Areas of application

Every person in the house should have an electric drill. A mini electric drill will not take up much space. It's good to have it at hand. It is needed quite often.

Different attachments are used to perform different jobs. One look at the photo of a mini-drill is enough to understand - this is a tool with which you can tighten a screw in a hard-to-reach place, and do it in such a way that it will not be visible even close up.

Often, during the interior decoration of a room, you have to spend more time on designing joints, corners, fixing all kinds of hinges and strips, beautiful decorative details with many small elements. They are needed under the ceiling, in grooves, near the floor.

What to do in this case? A regular electric drill will not work. It will damage them, the relief will be ruined. A mini drill or engraver will help you drill a small, neat hole.

The main thing is that the diameter is suitable. The thinnest screw can be tightened. The door hinges of an old-style wardrobe can be repaired and new ones screwed on.

You can also use a mini drill to process a surface with a small area. An interesting task is to make buttons with your own hands, for example. Once upon a time, people, faced with automation, standardization, and mass production for the first time, only dreamed about this.

You can use it to restore a coffee table and do it quickly and carefully. A variety of ideas are easy to put into practice.

This thing is necessary, useful, in a word, it allows you to save time and effort, and not waste it on solving super-tasks. How did primitive people manage to drill thin and neat holes in stone? No one knows. It’s better to buy a mini drill with attachments, just do it, entrust the search for an answer to such a difficult question to archaeologists and historians.

The characteristics of a mini-drill depend on the manufacturer and model. The configuration is constantly being improved and becomes more complex. How to choose a mini drill with optimal parameters?

Design

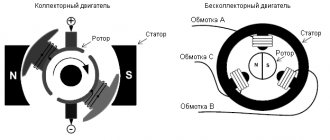

Inside any mini drill there is a grinding machine, that is, a device for direct grinding.

All of the above functions are performed thanks to attachments and cutting tools installed in the chuck. A significant difference between the design and a standard size drill is the rotation speed of the spindle sleeve. Popular models of mini hand drills maintain speeds from 10 to 30 thousand per minute. Due to the high speeds, there is no need to secure the workpiece being processed, because it will not be pulled out of your hands. This feature is very convenient when working with engraving and grinding.

To attach the necessary equipment or cutting tool, use a simple chuck with a collet mechanism.

Interestingly, the Hammer mini drill is equipped with a flexible shaft, which allows you to use attachments in the most difficult to reach places without unnecessary discomfort. It is very convenient to use a flexible shaft when you do not need to hold the drill in your hand. To do this, the electrical appliance is suspended on a special stand. This approach will free your hands, reduce vibration and overall noise levels.

Main characteristics

It is important to pay attention when purchasing a mini-electric drill or engraver to the speed of rotation. The best mini drills are those that have a higher RPM. After all, only in this case the drilled hole will be perfect. What about the nozzle for grinding and polishing?

It's no secret that this is a delicate process - grinding surfaces, polishing. In this case, a high speed of rotation is not always necessary. If a mini-drill has several operating modes and a speed switch, that’s great.

It’s good if the mini-drill works both from the mains and from the battery. Sometimes there is no outlet nearby. It happens that the lights go out. If the mini-drill has a battery, the lack of electricity will not prevent you from finishing the job you started.

It is necessary to pay attention to what voltage should be in the electrical network. Typically, power tools are designed to operate on a standard 220 V electrical outlet.

But increasingly, a new type of electrical network, three-phase, with a voltage of 380 V, is supplied to residential buildings. It is designed for the fact that many household electrical appliances with high power will work in the apartment at the same time. Many electrical appliances are manufactured for such an electrical network.

The ergonomic features of the case are of great importance. The color of the body is important. It depends on how quickly the drill can be found among the “working” mess. The weight of the device and configuration are important. If you don't like the appearance of the drill, you probably shouldn't buy it. It should be convenient to work - that’s why it was invented.

It is worth asking what set of attachments the manufacturer offers. It is important that the mini drill has a cooling system. It guarantees long-term continuous operation. If there is no cooling system, the tool will overheat and shut down. Is it convenient? A good question.

When solving various household and amateur radio problems, it is often convenient to use a mini-drill. This device allows you to significantly save time on drilling holes using an awl or other improvised means, with a much lower risk of breaking any part. And the result of the work is incomparably better - with a smooth cylindrical surface. The main stumbling block in working with such a device is the high cost of a high-quality model, so many people wonder how to make a mini drill with their own hands.

