Recently, a screwdriver has become an indispensable device for repairing removable structures and helps to quickly cope with small repair work. Considering that this is a non-stationary device, the operator often has to deal with the problem of rapid discharge. The material in this article will introduce the reader to ways to charge a battery without a native stationary charger.

When is it necessary?

There are situations when the screwdriver charger is not available. For example, it may fail, which may cause the operation to stop. In addition, the charger may be lost. The third reason is the elementary burnout and wear of the charger, as well as the unbending of the terminals in the battery itself, which causes the contact to come off. To fix the problem, you have to look for suitable charging options that will be compatible with the existing screwdriver model. In this case, it is preferable to buy the correct charger, which will facilitate safe operation and fully charge the tool’s battery.

Main classification

Experts distinguish the following categories of screwdrivers:

- domestic;

- semi-professional;

- professional.

Since the battery is designed for a specific job and load, each type of tool requires an appropriate charger. The operating time of the tool depends on the battery power. Experts distinguish the following types of batteries:

Table of characteristics of batteries for a screwdriver.

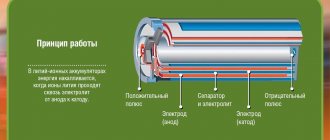

- Li-Ion;

- Ni-Cd;

- Ni-MH.

Type 2 batteries, unlike the others, are compact and have greater energy capacity. With proper use, the tool can be charged more than 1000 times. The screwdriver battery must be charged if the following rules are observed:

- Battery is fully charged. Otherwise, the energy capacity and operating life of the tool will be reduced.

- Toxicity of nickel-cadmium battery (do not drop).

- The nickel-metal hydride battery is developed using new technology and is environmentally friendly for humans. It can be charged frequently. If the tool is not in use, then the battery is stored in a charged state. If the screwdriver is left idle for a long time, the battery is completely discharged.

- The lithium-ion device does not have a memory effect. The battery has a high energy capacity. Due to exposure to the negative effects of low temperatures, the lithium-ion battery is not used in winter.

Return to contents

How can I charge it?

If the required charger is not available, there are three ways to solve the problem:

- use the car charger;

- buy a standard universal charger;

- Convert an electric tool to be powered by an external battery.

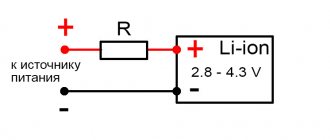

If you decide to use a car charger, you need to take into account that screwdriver batteries have their own characteristics, they are different from lead car batteries. Only a charger that is equipped with electronics with current and voltage regulation can be suitable. Here you will have to choose the charging current, because the desired value may simply not fit into the operating range. This in turn may force the user to limit the current through a ballast.

A universal device is purchased if, in addition to the screwdriver itself, there are battery-powered devices in the house. The advantage of such devices is a lot of settings, through which the master can determine the desired charging mode for the screwdriver and choose the right option for the screwdriver battery. If the existing screwdriver is already old, purchasing an external power source is impractical and simply costly. When choosing a rectifier for car batteries, it is important to pay attention to the polarity. Therefore, it is worth keeping a tester on hand. Yes, and you need to charge the screwdriver under constant supervision.

You can buy a direct current charger that will match the required parameters of the screwdriver battery. To do this, when purchasing, pay attention to three factors: charging current, power, and capacity. It is quite possible that you will have to upgrade the device by equipping special protection, for which you purchase a 10-amp fuse, which is connected to the electrical network. As for the wire, you will have to purchase an option with a larger cross-section (compared to conventional wiring).

How to charge without native charger?

If you choose a solution to charge the device with a car charger, first you need to set the device to the minimum value. The battery is removed and its polarity is determined (the “plus” and “minus” are found). After this, the charger terminals are directly connected to it. If this is not possible, the unit is improved, for which plates or paper clips are used. Charging is turned on for 15-20 minutes, and as soon as the battery becomes warm, the charger is turned off. Usually in this case a short charging time is sufficient. As for the charging current, it is selected between 0.5 and 0.1 depending on the capacity of the battery itself in ampere/hours.

