Drilling holes in the wall correctly: general rules and recommendations for what to drill

In order to correctly drill a wall, you need to take into account the material from which it is made, based on this you need to select a tool.

- When working, hold the tool correctly. For example, a drill

should be held straight in your hands and enter the surface in a vertical direction; - for convenience, use an additional handle;

- Depending on the surface material, select the necessary drills.

- concrete, stone, brick wall - use a carbide drill, usually a Pobedit one;

- metal – metal drill;

- tiles, ceramic tiles - special drills for these materials, sometimes they can be replaced with a drill for concrete with Pobedit surfacing;

- Chipboard, wood - for holes smaller than 10-12 mm, a metal drill is suitable; for larger ones, special wood drills are used.

READ How to Test a Drill Directly Without a Button

Use of lubricants

When drilling into hardened steel, there is a lot of friction. This is why it is recommended to obtain and use different lubricants. Among the features of this processing method, we note the following points:

- First, the drilling zone is processed. A small amount of lubricant is applied to the surface where the hole will be located.

- Oil has been added to the cutting edge. To process hardened steel, a small amount of the substance is required, but it must be added at times because it will fly apart when the tool is rotated.

- During work, it is recommended to take breaks to cool the cutting surface and the working surface.

READ Select a Handheld Circular Saw for Wood

Steel lubrication with special oil

This is because the oil can lower the temperature of the cutting edge.

What do the professionals advise?

Concrete structures are quite strong and difficult to drill. In addition, quite often drills come across crushed stone, which is part of the concrete mixture from which wall and ceiling slabs are formed.

Holes in concrete have to be made quite often, especially during the process:

- finishing works;

- furniture installation;

- air conditioner suspensions;

- additional electrical wiring device;

- installation of plumbing.

There are two ways to solve the problem of holes in a concrete wall:

- an impact drill, or better yet a hammer drill, with a Pobedit drill bit;

- diamond drilling.

Drilling concrete with a hammer drill

So how to drill

hole in a concrete slab using a hammer drill? The procedure is simple:

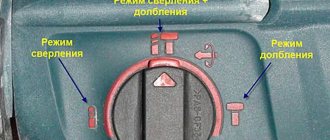

- the drill switches to impact mode, after which drilling begins; the tool must be held strictly at a right angle;

- after some time, the drill is moistened with water, this will help avoid overheating;

- after you succeed in drilling a reinforced concrete wall, the drill must be removed without turning off the device itself;

- To clean the resulting hole from dust, a drill is inserted into it several times.

Can't drill into a wall? Did the hammer drill hit something hard? This means you need to try making a hole in a different place.

Hammer

When using a hammer drill or impact drill, they must be switched to impact mode, a working tool with a pobedite tip is inserted and it must be directed perpendicular to the wall surface.

The eyes are afraid - the hands are doing || How to “drill” a hole in concrete WITHOUT A PERFORATOR

If drilling holes takes a long time, it is necessary to periodically wet the drill so that it does not overheat too much.

After you have drilled to the required depth, you must pull the working tool back without turning off the hammer drill. To clean the finished hole from dust, you need to deepen and pull out the drill several times.

Features of the work: advice from experts

Drilling a concrete wall with a simple drill has some nuances:

- At the moment when the drill is in the wall, the drill cannot be stopped: the tip will get stuck and it will be difficult to remove it. They stop pressing the key only after removing the drill from the wall.

- During operation, the drill is periodically wetted so that it does not overheat.

- Do not press the drill too hard; this will deform the drill bit or destroy the chuck.

- If a hole is drilled through a layer of plaster, the layout of communications is first examined. Otherwise there is a risk of damage, for example, to hidden electrical wiring.

Compliance with work technology and safety rules when drilling holes in concrete with a conventional drill will help not only to avoid the involvement of highly paid specialists, but also to avoid injuries.

Sources:

https://klub-masterov.ru/steny/kak-sdelat-otverstie-v-stene-bez-dreli.html https://stroisovety.Org/sverlenie-otverstij-v-betone/ https://2lzz.ru /elektroinstrument/drel/kak-prosverlit-betonnuyu-stenu

Choosing a tool

What is necessary, the first question that a home craftsman should ask himself is not how to drill a concrete wall with reinforcement, but with what. The main assistant here will be a hammer drill, because it is intended for stone and not concrete. Without looking at this, even massive drills can cope with a wall more than 12 cm wide. How to make a groove and secure the cable in it. a drill is preferable

, because a hammer drill will simply break it.

The property of the drill also determines whether it will be possible to drill

hole in a concrete wall.

#7 HOW TO DRILL? A hole in the wall without a hammer drill in 3 minutes “repair”

One good option is to use drill bits designed specifically for impact drilling. Their working part is a plate made of strong metal. With these drills the question is how to drill

a thin concrete wall can be considered solved.

READ Which drill to choose for home use?

A regular drill or screwdriver

If you do not have the tools described above, then this work can be done using a conventional electric drill or a powerful screwdriver.

HOW TO DRILL A HOLE IN THE WALL AND HANG A PICTURE

Drilling will take more time than using a hammer drill, but you can do it yourself.

