Cutting order

If the sheet is large, then you should not try to cut it yourself. It is possible to cut such a product without sad consequences only with the help of a laser machine. Naturally, this is not feasible in everyday life. The only correct option for cutting heat-resistant glass at home is to re-anneal the glass. Let's look at it in more detail.

Tools for work

Before cutting tempered glass at home, prepare the necessary tools and equipment. So, you will need:

A special oven with the ability to heat up to 700 degrees or more.

Important! There were many such furnaces in the laboratories of the research institute, which in the 90s were literally closed in batches. If there is no such furnace, you can order it from a forge (like a forge)

Thermometer with a high (the same 700 degrees) threshold.

Important! Laboratory ovens have a built-in thermostat and thermometer.

- A set of marking devices (markers, squares, rulers).

- Grinding stones.

- Wood rods.

- Diamond glass cutter.

- Powerful fan.

- Water.

Important! You need to work in protective equipment - overalls, glasses

Preparation and cutting of tempered glass at home

So, the only way to cut tempered glass at home is to make it less durable. Annealing helps eliminate the stress that appears during hardening. It is produced according to the following algorithm:

Soak the glass in water. Then gradually increase the water temperature to numbers equal to the viscosity temperature in the oven (1013 Poise).

Important! Different brands of glass have different viscosity values. In addition, the duration of the procedure is influenced by the size of the sheet

For example, the duration of soaking window glass varies from 12 to 16 hours.

Heating glass in a furnace to a glowing temperature. For different brands it is 470-680 degrees (Celsius). The necessary numbers can be found in the glass documentation.

Important! Manufacturing companies from the USA indicate the heat temperature in Fahrenheit. To convert to the usual degrees Celsius, you need to use the formula: TF = TC x 9 / 5 + 32 or reference tables

- Once the temperature has reached the desired peak, remove and cool the glass. In this case, it is necessary that the cooling be as slow as possible.

- Once the glass sheet reaches room temperature, mark cut lines on it. After the manipulations, the glass ceased to be “safe”, “tempered”, but turned into ordinary glass.

- Use a glass cutter to make a groove along a pre-marked line, and then use careful blows to knock off “all the excess.” To make the cut more accurate, place wooden rods under the “groove”.

- Is the glass cut? Now is the time to harden it again. Repeat the first 2 points of the described technology exactly.

- The cooling process when tempering glass must be fast. To do this, install a powerful ventilation device in the room in advance. You can lower the air temperature to 10 degrees, but a ventilation unit is still necessary. You need to blow on both sides of the sheet. Once the leaf temperature has reached room temperature, the procedure can be considered complete.

Selecting quality cutting material

To obtain a high-quality glass product for insertion into a frame, it is recommended to carefully prepare. Glass cutting will be more successful if you select high-quality material.

One of the signs of high-quality glass is the greenish or blue color of the ends. At the glass production stage, technological inaccuracies are allowed - during the process, sheets with stripes for them are obtained. There is no need to use such sheets to insert into a window - they noticeably distort the images. There is no need to take glass plates with scratches.

As for the thickness of the glass to be cut, it should depend on the size of the frame. If the height and width are less than 600 mm, a sheet with a width of 4.5 mm is sufficient. On the contrary, the height or width exceeds this value; the glass sheet is approximately 4 mm wide.

When performing glazing at home

a piece of glass should be cut so that it is 3–5 mm smaller than the size of the frame created to insert it. With the slightest misalignment, it is no longer possible to insert the glass into the frame.

Preparatory stage

To minimize problems, the glass should be washed thoroughly and dried completely. If the material is new, it is enough to wipe it with unnecessary newspapers. Old glass is washed, degreased with kerosene and dried.

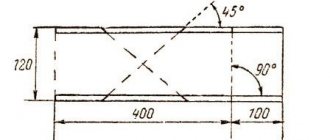

To ensure that the glass meets the required dimensions, it must be marked with a regular pencil. The cutting must be done in such a way as to minimize waste, so the long side of the glass is combined with the longer side of the future product.

