Hammer drill - what is it?

The tool is used for impact work when preparing surfaces and removing old materials. Mostly hard but fragile: tiles, concrete and masonry. A powerful hammer drill can crush concrete all day long. Among the main purposes are gating of concrete and brick, and other concrete works.

Equipment for a rotary hammer - impact drills or special chisels. They are installed in a cartridge (among the most popular is sds top).

How to choose a hammer drill based on basic technical and operational indicators

These indicators include the following instrument parameters:

1) Engine power determines the force of impacts in chiselling mode and the maximum torque developed by the tool in drilling mode. Household rotary hammers have a power of 420-720W, and professional tools are equipped with motors up to 2kW.

2) The energy of impacts in the chiseling mode depends on the engine power, the mass of the ram and can have values of 1-30J. The greater the impact force, the harder and more durable materials the hammer can handle.

3) The maximum diameter of holes in drilling mode depends on the motor power. It is indicated in the product passport for different materials and different tips, for example, for drills its values can range from 12-80mm, and the size of the crown tip can be 24-160mm.

4) Rotary hammers can have from 1 to 3 operating modes in their functionality. Single-mode instruments include highly functional professional devices with a simple and reliable structure. Typically, such devices perform the function of impact drilling. Models with a simple impact function are called jackhammers. In addition to impact drilling, dual-mode rotary hammers can have the additional function of clean chiselling or clean drilling. Three-mode tools have all the functions listed.

5) Cartridges for gripping drills can have one of 3 methods of fastening:

- SDS-plus, suitable for light hammer drills weighing up to 4 kg and designed for drills whose shanks have 2 pairs of locking grooves located diametrically opposite and ensuring quick installation and reliable grip;

- SDS-max, designed for heavy hammer drills and designed for large-diameter drills, the shanks of which have 2 locking closed grooves and 3 open control grooves;

- SDS-top, used in medium-sized rotary hammers from Bosch, differs from SDS-plus in the asymmetry of a pair of control grooves and the depth of the drill (70mm versus 40mm in SDS-plus).

Each type of cartridge has its own equipment. You cannot install a drill with one fastening system in a chuck with another gripping system. To secure the drills, you need to use three-jaw drill chucks that come with rotary hammers. They can be installed in place of the SDS cartridge or secured in them using a special adapter. The first option is preferable, as it provides more accurate fixation and alignment of the drill along the axis of rotation.

6) The engine location can be vertical or horizontal. The vertical position of the electric motor is convenient for chiselling, and the horizontal position is convenient for drilling holes. Therefore, in most cases, heavy tools have a vertical engine, while in light hammer drills it is installed horizontally. Based on the nature of the work to be done, you should choose the right model taking into account the operating position of the electric motor.

7) Built-in additional functions and accessories ensure the convenience and safety of using the tool. Different models may have:

- a device for stabilizing the spindle rotation speed when the load on the tool changes;

- soft start and overheating protection device, preventing burnout of the motor winding from overload and extra currents;

- a device for reversing the direction of rotation, allowing you to pull out a drill stuck in the material;

- speed switch, which ensures operation of the tool with various equipment - drills and drills that require different rotation speeds;

- pin stop designed to produce holes of equal depth.

The manufacturer's brand guarantees the quality of the purchased product. Professional rotary hammers of the Makita and Bosch brands have a high reputation for high-quality and reliable products. Among household brands, the most famous and popular are tools from VT, Einhell, Stern and Watt.

The manufacturer's brand guarantees the quality of the purchased product. Professional rotary hammers of the Makita and Bosch brands have a high reputation for high-quality and reliable products. Among household brands, the most famous and popular are tools from VT, Einhell, Stern and Watt.

Video: Rotary hammer tests (full version)

Now, imagining how to choose a hammer drill based on its main indicators and characteristics, we can state that a tool that meets the following requirements is quite suitable for household needs:

- power – from 500 to 900 W;

- impact energy – 1.2-2.2 J;

- three operating modes – chiselling, drilling, impact drilling;

- presence of spindle speed adjustment;

- the presence of an anti-jamming protective coupling;

- SDS-plus clamping chuck and drill chuck included.

Convenience of working with the tool is of great importance, which significantly reduces operator fatigue during operation of the hammer drill, which depends on the ergonomics and location of the handles. If the tool fits well in the palm of your hand and does not move to the side when you turn on the engine during test drilling, then such a hammer drill is worthy of purchase.

Add a comment Cancel reply

You must be logged in to post a comment.