Mini drills: characteristics, features of selection and application

A mini-drill is a universal tool with a wide range of applications, performing the functions of an electric drill, grinder and milling machine, only in much smaller volumes. This compact equipment, thanks to various types of equipment, has great functionality.

It is used in everyday life and craft activities, hand made home art, interior decoration and home decoration. Mini-drills are indispensable when performing high-precision manipulations for processing a variety of materials and carrying out work operations in places where access with large power tools is limited or impossible.

What is this device, what are its functions and key selection criteria taking into account the purpose of application - the answers to all these questions are in our article.

DIY mini drill

All the homemade mini drills that you can make yourself can be divided into electric (powered by an electric motor) and manual mini drills (rotated by hand). The first option has significant advantages due to autonomous operation, but at the same time, you need both a motor and a power source for it. The second version of the mini-drill does not require either power or an electric motor, so it is much easier to make if you have all the necessary materials. Having chosen which type suits you best, you can proceed to its manufacture.

Electric

Please note right away that this is a smaller version of the classic drilling device, so the work that can be performed with a mini-drill is limited to plastic, printed circuit boards, plywood, and soft wood. It will not be able to work on steel workpieces and concrete, therefore the power of the device is relatively low.

What do you need for an electric mini drill?

Each of us can find a huge number of improvised devices at home that we no longer use, but they can still be used to create a mini-drill.

Rice. 1: structural components of a homemade drill

To assemble such a tool yourself you will need:

- The small motor is the most important part, since the capabilities of the mini-drill will directly depend on its parameters. The most suitable options are engines from old hair dryers - they have quite good power and speed from 1000 to 1800 rpm, and the hair dryers themselves are often relegated to the rubbish category with a working engine. The motor from a blender or mixer is also good (you can leave the housing from them), the motors from a tape recorder and children's toys are less powerful, but they are quite suitable for a mini-drill.

- Power source - depending on the type of device, the motor can be powered either from a 220 V AC network or from a reduced voltage of 6 V DC. In the first case, it is enough to connect it to an outlet via a power cord. If the motor runs on DC voltage with a nominal voltage of 3, 6, 12 V, you will need a power supply with conversion to the appropriate level or several batteries.

- Chuck – as a chuck for a mini-drill, the ideal option would be the original element of a failed screwdriver or small drill. But not everyone can get hold of such a luxury, so a collet is considered a universal option - a part for clamping round elements or a homemade bushing made of a metal tube with bolt clamps.

Rice. 2: chuck collet

An important parameter of the collet is the internal diameter - it must clearly fit the diameter of the motor shaft. If the collet has a smaller diameter, it simply will not fit on the shaft; if it is too large, it will dangle, which will affect the drilling process. Therefore, before purchasing a specific model, measure the shaft, as a rule, it is 1.5 or 2.3 mm, but the value may vary.

- Frame – the main function of the housing is to protect both the device itself from clogging and exposure to external factors, and the person, isolating the electrical part of the mini-drill from hands. Therefore, plastic parts are perfect as a housing for a mini-drill: deodorant bottles, plastic pipes for the water supply system, housings from old flashlights and other options. The issue of insulation is especially relevant for devices powered from a 220 V network; if the drill is powered from a safe low voltage of up to 42 V AC and 110 V DC, the housing can be made from metal pipes, cans, etc.

Rice. 3: syringe housing option - Connecting wires - selected depending on the load, but due to the low amperage of the motor, you can choose insulated brands of small cross-section. To solder them you will need solder and a soldering iron or male-female connectors. The second option is relevant in situations where you need to turn on the reverse movement of the mini-drill.

- Drill and other attachments are installed in the collet; if desired, you can replace the drill with a cutter, etc. Selected according to the diameter of the collet hole.

You can find most of the parts at home, but if you can't find a chuck, it's best to purchase a collet or order a bushing from a turner. You should not solder the drill directly to the shaft, as some “craftsmen” advise. Such a mount can easily fail long before the first work with a mini-drill is completed.

Assembly procedure for an electric mini drill.

For assembly, choose a dry place so that no moisture gets inside the device at this stage. Because water or condensation can damage your drill when turned on or cause an electric shock. The whole process is conventionally divided into several stages, following which you will receive a mini-drill, which is not particularly different in parameters from factory products:

The best corded mini drills

Powered drills are used to carry out various jobs. Despite its small size, this hand-held power tool has good power and reliability. It is universal and can be used not only in household work, but also in small workshops of individual entrepreneurs engaged in furniture production, jewelry repair or other work related to drilling, engraving or grinding.

