The tool combines the functions of classic drilling and making holes through impact on the material being processed. A mode switch is built in for this purpose. The cutting equipment is fixed using the SDS+ system.

The cylindrical shank is secured with a replaceable key chuck. The use of the “two in one” principle expands the overall functionality of the tool. Technical characteristics for selection: power, speed, impact energy, diameter of the holes created.

The Enkor PE-420/12ER rotary hammer is one of the inexpensive ones

The lightweight tool combines the impact of a rotary hammer with the classic capabilities of a drill. For fastening cylindrical, hexagonal and similar shanks, it is equipped with a key chuck.

Replacement of equipment occurs without the use of additional devices - fixation is based on the SDS+ system. A safety clutch is built in and electronic reverse is used. It is possible to adjust the speed.

Pros:

- Inexpensive, advanced functionality.

- Speed adjustment, reverse.

- Light weight, case, cartridge included.

Minuses:

- The new product has a disgusting plastic smell for several days.

Hammer Elitech P 0519RE – for domestic purposes

A two-mode tool for solving everyday problems during home repairs. Reverse is applied by turning the carbon brushes, which allows you to extend the service life of the unit.

An additional factor is the absence of power loss during reverse rotation. Built-in SDS-plus equipment fixation system. The low weight of the tool helps reduce operator fatigue during the work process.

Pros:

- Not a bad price-quality ratio.

- Compact, light weight.

- A combination of a hammer drill and a hammer drill.

Minuses:

- It does not come with a drill chuck, so I had to buy it additionally.

Stanley STHR202K rotary hammer - good for beginners

A tool with clear and simple functions. It is equipped with a medium-power engine and has electronic reverse. Built-in speed adjustment mechanism.

The tool is designed for drilling holes in concrete, brick and similar materials. Switching the mode to drilling will allow you to work on wood, plastic, polymers, composites and metals.

Pros:

- Ergonomic case, fairly long cable.

- Easy to learn, just what a beginner needs.

- Durable, plus a strong case.

Minuses:

- There are no significant disadvantages.

Which is better: an impact drill or a hammer drill?

This question is often asked by inexperienced people who purchase an instrument for their home. Professionals, in principle, do not have such doubts, since they know for sure that behind the external similarity lies a great difference that determines the capabilities of these two tools.

The drill is initially intended for drilling holes in low-density materials - wood, plastic, soft metals. The addition of an impact function significantly expanded the capabilities of this tool, allowing, among other things, easy drilling into brickwork and structures made of low-quality concrete. At the same time, like hammerless drills, if equipped with the proper equipment, they are capable of working with fasteners. For all their versatility, drills have rather modest dimensions and are much cheaper than rotary hammers. Thus, the main reasons for the popularity of impact drills among domestic consumers include their versatility, compactness and affordability.

Accordingly, hammer drills are heavier and more expensive. If we compare tools with identical power, the weight and price advantage of rotary hammers will be obvious. For example, a thousand-watt two-speed drill Makita HP 2071 weighs 2.4 kg and costs about 5,000 rubles. With its help, you can drill holes with a diameter of up to 40 mm in wood, up to 16 mm in steel, and by connecting the impact function, you can “drill” into concrete with a 20 mm drill.

a Makita HR 4010 C hammer drill of similar power, you will have to pay three times more and it weighs 6.3 kg. In terms of functionality, a hammer drill is significantly inferior to a drill, since it only hammers or drills with impact, and these two modes are unacceptable for making holes in wood and metals. But when it comes to drilling concrete, the designated hammer drill is unrivaled, since it will “pull” not only a large-diameter drill (up to 40 mm), but also a drill bit (up to 105 mm). In addition, this tool can easily replace a jackhammer and will greatly facilitate the work of constructing niches and openings, laying communications, chipping old ceramic tiles, etc. Of course, such a hammer drill is intended exclusively for professionals and is unlikely to be useful in everyday life.

However, even among rotary hammers there are “lightweights”: for example, the Makita HR 1830 weighs only 1.7 kg, and is inferior in price to the Makita HP 2071 impact drill. Both of these tools operate in drilling and impact drilling modes. Moreover, with the help of a drill, you can make technical holes of a much larger diameter in concrete (without taking into account hardness), and in wood, and in steel.

A natural question arises: what is the difference then? First of all, the difference is in power consumption: for the compared hammer drill, the power consumption is 440 W, and for the drill – 1010 W. And this is the corresponding load on the network and the cost of paying for electricity on the one hand and a performance indicator on the other.