Hammer: purpose and application

The hammer drill is designed for making holes in hard but brittle materials.

It will be effective to work on materials where a conventional drill will not be enough. The working body (chisel or drill), moving back and forth, breaks and chops the material. Ideal for concrete and brick during construction and renovation work. Tool Application:

- during repair and finishing work;

- installation of equipment and communications;

- laying of pipelines;

- landscaping and clearing debris;

- other work that requires impact on the material.

What is a hammer drill and what work is it intended for?

A hammer drill is an electrical device that is used to drill holes in concrete and brick. It has more power and functionality than any impact drill and will help you cope with construction and repair tasks much easier and faster. With it you can:

- lay wires making grooves;

- drill walls for installation of sockets and switches;

- fix windows, doors, profiles;

- dismantle floors and tiles;

- install plinth;

- install a lock;

- mix solutions, putty, glue.

A modern hammer drill is a universal multifunctional device, thanks to which you can perform a large number of different jobs quickly and efficiently.

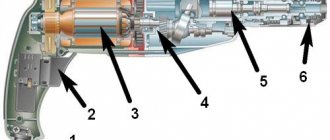

Perforator device

The device of the hammer drill itself requires separate detailed lighting (best seen in the video).

Perforator device

The action of a rotary hammer is to convert the rotation of the engine into reciprocating action of the working body. Main parts: electric motor (or pneumatic device), safety clutch, bearing, sds chuck, handle and controls.

There are designs with the engine mounted vertically and horizontally. Vertical models are usually of medium and high power. The motor is placed horizontally in light models.

Selection options

To ensure that the hammer drill lasts a long time and does not break down after six months due to excessive loads, it is recommended to select equipment taking into account its operational parameters. There are main points that you need to pay attention to.

Drill impact force

This is the main parameter of equipment performance. This parameter is measured in joules. What is meant here is not the pressure on the handle, but the features of the device, with what force it will hit concrete or other material. One of the parameters that is responsible for the drilling depth.

- For workers constantly engaged in repairs, it is preferable to choose models with an impact force of 4 to 12 J.

- For periodic use, a hammer drill with an indicator of 1-2 J is suitable.

- And for frequent work with concrete surfaces, equipment with an impact force of 27 J is required.

Impact frequency

Impact frequency is the second important operating parameter of a rotary hammer. If the push force is large and the impact frequency is low, then the work will proceed slowly.

- For professional use of equipment, parameters of 5-6 thousand beats per minute are suitable.

- If you plan to use a hammer drill at the household level, you can buy a tool with 3-4 thousand beats per minute.

Rotation speed and power

The drilling depth is affected by the force and frequency of the impact. And the power and rotation speed of the chuck with a drill is an important parameter on which the speed of processing thick surfaces depends. A powerful motor is required for fast speed.

- If it is necessary to work with thick walls and partitions, the power of the hammer drill should range from 700 to 1200 W (rotation speed within 2500 rpm).

- If you plan to work with thin partitions (up to 4 cm), a motor power of 500 W and a rotation speed of up to 1200 rpm is sufficient.

When choosing power parameters, you should pay attention to the diameter of the drill. A high rotation speed is justified if a thin drill is used in the work. A thick drill at high speeds will wear out quickly.

Operating modes

Each rotary hammer model has several operating modes. This is a feature of the tool. If the model operates in two modes - rotation and rotation with impact. Three-mode modifications can only work on impact.

The cost of a hammer drill directly depends on the number of modes. If the craftsman has a variety of activities (drilling through holes, installing fasteners), it is worth purchasing a three-mode tool. For the same type of work, you can purchase a dual-mode hammer drill.

Case shape and weight

Equipment of this type is used in work under different conditions, so the productivity and fatigue rate of the worker depend on the shape and weight of the housing. Lighter models have a horizontal engine. They are the best option for installing a suspended ceiling.

Rotary hammers with a vertical engine are heavier, but their body is more compact. They are more productive for drilling walls. The heaviest T-shaped models of rotary hammers were developed for work with road surfaces.

Battery capacity

When choosing a cordless hammer drill, you need to pay attention to the battery capacity. The operating time of the equipment depends on this indicator. For frequent use, you should pay attention to models with a battery capacity of 3-4 A.

Hammer hammer impact mechanism

The impact mechanism is the main feature of the hammer drill. Working like a jackhammer, the drill breaks the surface and individual pieces.

Hammer hammer impact mechanism

There is an electromechanical or electropneumatic mechanism. The most powerful is the second type; it produces more impact energy with a smaller motor.