An 18-volt battery with a capacity of 2 A/h requires a charger with a charging current of 18 volts and a power of 200 mA per hour. It is preferable that the charger performance be approximately 8 times less. To supply current, you need to use special alligator clips, hanging them on the current-dispersing plates of the battery connector. It is important whether the device itself has a charging socket.

If the charger is built into the battery, it can be charged using an adapter that lowers the voltage. In this case, you can pick up a universal charger in the store. If not, you will have to repair the existing charger or look for an analog device. It is important to use a charger with adjustable current, charging the battery for several hours.

In order for the contact to be sufficient, it is preferable to secure the crocodiles using metal wires. The voltage must match the battery device. Such a battery should only be charged when there is residual charge. If the device parameters do not match, but have slight differences, short-term charging is possible in some cases. However, it usually leads to rapid battery failure.

How long does it take to charge a screwdriver battery?

Each power tool is always accompanied by an instruction manual, which specifies exactly how long to charge the screwdriver battery. As already mentioned, the vast majority of modern chargers have charge level indicators, which makes them much easier to use. When the indicator lights up green or another color, indicating that the screwdriver’s battery charging time is coming to an end, you need to disconnect the battery in time.

The average time it takes for the battery to be fully charged is 7 hours. And if the battery just needs to be recharged, it can be left on charge for 30 minutes. Although, in the case of Ni Cd batteries that have a “memory effect”, frequent and short recharging is not recommended.

There are several types of chargers for screwdrivers, depending on their scope of application. An ordinary charger is usually included in the package of household power tools. The battery charging time with its help varies from three to seven hours. There are also powerful pulse-type chargers that come with professional tools. How long does it take to charge a screwdriver battery with such a device? “Impulse” devices can fully charge the battery within an hour, which is their undeniable advantage. However, the cost of such a tool is, of course, much higher.

What do you need to know?

When choosing one of the options that replaces the screwdriver charger, you need to remember: the safety of the process will depend on the correct connection of the devices. In addition, it is important to ensure that the charging mode matches the technical characteristics of the battery itself. Regardless of which charger option is chosen, you need to understand: temporary methods can save the situation several times. But it is undesirable to constantly use them, since only original chargers provide the required voltage and current values.

You cannot use chargers with a USB port from a laptop - they are not designed for this. If the battery does not charge, you can try to overclock the battery. To do this, the unit is disassembled and the cause of the malfunction is identified. Afterwards the block is charged first with a larger and then with a smaller current. This allows you to bring it back to life if there is still electrolyte left inside.

To learn how to charge a battery using a screwdriver without a charger, see the following video.

Anything can happen, I got behind the wheel, turned the key to start, and instead of a cheerful clack-clack of the retractor and silence, the battery was dead(

Buying a new battery is of course an option, but you need to go here and now. The charger is broken, is lying somewhere far away, or is not even in the garage.

What should I do other than light a cigarette or use the “push” method? Moreover, there is no one to light a cigarette (and you need to look for crocodiles), and not all engines will be digested from the pusher, because the timing belt may be cut or the chain may jump... The solution is simple, take a screwdriver and. and watch the video!

Who doesn't have a video:

With a screwdriver (for example, with Bosch, as in the photo)

charger just up to 14.4 V

True, the charging current is too small - 0.4A

but it is also quite enough for the battery to gain starting capacity in half an hour or an hour, which will allow you to start a working car. You will have 2-3 attempts to start it up, so the chances are high. And after starting, the battery can be recharged during the trip from the generator!