Required Tools

Before cutting glass with a glass cutter, you need to decide what kind of tool you have. The fact is that there are two types of glass cutters, and the technology for their use is significantly different:

- A diamond glass cutter

is expensive, but can cut glass 10 mm thick. With this tool you can cut out even complex designs with curved lines. The instrument is held like a regular writing pen at a slight angle (only more vertical). The cut line should be neat, thin and colorless. - A roller glass cutter

cuts glass 1-4 mm thick. There are models with 1, 3 and 6 rollers on sale. Recently, a roller glass cutter with oil has gained particular popularity, since it is the easiest to work with. The tool is held strictly perpendicular to the working surface, and the pressure force is adjusted with the index finger. If all cutting technologies are followed, the line will be white.

Choosing a tool for cutting glass is not difficult, but the work process itself is more difficult, because for a good result you need to be as careful and attentive as possible.

The glass is completely laid on the prepared work surface. To begin with, you can practice on a small piece. Experts recommend placing a thick wooden ruler under the glass cutter before cutting, positioning it so that it is away from the drawn line. To prevent the ruler from sliding, place several pieces of rubber under it.

When cutting, you need to apply equal force evenly and draw an accurate line right away. Repeated attempts to draw a line in the same place will result in cracks. If the line does not work out, you need to step back 1 mm from the place of the first attempt and try again. After the cut, the glass must be placed so that the cutting line coincides with the edge of the working surface. The suspended underside of the glass is carefully tapped with a glass cutter and broken off, holding part of the sheet on the table. You can break the glass with your hands or with pliers (with pieces of hose attached to the ends).

But if you don’t have one or the other tool at hand, you can try cutting the glass with sharp sewing scissors. It's simple: you need to mark the material and create microcracks using scissors.

Types of glass and features of work

There are practically no problems with cutting ordinary glass. But with other types of glass, serious difficulties can arise.

- Strained glass

.

Cutting tempered glass is practically impossible, since most often when trying to cut it, it simply breaks in random places. If the plans include interior items using tempered glass, its cutting should be carried out immediately before tempering. This means that such work should be entrusted only to professionals.

- Fluted glass

.

Patterned glass is often used for glazing doors or other interior items. The cutting process is no different from working with ordinary glass, only it is better to cut corrugated glass using a roller glass cutter exclusively on the smooth side.

Tools for work

Before you start cutting glass, you should decide which tool to do it with. Most often, glass sheets are cut using a special tool - a glass cutter. It is ideal for small workloads. But there are many other tools with which you can adjust the glass to size home

For example, many home craftsmen can successfully . Almost every home owner has such a tool in their arsenal. But you need to keep in mind that you can use a grinder to cut glass only when you need to make a short cut. Using a ruler is extremely difficult in this case.

To cut off a part, you will need to install a thin diamond blade on it. Carry out cutting at low speeds. This reduces the risk of premature splitting of the glass sheet and the production of glass dust in large quantities.

Further work is carried out as follows:

- A disk of suitable thickness is installed on the tool.

- The cut area is slightly moistened - it is better to simply pour water on the glass.

- Using a disk, a thin furrow is made across the glass.

- Then a chip is made along this groove.

So, to the question whether it is possible to cut glass with a grinder, the answer can be given in the affirmative. But it is necessary to pay attention while working

for various little things. In particular, the glass should not be allowed to overheat - for this you can stock up on cooling liquid.

To cut glass, you need to choose only high-quality tools. Otherwise from vibration during operation

glass may break. Before work, try to protect your vision and breathing organs well so that glass powder does not get into them.

Source

Where is glass ceramic or tempered glass used?

In construction requiring the use of safety glass: schools, kindergartens, sports facilities, administrative buildings.

In the design of commercial and residential objects: stairs, glazing of terraces and loggias, glass doors, railings, glass partitions.

In architecture: double-glazed windows, ceiling glazing, facade glazing.

In fences where large thermal loads are possible: glass located at a distance of less than 30 cm from heat sources.

In everyday life, stoves with glass-ceramic hobs, dishes made of impact-resistant tempered glass.

Our specialists also carry out professional glass cutting.

How to cut tempered glass

All credible experts say that cutting tempered glass is impossible. However, there are three known ways to cut tempered glass without resorting to supernatural forces.