A corded mini drill has one very important advantage. She can work all day. A powerful motor ensures high labor productivity. Below we will describe the best mini drills of 2020 that operate on electric power.

HAMMER MD050

For those who are interested in which mini drill is best for home use, you should pay attention to this model. It costs only 999 rubles. The wire is protected from kinks in the form of a special insert at its entrance to the tool casing.

The drill has a toggle switch to bring it into working condition. The tool operates at a speed of 15,000 rpm. This is enough to carry out various types of work in small volumes:

- grinding;

- cutting;

- drilling;

- polishing

The advantages include:

- the ability to install collets 1, 2.4, 3, 3.2 mm, designed for different attachments;

- a convenient button that locks the spindle and allows you to quickly change attachments;

- a set of 80 attachments that can be used to perform various tasks;

- light weight of 400 g;

- ease of use;

- ergonomic and small body that fits comfortably in the palm of your hand.

The disadvantages include:

- low power of 4.8 W;

- the absence of rubber inserts on the body, which prevent the palms from slipping during operation;

- lack of a bearing in the spindle, which does not allow working with hard materials;

- lack of a tool shutdown button;

- no storage box.

DIOLD MED-1 MF

This is the best mini drill engraver with a power of 170 W. It can process not only soft materials, but also hard ones:

- metal;

- marble;

- grant.

A mini drill of this type costs 2000 rubles. The tool operates at 35,000 rpm. It has a special thin shaft that allows you to do delicate work. A comfortable bent hand creates a stupor while drilling.

It has rubberized elements that improve the grip of the tool during operation. The drill itself is sold in a special plastic case, which simplifies its storage and transportation.

The advantages of this model are:

- precise speed control using an electronic control unit, with the ability to select different options from 2000 to 35000;

- the presence of a metal loop on the body, by which you can hang the tool while working with it;

- use of a special button for fixing the spindle, which speeds up the process of changing attachments;

- the presence of holes on the body for ventilation, protecting the tool from overheating during operation;

- affordable price;

- presence of a storage case;

- light weight 500 g;

- large set of attachments;

- compact dimensions;

- ease of maintenance provided by available parts;

- convenient slim body;

- low noise level during operation;

- possibility of installing a flashlight on the body.

The disadvantages include:

- the use of a 3.2 mm collet, which significantly reduces the number of nozzles used;

- inability to work at low temperatures;

- the presence of strong vibration in some products of this type;

- unreliable wire that quickly cracks;

- rapid wear of the nut on the body due to frequent loosening during operation.

In general, this model has more advantages than disadvantages. It is great for home use.

DREMEL 4000-4/65

This is a mini tool that even professionals can use. Its rotation speed ranges from 5000 to 35000 rpm. This is the best mini drill engraver that can be used by professional sculptors and carvers. The presence of a powerful motor and a body with a large number of ventilation holes allow it to be used throughout the day.

This model has a power of 175 W. It can engrave, drill and polish various materials:

- glass;

- stone;

- metal.

In addition to a large number of attachments, the kit includes a plastic case with a comfortable handle.

The advantages of this model are:

- the presence of a flexible shaft;

- one-year manufacturer's warranty;

- presence of an ergonomic hand;

- a large set of attachments of 65 elements;

- possibility of smooth adjustment;

- presence of spindle lock;

- light weight of only 660 g;

- high performance;

- presence of a lock on the power button;

- included milling compass;

- the presence of a platform for grinding work at an angle of 45 and 90 degrees.

A professional tool costs 9,000 rubles. This is, of course, cheaper than the cost of a grinding machine, but quite expensive for a hand tool.

The disadvantages of such a networked mini drill are:

- high cost;

- using a collet with a diameter of 3.2 mm.

Otherwise, such a tool has no disadvantages. The high price pays off with a long period of use.

What materials are needed to create a mini drill with your own hands?

- Of course, an electric motor . The power supply is preferably no more than 12 volts: at least for safety reasons.

- Power supply , if possible with a voltage regulator (to change the number of shaft revolutions).

- Housing (in the most primitive designs you can do without it).

- And the second most important part (after the motor) is the drill chuck .

Everything except the electric motor can be made independently. Although, the cost of the remaining components is so meager that you can limit yourself to only assembling power tools from ready-made components.

Let's look at a few tried and tested options.

How to choose?

Today's market for electrical appliances is replete with all kinds of mini-drill models, which creates certain difficulties when choosing the right tool. There are a few things you need to pay attention to when purchasing a Dremel to avoid mistakes and disappointments.