I have two chargers, I don’t mind soldering wires to one

I attach it to the battery without hesitation, and the first thing I come across are clothespins “stolen” from my wife’s clothesline))))

Then I waited half an hour, put it on the car, started it the second time and went about my business! After half an hour or an hour of driving, the battery will be fully charged for further use (it will start in the morning or every other day)

Tags: extreme winding

Comments 80

Thanks for the idea, at my dacha I don’t have anything other than a screwdriver and 220v) It was this idea that helped me

Not a single literate phrase! For example: “but not all engines will be digested from the pusher, because the timing belt may be cut off or the chain may jump,” what nonsense. From the pushrod we rotate the engine using the same pulley as the starter, only through the clutch disc. What are we talking about? If you treat technology this way, then tomorrow you will have to take a gearbox from the same drill and screw a wheel onto it in order to urgently get somewhere. Well, there must be boundaries even in rationalization.

From the pusher. Moreover, with the first one, with a sharp release of the clutch, you can do business with this sharp impulse, this is not a joke. The starter starts to turn smoothly, but the transmission starts to turn sharply.

good luck with starting from the pushrod)

You need to start it not from the first, but from the third and higher gears and there will be no impulses, the starter cannot turn smoothly, it has one rotation speed, but with the help of the clutch you can smoothly spin the engine and there is no need for fairy tales about the timing belt and chain . It’s better to listen to a competent person and draw conclusions, why snap back. If you don’t want to listen, then teach me the materiel. And if you’re lazy, just say so, it’s not difficult for me to delete my entry.

Can I ask a question?) If I’m standing with my face on a gazelle uphill, which gear should I start with the push?

Where's your screwdriver?

You need to start it not from the first, but from the third and higher gears and there will be no impulses, the starter cannot turn smoothly, it has one rotation speed, but with the help of the clutch you can smoothly spin the engine and there is no need for fairy tales about the timing belt and chain . It’s better to listen to a competent person and draw conclusions, why snap back. If you don’t want to listen, then teach me the materiel. And if you’re lazy, just say so, it’s not difficult for me to delete my entry.

Great post! And if it’s easier for you to push, then go ahead and join the team...

I once charged it using a laptop charger, 19V, 4A. It charged normally.

The meaning of perversion is not clear when there is a 220V outlet nearby. This way you can charge the battery using a normal charger...

A representative of the BOSCH company, seeing how the Russian rural genius was being perverted over their instrument, cried bitterly and resigned. Russia is invincible!

The Mercedes also went nuts

I charge via bluetooth...

“After half an hour or an hour of driving, the battery will be fully charged for further use (it will start in the morning or every other day)” - the author is a storyteller. Don't believe such nonsense. On the way from Minsk to Moscow, in a discharged battery, the density increased by only 2 hundred parts. Only a stationary charger will help.

Gena will never fully charge the battery. Charger only!

A working gene charges completely perfectly

Up to par, never completely

What nonsense about half an hour or an hour for a full charge? Will you charge it with 1C current? That is, you will charge 60An with a current of 60A?

Wash the battery, there is a constant discharge through this dirt from the top. For clarity, take a voltmeter and one contact to +, and move the second one along this dirt from above, the voltage will show.

With such an attitude towards the battery (I think the same applies to the car), it is very expected that this happened.

The car is German too, Shurik. Are you a FAN of Hitler?

So this is all trophy)))) Look at my other cars, there will be no questions

Then I just looked at the history of the car)

No matter how much masturbation people engage in, they won’t even replace the battery with a new one.

Great idea. In a critical situation it can be a great help.

And once I thought of warming up the dead battery on the stove while I was having dinner instead of charging it. He had enough for 1 start)

so as not to masturbate with soldering and clothespins, not to wait for half an hour guys - one call to any taxi and in 5-10 minutes a cheerful Vasya will fly to you with wires for a freebie, light a cigarette. issue price - 200 rubles! Well, whoever doesn’t have two hundred square meters in his pocket is no longer a man))

A taxi will take an hour and a half to get to my collective farm + 2000-3000 rubles. Since when does a man know if he has change in his pocket?

Right! A man is defined by his actions and his pussy.

I started it a couple of times this way, but I always keep an eye on the battery. www.drive2.ru/l/5021176/ Yes, expensive. But they gave it to me. I often use it as a compressor.

