Is it possible to cut tiles with a grinder?

Indeed, a grinder is suitable for processing tiles, especially if you need to cut narrow strips or cut round and rectangular holes.

Another tool for processing tile flooring is a tile cutter. But not every owner has this device in their arsenal, but with an angle grinder everything is somewhat simpler. In addition, the tile cutter is not capable of complex shaped cuts with precise adherence to the given geometry and parameters.

Another advantage of an angle grinder is the ability to use a variety of discs. They can be selected according to the type of tile, its thickness and coating characteristics.

Most tile cutters are designed to process tiles up to 30 cm in length. Anything longer will have to be cut only with a grinder.

Basic woodworking techniques

When using the device in question, it is possible to process wood efficiently and correctly. To do this, the following replacement disks are installed:

- Wire brushes.

- Petal type discs.

- Sanding pads.

Processing soft materials is considered one of the safest operations, since the attachment used cannot jam, and the master does not have to put a lot of pressure on the angle grinder. Sawing should take into account the fact that cutting with a grinder can lead to scorching of the edges of the wood; it is correct to take breaks.

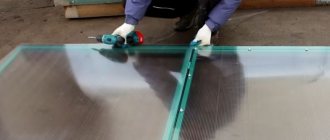

How to turn an angle grinder into a tile cutter?

The design of the grinder does not allow cutting with maximum emphasis - the device will have to be constantly suspended or an assistant must be involved. The most rational solution is to slightly modify the grinder, turning it into a convenient and safer electric tile cutter.

To begin with, choose the most convenient and spacious place to locate the machine. The base for the grinder can be a sheet of metal with a groove to deepen the cutting edge. The gutter will be a kind of mark that you can use as a guide when performing work.

Then they begin to fix the grinding machine. Special clamps that can firmly fix the tool body will help in this matter. You can improve an improvised tile cutter by adding a container of water to the structure to cool the disc and an attachment for wet cutting.

Test cutting is carried out only when the machine is securely fixed. The tiles are laid according to the mark, face up, turn on the grinder and deepen the cutting edge, feeding the tiles away from you.

How to work with a grinder on metal

How to do it correctly and safely

Today it is difficult to imagine the work of mechanics, repairmen and other similar professions without an angle grinder. } myth tool is actively used for cutting various materials, grinding cuts and other actions. The simpler the attachments in a personal computer, the more universal functions it has.

How to safely work with an angle grinder

The grinder is an indispensable tool, but at the same time the most traumatic. It is for this reason that it is necessary to know not to follow the rules of safe work.

Preparation

Without following the rules, this tool becomes extremely dangerous, so it is better not to work with a child who is drunk, very tired or has not had enough sleep. These conditions lead to lack of concentration and negligence, which can lead to danger.

Before starting work, it is recommended to prepare all the necessary protective equipment. It is immediately necessary to have special glasses nearby without a casing. Sparks will of course get into the face, and especially into the eyes, which will lead to injury.

Without face protection or vision protection, specifically speaking, working with the tool is prohibited.

The casing is necessary to organize protection between the tool itself and not the person. You should also have protective gloves. When working, your hands are absolutely close to the disk. This means that particles, sparks and not scale will fly from them. The best way to protect your hands is to use thick gloves or mittens made of genuine leather.

Protective gloves ensure the safety of the skin of your hands.

Before starting a working day with the unit, it is necessary to prepare the following elements and accessories:

- Glasses or mask (preferably the second option);

- A respirator is also called a vacuum cleaner;

- Protective clothing that covers the client's body parts;

- Necessary attachments that are allowed to be used according to the instructions.

Having prepared these items, we begin to work directly with the grinder

.

Features of work

Use requires compliance with several recommendations.

- It is necessary to hold the tool with both hands when working. This will allow, in the event of a possible reverse impact, to maintain its minimum displacement.

- Work should only be done on a flat surface without feeling a loss of balance.

The grinder is held with only two hands, otherwise the risk of injury increases.

- The power cord is located on the opposite side of the drive to prevent damage to it. A cut cord can not only lead to a shock wave of the unit, but can also cause...

- The instrument is held firmly in the palm of your hand until its disk comes to a complete stop.

- To change the cutting location, you need to turn off the grinder. Otherwise, you may accidentally hit surrounding objects.

- When there is a power outage, it is not the instrument itself that must be unplugged from the network. This is done so that when electricity is supplied, it does not start working without operator control.

- The work process significantly heats the discs, so after turning off the grinder, they should not be touched until they cool completely.

How to cut correctly with a grinder

It is necessary to cut tiles, metal, stone and concrete using different circles designed for a specific material.

How to cut concrete with a grinder ()

For shallow depths, use a grinder with a sintered diamond non-segmented disk with a diameter of 105-125 mm. At the same time, working with the material requires compliance with certain rules:

- Using a regular spray bottle, spray water directly onto the furrow, this will reduce the amount of dust.

- Spray water on the disc itself if there is no power source nearby. It is known that diamond discs heat up quickly, water will not only cool them down, but will also extend their life.

- If spraying liquid onto the disk is not possible, then cooling is done with air. It is worth regularly removing the disk from the cut to prevent it from working in the air.

How to cut tiles ()

Mistakes made during work cause not only material damage, but also health.

How to work with an angle grinder correctly

Our group Some simple tips on the topic. how to work

with

a grinder

. Mainly for.

If you don’t have a tile cutter at hand, you can use a grinder to cut tiles and tiles. To do this you will need a wet or dry cutter. The first option is used for long-term work, the second is preferable for creating a small cut.

Before cutting, it is important to thoroughly inspect the unit and securely fasten all parts. For your own safety, you should use gloves, a mask or goggles.

How to cut stone

The cutting machine is designed to work specifically with this material. It is a circle with segments necessary for cooling.

Such discs are quite durable and can serve for a long time, provided they are used correctly. You should not continuously work with the stone; diamond coating will become unusable after 3-5 minutes.