- Rated power is a criterion that determines the performance of a tool. When selecting equipment with optimal power, it is necessary to take into account the purpose of its use. If we are talking about home use, then it is better to give preference to models with power ratings of up to 200 W, and for professionals, units from 240 W are suitable.

- Maximum operating speed. Comfort of work is provided by units with rotation speeds of 20,000 rpm. Although, compared to branded models with a power of 150-160 W, capable of delivering 30,000-35,000 rpm, this value seems more than modest. For the simplest engravers for amateur purposes, the number of revolutions varies between 6000-10000 rpm.

- Rotation speed control. The presence of a speed controller increases the ease of use of the tool. Most mini-drills have smooth speed control, which makes it possible to adjust the motor rotation speed from a safe minimum to maximum.

- Weight and ergonomics. Manual units should not be heavy, otherwise the hand will quickly get tired, which can negatively affect the quality of work. It is optimal when the instruments weigh 600-800 grams. and have high power.

- Noise characteristics. If in repair shops the noise level of an engraver is not so important, then for use in residential premises, low-noise equipment is definitely necessary so as not to cause dissatisfaction with neighbors.

- Working diameter of the collet. It is the collet parameters that determine the possibility of installing certain attachments in the tool. The most common collet options are Ø 2.4 and Ø 3.2 mm. They are equally suitable for home use, hobby and professional processing.

- Equipment. The cheapest mini-drills are sold without accessories. By choosing products in a more expensive price segment, you can become the owner of an expanded basic set, consisting of a flexible shaft, an angle adapter, a box with accessories, spare graphite brushes for the motor, collets with different diameters, letter templates for engraving work, a suspension stand and a case.

- Manufacturer and cost. Now there are many reputable manufacturers of high-quality and reliable power tools, including Boshe, Dremel, Einhell, Elitech, Hammer, Patriot, Sturm, Vikhr, Diold, Zubr, Caliber. Prices for equipment from different brands differ – and quite significantly. When your plans include using an engraver occasionally, there is no point in overpaying for expensive professional equipment from a renowned manufacturer.

Only suspiciously cheap engravers of unknown “origin” that do not come with a warranty are subject to doubt.

Complete analogue of the factory “Dremel”

To make it, you will need a motor with a 5V or 12V power supply, which can be removed from a broken children's toy, a miniature fan, a printer, a tape recorder, or simply bought on Aliexpress. If you plan to use the drill for more than just drilling printed circuit boards, you can make a convenient housing from a polypropylene water pipe. We select the diameter so that the motor holds tightly to the walls. Ventilation usually runs along the shaft. You can use an empty tube of construction sealant.

Drill made from a toothbrush

At first glance, it sounds absurd. But we will talk about an electric brush, which has a completely reliable motor inside. It is enough to get to the steel shaft on which the gearbox with rotating bristles is placed, and the workpiece is in your hands.

The same collet chuck is put on the shaft, and batteries are installed instead of batteries. Or you can adapt a suitable mains power supply.

Drilling walls with such a device will not work, but holes in a printed circuit board will be easy. In principle, you can use any compact electrical appliance that has a conveniently located motor shaft. For example, an old electric razor.

Classification and types

Depending on the power source and design solution, there are three types of mini-drills.

- Standard electrical appliances powered by electricity. An ordinary corded mini-drill has a vague resemblance in appearance to a thick, large ballpoint pen, the end of which is equipped with a rotating working attachment. Due to its small size and ergonomic shape, such a device is convenient to take with one hand. Electrical equipment is often equipped with a flexible shaft (sleeve), which serves as an extension cord, which is attached to the main collet. The tip of the sleeve is equipped with a clamping chuck, which simplifies the work with the Dremel. The device itself can be conveniently placed on a table, and you can hold one end of the bendable attachment with your hand.

The presence of a shaft allows you to achieve the necessary maneuverability when processing the thinnest workpieces and obtain a high-quality result, regardless of the complexity of the working conditions.

- Mobile devices with rechargeable battery. Although the cost of cordless mini-drills is higher than corded models, there is no fundamental difference between them. The only difference between devices with a battery is that they have their own power source, which makes it possible to use them without being tied to an electrical outlet. This equipment is equipped with a conventional charger and an adapter for connecting to the car's cigarette lighter socket.

- Suspended type devices. Hanging models are equipped with a short square or cylindrical body with the ability to be brought to a table or wall. The same sleeve extends from the body part as in standard electric engravers. Suspended devices are equipped with a foot pedal, after pressing which power is transferred to an electric motor that rotates the working tip inserted into the collet on the spindle. The advantage of mini-drills of the suspended type is the high-quality design of the flexible shaft, which is very light and easy to grip by hand.