By the way, the battery must be washed with water, preferably with fairy water. Don't you feel disgusted when you're such an asshole? Meanwhile, the film of acids and salts very noticeably discharges the battery, and can drain it in almost a couple of days in particularly advanced cases...

Not ferri, but baking soda or caustic soda to start deactivating the acid.

It washes off perfectly with plain water. And fairy (lye, by the way), also perfectly washes away the greasy dirt that is always in the engine compartment.

And soda copes well with dirt.))

I believe. I myself actively use soda ash (as the strongest, quickly purchased alkali. It’s strange that it has not yet been banned by anti-terrorism fighters)

it’s just that the vast majority of people, with a 98% probability, don’t have any soda, but fairies (or analogues) are guaranteed to have them

I keep baking soda especially for these purposes. By the way, this is the most natural product for lovers of healthy lifestyle.))

By the way, the danger of damage to the timing belt when starting from a pusher is another “urban legend”: from the point of view of the timing belt, it is absolutely “below the belt” by what causes the crankshaft to rotate: the starter or the gearbox gears

what does shurik have to do with it? The title of the topic is completely wrong. The topic should have been called “charging the car battery using improvised means.”

An attempt to light a cigarette from a Shurik battery is guaranteed to damage it.

and so, a charger “made of shit and sticks”: we assemble a series circuit “mains - ballast (for example, a heater of a couple of kW) - diode - car battery.” You just need to disconnect the car battery from the car, because... it will be under mains voltage... The charging current is small, a couple of Amps. But in a situation where “it’s as good as it should be,” it’s quite suitable. Well, remember about electrical safety. It is better to remove the battery from the car, and place it on an insulating base (for example, a wooden stool), and not touch it until disconnected from the network, because the battery is not at all designed for the network voltage on it

Ahh, nonsense! My alternator belt snapped on the road; I didn’t have a spare one. It was about 25 km to the store, I would have gotten there easily if I hadn’t had the urge to need it, well, naturally I stopped and turned it off out of habit) So, I tied a battery from a Shurik Hitachi parallel to the battery. I waited 10 minutes and the car started! And I even drove about 7 km to the store. This is the power of a hitachi assembled in China!

I had something similar: I was carrying computer equipment. Out of charge. I thought I could reach the base on a battery. Didn't make it. I pulled the batteries out of the UPS, started it from the pusher, and drove 150 kilometers.

Is it possible to charge a car battery using a screwdriver?

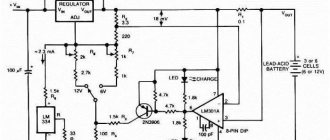

First, it’s worth considering how a standard car battery charger works. This is a converter that recharges the battery from an external energy source. The simplest design consists of two parts, one of them is a diode bridge. It converts alternating current into pulsating current. The second part is a 220 Volt step-down transformer, which reduces the current resistance of the electrical network.

Charger for car battery

The voltage entering the charger is converted from alternating to direct - 15 V. When the charge level drops, the density of the electrolyte decreases. The color of the indicator on the lid also indicates a lack of power. Theoretically, you can charge the battery using a charger from a screwdriver. But you cannot be sure that the charger will definitely fit and that the built-in protection will not work.

Charger for screwdriver

Specialized chargers are distinguished by the presence of adjustment of current and voltage. Therefore, their use is more effective and safe. In the absence of specialized equipment, it is advisable to charge the battery with a lower current, albeit for a longer time.

The influence of different types of chargers on charging time

There are 2 main types of charging for screwdrivers:

- Pulse;

- Non-pulse (regular).

When using a pulse charger, the screwdriver restores its energy capacity within an hour, and there is no need to keep the device connected longer. If you have a regular charger, then approximately you will need from 3 to 7 hours for the entire charging process.