But the main difference is the purpose, in particular the main object of effort. For a drill, drilling concrete is an additional option, and in the impact drilling mode, the tool works to “self-destruct” (more on this below). A hammer drill, which easily crushes a monolith, will not provide high precision drilling of holes in steel, wood and plastic. The reason for this is the design features of the impact mechanisms of drills and rotary hammers and the cartridges used for fixing the equipment.

In impact drills, the impact is generated through mechanics. Everything is extremely simple there. In drilling mode without impact, two toothed ratchets rotate with their teeth interlocked as a single unit. When the impact function is turned on, the internal ratchet (located closer to the engine) moves back, and the external one begins to “recount” its teeth with its own. As a result, impact energy as such is not generated: the impact force is predetermined by the height of the teeth and the pressure exerted on the tool by the user, and the frequency of impacts is determined by the number of teeth and the speed of rotation.

This is where the “self-destruction” mentioned above comes from. No matter how strong and wear-resistant the material used to make ratchets is, sooner or later the teeth will “stick together” and the impact mechanism will finally fail.

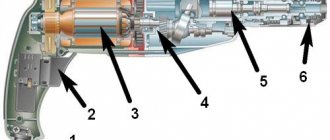

The nature of the impact in rotary hammers is completely different. The crank mechanism converts rotation from the engine into reciprocating movements imparted to the piston. This, in turn, drives the firing pin, but not directly, but through an air gap, which reduces the load on the piston, thereby contributing to the durability of the tool as a whole, and reduces recoil. Such an impact mechanism is three times more effective and, of course, more reliable than a drill ratchet. In the presented model range of Makita rotary hammers, the impact energy ranges from 1.3 to 19.7 J (models HR 1830 and HR 5210C, respectively).

From the above, some conclusions can already be drawn. For example, that if intensive work is to be done on drilling concrete, then the impact drill will “die” pretty soon, and the “heavy” drill will not prevail at all. And it is true. But you shouldn’t be fascinated by the versatility of three-mode rotary hammers, which are declared by manufacturers to be a jack of all trades. As a rule, these are light (up to 4 kg) and medium (5-8 kg) class instruments. Such hammer drills, and “heavy” ones too, are equipped with quick-release chucks SDS-plus and SDS-max, designed exclusively for special attachments - drills, blades, etc. - the shanks of which have a very specific shape (the presence of grooves and their number). Consumables for hammer drills are much more expensive than conventional drills, and the use of the latter is not possible due to the specifics of the cartridges. To expand the capabilities of hammer drills, manufacturers quite often equip their models with additional jaw chucks, which are mounted in standard SDS-type holders using special adapters. At the same time, the tool becomes more cumbersome, and the chuck runout increases noticeably, which does not benefit quality. An alternative for more precise drilling is interchangeable chucks. In this case, the main SDS chuck can be easily dismantled, and in its place, thanks to an adapted tip, a conventional cam chuck is installed - for cylindrical drills. An example is a Makita HR 2811 FT with a removable SDS-plus chuck. It is worth noting that such an arrangement is not yet common and significantly affects the price of the instrument.

So, answering the first question, we have already noted its incorrectness. Both drills and hammer drills are equally good, but only in the area for which they are intended. The impact drill is optimal for drilling holes in wood, metals, plastic, brick and lightweight concrete. In addition, it can be used to work with fasteners, and at low speeds as a mixer. A hammer drill is preferable where it is often necessary to drill and chisel concrete (and reinforced concrete) of varying degrees of density, but it will not provide precision drilling accuracy in metals and wood. Rotary hammers, equivalent in power to impact drills, significantly exceed them in weight and cost. When working with concrete, hammer drills are much more reliable, practical and durable than impact drills. The versatility of impact drills will come in handy at home, while rotary hammers are more “professional”. But if you live in a building made of glass and concrete, then in addition to an impact drill, it would be useful to have on hand, even if not the most expensive and powerful, a hammer drill.

Rotary hammer HAMMER PRT620C PREMIUM – home renovation

Optimal power tool. Combines the classic functions of a rotary hammer - drilling and drilling, - drilling through and blind holes. The design is made in modern technical design.

The safety clutch protects the operator from possible injury and the tool from damage. Features a high impact frequency. Built-in reverse function.

Pros:

- The optimal tool for home repairs, fully meets your needs.

- Durable and spacious case.

- Lightweight, convenient to work under the ceiling.

Minuses:

- Sometimes you need a chiselling mode, more power.