To prevent this from happening, you need to cut the stone for no more than one minute, then remove the disk from the furrow and let it stop.

How to cut metal ()

The protective cover can protect the operator in case of damage to the disk.

If you work with metal, but do not have the appropriate skills, it is better to practice on unnecessary metal products. In general, a number of recommendations must be followed:

- It is safe to apply only radial forces to the circle. Changing the plane during the cutting process will cause it to break and create a risk of injury.

- It is recommended to cut this material using the lower half of the disk (in particular its near part).

- For long-term operation of the unit, it is necessary to take a half-hour break every five minutes.

- You can cool the discs and thereby prolong their service life by slightly watering the cut area.

- When working with aluminum, drip kerosene onto the cut (if the sheet is thick).

How to cut pipes ()

If it is necessary to work with long pipes installed on supports, then it is their hanging edge that should be cut. If this process is carried out between the supports, the pipes will begin to bend under their own weight, which will lead to jamming of the disk.

During the work process, you should not put much effort into the tool. This can cause overheating of the device itself, as well as disk failure. After the cut has been made, a special disk is used to process it, but not the one that was used for cutting pipes.

Grinding rules

The grinding process should be carried out using normal thickness. Their choice directly depends on the material being processed.

Sanding wood ()

Sanding a wooden surface using a grinder includes three stages:

- Preliminary preparation. If there are traces of varnish or paint on the surface, they must be removed before sanding. To do this you will need a grinder with a special one.

- Rough grinding. For this stage it is necessary to use grinding and polishing wheels. If you don’t have these in your arsenal, you can take a regular disc and attach an emery wheel to it.

- Fine grinding. If such grinding is necessary, to organize it it is enough to place a zero-grade emery wheel on the disk.

Concrete grinding ()

surfaces can be produced in two ways:

- Dry grinding method. This is a fairly lengthy procedure, during which a large amount of dust is generated, so it is necessary to use a respirator to protect the respiratory tract.

- Wet sanding method. Typically used to process mosaic or marble chip flooring, less commonly for concrete. Helps to obtain an ideal surface, which in appearance is equivalent to polished.

Metal grinding ()

For a metal surface, you will need a flap or abrasive wheel.

The first option is used for high-quality grinding of an already flat surface, since it is not able to eliminate hard irregularities.

The second option is able to eliminate protrusions on the metal surface (welding seams or burrs left after cutting). High-quality work can only be obtained by combining these two disks.

How to choose an angle grinder ()

Choosing the right grinder is the key to high-quality and durable operation of the tool. Therefore, the acquisition process must be taken quite seriously, paying attention to its main parameters: cutting blade diameter and power.

buyers are afraid to purchase professional models, choosing units with low power. However, this is completely unfounded! The fact is that it is in machines with low power that disks often jam when the device is simply unable to pull it out.

Professional models are safer to drive than low-power ones.

Therefore, for beginners, the optimal choice would be a tool with a power of 900-1000 W, with a spindle speed of about ten thousand rpm and with disks of one hundred twenty-five mm. Such technical characteristics make it possible to saw iron.

To work with metal surfaces, it is better to use models that are designed for a one hundred fifteen mm disc and are powered by a battery. However, as practice shows, their considerable cost is not always justified for everyday use.

If the selected model suits you in terms of technical characteristics, but it is inconvenient to hold while working, you should think about another option.

How to select disks ()

Before selecting discs for a tool, you need to know exactly for what purpose they will be used. Already on the basis of this knowledge we can talk about their thickness and diameter.

The smallest is one hundred twenty five mm, the largest is two mm (for professional models this value may be higher).

The thickness of the workpiece, as well as the depth of the cut itself, will depend on this value.

The disk must be designed for the material to be worked with; the correct choice of disk is the key to successful work

If you need to purchase a grinder for metal

, then it would be more advisable to choose a special cutting disc. For household models, its thickness can vary between 1-1.2 mm, for industrial models – up to 2.5 mm. Thus, the cuts will come out neatly and the physical stress, both on the operator and on the instrument itself, will be minimal.

Correctly selected tools and compliance with all safety standards are the key to successful work. So, at first glance, a dangerous grinder turns into an indispensable assistant, both in everyday life and in the professional sphere.

RESULTS Ñ Ñ Ð´Ð»Ñ Ñ€Ð°Ð·Ñ€ÐµÐ·Ð° Ð½Ð¸Ñ Ñ€Ð°Ð·Ð»Ð¸Ñ‡Ð½Ñ‹Ñ……”,”word_count”:1375,”direction”:”ltr”,”total_pages”:1,”rendered_pages”:1}

Source: https://ctln.ru/kak-rabotat-bolgarkoj-po-metallu-video/

Which disc to cut ceramic tiles with a grinder?

There are at least 6 types of discs suitable for use with an angle grinder. The quality of work and the achievement of various results at the request of the master will depend on the choice of nozzle.

Stone discs

Sharpening bits are most often made from stone. They provide a solid base with a minimum thickness of 6 mm. Thanks to their solid base, stone discs are ideal for sharpening tools that conventional thin blades cannot handle.

As a rule, stone discs are not suitable for cutting tiles due to their large thickness. But they can make the tools at hand sharper without much effort. A stone wheel with sandpaper petals glued on is suitable for sanding work. It is recommended to clean the tiles with a soft abrasive marked No. 120, 150, 180.

Steel wheels

Steel is a complex alloy of iron with carbon and impurities in the form of silicon, sulfur, manganese and phosphorus. The carbon component, the content of which does not exceed 2.14%, gives the steel high strength and hardness. This allows the use of metal as a base material for the production of cutting discs for grinders.

In some cases, diamond coating is applied to steel discs, giving the cutting edge unprecedented strength.

