Jack: what is it, how it works

To lift a small load in a small space, you should use special equipment. The optimal solution is a low tablet, that is, a jack. Particularly popular are hydraulic tools, which are distinguished not only by reliability, but also by performance characteristics.

Jack

The operating principle of this device is extremely simple. The main ones are the vessels that power the structure. The equipment contains a pressure pump. Thanks to this element, the working fluid can be pumped from the reserve tank. Due to this, the pressure increases, which helps to raise the piston.

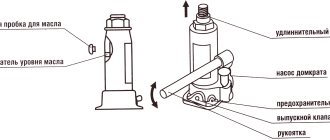

To understand what a good hydraulic jack is, you should familiarize yourself with the following components:

- Reserve capacity. It contains a lever system designed to pump the working fluid. This mass enters the main cylinder.

- Working cylinder. This element is equipped with a piston.

- Supports with a large surface. Due to this, the mechanical pressure that occurs when lifting a load in a small space is compensated. Therefore, before starting action, it is necessary to study the size of the support.

Note!

A jack is a device whose main parameter is lifting capacity.

When choosing equipment, you need to pay attention to the permissible pick-up height. The operating principle of this design completely depends on this parameter.

Possible breakdowns and how to repair them yourself

Over time, any equipment begins to fail and require special maintenance. The first thing you need for a hydraulic jack is periodic inspection of the mechanism and topping up the oil. Also, after a certain interval it will be necessary to wash it and completely change the oil.

The most common cause of failure of such a device is failure of oil seals and gaskets. This leads to oil leakage from the working tank. The rod may also get stuck on the reverse stroke. It can be prevented if the problem is corrected the first time an oil leak is detected. To do this, you need to drain the oil, disassemble the mechanism and replace the seals with oil seals and refill with fresh oil. When everything is ready, liquid is pumped through the assembled device.

Sometimes the rod can simply jam due to accumulated dirt or corrosion, which is why disassembling and washing the device, as well as a special anti-corrosion treatment, helps.

Repair kit for jack

Other breakdowns occur if the device was operated incorrectly, then the following may occur:

- The piston moves jerkily or slowly. This indicates that air has entered the working compartment and you need to add oil and pump it.

- Reduced pressure on the piston. Most often, the problem lies in the intake valve, which may require repair or replacement.

- Stopping the lifting piston. This phenomenon with a rolling jack is associated with a clogged filter or the fact that the oil has run out.

- The piston stops rising completely. Often the problem is the lack of liquid in the reserve tank.

Most of the damage that occurs to the jack can be repaired after disassembly. However, if the problem arose due to mechanical damage to the piston or something happened to the outer casing, then replacing the device is recommended.

Important! If the jack breaks, you need to read the instructions, which must be included with each device. It contains a diagram, the necessary information about operation and maintenance periods. It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select one that has a load capacity of several tons.

If the jack is subjected to extreme loads and is not inspected from time to time for lack of oil, then a whole series of breakdowns will not be long in coming

It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select one that has a load capacity of several tons. If the jack is subjected to extreme loads and is not inspected from time to time for lack of oil, then a whole series of breakdowns will not be long in coming.

Advantages of rolling jacks for cars:

- Compared to other types of jacks, there are models with very high load capacities.

- As a rule, such devices are equipped with reliable fixation and there is no fear of failure.

- The design is very stable and comfortable.

- A person spends little effort.

However, it should be noted that such a device has two drawbacks: the need for a flat surface, which does not always happen when there is a breakdown on the road, and oil freezing when operating at low temperatures.

In all other respects, rolling jacks are very practical. They save the effort of drivers and craftsmen. In addition, a wide variety of models allows you to choose exactly the device that is most suitable for working with a particular car or for service in a service station.

What types of jacks are there: description and characteristics

What types are they divided into?

When choosing a long or short jack, you should determine in advance the required performance characteristics. Auto repair shops require some models, and private enterprises require others. Initially, you need to determine the maximum load capacity.

When choosing a specific model, this figure should be 10-15% higher. This way you can extend the service life.

The room temperature should be checked regularly. This indicator can have a negative impact on the quality of the working fluid.