Many people wonder: which one is better? The answer depends on the model of screwdriver. Pulse chargers are designed for professional tools and devices with high power. In addition, it will not hurt to look at the instructions to check the compatibility of your electrical network with the rated power of the screwdriver. If the network voltage is higher than required, do not forget to purchase an adapter or small-caliber transformer to compensate for the discrepancy. Otherwise, the device may burn out, a short circuit will occur, and if there is an internal fuse, it simply will not charge.

If you still have doubts about how to charge the screwdriver battery correctly, it is best to look for information on the manufacturer’s website page, where you will always find all the necessary data, including technical specifications, operating instructions and troubleshooting tips.

What batteries can be charged this way?

The average charger for a cordless drill has 12-20 V. But the charging current is about 0.4 A, and for fast charging you need 20-30 A. However, it is better not to subject the battery to such loads. It can get damaged and quickly fail, so -0.4 A is quite enough.

The voltage at the charger terminals should be 10 percent higher than that available at the battery contacts. It is necessary to disable the protection system that analyzes charging time and temperature. Then the device works like a regular current source. You should be prepared that due to the difference in current strength, the charger may burn out.

Laptop charger and car lamp

If a motorist has a laptop, then he can use its power supply to “boost” a dead car battery. In addition, you will need a car headlight bulb H4 (100 W/12 V). The laptop charger parameters are 19 Volts, 4.74 Amps.

It is recommended to use elements for recharging the starter battery in the following order:

- First, connect the “plus” charger to the positive contact of the battery.

- Connect the “minus” charge from the laptop through the car lamp to the negative pole of the starter battery.

This technology allows you to charge the battery in about 9 hours. In this case, a working car will start even at negative ambient temperatures.

It is important to consider that the lamp here solves the problem of setting a specific current strength against the background of a stable voltage of about 20 Volts. A more powerful lamp will produce a higher current.

If you do not use a light source, the laptop's power supply may simply burn out. This is due to the fact that the battery has minimal internal resistance against the background of increasing charging current.

For which batteries is charging from a screwdriver suitable?

Like standard chargers for motorists, it is compatible with acid batteries. The standard parameters for most chargers from cordless drills are a voltage of about 14.5 V. A current of 2.5 to 2.7 A. For comparison, specialized chargers for car batteries have a current twice as high - 5 A.

You need to make sure that the battery is really discharged. It is easy to check the electrolyte level by opening the filler plugs. In normal condition, it covers the plates; the presence of foreign impurities is unacceptable. Also, there should be no cracks or punctures on the body. If a crack has formed on the case, then the electrolyte has already leaked out, and it is useless to charge the damaged battery.

How to bypass protection

The socket to which the screwdriver battery is connected contains four terminals. Two of them are negative and positive. The other two terminals go to the relay for protection against short circuits, overheating, and other things. To bypass the protection and not have to deal with the electrical circuit, you can use an unnecessary battery from a drill.

Screwdriver battery disassembled

The screwdriver battery is removed from the housing. The small white plastic box will say that it is a thermal protector. This element, along with the black wires, must be desoldered and soldered to the terminals of the charger. Now the white and black wires are soldered to the protection, observing the polarity.

When connecting a battery or other devices, the indicator should show that charging is working normally. If you just turn on the charger, it will blink, indicating that you need to add a battery. That is, the blinking will disappear and the red light will remain on. When the battery or other device is fully charged, the green light should light up.

An example of a diagram for connecting a screwdriver charging to a car battery

To charge a car battery, a wire is brought out from the side of the case. You need to connect the terminal blocks, and then connect the wire to the power supply. Otherwise, the protection system will work and charging will not start. The positive and negative wires are connected to the corresponding terminals of the car battery. If the charger is working properly, it should not overheat or melt.

Connecting terminals to charging a screwdriver

Checking the battery condition with a multimeter

A tool like STHT0-77364 helps you find faults in various electrical parts, including screwdriver batteries. To achieve reliability, it is better to use it in conjunction with other testers. This allows you to compare the indicators and calculate the error.

Note : Before you start measuring, you need to make sure that the multimeter itself is working. To do this, you just need to connect it to an outlet along with another similar device and compare the readings.