1. Waterjet cutting of tempered glass - the method consists of supplying water under enormous pressure (up to 4 thousand atm.) into a special chamber, where the water is mixed with abrasive powder, and then through a very thin nozzle (0.2-0.4 mm in diameter ), is shot onto the surface to be treated. The water speed reaches 1000 m/sec (3 speeds of sound). It will also cut through steel armor, not like glass.

Cutting tempered glass with a vulcanite wheel

2. Cutting with an abrasive wheel - the glass is mounted on a movable table, and something like a grinder with an abrasive wheel (for example, made of vulcanite) of small thickness is lowered on top of it. It is believed that with a low feed rate of the table relative to the wheel and intensive watering of the cutting area with a lubricant and cooling liquid, the process can lead to success.

3. Cutting with tempering. In this case, “vacation” (or “annealing”) does not mean a trip to the south, but heating the glass to the temperature at which the hardening effect will be removed.

That is, the glass will return to its normal state, after which it can be processed and, if necessary, tempered again.

Annealing tempered glass

Perhaps, theoretically, this operation is feasible, but the most primitive calculations suggest that it is cheaper to re-buy (see the article “Where to buy tempered glass?”) ordinary glass, cut it into pieces of the desired shape, drill the necessary holes, and then temper it.

If you are interested in the place and methods of using tempered glass for the home, read about it at: https://oknanagoda.com/steklo/osteklenie-steklo/steklopaketi/kalenoe-steklo-dlya-doma.html

You will also find how, where and why coated glass is used on our website.

Preparatory stage

To minimize problems, the glass should be washed thoroughly and dried completely. If the material is new, it is enough to wipe it with unnecessary newspapers. Old glass is washed, degreased with kerosene and dried.

To ensure that the glass meets the required dimensions, it must be marked with a regular pencil. The cutting must be done in such a way as to minimize waste, so the long side of the glass is combined with the longer side of the future product.

Required Tools

Before cutting glass with a glass cutter, you need to decide what kind of tool you have. The fact is that there are two types of glass cutters, and the technology for their use is significantly different:

- A diamond glass cutter is expensive, but can cut glass 10 mm thick. With this tool you can cut out even complex designs with curved lines. The instrument is held like a regular writing pen at a slight angle (only more vertical). The cut line should be neat, thin and colorless.

- A roller glass cutter cuts glass 1-4 mm thick. There are models with 1, 3 and 6 rollers on sale. Recently, a roller glass cutter with oil has gained particular popularity, since it is the easiest to work with. The tool is held strictly perpendicular to the working surface, and the pressure force is adjusted with the index finger. If all cutting technologies are followed, the line will be white.

Choosing a tool for cutting glass is not difficult, but the work process itself is more difficult, because for a good result you need to be as careful and attentive as possible.

The glass is completely laid on the prepared work surface. To begin with, you can practice on a small piece. Experts recommend placing a thick wooden ruler under the glass cutter before cutting, positioning it so that it is away from the drawn line. To prevent the ruler from sliding, place several pieces of rubber under it.

When cutting, you need to apply equal force evenly and draw an accurate line right away. Repeated attempts to draw a line in the same place will result in cracks. If the line does not work out, you need to step back 1 mm from the place of the first attempt and try again. After the cut, the glass must be placed so that the cutting line coincides with the edge of the working surface. The suspended underside of the glass is carefully tapped with a glass cutter and broken off, holding part of the sheet on the table. You can break the glass with your hands or with pliers (with pieces of hose attached to the ends).

But if you don’t have one or the other tool at hand, you can try cutting the glass with sharp sewing scissors. It's simple: you need to mark the material and create microcracks using scissors.

Types of glass and features of work

There are practically no problems with cutting ordinary glass. But with other types of glass, serious difficulties can arise.

- Strained glass.

Cutting tempered glass is practically impossible, since most often when trying to cut it, it simply breaks in random places. If the plans include interior items using tempered glass, its cutting should be carried out immediately before tempering. This means that such work should be entrusted only to professionals.

- Corrugated glass.