Another option for coating steel nozzles is electrocorundum. This is an abrasive made from crystalline alumina or synthetic corundum, which increases the sawing properties of the disc. Such nozzles are marked blue and are used for cutting a variety of metal elements - profiles, sheets, angles, fittings and pipes.

Even more so, such attachments can handle cutting tiles without difficulty, even if you have to work with very thick floor tiles and porcelain stoneware.

Segmented dry cutters

The disk of this modification is also made of steel, but differs from the standard attachment in the presence of slots. They are located along the edge of the product towards the central part and divide it into equal segments.

Segmented dry-cutting discs are used for processing very durable porcelain stoneware tiles and natural stone materials. Thanks to the presence of segmented slots, the nozzle lasts longer than other models. Increases service life and air cooling during cutting.

The only drawback of dry cutters is the high probability of chipping.

Solid dry cutters

The solid type attachment, despite the name, is used for wet cutting. It does not have cuts responsible for thermal relief, and therefore requires the use of a coolant - water supply to the cutting zone. Due to the tendency to overheat, a continuous dry cutter operates continuously for no longer than 15 seconds. At idle, leave it for another half a minute to cool down.

Failure to do so will cause the silver solder to weaken, the diamond coating to wear off, and the wheel to lose its original shape.

A continuous dry cutter provides a better quality cut. The most important thing is not to forget about the water supply. Its supply can be ensured by connecting a hose or attaching a specialized device.

Combined disc models

Discs for cutting tiles with a grinder received this name due to their ability to work both dry and wet. This is an intermediate option between segmented circles and dry cutters:

- cuts better than segmented, but worse than solid;

- continuously works more than solid cutting, but less than dry cutting.

Most often, combined wheels are used in the field of cutting brick and concrete, but their use is allowed when carrying out facing work. The disadvantage of combi models is their tendency to quickly become clogged with dust.

Diamond wheel

A tool for cutting ceramic tiles for an angle grinder with diamond coating is the most expensive, but at the same time the highest quality option for attachments for an angle grinder. What can a diamond wheel cut?

- tile;

- stone;

- plastic;

- tree;

- ferrous and non-ferrous metals;

- concrete;

- marble.

The carbon coating on the nozzles has different hardness and composition.

Cutting tiles with a grinder using a diamond wheel is permitted only with diamond discs whose coating is compatible with tiles.

Diamond attachments for grinders are also solid and segmented. There is another variety - turbo circles. They are used where you need to cut tiles at an angle at high speed.

Choosing disks: how to cut correctly with a grinder

To simplify the process of using the tool, all working surfaces received special markings. This indicator is measured in millimeters. It is enough to take a short glance at the disk to find out everything about its scope of use. The list opens with the smallest of all diameters – 115 mm. It is intended for grinding purposes only. It is strictly forbidden to use it to cut metal products or stone.

The list continues with a diameter of 125 mm, which is considered to be the “golden mean”. As in the first case, the scope of application of such a device is limited. We are only talking about the ability to make the surface smooth with your own hands.

For the grinder to work correctly, you need to choose the right disc

In addition to the two varieties mentioned, there are several additional diameters:

- Diameter 150 mm - it is equipped with a tool used for sanding walls and floor coverings. In this case, it is necessary to emphasize that a grinding machine equipped with such a disk is not used for cutting.

- Diameter 180 mm - such devices are suitable for cutting off part of a not very dense material, for example, aluminum. For cast iron, such a circle will not work, but you can still process the tiles, cut out a small area of the surface, and so on.

- Diameter 230 mm - used exclusively for professional construction and installation work. This disc is equipped with diamond coating, thanks to which it can do almost anything. Cut bricks whose thickness reaches several centimeters. Clean granite or polish walls.

A stationary or portable grinder needs a properly selected disc. It must be remembered that even the smallest disk cannot be used for processing wood. Before installing a particular disc, you should study the characteristics of the surface being treated.

Safety precautions

A grinder for cutting tiles is one of the most dangerous power tools. Therefore, following safety precautions will help preserve not only the health, but sometimes even the life of the master.

What rules should you follow:

- work only in a special suit, glasses, gloves, respirator, safety shoes;

- do not remove the protective casing from the device body;

- remove the power cord from under your feet, do not allow it to get under your feet or into the cutting area;

- cutting tiles with a grinder without chipping is performed only in the direction away from you, firmly holding the unit with both hands;

- immerse the nozzle into the tile no more than ⅓ of the radius of the circle;

- avoid maximum and minimum rotation speeds;

- do not allow any liquids to get under the body of the angle grinder;

- Work only in a well-ventilated area due to the highly explosive dust.

How to Use a Grinder Correctly

How to work with an angle grinder correctly: step-by-step instructions

Knowledge of how to work with an angle grinder correctly will help you achieve your goal of saving life and, in addition, health. The mentioned tool does not tolerate neglect of safety precautions. Manufacturers} {domestic) emphasize that the operation of the equipment must be accompanied by compliance with the instructions.

An angle grinder today is much more functional than a few years ago, when the tool could only be useful for grinding work. Today, these devices are indispensable in metalworking and construction.

Externally, the grinder looks unpretentious; it is similar to oil and has a cylindrical body, on which there is a handle, and on the other - a mount for attachments. It is the attachments that make this unit multifunctional. How to use an angle grinder correctly video. Adviсe.

They are fixed to the spindle, while the discs are additionally secured with a clamping nut and not a flange. This measure is mandatory when working with the described tool.

Why do you need an angle grinder?

Having examined modern angle grinders, you will note that they are able to cope with many tasks, including:

- polishing;

- grinding;

- cutting glass, tiles, stone, plywood, concrete, brick and metal.

For all types of non-material work, a specific abrasive tool should be used.

General recommendations for working with an angle grinder

To figure out how to work properly

grinder, you need to find out the range of attachments, including. brushes are not circles. The first ones are intended for polishing and not cleaning surfaces.