Based on these characteristics, it is possible to select the following types of hydraulic jack for the working machine:

- the rolling type is equipped with a frame on which the entire portable mechanism is located. The load can be lifted thanks to the action of a hydraulic piston on the lever system. The equipment is equipped with special wheels. When lifting a load, their displacement occurs relative to the frame, since the full load falls on it;

- drive type - bottle. This design with the working cylinder is vertical. This model is mainly distinguished by its small size. A load of up to 12 tons will be lifted by a jack;

- drive type - manual or electric. The working fluid is pumped according to the principle of a mechanical lever. To enhance the development effect or lift a large load, you should use a design that has an electric drive.

You might be interested in About wheel wrenches: description and comparison

Do-it-yourself repair of a rolling hydraulic jack

Rolling jacks have mechanical and hydraulic parts that require maintenance and repair. If for hydraulics the lack of oil is the reason for failure, then the elements of the mechanical structure are susceptible to destruction. They can be repaired, repaired, replaced or made new.

Leaks of working fluid occur through oil seals, seals, and gaskets. To repair a jack at home, you need to purchase a repair kit from a store. Disassemble and reassemble in the following sequence:

- Prepare a container to collect the oil.

- Unscrew the fasteners using a wrench or spanner.

- Remove the piston with rod and valve.

- The body and parts are checked for corrosion. If found, such areas should be cleaned. Remove dirt.

- Check the stem for bending. If it is bent, it is unlikely to be straightened.

- The bypass valve is inspected for mechanical damage. If there are any, it should be replaced. If there is no damage, the valve should be washed to eliminate contaminants that prevent the ball from closing the seat.

- Drain the old oil. Using a pump, remove all the oil.

- It is advisable to wash the housing and pump. To do this, you need to pour kerosene or gasoline inside.

- Replace rubber seals.

- Top up with fresh oil.

- Bleed to remove air bubbles.

Bleeding is used to improve the performance of the jack after it has been attempted to be repaired. The procedure is not difficult. After unscrewing the filler plug and turning the valve counterclockwise, you need to vigorously rock the lever.

The air remaining in the working chamber will be displaced by the liquid into the storage tank. Screw on the valve and replace the cap. Correctly performed actions will allow the jack to work like new.

Comparison of popular models and manufacturers

Comparison of models

When choosing the appropriate design, a compiled list will help the buyer, where all the tools and jacks from the best manufacturers are presented. There are many competitors in the global technology market, so among the best manufacturers you need to pay special attention to:

- "Bison".

- Matrix.

- STAYER.

- Autoprofi.

Zubr 43056-2 - the main advantages include a rolling hydraulic jack with a maximum load of up to 2 tons.

On a note.

The device allows you to quickly and smoothly lift a vehicle in a wide working height range from 85 to 330 mm for repair work or technical inspection.

Thanks to the design features and low pick-up point, the tool is convenient to use in inconvenient places or limited space.

Despite its light weight and compact dimensions, a high car jack is used on all passenger cars and heavier vehicles (pick-ups, minibuses, minivans). The jack up to 50t has a convenient carrying handle and a plastic case for easy transportation and storage.

Matrix 50715 is a vertical (bottle) type hydraulic jack for lifting loads weighing up to 2 tons. The safety valve protects the device from overload, preventing it from lifting more than the stated technical specifications. It protects the car jack from damage and extends its service life.

The durable cast iron body is painted with an anti-corrosion compound to prevent negative environmental influences and rust.

The rod, made of ground and polished hardened steel, ensures smooth lifting and fixation of the load at a certain height, which increases ease of use. The low weight of 3.17 kg makes it easy to manipulate the tool and facilitates storage and transportation.

STAYER 43160-6 is a 12-volt vertical bottle hydraulic jack with a maximum lifting weight of 6 tons. The compact design and low weight with a large load capacity allow the tool to be used effectively for inspection and repair of vehicles or special equipment, as well as for moving loads during repair or construction works

On a note.

The low pick-up level of 216 mm allows the device to be used in more confined spaces compared to mechanical models. The maximum lifting height of 413 mm allows for a wide range of applications, and the retractable threaded rod with a wide “heel” allows you to accurately install the tool in the desired location. The plastic case makes it easy to transport and store the jack.