Patterned glass is often used for glazing doors or other interior items. The cutting process is no different from working with ordinary glass, only it is better to cut corrugated glass using a roller glass cutter exclusively on the smooth side.

- Acrylic or organic glass.

This synthetic plastic material can be cut with any available tools, including a cutter, sewing scissors and a metal saw. If the plexiglass is very thin (no more than 2 mm), a sharpened stationery knife can be used as a cutting tool.

It is most convenient to cut glass on a large fiberboard table. Before using a glass cutter to cut glass, it is better to wear safety glasses and gloves: tiny shards can get into your eyes, and chipped edges can seriously injure your hands. It is worth taking care of closed shoes to avoid unwanted cuts.

How to cut glass with a glass cutter. Photos and videos of the process

Probably every man has had to replace broken glass at some point. Marking new glass is not difficult, but cutting it neatly is not so easy. Cutting glass at home requires the use of only special high-quality tools.

Article navigation:

Preparation

Tools

Types of glass and features of work

Video

Preparatory stage

To minimize problems, the glass should be washed thoroughly and dried completely. If the material is new, it is enough to wipe it with unnecessary newspapers. Old glass is washed, degreased with kerosene and dried.

To ensure that the glass meets the required dimensions, it must be marked with a regular pencil. The cutting must be done in such a way as to minimize waste, so the long side of the glass is combined with the longer side of the future product.

Required Tools

Before cutting glass with a glass cutter, you need to decide what kind of tool you have. The fact is that there are two types of glass cutters, and the technology for their use is significantly different:

A diamond glass cutter is expensive, but can cut glass 10 mm thick. With this tool you can cut out even complex designs with curved lines. The instrument is held like a regular writing pen at a slight angle (only more vertical). The cut line should be neat, thin and colorless. A roller glass cutter cuts glass 1-4 mm thick. There are models with 1, 3 and 6 rollers on sale. Recently, a roller glass cutter with oil has gained particular popularity, since it is the easiest to work with. The tool is held strictly perpendicular to the working surface, and the pressure force is adjusted with the index finger. If all cutting technologies are followed, the line will be white.

We recommend: Finishing walls with plasterboard without a frame and profile: we do the finishing according to the instructions with our own hands

Choosing a tool for cutting glass is not difficult, but the work process itself is more difficult, because for a good result you need to be as careful and attentive as possible.

The glass is completely laid on the prepared work surface. To begin with, you can practice on a small piece. Experts recommend placing a thick wooden ruler under the glass cutter before cutting, positioning it so that it is away from the drawn line. To prevent the ruler from sliding, place several pieces of rubber under it.

When cutting, you need to apply equal force evenly and draw an accurate line right away. Repeated attempts to draw a line in the same place will result in cracks. If the line does not work out, you need to step back 1 mm from the place of the first attempt and try again. After the cut, the glass must be placed so that the cutting line coincides with the edge of the working surface. The suspended underside of the glass is carefully tapped with a glass cutter and broken off, holding part of the sheet on the table. You can break the glass with your hands or with pliers (with pieces of hose attached to the ends).

But if you don’t have one or the other tool at hand, you can try cutting the glass with sharp sewing scissors. It's simple: you need to mark the material and create microcracks using scissors.

Types of glass and features of work

There are practically no problems with cutting ordinary glass. But with other types of glass, serious difficulties can arise.

Strained glass.

Cutting tempered glass is practically impossible, since most often when trying to cut it, it simply breaks in random places. If the plans include interior items using tempered glass, its cutting should be carried out immediately before tempering. This means that such work should be entrusted only to professionals.

Corrugated glass.

Patterned glass is often used for glazing doors or other interior items. The cutting process is no different from working with ordinary glass, only it is better to cut corrugated glass using a roller glass cutter exclusively on the smooth side.

Acrylic or organic glass.

This synthetic plastic material can be cut with any available tools, including a cutter, sewing scissors and a metal saw. If the plexiglass is very thin (no more than 2 mm), a sharpened stationery knife can be used as a cutting tool.

It is most convenient to cut glass on a large fiberboard table. Before using a glass cutter to cut glass, it is better to wear safety glasses and gloves: tiny shards can get into your eyes, and chipped edges can seriously injure your hands. It is worth taking care of closed shoes to avoid unwanted cuts.