Attachments included with the hammer drill

In order to understand which attachments you may need, evaluate their functions. Offered:

- spare brushes for the electric motor (sometimes this is beneficial, since the cost of such brushes separately is much higher than in the kit; when using a rotary hammer at home, replacement of brushes is rarely required, but for professionals they will not be superfluous, since they will have to be changed often, the savings will be 8-10 dollars);

- adapter chuck for drills from a standard drill - if it is missing, you need to ask if it is possible to install an adapter, i.e. Is it possible to disable the shock function, which is very important for saving;

- a set of drills, which many manufacturers minimize, offering only a basic set (drills for hammer drills are expensive, significantly more expensive than standard drills intended for impact drills, since the requirements for strength and reliability of hammer drills are much higher than standard ones).

What should a master choose, a rotary hammer or a drill? The first one is indispensable for professional work and drilling of hard materials; it will last a long time and provide high-quality impact function, efficiency, and reliability. The second one is easy to use and light in weight.

If you have to renovate a house or a large apartment or office, and you have to drill a lot of holes in solid concrete walls, give preference to a hammer drill. Its price is slightly higher than the cost of a standard drill, but the capabilities are much higher and the service life is longer. It will make repairs easier.

Having an adapter for standard drill bits included, you can perform all types of work with one universal tool.

Rotary hammer Caliber Master EP-1300/30M – vertical layout

A rotary hammer with the function of a classic vertical drill of a professional class. Equipped with a powerful motor that provides effective impact force.

A built-in safety clutch prevents the tool from turning. Electronic reverse is provided. The vibration-damping handle ensures operator comfort.

Pros:

- Power, vibration damping, “two in one”.

- Rich equipment, ergonomics.

- Case, drill chuck included.

Minuses:

- Heavy, gets hot, lacks power.

Rotary hammer Makita HR 1830 – professional for home

A small compact tool with hammer and drill functions. Made according to the classic axial (horizontal) scheme. A safety clutch prevents the tool from turning in the operator's hands.

Reversing is carried out by turning the brush holder - this prolongs the service life. The tool is optimal for doing work at home.

Pros:

- Lightweight, compact, moderately powerful.

- Safety coupling, high-quality assembly.

- Ideal for home work.

Minuses:

- High price for a household tool.

Rotary hammer: technical specifications

Among the main characteristics of a hammer drill is power. The higher it is, the greater the drilling speed. The thickness of the drill directly depends on it. A certain drill will be suitable for your hammer drill at a certain power. You should also focus on the individual parameters of the master: a powerful hammer drill will require strength, since it is heavier and more difficult to operate.

The second characteristic is the rotation speed adjustment. It is present in almost all models of hammer drills. This is a very positive characteristic. Having an adjustable maximum speed limit is a big plus. In fact, it is enough to set the maximum speed, press the trigger all the way, and hammer and drill for a long time.

The next characteristic is the switch stopper, i.e. a button that allows you to set a stopper, lock the switch instantly, without even pressing it with your finger. This function is useful if you need to drill a particular hard material for a long time. The master's fingers are resting.

The function of disabling the hammer drill’s impact function is important for the master. It helps to use the hammer drill as a standard drill. This expands her capabilities. This function is secondary in a hammer drill, however, sometimes it is extremely necessary.

All these parameters are decisive when choosing a drill, however, many craftsmen never come to the final conclusion of what to choose, a drill with the functions of a hammer drill or a hammer drill with the functions of a drill.

Hammer hammer HITACHI DH26PB – for occasional work

Medium-power dual-mode tool. Performs basic operations to create holes and recesses in concrete structures and brick walls.

In drill mode, it processes wood blanks and its processed products. Drills plastic, non-ferrous and ferrous metal. Increased durability due to changes to the impact mechanism.

Pros:

- Optimal price for the stated characteristics.

- Combination of size, weight and power.

- Beneficial for periodic commercial part-time jobs.

Minuses:

- Sometimes the hammer mode is really missing.

How much does an impact drill and hammer drill cost?

Many craftsmen prefer to drill holes in concrete with a drill, since the cost of this tool is always at an affordable level. Only as a result of such use it turns out that the tool quickly breaks down when drilling concrete frequently, or its performance decreases due to wear of parts. As a result, you have to repair the drill or buy a new one.

A hammer drill is more expensive than a drill, but it is worth the cost. The high price is due to the use of a powerful electric motor and a complex impact mechanism. However, compared to an electric hammer, a hammer drill will last 10 times longer if used as intended for concrete processing.

The average cost of an impact drill is 2,000 rubles, while a hammer drill can be purchased for at least 3.5-4 thousand rubles. There are cheap models of rotary hammers - household ones, which are intended only for occasional use.

This is interesting!

When buying a percussion instrument, do not look at its cost. First you need to decide how often you plan to use the device for drilling concrete. If often, then we definitely choose a hammer drill. If you need to use a tool for drilling holes in concrete from time to time, then there is no point in overpaying, and it is better to buy an impact drill.