From the rotation of the motor shaft, the bearing moves in the longitudinal direction. It transmits force to the pneumatic cylinder. The cylinder, in turn, pushes the working tool.

The difference between rotary hammers by the type of equipment fastening system used

The capabilities of the tool are largely determined by the method of fixing the equipment.

There are three known systems for fixing equipment:

SDS-plus.

SDS-max.

SDS-top.

SDS+ is used on household compact hammer drills. The diameter of the tool shank for this type of fastening is 10 mm. A device equipped with this system is capable of making a hole with a diameter of up to 30 mm. Tools with SDS-plus are in greater demand than others, since they are cheaper than hammer drills with other types of fasteners.

Professional devices are equipped with the SDS-max system. They make holes up to 52 mm, so the drill must be securely attached. The tool shank diameter is 18 mm. If the hammer drill weighs more than 8 kg, most likely it has an SDS-max fastening system.

There are rotary hammer models equipped with the SDS-top system, which is based on the SDS+ system, but has a shank with a diameter of 14 mm. Hammers equipped with this system are used to produce small holes from 16 to 25 mm in diameter. These types of hammer drills are reliable and durable. Some Bosch rotary hammers have this particular drill mounting system.

The drill is fixed using oval grooves. Each system has two of them, but the diameter of the attached shank is different: plus - 10 mm, top - 14 mm, max - 18 mm.

Torque is transmitted through long splines. The plus system has two of these, both symmetrical, the top has two asymmetrical, and the max has three asymmetrical slots.

Types and types of rotary hammers

The hammer drill is a universal tool. Many types of machines are used in a variety of fields. These can be a hammer drill: a chipper; with battery; for siding; for chipping concrete.

Even non-industrial models are known.

Rotary hammer with vacuum cleaner

The main problem when working with brick and concrete is strong dust formation. The size of the dust particles is such that they are not easy to wash off from the skin; they will cause trouble in the lungs during long-term work. Overall cleanliness suffers, and the instrument itself becomes dirty.

With a vacuum cleaner

There are a variety of types of dust collection devices available. This could be a dust bag, a mounted or an installed vacuum cleaner.

The bag collects particles and dust through a cuff that fits over the cartridge. You can make this one yourself.

The vacuum cleaner will collect dirt much better. Depending on its power and characteristics, the workplace can become quite clean.

Hydraulic hammer drill

The hydraulic hammer is used for field work and production operations. The main purpose is punching wells and breaking through rocks.

Hydraulic

This professional hammer drill has a simple, reliable design and is driven by the supply of compressed liquid. Consists of impact and rotary mechanisms, power drive and control.

The hydraulic hammer drill is powered by a hydraulic pump. It can limit the work - pipelines and connecting fittings. But the ease of repair is lower than that of an electric one.

A hydraulic hammer drill has up to 2 times more drilling power than other designs.

Laser hammer drill

The smallest and most compact hammer drill designed for making holes is the medical type. It is very quiet and serves as an alternative to a scarifier.

Laser

Used to collect blood, it punctures the skin with laser radiation. It is called so because of the “piercing” and the similarity of the effect to the usual type of machine.

Rechargeable

There is a variety that does not work from the mains - a cordless hammer drill. It is safe and good outdoors and in rooms with very high humidity.

Rechargeable

The main use of such rotary hammers is mobile operations and manipulations in hard-to-reach places. Powered by battery. This cordless hammer drill is made in a plastic case for low weight.

Characteristics: battery type and parameters, electrical voltage, weight, impact and rotation parameters. For mini models - reverse options, speed control. The ability to install a handle and lighting will improve the convenience of working with rotary hammers.

Pneumatic

A pneumatic hammer drill differs from a hydraulic hammer in the type of feeding medium. Instead of liquid, it is launched by compressed air.

Pneumatic

Pneumatic hand tools work in the same way for impact and rotation. Work in mechanical engineering and repair shops is carried out with extensive use of such a mechanism.

A pneumatic hammer drill consists of a practically sealed housing with an air outlet. A ratchet wheel, piston, and cylinder are mounted in it. The cartridge may have a cooling system, which is necessary for high power.

Kinds

There are several types of rotary hammers on the market, differing in functionality and scope of application. Classifying instruments based on these differences will make instrument selection easier.