In this case, there is an option to polish the welds without cleaning the rust from the metal. Based on the composition, different circles are used to perform different tasks. Some are of course suitable for cutting ceramics, while others are suitable for metal.

You can get acquainted with this information by looking at the instructions on the disk, or in the packaging.

Which grinder to choose

If the question arises here: how to work correctly with an angle grinder

, then you need to know that not only the attachments are different, but also the angle grinders. See photos and videos about how to properly cut tiles with a tile cutter. They are presented in different classes, including:

The latter option is suitable for use for a limited period of time on any day. A professional angle grinder can work for several hours every day.

As for industrial equipment, it is a device that works almost tirelessly. The tools do not differ in appearance.

Thus, the body you will like is complemented by one or two handles, and in addition vibration-absorbing handles.

Safety precautions when operating an angle grinder

Before you begin the work process, you need to prepare the tool. For this purpose, a circle is not selected. The motor has a certain power, it requires the selection of a circle of certain sizes. The smaller the circle, the higher the rotation speed it can maintain.

6 videos: how to use a manual tile cutter - simple and how to cut correctly. shows how to properly drill a concrete wall in a panel house with a hammer drill in order to attach fasteners to the dowels for laying water pipes.

If the wheel is used incorrectly, this will cause wear on the equipment and deformation of the nozzles.

If you should think about the question of what it really is, how to work with an angle grinder

To avoid injury, you must be aware that the tool does not have to be equipped with discs whose dimensions are different from those for which the unit is intended. The nozzles are not deformed. If cracks or potholes appear on the wheel, they should be removed. It makes no sense to use those circles that deviate from the original shape.

Fire safety and fastening of parts

The operator must ensure that no one is in the cutting plane. Do not let go of the tool until the disk stops completely. The equipment should not be touched before it has cooled down. There should be no flammable objects in the work area, namely:

If you are interested in the question of how to properly work with an angle grinder, then you should think about securely fastening the parts. Everything that is processed and cut must be recorded.

As an exception, there are elements that will remain motionless under the influence of their own weight, this includes slabs and stones. The part can be fixed in a vice.

If this is not possible, you should use the help of a partner who will fix the workpiece or pipe with an adjustable wrench. It is prohibited to hold workpieces in your hands.

How to cut with a grinder

Many owners of the equipment described in the first stages of its operation are interested in the question of how to properly operate a small angle grinder. How to properly use a tile cutter video. Manual tile cutter - how to use it correctly.

It is worth noting that the method of cutting the workpiece in this case is no different from that when a professional-class tool is used in the work.

Work areas must be cleaned, the workpiece must be marked, and only then can you begin work.

The equipment must be held with both hands. If the wheel jams, the tool should not be torn out of your hands. You should always be prepared for kickback, which can cause severe displacement.

This video shows how to use and how to cut correctly. In general, kickback is one of the most dangerous moments when operating an angle grinder.

In this case, a sharp sudden kickback of the tool occurs when the disk jams in the workpiece.

What else should definitely be mentioned when talking about how to work with an angle grinder correctly? Where sparks fly during certain manipulations. This is what the master needs to keep an eye on. They should not come into contact with the face, legs or clothing. It is important to make sure that the power cord is out of reach of the drive.

If you need to move to another object, then first turn off the equipment and drag the cord. If there are power outages, the device must also be de-energized. It is very important to understand the question of how to properly work with an angle grinder - for yourself or for yourself.

The answer to this question is the following statement: the movement of the tool and the direction of rotation of the disk must coincide. However, sparks will cover the markings. It is for this reason that operating rules are often ignored, but in vain.

In order to prevent the wheel from jamming, the disk should be brought into contact with the workpiece at full spindle speed.

Basic rules for cutting

When cutting a workpiece, it is important to make sure that you follow the basic rules. How to use a manual tile cutter, how to properly cut porcelain tiles with a tile cutter.

The cutting line should pass the person, but not rest against him. If a disc jams, the jet motion of the equipment will bypass the operator. It is important to provide protection with a casing.

It should be located between the worker and the circle.

There is no need to apply excessive pressure on the tool. The unit will be able to cope with tasks using its own weight. Whereas overloads will cause the circle to skew. It is impossible to turn on the angle grinder when the disc is in the profile of the workpiece. You should start cutting the profile from the place where the cross section is smallest.

It is important to remember that cutting tiles, concrete and stone will generate a lot of dust. Cutting tiles with a tile cutter. about how to cut correctly, how to cut correctly. The respiratory system should be protected from it. The likelihood of getting injured at any time is high, but knowing how to work with an angle grinder correctly and following these rules, p.

Some manufacturers produce casings with a pipe for a vacuum cleaner. You can also suppress dust with water, directing the stream into the cut. If you need to work on cutting a wall, you must be prepared for the fact that reinforcement, pipe or cable may get under the circle. This will certainly cause a backlash.

To avoid injury, stay clear of the equipment's offset line.

Conclusion

Even before purchasing the equipment described in the article, you should learn everything about how an angle grinder should work correctly. This applies not only to the operating instructions for the instrument, but also to the sound that accompanies the operation of the unit.

How to use a screwdriver correctly: 5 rules. It should be smooth; You should make sure of this by putting on the disk. You should not hear or feel any unnecessary sounds or vibrations during operation. Popping sounds, foreign odors and heating of the case are eliminated.

If you notice such signs, then it is better to exchange the instrument.

Source: https://vdiweb.ru/kak-pravilno-polzovatsja-bolgarkoj-video/

How to cut tiles with a grinder without chips and dust?

Before processing, careful measurements are taken - the markings are applied with a marker on the outside of the ceramic tiles. Since it is impossible to make a perfectly even cut in most cases, small allowances are made for trimming with a sharpener or a needle file.