Autoprofi DT-04 is a vertical hydraulic jack with a lifting capacity of up to 3 tons and a minimum pick-up height of 158 mm. The small size allows the device to be used not only for car repair and maintenance, but also in the construction or rigging industry. The bypass valve allows, if necessary, a short-term overload of 25%.

Thanks to the two-rod design of the telescopic lifting mechanism, the jack has a compact height, which makes it easy to store in the car. The wide support platform ensures a stable position of the tool and the ability to lift loads to a height of 380 mm.

You might be interested in this About Matrix jacks: torque, hydraulic - what to choose

Specialized jacks

The following tools are mainly used in car repairs:

Auto tipper

Designed for lifting a car from the side, with emphasis on the wheels opposite to the installation of the mechanism.

Repair stand

Also known as a car rack, it is a device that performs a safety function for additional support of a car raised by other devices. The support stand under the car prevents it from falling by firmly fixing it at a given height. Not intended for lifting loads

Transmission stand jack

Used for installing and dismantling a vehicle's gearbox.

This transmission option is specific and highly targeted equipment.

Yamny

An auxiliary mechanism for hanging car axles on a pit or scissor lift. Another name is ditch jack.

According to design features, they are distinguished:

- Two-stage with two pickups located at different heights. This two-level bottle-type mechanism combines a classic and low-lift jack, described below.

- With a low paw - has a minimum pick-up height, up to 20 millimeters or less. A characteristic feature is a pick-up arm protruding to the side, which hooks the load under its lower edge. Hence another name - toe jack.

- Low profile - for lifting a car with low ground clearance.

Purely conditionally, jacks can be divided into:

- Household - relatively cheap models designed for lifting light weight loads, in particular cars. These are so-called garage jacks - inexpensive mechanisms that allow you to independently repair vehicles at home, including replacing wheels. In general, we are talking about budget products.

- Professional – hydraulically reinforced structures designed for quick lifting of light and heavy loads. They are used in modern service centers, repair shops and even industrial enterprises. This includes highly specialized models.

How to choose a quality tool: what to look for when buying

Choosing a quality product

You can choose a new device based on its performance characteristics. Experts recommend first of all paying attention to the carrying capacity. This is the most important parameter that should be taken into account when purchasing a new design for a specific car. Initially, you need to determine the actual weight of the car, and then add up to 250 kg. This way you can avoid breakages and other damage when lifting a load.

Additional Information!

The next stage is the material issue. Many buyers are interested in how much the product will cost and how long it will serve the owner. The cost of new models starts from 30,000 rubles. A pressure gauge is also sold with the device.

An equally important indicator is the lifting height. Its reserve is approximately 30-50 cm. Given this indicator, you can easily replace the wheel, as well as the steering rack. If necessary, you can purchase special stands. Sometimes they are sold as a set.

Pickup height for a jack - what is it? This is the distance between the surface and the pick-up in the lower working position. It is important that the mechanism fits freely under the bottom even if the load sag. In this case, the rhombic and screw versions are not suitable, but you will need a rolling jack.

Important!

When working with this structure, each person should become familiar with the safety rules. Experts recommend carrying out various types of work on a horizontal platform. Before proceeding, you should block the wheels. To do this, you can use blocks or bricks.

Characteristics of rack jacks

These tools are widely used when performing installation and dismantling, as well as repair and construction work. Among the main types of this equipment are gear and lever mechanisms. The latter are complemented by a swinging lever that moves the rack. Instead of a drive lever, rack and pinion jacks use a gear, which is driven by a handle. To hold the load on the axis of one of the gears, a ratchet is provided.

In both types of jacks described, the main unit is a load-carrying rail with a cup. If the load has a low supporting surface, then a rack jack will help with this, the lower end of the rack of which is bent at an angle of 90°. Considering the types and types of jacks, you will be able to note that an important feature of rack and pinion devices is the low location of the lifting platform. On sale you can find options in which the distance to the floor is only 90 mm. Such equipment may have one-, two-, or three-stage transmission. Each variety is used for lifting loads:

- up to 6 tons;

- from 6 to 15 tons;

- more than 15 tons, respectively.