Economical option without housing

Let's move on to creating a mini drill at minimal cost. We don’t buy anything except the motor itself (although it can be found for free in old equipment). Most compact electric motors are rated at 12 volts DC. We create a power supply for it.

Since there will be no additional options (speed controller, voltage stabilizer), the power supply is stabilized by a constant load. A typical 12 volt micromotor operates with a current of no more than 2 amps. A simple calculation shows that the output power should be 24 W. Add 25% for rectification losses, we get a 30 W transformer.

To get 12 volts under load, 16 volts must be removed from the secondary winding. You can make such a transformer in an hour, from any unnecessary power supply. Next is a rectifier bridge using any diodes: for example, 1N1007.

Our motor does not need rectified voltage ripple, so we connect a 25-volt electrolytic capacitor with a capacity of about 1000 μF at the output. It will smooth the output current. Despite its simplicity, such a tandem works stably, with only one drawback: as the load increases, the voltage drops. That is, with uniform rotation, the power supply produces 12 volts. And if you are drilling “heavy” material, you need to monitor the speed, not letting it drop. Otherwise the shaft will simply stop.

You can slightly complicate the power supply circuit by adding a suitable voltage regulator. For example, KR142EN8B or L7812CV.

In this case, there will be no voltage drop when the drill is loaded.

Next, you need to make a fairly accurate structural element - a drill chuck. If you don't want to spend money on a factory collet clamp, any bushing will do. It all depends on the scope of application of the mini drill:

- If you only drill PCB textolite, you will not need to change the drill. So we attach it permanently. The adapter sleeve can be made from anything: a tube from a telescopic antenna, a needle from a medical syringe, a refill from a gel pen.

Given the miniature design, no clamps are needed. Everything can be secured with glue or tape.

- When using a drill for universal use, which involves changing a drill or installing other attachments, it would be better to purchase a universal collet chuck.

- You can use a standard jaw chuck and install it on the shaft using an adapter sleeve.

The execution of the case depends only on your imagination. Most craftsmen leave a “bare” utilitarian design: the supply voltage is safe, the dimensions of the motor allow it to be held in hands without a housing.

If you want basic aesthetics, there are many options: and they are all free.

A homemade tool doesn’t just save money. It can be made exactly to suit your needs, unlike universal factory options.

The best cordless mini drills

Often you have to drill, cut or grind in conditions where it is impossible to use a network tool. In this case, you will need compact drills that run on batteries. Analysis of such models will allow the buyer to understand which mini drill is better from this type of battery-powered units. When choosing such a tool, you need to take into account the battery power, price and set of attachments.

Hammer AMD

A convenient and affordable model that costs only 2,300 rubles. Despite the affordable price, it is not a cheap or inexpensive type of hand drilling tool. The set includes a plastic suitcase in which it can be stored and transported. It comes with a large number of attachments:

- for cutting splines;

- abrasive cutters for wood processing;

- drills of different diameters;

- polishing attachments;

- cord brushes.

There are different collets that allow you to use attachments of different diameters. The battery power is 36 V and the capacity is 1.3 A/. If the buyer wants the best mini drills of 2021 that work offline, then you can choose this model.

Its advantages are:

- the ability to regulate the number of revolutions from 0 to 18,000 per minute, choosing different modes of material processing;

- light weight of 945 g, allowing you to work with the tool for a long time;

- availability of a 36 month warranty;

- powerful battery that can hold a charge for a long time;

- ability to work continuously for one hour;

- presence of 118 nozzles;

- the ability to use attachments from other drills;

- A plastic suitcase is included.

The disadvantages include:

- the need for regular charging;

- The indicator lights do not always work.

There are far fewer disadvantages than advantages. A worthy tool that can be purchased for home or work.

Bosch GRO 10.8 V-LI Professional

This is the best mini drill engraver that can work on hard metals. It can make up to 35,000 revolutions per minute.

It is easily adjusted using a special wheel, the battery provides uninterrupted operation for 60-90 minutes. The lightweight tool weighs only 600 g, which allows you to hold it in your hands for a long time while working. A professional model costs 10 thousand rubles.

The advantages include:

- the presence of a convenient storage case;

- 3 year warranty;

- low energy consumption of 10.8 V;

- LED backlight;

- battery indicator;

- presence of two batteries;

- low noise level;

- automatic speed fixation.

The only disadvantage of such a tool is its high cost.

Which mini drill is better also depends on the purpose for which it is purchased. For daily work, it is best to use a more powerful professional tool.