Straight cutting

The simplest processing option, which even beginners can handle, is cutting tiles with a grinder in a straight line. To begin with, the tool is fixed on a flat surface. It must be positioned so that the cutting edge hangs from the platform. The cutting direction should remain within the tiler's line of sight and the tiles should be laid face up.

Hold the grinder with the cutting direction away from you, moving along the intended line. Ideally, the cut should be done in one pass, only then will it turn out smooth.

If the grinder involves adjusting speeds, reduce the speed at the beginning and end of work.

Shaped cutting

It is more difficult to perform than the first option and requires some skill. The tiles are processed with short cuts along a tangent line to the outer contour of the drawn figure (oval, circle). This will allow you to cut off small unnecessary fragments, and then achieve the desired configuration.

They also plan small allowances for trimming, and at the end they refine the contour by sanding, achieving smooth lines and removing chips.

Making rectangular holes in tiles

After delineating the boundaries of the rectangle, steel plates are applied to its outer surface. The longitudinal plate will act as a ruler, and the transverse plate will act as a limiter for the movement of the cutting tool.

To fix the plates, use tape or clamps. Next, small grooves are cut, bypassing the contour created by the device, and then gradually going deeper inside.

You can make the job easier with the help of a drill. It is used to drill several holes with a diameter of about 5 mm inside the contour, and then using a grinder to create through cuts between the perforations.

Hole cutting

Only large diameter holes are cut with a grinder; small ones are made with a drill or hammer drill.

Step-by-step instruction:

- Two straight lines are drawn through the center of the circle hole, located perpendicular to each other.

- Pointing the grinder at an angle, make a small indentation along the length of the circle, trying to adhere to its internal diameter.

- Gradually move in a circle, evenly filing the thickness of the tile.

- Once the recess is sufficient, straight perpendicular lines are filed through the center of the circle.

- Carefully remove the first segment to avoid chipping, then remove or knock out the remaining three.

To trim the cut line, use a file, sanding paper wrapped around a block, and a drill with a sanding attachment.

45 degree cutting

Cutting tiles with a grinder is necessary when installing plastic or metal corners. This will help form a beautiful beveled edge when laying the tiles diagonally.

An even and fast cut can only be achieved with a diamond-coated nozzle. The tiles are placed under the edge with the glazed side down. Positioning the grinder at an angle of 45°, grind the back side. As soon as the angle is formed, the actions are repeated, moving in a circle along the edge of the cut.

Some craftsmen begin work by cutting tiles rectangularly. The nozzle is then directed to remove excess ceramic at a given angle. The work is completed by sanding the edge.

It is recommended to perform angular cutting of ceramic tiles with a grinder at home using those models of grinders that have adjustable disk rotation speeds.

Rules for using an angle grinder when processing various materials

Due to its versatility of use, angle grinders have become widespread both at construction sites and in everyday life. It has firmly entered the sphere of activity of professionals and simply craftsmen. With its help, you can process almost all known materials, as well as successfully carry out installation and plumbing work. Let's consider the main areas of application of angle grinders.

Woodworking

When working with wood, an angle grinder equipped with a flap or disc sanding disc will be an excellent assistant for grinding and polishing smooth surfaces. By changing the grain size of the sandpaper, you can perform a wide range of operations to level a wooden surface. It is very convenient to remove old paint using an angle grinder. When sanding wood with a grinder, it is vital to use a respirator that protects the respiratory system from dust.

The main rule of safety. It is strictly forbidden to saw, drill or mill wood using an angle grinder. High speeds of the working tool, multiplied by the tendency of wood to split, create very dangerous factors. Numerous tragic cases are clear evidence of this.

Sanding logs is done quickly and efficiently with a grinder

Working with ceramic tiles

A grinder is often used when working with ceramic tiles. Of course, the main tool of a professional tiler is a manual tile cutter. But a grinder is also necessary; with its help, small cuts are made on the tiles, the edges are leveled, and unwanted sharp corners are smoothed out.

Using modern diamond-coated bits, you can cut ceramic products with high precision, while avoiding chips or cracks.

Sometimes professionals prefer cutting with a grinder, since a manual tile cutter causes chips along the cut line. This is especially true when the front surface of the tile is not glossy, but lumpy (for example, in a bathroom, where it is customary to lay tiles on the floor that have anti-slip properties).

An angle grinder also helps out if you need to do a small amount of work. For example, lay a tile apron over the table in the kitchen. Any person can do this task. An angle grinder with a diamond blade will help you save on the purchase of an expensive tile cutter.

Fitting tiles using a grinder is done in one motion

Sharpening a chain saw

Sharpening a chainsaw chain is an operation that requires certain skills. A person without experience is more likely to ruin a chain than to sharpen it correctly. Deviation from the sharpening angle leads to the fact that the chain during operation turns out the chainsaw bar, produces an arched cut and gets jammed in the thickness of the wood.

When sharpening a chain saw, the grinder must be secured

When starting to sharpen a chain using a grinder, you need to clearly understand that the main thing is to maintain the same sharpening angle on all links. To do this, either the grinder itself or the chain is rigidly secured using special clamps or clamps. The thickness of the sharpening disc should be equal to the inner diameter of the chainsaw tooth circumference (3–5 mm).

If the grinder has a disc speed regulator, then you should set it to the minimum position, corresponding to 2.5–3 thousand rpm. Do not allow the metal to overheat (blue) when sharpening - this will lead to tempering and a decrease in strength.

Video: sharpening a chain saw using an angle grinder

Metal cutting and cutting

The grinder is widely used in the field of cutting and cutting metal products. Using discs made specifically for working with metal, even a low-power angle grinder can cut steel, aluminum or cast iron products, as well as sheet iron.

Cutting steel structures with a grinder is performed with a metal disc

Of all the types of metal discs, there are two that are most often used in practice:

- cutting wheel;

- peeling disc.

The first is designed for cutting all types of metal. The second is for processing metal surfaces (grinding and polishing). Using a cutting wheel, you can also cut sheet metal according to certain patterns, cut out specified shapes, circles, etc. The sanding disc perfectly removes rust, removes old paint, and levels any metal surface.