Video analysis of the process

Liked? Share on social media networks!

Source: remontcap.ru

This is interesting: Miter box - how to make it yourself, what is it, how to use it?

Nuances when cutting at home

When considering the question of how to cut tempered glass at home, you need to pay attention to choosing a more suitable tool. The following glass cutters are widely used:

- Diamonds are used extremely often today. Due to the use of durable and hard material, the tool can last for a long period. From time to time it is necessary to sharpen the cutting edge using a special sharpening stone.

- Roller. Cutting tempered glass at home is often done using a tool like this, as it is ideal for the job in question. The set may contain 6 rollers, which are often made of cobalt and tungsten. Due to the combination of a large number of rollers made of durable and wear-resistant material, the cutting task is greatly simplified.

- The oil version is similar to the version with rollers, but the design has a special container for storing oil. When performing work, lubricants are added to the cutting zone, thereby greatly simplifying the cutting process. That is why this design option is used more often than others.

Before starting work, you need to check the degree of sharpening of the cutting edge. When using a worn tool, the quality of processing is significantly reduced, and there is a possibility that the cut line created will have insufficient depth.

If you find an error, please select a piece of text and press Ctrl+Enter.

In a review article on our website dedicated to tempered glass, it was said that it cannot be processed. “And if you can’t, but really want to, then it’s possible,” and then we will try to tell you how this principle is implemented in practice in relation to tempered glass.

Cutting tempered glass at home

Tempered glass is considered one of the most common materials. To increase its strength, hardening technology is used. After carrying out such a procedure, the degree of machinability of the material is significantly reduced. When considering whether it is possible to cut tempered glass, we note that only by using special technologies can the occurrence of a defect be avoided. Today, cutting tempered glass can be done at home, using a variety of tools.

Tempered glass cutting

Properties of tempered glass

Before tempered glass is processed, its basic properties should be considered. These include:

The structure is characterized by high mechanical strength. Due to this, they can be used for glazing balconies and loggias. Strength and hardness allow the material to be used in the manufacture of furniture and other products. To improve ordinary glass, heat treatment is carried out in a special furnace. The medium is heated to a temperature of 670 °C. The thermal resistance indicator increases significantly. In the manufacture of various devices that are operated at elevated temperatures, tempered glass is often used. When heated, the hardness indicator remains unchanged.

Application of tempered glass

As the results of ongoing research show, the strength of tempered glass is 7 times greater than that of ordinary glass.

That is why it is quite difficult to damage the material and carry out mechanical processing.

Preparatory stage

When considering how to cut tempered glass, you should consider the preparatory stage. Careful preparation allows us to achieve high quality. Cutting tempered glass at home is carried out taking into account the information below:

During the production of the material, zones with internal areas of stress are formed. With rapid heating and cooling, such areas are redistributed. The inside of the glass becomes more viscous compared to the outer layer. At the time of processing, the workpiece must be securely fastened. A variety of devices can be used for this. The surface of tempered glass must be cleaned of contaminants. An example is oils or paint, which can significantly reduce the quality of processing.

Glass preparation

In general, we can say that preparation for work is quite simple. However, without special tools and equipment, cutting will not be possible.

Required Tools

As previously noted, cutting tempered glass can only be done using special equipment and tools. It is as follows:

Special furnace for processing tempered glass. Thermostat. Square. Marker for marking the surface. Grinding stone. Special glass cutter. A rod with a diameter of 6 mm, made of wood. Goggles designed to protect the eyes. When cutting, chips may be formed that fly away from the cutting zone.

Cutting tempered glass with a grinder

Using special equipment, tempered glass can be cut to precise dimensions and high quality edges.