Tester

A device that allows you to diagnose element malfunctions yourself.

The main types of such devices:

- Test lamp (continuity) - equipped with two wires and makes it possible to determine breaks in the wiring of an electrical appliance.

- Pointer - a device with a digital scale and arrow. Such models are not very convenient to use. So that the numbers are clearly visible, the measurement scale should be the size of half a page. In addition, such testers often have confusing graduations and can only be used in a horizontal position.

Tip : If you need an inexpensive multimeter, the 94W101 will do the trick.

- Digital - with LCD display. The scale shows absolute values only. The switch, as in the previous case, is manual. The tester is not suitable for AC current.

- Automatic - as the name implies, this type of tester does not require manually changing the position of the regulator. It is enough to indicate the required value using a special button.

Instructions: Do-it-yourself screwdriver repair: 2 types of faults

Multimeter

An excellent tool for checking the condition of the battery.

Helps determine:

- voltage and current - to ensure the reliability of the indicators, you need to take measurements in turn with an ammeter;

- resistance - for everything to be accurate, you need to take a dial multimeter and check it with the tester’s readings.

Interesting: 94W102 has a HOLD function. It allows you to record measurements.

In order for the battery to “live” longer, you need to keep in mind its features, namely the nuances of storage and charging. If you do everything according to the rules, you won’t need to change the battery for a long time.

How to charge a car battery by charging a screwdriver

This method is suitable for those who know how to make solders for boards and are ready to remake the charger. Below is an example of disassembling the Makita DC 1440 charger.

First, check the voltage on an uncharged battery. You also need to remove the plastic cover.

Then unsolder the drill battery stand. In this case, 4 pins will remain in place of the stand.

We need to see where the pins went. It is convenient to use a ready-made diagram, but it is difficult to find it on the Internet. Therefore, you will have to figure it out on your own. When viewed from the corner, the first contact has a positive charge. The second is a thermal breaker, the third is a negative charge, and the fourth is a thermistor. The thermistor is shorted to ground.

First, instead of a thermistor, a regular resistor is connected.

The second and third legs from the corner need to be soldered together. This is a thermal breaker and a minus.

You need to set the voltage. By default, the zener diode is set to 27 Volts, which is the output.

It is necessary to connect two zener diodes in series at 3.9 and 9 Volts. The output will be 14.65 V. To make charging suitable for different batteries, you need to add a protection circuit. In this case, it is necessary to bypass the native scheme.

Next, the charger is plugged into the outlet. When voltage appears in the network, you will need to look at the output voltage. It should be 14.5 Volts, this value is enough to charge a car battery.

The device is connected to a load, which can be a 21 Watt light bulb or approximately 2 A.

The light should light up and the voltage will be displayed on the multimeter screen. If it is a little less, for example, 14.36 V, this is not a problem. The charger will still work.

For more information about this method, watch the video:

A simple way to recharge the battery using a screwdriver

The described method allows you to charge the battery without modifying the charger. But weak currents will be used, designed for a low-power cordless drill. Therefore, it will take longer to gain starting power than using the previously described method. To start charging, the charger is connected to the mains. It is connected to the battery using terminals, while observing the polarity.

When connected, it may flash green and red, this indicates that the battery is faulty. If the process is proceeding normally, the charger operation indicator light should gradually turn red.

More detailed video:

| SHARE: |

Safety and Precautions

When using any method of charging the device, you must be careful and follow the following precautions:

- Watch the process. When the battery is filled with energy, the procedure is stopped. Otherwise, overfilling the battery may lead to boiling of its electrical elements. With a sharp increase in temperature, a small spark will cause the entire structure to explode.

- All parts must be correctly connected to the circuit. During assembly, strict records of the technical parameters of the device are kept, ensuring the safety of the procedure and observing polarity. Self-made chargers can completely damage the battery, eliminating the possibility of its restoration in the future.

- The battery is charged in a short period of time with small differences in the characteristics of the modules (10-12 Volts)