Video: how to cut a round hole in metal

Cutting metal pipes

The grinder has become an indispensable tool in work related to the installation of heating, drainage and water supply. Wherever there is a need to cut pipes, the use of angle grinders together with metal discs gives practical results, significant time savings and increases labor efficiency. To cut the pipe straight, the cut must be made strictly at a right angle.

When cutting a pipe with a grinder, you must protect your hands with gloves.

How to cut a gas cylinder

Sometimes on the farm there is a need to cut up an old gas cylinder. Since gas cylinders have a thick-walled (3 mm) design, they can be used for various household needs.

The cylinder can become a reservoir for storing water, a water tank for a summer shower, a barbecue, and a fireplace for a home forge.

To disassemble a propane tank you will need:

- Bulgarian;

- metal cutting disc;

- hacksaw for metal;

- several buckets of water.

The sequence of steps is as follows:

- Release the remaining gas from the cylinder by completely unscrewing the control valve.

- Use a hacksaw to cut off the brass valve. During the sawing process, the cut area should be watered generously with water to prevent the possibility of sparks when cutting.

- After the tap has been cut down and a wide hole has opened in the upper part of the cylinder, several buckets of water should be poured inside through the funnel, or, best of all, the entire volume of the cylinder should be filled with it. This procedure will allow you to clean the bottom and walls of the cylinder from gas condensate, which is a thick liquid similar to liquid soap. When a spark hits the condensate, a fire occurs. You can cut the walls of the cylinder with a grinder only after the procedure of “washing” it with water.

- Cut the walls of the cylinder.

To flush out gas condensate, the cylinder is washed with water.

Brick cutting

When laying a brick wall, constructing stoves and fireplaces, builders are regularly faced with the need to cut bricks to the required size. If earlier this operation was carried out using a trowel or a mason's hammer, today the brick is cut with a grinder. The advantages of such a transition are obvious - when cutting with an angle grinder, precision is maintained, and the amount of waste and scrap is significantly reduced. The quality of the masonry increases, and the consumption of the cement mixture decreases.

A grinder for cutting bricks must be powerful and the disk must be large

For cutting bricks, grinders with a power of at least 2 kW and a disk with a diameter of 230 mm are used. If you use a smaller blade, you will not be able to cut the brick in one pass. Accordingly, the grinder must be designed to work with discs of this particular size.

Attention! It is completely unacceptable to remove the casing from a less powerful angle grinder and install a larger disc on it. Such “modernization”, as a rule, ends with a burnt angle grinder or injuries.

To cut brick with a grinder, it is best to take a diamond blade with a turbocharged edge. It is with this shape of the cutting edge that the disc can be used for dry and wet cutting of bricks. Abrasive discs, although more affordable, wear out quickly.

Attention! Neglecting safety rules when cutting bricks with an angle grinder leads to severe chronic pathologies. During operation, fine dust penetrates into all accessible and open places on the body. It is especially dangerous for the eyes and mucous membrane of the lungs. This type of dust is not excreted from the body and, settling in the respiratory organs, causes silicosis.

Video: how to properly cut bricks with a grinder

Ways to cut bricks without dust

To cut bricks without dust, two main methods are used.

- Abundantly wetting and watering the brick with water.

- Connecting a construction vacuum cleaner to an angle grinder.

Both significantly reduce the amount of dust rising into the air, but do not completely solve the problem. Therefore, even when using water and a vacuum cleaner, it is recommended to carry out work outdoors. During the cutting process, the master must use personal protective equipment.

The attached vacuum cleaner will remove excess dust from the cutting area

Glass cutting

Cutting glass at home using a grinder can only be done by those who have certain skills in working with this material. Glass is an amorphous substance, but it is also very fragile. In glass-cutting workshops, almost all operations, including the production of curved contours, are performed by a glass cutter. But for this you need to have the appropriate qualifications and work experience.

The glass cut area is wetted with water

It is possible to use a grinder for cutting glass if the length of the cut is short and it can be made without using a ruler. To do this, a shallow cut is made in the glass along the entire length and then the plate is broken, as after a glass cutter.

Attention! When cutting glass with a grinder, you should remember that glass dust getting into your eyes can cause severe damage to the tissue of the eyeball.

Glass cutting with a grinder is carried out at low speeds and with a disk coated with fine diamond dust. This reduces the risk of glass breaking and large amounts of dust being generated. It is advisable to moisten the cutting area with water.

Video: how to cut glass with a grinder

How to cut a bottle

Since the bottle was born, the interest of folk craftsmen in it has not waned. Either they will make a house out of bottles, or they will lay out a transparent wall. When the grinder also fell into the hands of the craftsman, it was decided to immediately cut the bottle and make a large glass out of it.

A glass bottle is cut with a diamond blade

When cutting a bottle with a grinder, you need to ensure that the cutting line is in the same plane. If the beginning of the cut does not coincide with its end, the glass will break. Therefore, before you start cutting a bottle with a grinder, it is best to draw a cutting line in advance. The bottle must be secured well, and the cutting must be done with a diamond blade at low speed.

Video: how to cut a glass bottle with a grinder

Concrete processing

The grinder has gained enormous popularity in the field of concrete processing. A whole line of attachments has been developed to work with this common material. According to their purpose, they are divided into cutting and grinding attachments.

- Cutting blades are necessary for cutting and are diamond discs with different working edge configurations.

- Grinding attachments are designed to level the concrete surface. They are produced in the form of metal circles with a ribbed plane, with the help of which all irregularities are cut off from the concrete surface.

The amount of dust is significantly reduced when concrete is wetted

Working with concrete is the dustiest type of grinder work. Therefore, the master must use all protective equipment, including headphones. If the work is carried out indoors and there is no possibility of ventilation, the best solution to the problem is to extract dust using a construction vacuum cleaner. In addition, abundant wetting of the processed material with water significantly reduces the formation of dust.