Tempered glass cutting instructions

The high strength and hardness of the surface determines that quite serious problems can arise when cutting. When considering how to cut tempered glass, you should pay attention to the following points:

The workpiece is prepared by annealing. This technology provides uniform heating of the surface. Due to this, the stress that forms inside the material at the time of hardening is eliminated. Due to such tension, it becomes much more difficult to achieve the required dimensions. The annealing process involves heating water to a certain temperature, after which the workpiece is lowered into it. It is worth considering that car glass or decorative glass should be cut at different temperatures, it all depends on the brand of material. The exposure time of tempered glass in water can vary significantly. In some cases it takes about an hour, the most difficult versions are aged for a month. After reaching the required temperature, the product is slowly cooled. The work is performed slowly, thereby eliminating the possibility of even the smallest defects. Once the surface temperature has dropped, you can put on glasses and cut using a glass cutter. You can cut glass for your phone in a similar way. Markings should be made before cutting. Smooth and accurate lines are achieved by using a square and other measuring instruments. The material should be pressed with medium force, as a high load can lead to serious defects. The cut is carried out quickly; attempting to make the line again is not recommended due to the fact that such actions can lead to splits and cracks. You should be careful when cutting, as it will not be possible to re-make the cut line. After obtaining the required line, a rod is placed under it, and with a sharp push the product is divided into two parts.

We recommend: Aerated concrete blocks - pros and cons, characteristics, DIY masonry technology

If you do the work carefully, you can get a high-quality cut. The end surface can be finished using a grinding stone.

Nuances when cutting at home

When considering the question of how to cut tempered glass at home, you need to pay attention to choosing a more suitable tool. The following glass cutters are widely used:

Diamonds are used extremely often today. Due to the use of durable and hard material, the tool can last for a long period. From time to time it is necessary to sharpen the cutting edge using a special sharpening stone. Roller. Cutting tempered glass at home is often done using a tool like this, as it is ideal for the job in question. The set may contain 6 rollers, which are often made of cobalt and tungsten. Due to the combination of a large number of rollers made of durable and wear-resistant material, the cutting task is greatly simplified. The oil version is similar to the version with rollers, but the design has a special container for storing oil. When performing work, lubricants are added to the cutting zone, thereby greatly simplifying the cutting process. That is why this design option is used more often than others.

Before starting work, you need to check the degree of sharpening of the cutting edge. When using a worn tool, the quality of processing is significantly reduced, and there is a possibility that the cut line created will have insufficient depth.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source: StankiExpert.ru

Preparation

You should never neglect preparation for the glass cutting process. This operation is impossible without its preliminary preparation. It is necessary to wipe the surface with a damp cloth to remove all unnecessary inclusions. After the glass is dry, dry it with a dry cloth.

Many experts advise using old paper rather than rags. It does not leave fibers on the surface that interfere with the cutting process. Glass that has already been used is much more difficult to cut, so it takes longer to prepare it. In addition to cleaning and drying, such material must be degreased with kerosene.

Features of cutting different types

Tempered glass, also known as tempered glass, is made by heating it in an oven to a temperature of 680 degrees and then quickly cooling it with even air currents. This product is used as windshield and window glass in cars, and also as a heat-resistant and fire-resistant ceiling. Typically, glass is cut and processed immediately before annealing, eliminating other problems. Processing such material by conventional methods is impossible due to its mechanical properties.

There are different cutting methods available for tempered glass. The first is laser cutting of glass. Because the laser cuts the material with heat at a specific point, the internal stresses at that point drop and prevent the glass from cracking, producing a smooth, high-quality cut. The second and more complex method involves preliminary annealing. The main goal of this method is to completely remove residual stresses over the entire area of the material and thus transform it into ordinary sheet quartz glass. Annealing is carried out by soaking the material in water to the temperature of the solidification viscosity in an oven. This is followed by slow cooling to a temperature below strain. As a result of these actions, the glass loses its tempered properties and can be subjected to mechanical cutting.

Acrylic glass, also known as organic glass, is a synthetic polymer of methyl methacrylate, a clear thermoplastic plastic. It is called glass only formally because of its transparency. The remaining properties are significantly different and have nothing in common with real glass, which allows completely different processing methods to be applied to it. In this regard, one of the most popular cutting methods is dissection using a milling machine, when specialized equipment is not required, but is used the same as for processing wood and metals.