Mains powered

They are characterized by increased power and good performance. They are used in closed facilities to which electricity is supplied. They can be used for dismantling walls, creating openings and gating.

| Disadvantages of network models include limited use by the length of the cord, weakening of the fixation of components during intensive use. If the mains voltage is unstable, the performance of the tool decreases. |

With battery

Such models are used exclusively for domestic purposes. They are designed for short-term operation where there is no power supply. With this tool you can create holes for fastenings and ventilation. Such a hammer drill cannot be used to create large openings and dismantle them.

| Among the disadvantages of cordless hammer drills are the limitation of operation by the battery capacity, which is not suitable for frequent use. The battery may fail when dropped, and it is difficult to buy a new one. |

Pneumatic equipment

In such models, the electric motor is brought into operation using the air flow supplied from the compressor. They operate from the mains, but the impact force is generated by a pneumatic piston.

Such models are used in industrial conditions at facilities equipped with a centralized air network, which allows saving electricity when operating such powerful equipment, or in conditions of increased fire safety.

| Among the disadvantages, the main one is the high cost of pneumatic equipment and the ability to work only when connected to a compressor. |

Petrol

Such models are usually used when dismantling various objects:

- old walls made of brick or concrete;

- old foundation;

- when removing old road surfaces.

They have great destructive power, independence from energy sources and increased power, allowing them to be used throughout the entire working day.

| Among the disadvantages of the equipment is the high cost, impressive size and weight, the inability to regulate the impact force of the drill, which increases the chance of unnecessary cracks on the surface. Using a gasoline hammer drill means additional fuel costs. |

Features of choice

What are the difficulties when choosing? The main thing is not to get confused in the characteristics.

- vertical or horizontal – power, type of work and convenience are important;

- power: less than 600 W for household work up to 2 kW for professional tasks;

- impact frequency: up to 5000 per minute, and the reliability of penetration is more indicated by the impact energy - up to 20 J/impact, which will create a hole in a concrete wall;

- weight: the lighter, the weaker, so the weight depends very much on the operating mode;

- speed: rotation is needed to remove dust, so the drill will be a variation of a rotary hammer (up to 1000 revolutions for industrial models);

- work in two or three modes (drill / drill with impact / impact);

- drilling diameter of the sds plus chuck and mains operation – the ability to work as a drill;

- chuck type - better sds max (for a larger nozzle diameter) or sds plus, mains operation and 3 modes will complement the functionality.

Choosing tools is never easy. There are models without a case, and the hammer drill will more than serve its purpose. A vertical hammer drill is more powerful, which is already enough for work such as long-term breaking of concrete. For home work, the location of the motor is not very important.

Among the best are bosch gbh 18v 26 professional, interskol p 18 450er, makita hr2470. These machines are enough both at home and at a construction site.

What is a hammer drill and what does it look like?

There are countless hammer drills on the market today. And to make it easier for you to navigate, I even created a whole section in which only instruments of excellent quality are selected. I studied various brands for quite a long time and selected the following for myself: Hilti, Metabo, Bosch, Makita, Dewalt.

Well, I’ll tell you about my Bosch power tool:

Here is a BOSCH GBH 2400 hammer drill with a power of 720 W.

When you decide to purchase such a tool for yourself, I recommend that you contact only professional stores. And when choosing a specific brand, look at the tags stamped on the case or built into it.

Always give preference to those instruments that clearly indicate the phrases: “Made in Japan” or “Made in Germany”:

You rarely see such inscriptions anymore, but if you are lucky, there is a chance that you will acquire your own instruments. If the instrument is simply stamped with “Japan” or “Germany”, then this instrument is definitely made in China, although their quality has become much better recently.

Types of rotary hammers by weight and purpose

The following groups of devices are distinguished by weight and purpose:

Lightweight (household) hammer drills – 2-4 kg.

Medium (semi-professional) rotary hammers – 5-8 kg.

Heavy (professional) rotary hammers – 8-10 kg.

Household hammer drills

Rotary hammers weighing less than 4 kg are considered light. They are purchased for periodic repair work at home or in the garage. Better known as “household hammer drills”.

Semi-professional hammer drills

The middle class includes semi-professional instruments weighing from 5 to 8 kg; they are distinguished by increased power and impact force (5-7 J). The tool can even cut through a steel grating, not to mention making an opening in a concrete wall.

Professional rotary hammers

The heavy class includes hammer drills weighing over 8 kg and an impact force of more than 8 J. The tool is designed for long-term, continuous operation. It is usually used by repair teams, which is why it is called professional. Buying a heavy hammer drill for domestic use is an unjustified investment.

Rotary hammer or impact drill?