Video: cutting concrete with a grinder

Porcelain stoneware processing

Porcelain stoneware is a durable material of artificial origin, widely used in finishing construction work. Processing porcelain stoneware using an angle grinder allows you not only to adjust standard elements to each other during installation, but also to cut out original shapes for artistic panels and mosaics.

Processing porcelain stoneware requires not only high qualifications and experience, but also special equipment. The capabilities of an angle grinder for porcelain tiles are limited to straight cuts.

The cutting of porcelain stoneware into curved fragments is carried out only on industrial equipment in a factory environment.

In addition, with the help of a grinder, cutting defects are perfectly eliminated - the edge is polished, the chamfer is rounded, holes for pipes are cut, etc.

If the thickness of the slab is significant, the cut is made in several passes

High-strength diamond discs are used to work with porcelain stoneware. The grinding “turtle” has proven itself well in processing tile edges. When working with porcelain stoneware, all precautions must be taken. Small particles of hot material can damage the skin and eyes. It is better to cut the material outdoors, as this generates a large amount of dust.

Wall chipping

Using a grinder, you can groove walls for laying cables or water pipes. To do this you need to follow these steps:

- Mark the line of the future channel.

- Cut two furrows to the required depth.

- Using a hammer drill or chisel, chop off the resulting edge, freeing up the internal space for laying the cable.

- Clean the channel from dust and small fragments of concrete.

Diamond discs are usually used for grooving walls with a grinder. The disk speed, if it is adjusted, is set to increased. To prevent the formation of large amounts of dust, the wall is moistened with water. If possible, connect a vacuum cleaner hood to the grinder.

A construction vacuum cleaner pulls dust out of a groove

Grooving must be carried out with precautions, especially when working with the walls of old buildings. They often contain wooden elements invisible from the outside - both supporting and beacon elements (for plaster). If wood gets under the teeth of the disc, it will cause numerous fragments to fly out, which can cause injury.

How to cut teeth on a steering rack

Cutting teeth on the rack of an automobile power steering device is not the best solution to the problem of their wear. However, it is quite often used in metalwork practice in cases where the wear of the teeth is partial. This is a temporary measure before completely replacing the unit.

When editing the rack with a grinder, you need to be careful and not damage the basic geometry of the mechanism. When cutting teeth with a grinder, a cutting wheel for metal is used, the speed is set to high. The rail must be securely fastened.

Cutting teeth on a rack using a grinder is done with an abrasive cutting wheel for metal

Cutting corrugated sheets

When arranging fences or roofing work, it becomes necessary to cut corrugated sheets. Most often, nibblers are used for this, but this is not always convenient. And then the grinder comes into play. Using a metal cutting disc, an angle grinder can cut this fairly thin material in a matter of minutes. But at the same time, certain rules must be followed. It is best to carry out unraveling work with an assistant, who should hold the far edge of the sheet so that there is no overlap and, accordingly, pinching of the rotating disc of the angle grinder. Under no circumstances should the protective cover on the angle grinder be removed.

If the source material (for example, corrugated board) is coated with protective paint, you should reduce the speed of the grinder to avoid overheating and burning of the paint during operation.

When cutting, the corrugated sheet should lie horizontally

When working with corrugated sheets, you only need to wear gloves, since the sharp edges of the cuts are very dangerous for exposed skin.

Removing paint

There are many different attachments for removing paint using an angle grinder. Conventionally, they can be divided into two types. One is rotating brushes that remove paint with hard metal hairs. The second is various types of sandpaper, which are used to clean the surface from paint to the required condition.

When working with brushes, it is advisable not only to close your eyes and hands, but also to use a mask that protects your entire face. Clothing should be selected in such a way that the fabric protects the skin from small but sharp flying bristles.

Sometimes brushes fall apart during operation and you need to be prepared for this.

The speed of rotation of the nozzle is adjusted depending on the specific situation. The classic version of removing paint with an angle grinder requires low engine speeds.

Gallery: paint remover attachments

Hard rotating brush

Sharp wires “scratch” rust

Care must be taken not to damage the skin when working

Cutting a car tire

If you need to cut a car tire, you should use a cutting wheel designed for cutting metal. The cord inside the rubber consists of steel wires with a diameter of about 1 mm. The specificity of working with rubber is that when it is exposed to a rotating disk, it begins to melt and burn. A large amount of smoke and soot is released, which is harmful to human health. Inhaling this smoke is very harmful, you can even lose consciousness.

Increasing tread depth using a grinder

Attention! When starting to cut a tire with a grinder, make sure that children will not inhale toxic smoke and that the wind will not carry it to the neighbors.

You can cut tires with a grinder only in the open air; there should be fire extinguishing equipment and sufficient water nearby. It is mandatory to use a respirator (or better yet, a gas mask). Among other things, it is necessary to provide measures to protect against melted rubber, which can fly off the tire during operation.

How to Level an Anvil

If the anvil, after forging work on it, has been subjected to too much mechanical or thermal influence, its working plane may undergo geometric distortions. Welding especially spoils the working surface of the anvil. This problem can be solved by using roughing (or grinding) attachments on an angle grinder.

Checking the working plane of the anvil before leveling

Aligning the anvil is exactly the classic case for which the angle grinder was originally designed. The process should be controlled using a level rod. All bumps visible to the eye are carefully cut off with a grinder. As a result, the surface of the anvil should become smooth.

How to cut slate

Installation of the roof is one of the most critical moments in building a house. The “lifetime” of the entire structure depends on how well the roof is made. When covering a roof with slate, you can use either an electric jigsaw or a grinder. Both tools cope with the task of cutting the cement structure of slate, but the replaceable jigsaw files quickly lose their sharpness and have to be changed frequently. The grinder disc shows the best results when sawing slate, since it was originally designed for working with concrete or stone. The asbestos cement pipe is cut in the same way.