Selection criteria: how to choose the right tool

Criteria for choosing a hydraulic product

Which car jack should you choose instead of the standard one or in addition to it? There really is no universal option. Suffice it to say that a jack with a lifting capacity of 3 tons, which suits the owner of a sedan, will almost certainly not suit someone who drives an SUV.

According to the type of drive, professional aluminum jacks are divided into manual (mechanical or hydraulic), electric and pneumatic (it is connected to the exhaust pipe). They can also be classified and used according to the design of the actuators: rhombic and rolling, bottle (screw and hydraulic) and rack and pinion, lever-screw and “cushion” type.

Possible breakdowns, how to fix them yourself, where to go for repair services

Structural breakdowns - repair service

The similarity of the designs of various jacks allows us to identify the most typical faults inherent in most of these units. The main signs of their manifestation are the following:

- After completing the process of raising the load to the required height, a spontaneous slow lowering begins (the load is not fixed at the desired point).

- There is a complete inability to lift the permissible load to the required height.

- Incomplete return of the jack rod to its original position.

All these malfunctions appear due to the release of the corresponding elements of the jack design.

The first type of malfunction occurs due to loss of performance of cuffs and seals. During use, they lose their elasticity. This leads to loss of tightness. As a result, dirt and moisture enter the work area, which can lead to corrosion.

You might be interested in this About High Jack jacks: features of the rack and pinion mechanism, selection criteria

It affects the internal walls of the housing, the surface of the retractable piston, the internal walls of pipelines, and elements of the manual and hydraulic control system. To find the place of corrosion formation, it is necessary to disassemble the entire jack and carefully examine all structural elements.

Note!

If the spring does not return to its original position, this is evidence of worn-out springs. The manifestation of such malfunctions allows us to draw an unambiguous conclusion - the pneumohydraulic jack intended for a passenger car needs to be repaired.

In addition to hidden faults, obvious ones can also be observed. They can be determined visually - this is a deformation of the rod, an oil leak. A decrease in the oil level in the working area leads to the entry of atmospheric air into it. As a result, it is not possible to create the necessary pressure to ensure the declared characteristics. Sometimes this deficiency (low oil level) occurs as a result of so-called natural loss. Elimination of this malfunction is carried out by simply adding oil to the jack system. However, it should be remembered that after this operation it is necessary to carry out bleeding.

Recommendations for use

After finishing use, the jack must be freed from loads. The device should be stored in a warm and dry place. Due to excess moisture, the mechanism may rust, and cold will negatively affect the quality of the oil. It is recommended not to work with a jack in severe frost.

Loads on the device should not exceed those for which it is designed.

With constant use, pumping (oil change) should be carried out every 2-3 months. For rare use - once every six months.

Thus, in the event of a hydraulic jack failure, it is necessary to check 3 components:

- Quality and quantity of liquid.

- Presence of air bubbles in the system.

- Contamination, loose valve fit.

In most situations, to solve all problems with the device, it is enough to clean it and change the oil.

Man has invented many devices for lifting weights. To briefly describe the principle of their operation - the transformation of the distance traveled into effort.

Let's look at examples of such transformations:

- Lever arm. On the long side, the distance traveled is greater and the effort is less. On the short side it's the opposite;

- Block system. The cable, passing through a certain number of blocks, loses distance with each loop, proportionally acquiring additional traction force;

- Gears with different gear ratios. The small gear rotates quickly and with less force. Big – on the contrary;

- Chain (belt) pair. A smaller diameter pulley rotates effortlessly and faster. A larger diameter pulley develops high torque on the shaft at a lower rotation speed;

- Communicating vessels. Two piston pairs connected to each other operate on the principle of a lever. A piston of a smaller diameter moves with a small force with a large swing. While its larger “brother” moves a short distance with proportionally increased effort.

A hydraulic jack operates on the principle of communicating vessels.

Relatively compact dimensions (compared to the force that the tool can develop) make it indispensable when working with large weights. Portable bottle jacks (this is their second name) develop a force from 1 to 20 tons. Larger specimens can weigh up to 200 tons.

At the same time, hydraulics are among the safest devices for lifting heavy objects.