All modern electric drills have a hammer drilling mode. Can a drill compete with a hammer drill in processing hard materials - concrete and stone? Our answer is clearly negative. The fact is that the impact of the drill is very weak; its strength is not even indicated in the technical specifications.

Ratchet wheels bouncing over each other

The picture shows how the drill is structured: the reciprocating motion of the chuck is provided by ratchet wheels that jump over each other as they rotate. When drilling, this is felt as a slight vibration of the tool. To get at least some effect, you need to press the drill into the wall with a force of 10–15 kilograms.

Another thing is a hammer drill. He drills a hole in any concrete, just like in wood. It's all about the impact force, which reaches tens of joules. Pneumatics help develop such strength.

Air pressure increases impact energyThe diagram shows one of the design options for the hammer drill. The electric motor rotates the shaft on which the swing bearing is mounted - it is also called “drunk”. The bearing is connected to the wall of the air cylinder. Inside the cylinder, an air gap separates the flying piston from the wall, to which the firing pin is attached, acting on the tool. Due to the rocking of the bearing, the pressure in the cylinder either increases or decreases. Due to air pumping, the force of impact on the striker increases significantly.

Although a drill and a hammer drill are similar in appearance, they are completely different tools. A DIYer's closet, of course, should have an electric drill for drilling holes. But, if you are renovating an apartment with concrete walls, your plans include installing sockets, hanging shelves and chiseling grooves, we recommend taking a hammer drill - you will spend ten times less effort on putting the apartment in order.

A hammer drill is more expensive than a drill, but your doubts will disappear as soon as you make your first hole and feel what this powerful machine is capable of.

Pros and cons of a barrel perforator

In barrel (vertical) hammer drills, the engine is located perpendicular to the impact axis. The vertical type has good engine cooling and power. The majority of professional hammer drills are vertical.

A hammer drill like this delivers powerful blows, allowing you to get more work done in less time. For professional use, convenient and easy bit changes are available, and its multi-function selector also allows you to effortlessly switch between drilling modes, hammer only or hammer drill.

The barrel type can handle any task, including simply securing objects or breaking up huge pieces of thick materials.

Main advantages:

- wear resistance, when chiseling it has a sufficient strength resource;

- and due to the high torque it can be functionally used as a mixer;

- capable of making large diameter holes in hard surfaces;

- impact capabilities are suitable for dismantling walls;

- effective drilling in the vertical direction.

The only downsides are the heavy weight and high cost when comparing the vertical type with the horizontal one.

Differences from impact drill

Hammer drilling can be done not only with a hammer drill. An impact drill can also do this. But there is a fundamental difference between the two tools, which makes the hammer drill primarily an impact tool, and the drill a drilling tool.

Drill specifics

Drill device

The impact of the drill in the drill is carried out using two ratchets, which are located opposite each other.

In the normal state, two ratchet wheels are separated by a special mechanism.

When the hammer drilling mode is turned on, the mechanism is retracted and the ratchets are pressed against each other.

When rotating, there is a slippage on the ridges of the ratchets, due to which the drill rotates and at the same time periodically moves forward.

The impact force in the drill is extremely low and is not intended for heavy loads. It is useless to lean on the drill in order to increase its penetration power; this will lead to accelerated wear of the mechanism, and the load on the electric motor will only increase. The use of an impact drill is justified for some types of brick, cellular concrete and other not too hard materials.

Specifics of the hammer drill mechanism

Unlike a drill, a hammer drill uses a completely different mechanism to impart forward motion to the drill. The most common are rotary hammers with a pneumatic impact system. They use a cylinder with a piston that compresses air. The force of compressed air pushes the striker, which acts on the shank of a drill, chisel or other device.

The first piston is driven in two ways: either by a crank mechanism, as in an internal combustion engine, or by means of a special swinging bearing, which is often colloquially called “drunk” because of the peculiarities of its movement.

The second, impact piston returns to its original position due to the rebound energy. Therefore, the drill itself, which does not rest against the wall, practically does not move in the longitudinal direction. By resting it against the wall, you can get a stable rebound and the operation of the entire mechanism. At the same time, the drill can rotate by means of a gear transmission.

Details about the design of the hammer drill

There is a huge selection of rotary hammers on the market, but how to choose the right tool that is right for you?

Using different types of cartridges

Diagram of the impact mechanism.

The drill chuck is used to secure working attachments, which include all kinds of drills, crowns, drills, and chisels. Most often, these mechanisms are equipped with one of two types of cartridges - SDS+ or SDS max.