In this case, in addition to a drill and a drill bit, you will also need a punch. First, a small depression is made at the drilling site using a punch and a hammer.

After this, they insert the working tool into it and begin to drill. If the drill stops, break the hard areas again with a punch and continue working.

Safety regulations

First of all, you should know that concrete dust (like asbestos dust) is very harmful to the respiratory system. If you drill without personal protective equipment, you can develop respiratory diseases in a very severe form. Protection is also needed for the eyes, since dust getting under the conjunctiva and on the cornea causes very painful inflammation, after which you can easily lose your vision. Therefore, when working, be sure to remember to use goggles, a respirator, special clothing and, if possible, a helmet. It is also worth purchasing a face shield. The thing is very convenient, and it can be used together with glasses, and is strong enough so that nothing unnecessary will fly in.

When carrying out this type of work, in accordance with safety regulations, there should be no unauthorized persons without personal protective equipment within a radius of 2.5 meters from the object. Also, to work at a height of more than 1.5 meters with a hammer drill, you need a solid foundation - scaffolding or sawhorses. A stepladder or ladder is not an option. Before starting work, carefully study the electrical and gas communications diagram. Pay special attention to whether there is reinforcement in the wall. To make sure, “ring” the wall. However, not a single device gives a 100% guarantee that there are no wires in the wall, especially under decorative trim. Therefore, if you are not sure, do not drill.

Choosing a tool

What is necessary, the first question that a home craftsman should ask himself is not how to drill a concrete wall with reinforcement, but with what. The main assistant here will be a hammer drill, because it is intended for stone and not concrete. Without looking at this, even massive drills can cope with a wall more than 12 cm wide. How to make a groove and secure the cable in it. a drill is preferable

, because a hammer drill will simply break it.

The property of the drill also determines whether it will be possible to drill

hole in a concrete wall.

One good option is to use drill bits designed specifically for impact drilling. Their working part is a plate made of strong metal. With these drills the question is how to drill

a thin concrete wall can be considered solved.

There are also annular drills that are diamond coated. They are very strong, they are used in special drilling rigs, and therefore cost quite a lot. Therefore, solving the problem of how to drill a hole in a concrete wall at home with them is at least impractical.

Step-by-step instruction

How to make a hole in a concrete wall or ceiling slab without a hammer drill and other similar tools?

First you need to prepare everything.

Despite the presence of a special drill, work on a concrete wall is carried out taking into account the recommendations of specialists.

An incorrect approach can lead to tool breakage and partial destruction of the wall. Before starting work, prepare the following set of tools and materials:

- drill

of sufficient power; - drill with pobedite (carbide) surfacing;

- punch - a metal pin of the required diameter;

- hammer or sledgehammer;

- vacuum cleaner.

The process of drilling concrete with a conventional drill is not fast, so the home craftsman should be patient. Concrete dust eats into the floor covering, and to maintain cleanliness, it is recommended to cover the surface with newspapers. Periodically collect spilled particles with a vacuum cleaner. The sequence of work is as follows:

- An appropriate drill is installed on the tool. A drilling point is marked on the wall.

- Mark the drilling point, working at minimum speed, with light pressure. A small hole is made in the surface so that the drill does not slip during intensive actions.

- They go deep into the wall by 8-10 mm. The tool is held at a right angle while drilling. If misaligned, there is a risk of damage to the surface, tip or hands.

- Take out the drill and pierce the concrete with a steel rod.

- They go deeper into the wall another 10-15 mm and again finish off the concrete with a punch. After each stage of work, the drill is cleaned of concrete particles.

READ How to make a grinding wheel for a drill

Drilling concrete with a diamond core bit can be seen at

In the video, the author explains how to drill

concrete without impact:

How to Make a Hole in Concrete Without a Drill

How to drill a concrete wall with a regular drill and hammer drill?

How to drill through a concrete wall with a regular drill? - this is the question that the craftsmen probably asked when they had to hang shelves, cornices and so on.

Concrete is a strong material and therefore can be drilled very poorly. Even how to drill a wall in a panel house seems an unsolvable problem.

Although, if you know certain secrets, this process will be significantly simplified for you.

Sources:

https://klub-masterov.ru/steny/kak-sdelat-otverstie-v-stene-bez-dreli.html

Nuances when drilling

The development in question has quite a huge number of features that need to be taken into account. Drilling of hardened metal is carried out taking into account the following points:

- Before carrying out work, pay attention to the hardness of the surface. This parameter is used to select a more suitable drill. Hardness can be found using different technologies.

- During drilling, a lot of heat is generated. Because of this, rapid wear of the cutting edge occurs. In this regard, in almost all cases, cooling liquid is supplied to the cutting zone.

- When cutting difficult-to-cut material, you need to sharpen the cutting edge from time to time. To do this, use an ordinary sharpening machine or a special tool. Only a diamond-coated wheel is suitable as an abrasive.

Steel Drilling Tool

There are a huge number of ways to cut hardened steel. Some of them significantly simplify processing. Only by taking into account all aspects can the quality of the resulting hole be improved.