lubricate the necessary parts inside the housing in a timely manner.

- If abnormal operation is noticeable, stop operation and inspect for problems.

- Replace wearing parts in a timely manner.

- If the grinder smokes, immediately stop working and do not turn it on again.

- Do not use the tool when processing wood-type materials.

- Hold the grinder firmly during operation so as not to drop or damage it.

By adhering to the listed simple recommendations and rules when working with a tool called an angle grinder, you can extend its service life longer than the warranty period.

Source: https://pro-instrument.com/ruchnoj/remont-bolgarki.html

What other breakdowns happen?

Some common electrical breakdowns are:

1. Breakage of carbon brushes. You can also deal with this problem on your own. Procedure:

- The design of the angle grinder "Interskol" UShM-125/1100E is designed in such a way that the carbon brushes are located in special brush holders. You can get to them after removing the back cover in the stator housing;

- Unscrew the screws that secure the brush holder;

- Determine the wear level of carbon brushes. This can be done after measuring their remaining length. If the brush is in working condition, its length should be at least 0.5 cm.

2. Damage to the power cable. This malfunction mainly occurs at the points where the wire enters the tool and into the plug. Twists in these cases will not solve the problem. A faulty electrical cable must be replaced.

The grinder does not turn on - the simplest DIY power tool repair

Many people are familiar with the situation when a favorite instrument stops working

for no apparent reason.

And if the grinder does not turn on, then, often, the prerequisite for this is a slight breakdown, which can be quickly removed without any special knowledge or tools.

Next, let’s look at common methods for diagnosing and repairing power tools using an angle grinder as an example. The initial state is that the grinder does not start when the power button is pressed. To carry out the work, we will need a multimeter with a ringing function and a screwdriver. The first thing you need to check is the wire, or more precisely, the plug and the place where the wire enters the housing. We press the button and “massage” the suspicious areas. In most cases, difficulties arise in the body. If this does not help and the grinder does not work as before, move on to the next step.

Let's disassemble the body. To be sure, you can turn our tester into ringing mode and check the integrity of the wires from the plug to the entrance to the button.

Next in the electronic circuit is a button. Often the specific malfunction of this unit is the prerequisite for the fact that the grinder

won't start. In order to check this node, you need to turn it to the ON position and “ring”, as shown in the following

The next thing you should pay attention to if the angle grinder does not turn on is the brushes. In large angle grinders, the brush holders are placed outside, in our case, inside the body. We remove the brushes and inspect them. You need to make sure that the contacts on the brush itself are intact. The main aspect of the brush’s performance is its degree of wear or size. In this grinder, it was their wear that became the prerequisite for its failure. Therefore, replacing the grinder brushes will help eliminate the problem. For clarity, a comparison of new brushes and completely worn ones is shown.

If in your case all this turned out to be in good order, but the angle grinder does not work, then the last thing you can check without a special tool is the anchor. To begin with, we “ring” between the steel parts of the armature and the lamellas of the collector. If it rings, it means that there is an insulation breakdown and the armature must be replaced.

READ Which Way to Unscrew the Disc on a Grinder

Next you need to measure the resistance between the adjacent lamellas on the collector. It should be similar on all pairs. If at any point of measurement the resistance is several times higher, then we can talk about a winding break. It should be noted that such a malfunction occasionally leads to a complete stop of the motor.

If, after carrying out the above diagnostics, it was not possible to identify the malfunction and the angle grinder does not turn on, then it seems that you will have to contact a specialist.

77, total, now

Final stage

After all the necessary repairs have been carried out, the angle grinder is reassembled in the same sequence as it was disassembled. But before assembly itself, it is necessary to lubricate all mechanical components of the angle grinder.

For this purpose, experts recommend domestically produced lubricants. On the shelves of stores selling household electrical appliances you can find lubricants from foreign manufacturers, but they are much more expensive, although their quality is no better than domestic ones. Among the huge selection of lubricants, you should choose those products that have high adhesion rates (they are recommended for gearboxes of all angle grinders). Such lubricants adhere better to the surface.