The SDS+ chuck is used on relatively small tools – household or light construction tools. Such chucks hold drills (drills) with a diameter of up to 20 mm. For relatively minor household work, such diameters are usually quite sufficient.

For drills with a diameter exceeding 20 mm, the SDS max chuck is most often used. Drilling holes of increased diameter can be done by heavier professional hammer drills. Since when drilling wide holes one has to deal with greater material resistance than in the case of household devices, the SDS max chucks provide an increased area for gripping the drill with chuck wedges compared to SDS+ chucks.

HOW A PERFORATOR WORKS

The first electric hammer drills appeared in 1932. They were produced by Bosch, which, we note, has many achievements and records in this area. At that time, hammer drills were used primarily for industrial needs and construction.

However, over time, the instrument gained great popularity among the people. Perhaps ordinary people will not find much difference between an impact drill and a hammer drill, especially since many models at first glance are almost indistinguishable. But cars serve different purposes. The hammer drill is designed for drilling holes in particularly hard materials - concrete, stone, etc. You can’t “deal” with them with regular drilling, so they use drilling plus impact or pure chiselling (in this case, it is more appropriate to call the device not a hammer drill, but a jackhammer, regardless of the weight of the machine).

Accordingly, the “birth” of a blow occurs differently in a hammer drill and an impact drill. If in a drill the impact occurs due to mechanics, and the force of the impact depends on the force of pressing the tool, then in a hammer drill a pneumatic impact mechanism is responsible for generating the impact - this is the most common option.

The impact mechanism of a rotary hammer consists of an intermediate shaft, on the axis of which there is a “drunk” bearing, a barrel, a piston, a striker and a cylinder. The oscillating drive converts the rotational movements transmitted from the motor to the shaft into translational movements of the cylinder. When the latter operates, an air space is created between it and the piston (and between the piston and the striker). That is, the piston moves under the influence of compressed air, which acts as a spring.

The design of the impact mechanism of a rotary hammer is more complex than that of a drill. However, a drill is not even worth competing with a hammer drill: its impact energy (and it is measured in joules) is tens of times less than that of a hammer drill, in which, moreover, this energy does not depend on the force of pressing the tool. Therefore, when choosing, consumers should think about what kind of car they need. The drill is suitable for rare and short-term work with soft concrete and brick, especially with good equipment - the user will not suffer for particularly long. The same cannot be said about the tool itself, which wears out faster in shock mode.

But for “uncompromising” drilling in problematic materials, you can’t do without a hammer drill. What an impact drill will spend a lot of time and a significant percentage of its resource on, a hammer drill will deal with in seconds. Not to mention the fact that a number of jobs can only be performed by a rotary hammer (they depend on the class of the machine): beating ceramic tiles, chipping cement layers, destroying road surfaces and much more. And more precisely, models are selected for specific tasks, for the required diameter. If necessary, you can always use the help of consultants in stores.

We advise you to study - Autonomous water supply: which is better, a well or a well

Many manufacturers offer universal devices capable of drilling, hammer drilling and only chiseling material. Such “three-mode machines”, created, one might say, for all occasions, belong only to the light class - heavy machines do not have a drilling function.

The best hammer drills with two operating modes

Rotary hammer Makita HR2300

Inexpensive (up to 8 thousand rubles) semi-professional device for working at heights. Light weight and ergonomics allow you to operate the device even when climbing to the very top of a stepladder.

The engineers thought about left-handed people and created a convenient system for controlling the drill's reverse motion. Now the reverse can be started and adjusted with one hand, and with the other hand you can hold the device itself by the handle.

We advise you to study - Better electric planers - comparisons, reviews, ratings

The delivery set, in addition to the case without additional drills, includes an additional handle with a locking button. In addition, you can adjust the rotation speed of the drill to accurately drill holes in ceramics or other difficult surfaces. Due to its versatility and low price, the model is perfect for home use.

Interskol P-32/1000E

Domestic hammer drill with a vertically mounted motor. This simplifies the design and allows all components to be contained in a smaller housing. As a result, Interskol managed to make a semi-professional device weighing less than 6 kg.

Russian engineers also used an anti-vibration system and an additional handle to adjust the drilling depth. Thus, the tool has become even more convenient when performing work that requires accuracy and precision. Adjusting the rotation speed of the drill also serves these purposes.

The delivery set already includes the usual case, but the manufacturer was greedy and did not include additional drills in the kit. In addition, many may not like the 2 unfortunate meter long cord.