Cutting an asbestos cement pipe with a grinder

Most often, experienced craftsmen use both a grinder and a jigsaw to work with slate. For example, it is better to make a longitudinal cut with a grinder, and a jigsaw will help to cut a hole for the chimney.

Attention! Slate contains a carcinogenic material - asbestos. When working, respiratory protection is required.

Slate is sawed with a cutting disc on concrete or stone at low speed. Compliance with safety measures when working with slate is the same prerequisite as when working with other materials.

How to cut a rail

The need to cut a rail in everyday life rarely arises. Therefore, if you don’t have an autogen at your disposal, then a grinder with good power (more than 2 kW) with a disk diameter of at least 230 mm can help out.

There is no need to completely saw through the rail; it is enough to make two deep (up to 3 cm) cuts on the stiffening ribs and a groove on the supporting bottom plane. After this, you need to either drop the rail from a height of a couple of meters, or hit the cut area hard with a sledgehammer. The cast iron from which rails are made is a hard but brittle material. With this impact it breaks easily. If you don’t have a sledgehammer, you’ll have to cut right through the rail.

Video: how to cut a rail

How to sharpen a circular saw

In order to sharpen a circular saw circle using a grinder, you need to securely fasten the grinder itself. This must be done so that access to the rotating part of the tool is convenient and safe. Most often, clamps, vices or special clamps are used for this.

When sharpening a circular saw blade with a grinder, the correct tooth spacing must be observed.

When bringing the saw blade to the rotating grinding wheel, do not apply any force to it. Sharpening a saw blade with a grinder should be done using a light touch. It is important to monitor the sharpening plane, since it is this that most influences the dynamics of the cutting wheel when cutting wood. You can also sharpen the circular disc without unscrewing it from its working position. In this case, each tooth is sharpened sequentially with a grinder, and the disk is gradually rotated around its axis.

How to cut a mirror

In order to cut the mirror and give it the required dimensions, it is best to use an ordinary glass cutter. If you don’t have a glass cutter, you can use a grinder with a solid diamond blade.

When cutting glass with a grinder, do not put pressure on the material.

The sequence of actions is as follows:

- Mark a cutting line on the “wrong” side of the mirror with a marker or chalk.

- Carefully and without pressing, go along the line with the edge of the diamond disc. It is enough to make a recess of a few mm.

- Turn off and put the angle grinder aside.

- Break the mirror like ordinary glass cut with a glass cutter.

When cutting a mirror with a grinder, all safety precautions must be observed. The process produces harmful glass dust; it is recommended to moisten the cut area with water.

How to cut a tin can

Cutting a can with a grinder is no different from cutting any other metal object. It’s another matter if this jar is not empty, but filled with food. This changes everything! The task is not just to open it, but to open it in such a way as not to damage the food contained in it.

A tin can can be easily opened with a grinder if you cut the tin side

Of course, it would be easier (and safer) to do this the traditional way - using a can opener or an ordinary opener. But if there are none, and there is only a grinder, then you will have to get out of the situation with what you have. To open a tin can using a grinder, just carefully cut off the metal rim around the perimeter of the can. When it is removed, the top lid opens freely and the food remains safe.

How to cut stone

Cutting stone differs from cutting concrete or ceramic tiles in that the hardness of natural stone is usually higher. Therefore, the stone processing process takes longer. In this case, the same tools and attachments are used that are applicable for concrete.

For stone work, high-strength diamond discs are placed on the grinder

Natural stone has a different structure, sometimes quite fragile. When cutting stone, it is recommended to use a tool with adjustable disk rotation speed. Different speeds are used for certain minerals.

The main tool for cutting stone with a grinder is a diamond cutting wheel. When cutting stone, the wet method is most often used, with abundant irrigation of the cut site with water.

Video: cutting and polishing granite

Adviсe

- Cutting the material in one pass will help minimize chipping.

- With the exception of corner cutting, tiles are placed with the front side facing out.

- To ensure that the edges of the tiles are polished and not burnt, trimming begins at low speeds.

- Tiles that are prone to the formation of burrs are cut so as not to reach 0.5-1 mm from the glaze.

- The best results are achieved with fine diamond-coated dry cutting attachments.

- There will be less dust if you do not cut the ceramics to the end, but break the remaining thickness.

- A construction vacuum cleaner will help get rid of dust in your workshop.

- The edge will be smoother if you cut the tile with a glass cutter, securing a steel ruler along the cut line.

Cutting tiles with a grinder is a painstaking and complex process. Therefore, it is recommended to first practice handling the device - try to process several elements, and then begin finishing work.

Recommendations

- When cutting metal, the disc is not only worn around its circumference, but also its thickness is worn away. After replacing it with a new one, do not immediately go into the cut. This will lead to inevitable pinching and rupture of the disc. I recommend resuming cutting from the reverse side.

- There is such a nuance - the larger the disk, the greater its play will be. It's not about the grinder, but about the cutting element itself. Since its thickness is relatively small, it bends naturally. There is no way to rid yourself of such inconvenience. Just consider this fact.

- When cutting soft metals with a grinder, you should be extremely careful, since clamping of the disc in such products occurs much more often.

- Try to position the grinder in such a way that if the disc jams, it will not hit you in the forehead or stomach.

- When working with an angle grinder, you must be confident in what will happen in a second. If you don’t understand what could happen in the next moment, then it’s better to stop working and analyze the situation. There is no need to rush when working with an angle grinder.

- Start cutting metal only with a working grinder. That is, first turn on the device, and then come into contact with the product, and not vice versa. Securely tighten the nut holding the disc.

- Advice from me personally. If your discs jam, the cut turns out crooked, and the work generally doesn’t stick, then it’s better to just go and rest. Return to your work process with a fresh head and a positive attitude.