Other methods used to disassemble glass also apply to the acrylic version. Waterjet and laser cutting machines interact with plexiglass with great efficiency and provide faster cutting speeds than using the same equipment to process regular glass. Cutting thick reinforced glass is made difficult by the presence of a metal mesh in it.

Types of glass and features of work

Cutting ordinary glass does not pose any difficulties. Not only glass cutters, but also ordinary tailor’s scissors do an excellent job with this task. But what should those who have set themselves the task of obtaining a glass product with a more complex configuration do? To do this, it is worth familiarizing yourself with the properties of some glasses.

- Tempered glass products

. In fact, it is impossible to cut tempered glass at home - it loses its properties. If you want to purchase an item with elements of this material, it is worth considering cutting it in the early stages. In addition, work with it must be carried out by professionals, since the hardening process of the resulting product can only be carried out under certain conditions. - Fluted glass

. This patterned glass is especially popular in glazing doors or creating decorative interior elements. Unlike tempered glass, you can cut such glass yourself. Working with it is not much different from working with ordinary glass, the only difference is that the cut is made from the smooth side. A roller glass cutter is best suited for this. - Acrylic or organic glass

is a transparent plastic created on the basis of synthetic resins. No special tools are required to cut it. At home, a metal saw, cutter and other tools used for edge processing do an excellent job of this task. In addition, a regular stationery knife can handle glass whose thickness does not exceed 2 mm.

In any case, it is worth remembering that working with any glass must be accompanied by compliance with certain precautions. The presence of thick gloves and safety glasses are the main conditions for ensuring your own safety. It will not be superfluous to take care of the arrangement of the workplace. Since working with glass involves the presence of fragments, cover the work surface with any material that you won’t mind getting rid of. Feeling safe will allow you to achieve the best results.

Discussion:

- Pavel said:

For some reason, everyone writes about scissors as science fiction. About 25 years ago I read somewhere about this method... and tried it - I had to cut out shaped glass. In a basin of water, ordinary scissors, glass and off you go! – I didn’t expect it to be so simple! Of course, it didn’t cut, but pieces broke off, but exactly in the right place!..

Glass cutting is carried out mainly in production, but sometimes such a need arises at home. Of course, it is very good if a person has cut glass at least once in his life, but what should those who have no idea how to cut tempered glass do?

To cut glass, you need to purchase a glass cutter; it looks very similar to a can opener. In production, they use special, equipped tables for cutting tempered glass, and in domestic conditions, you can use an ordinary dining table, having previously covered it with a thin cloth.

The glass you are going to cut must be clean and dry, and you must also determine its thickness by eye. Cutting must be carried out parallel to the long side of the glass; if you have a factory-cut sheet for processing, then pay special attention to the corners, as they will most likely not be even. This important fact must be taken into account, so be sure to check the correct angles.

If your frame is very skewed, then before cutting you need to mark the run diagonally. The markings are done with ink, pencils (4M, 5M) or a marker on the reverse side. If you need glass for window frames, then the size of the glass should be three millimeters smaller than the distance between the frame folds (the folds are the recesses in the frame under the glass). This gap is made so that when the window frame swells or heats up, the glass does not succumb to strong stress. Over time, glass becomes more fragile, so cutting must be done carefully and after lubricating the glass with turpentine.

Before cutting glass, let’s define what tempered glass is.

. Tempered glass is called glass, which is several times stronger than ordinary glass; it can be tempered several times at high temperatures, and therefore can withstand heavy loads (300 kg per sq.m.). Such glass can only be broken by a strong blow with a blunt or sharp object.

They cut glass using an eight-millimeter ruler; this is necessary so that the glass cutter does not slip from your hands during cutting. If you don’t have a ruler at hand, then you can use any level strip, because, as you know, wood does not slide on glass. So, we apply the ruler to the glass, just not exactly to the markings, but leaving room for the glass cutter, and start cutting. There are two types of glass cutters - roller and diamond. A diamond glass cutter cuts better, but for cutting corrugated sheets, it is better to use a roller cutter.

The quality of the tool matters, but what matters more is the virtuosity of the craftsman who will cut the glass. The table is of no small importance when cutting glass; it must have a perfectly flat surface and the glass must fit on it in its entire plane.