Types

- There are two types of popular materials on sale - monolithic sheets of various sizes and cellular (cellular) polycarbonate.

- The second type has in its structure from one to three rows of cells that act as stiffeners.

- Due to the fact that the material has a wide range of applications, it is readily purchased for performing various works both in the apartment and on personal plots.

- It is necessary to take into account the fact that working with each type requires different tools and you need to know exactly what is best for cutting polycarbonate at home.

Tips and tricks

When cutting monolithic or cellular polycarbonate, you must adhere to some very important recommendations, as a result of which the finished result will exceed all expectations:

- Before you start cutting building material at home, it is recommended that you first prepare the surface on which all work will be carried out - this is due to the fact that if the material lies on a foreign object or debris, then there is a high probability that it will be damaged;

- When using electric tools, you should always remember personal safety measures, as a result of which you should use safety glasses and have certain skills in working with the device;

- the use of a jigsaw or grinder requires the presence of a special support, which is placed under polycarbonate sheets;

- For convenience, appropriate markings are made on the material and only after that it is cut.

The work should be done according to a step-by-step algorithm.

If necessary, you can watch exactly how the process of cutting polycarbonate is carried out on video.

Selecting Tools

When planning to use polycarbonate for household needs, the master is faced with a problem - in general, is polycarbonate cut?

Let us immediately reassure novice craftsmen - they cut, and for this purpose you can use a variety of tools:

- grinder;

- painting (stationery) knife;

- electric jigsaw;

- hacksaw;

- large scissors;

- laser.

We will not dwell on the last option - here, in addition to a special tool, experience and certain skills are required. Let's leave laser cutting to people who professionally work with polycarbonate material. Let's look at the first five options in more detail.

Completion of installation

Since polycarbonate has proven itself to be the best, its areas of application have become very diverse. Thus, it is used to make glazing for summer terraces, gazebos or greenhouses, and to equip temporary partitions, fences or canopies.

Before laying polycarbonate, its sheets must be cut to the required size. For this, a grinder, an electric jigsaw, and even an ordinary stationery knife are often used. Of course, if you are not going to stop at disposable equipment, it makes sense to purchase a laser cutting machine. In this case, the cut will be perfectly smooth and clear.

Taboo

Before we talk about the necessary tools, let us note that you should never use them to cut polycarbonate:

- A hacksaw for wood, because it has large teeth that do not cut, but tear the material.

- Circles designed for cutting steel products due to the fact that due to the high temperature, the cut points of the polycarbonate melt.

Basic methods of cutting polycarbonate sheets

- Date: 07/27/2015

- 2768

- : 12

Recent trends indicate that more and more people have begun to do work that was once left to specialists themselves. This is especially true for those citizens who live in private houses, and even summer residents who devote themselves to seasonal work.

So at the beginning of spring, more and more people go out of town for the weekend in order to put in order their properties left unattended for the winter. The work begins, as everyone knows, not from the house, but from the garden plot, for which this whole outing is being started.

Here new beds are being built, plants, shrubs and trees are fed. Moreover, summer showers, greenhouses and greenhouses are being built.

In order to build greenhouses, greenhouses, beds, etc., monolithic polycarbonate is used. Polycarbonate is the most durable of all transparent materials existing on the construction market.

And the most popular material used in this type of construction work is currently monolithic polycarbonate, cutting to size has its own characteristics. They are explained by the special structure of the cast panels. Cutting cellular and cast polycarbonate is no different.

Basic tools and methods for cutting cellular polycarbonate

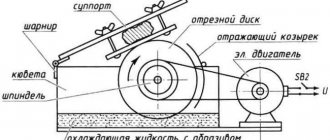

Polycarbonate device diagram.

The main advantage of this almost unique material is its impact strength, thanks to which it can be used for the following needs:

- construction of protective barriers and canopies;

- construction of roads and related infrastructure, such as transport stops;

- billboard devices, etc.

Quality characteristics include:

- Transparency of monolithic polycarbonate. It is achieved by a maximum light transmittance through the sheet - 90%, which almost completely replicates the transparent properties of glass.

- Providing excellent sound insulation.

- Relatively light weight - almost half less than glass or aluminum.

- Ease of installation.

- There are no difficulties in processing sheets that have the ability to bend both in cold and heated states. Cutting this polycarbonate is also not particularly difficult.

- Resistance to any weather conditions and even harmful environmental influences, which guarantees long service life.

- High thermal insulation qualities.

- In addition to natural, natural influences, the ability to withstand exposure to most inorganic compounds and chemicals.

- Fire and heat resistance, which makes it possible to construct light diffusers, lampshades for street lamps and lamps located indoors from monolithic polycarbonate.

Cutting polycarbonate monolith

In order to cut monolithic polycarbonate, it is necessary to use circular saws with fine teeth.

In order to cut the polycarbonate monolith, you can use circular saws with fine teeth. The best result can be achieved if you use a circular saw with teeth that have hard inserts. This is explained by a decrease in the contact area of this tool with the building material, which is why the polycarbonate sheet heats up less.

Experts point out that if the thickness of the sheets being cut is less than 2 mm, then it is worth folding 10-15 sheets and cutting them, and it is advisable to place a 3 mm sheet or a cardboard layer on the back side under the formed layer.

If you decide to cut one thin sheet, which increases the risk of cracking the material along the cut line, make sure that the tool is sharpened as well as possible. But the best option, in this case, would be to cut cellular polycarbonate on a guillotine.

But it’s worth noting right away that the cut edge in this case will be rough and deformed. Moreover, to cut polycarbonate sheets, you can also use band saws, which, for the most part, are used only for rough cutting of already molded panels.

It is recommended to use a saw with a width of up to 20 mm.

Laser machines are also used to cut polycarbonate. To do this, you will have to seek help from specialists.

In addition to the above methods, monolithic cellular polycarbonate can be cut using a laser.

To do this, you will need a laser system with an infrared range. To carry out this process, you must have the appropriate skills, so you are unlikely to be able to cut monolithic polycarbonate with your own hands, and not every amateur craftsman can boast of having this installation in his home workshop.

During laser cutting, the temperature at the cut site reaches the highest levels, and as a result, the cut edge appears burnt. Severe stress can also occur within the material.

Therefore, after cutting the polycarbonate sheet is completed, the finished product must be annealed for about a couple of hours, at a temperature of at least 125°C.

It is highly undesirable to cut polycarbonate with a hacksaw, otherwise it may peel off.

But the most common method is cutting cellular polycarbonate using water. Here you can use a circular saw, a band saw, and even a milling cutter. The main condition concerns laminated and mirror materials. Here you need to place the sheet correctly on the work surface. A sheet of monolithic polycarbonate should lie upward with a mirror or laminated layer. Otherwise it may peel off.

Under no circumstances is it recommended to cut off unnecessary parts of cellular polycarbonate using a hand saw or hacksaw. Most often, a grinder or a circular saw is used for this. In this case, it is necessary to preset it so that the number of disk revolutions per minute is approximately 4000. As for the size of the disk, a diameter of 25 cm is sufficient for it.

Milling of cellular polycarbonate as a cutting method

In this case, it is recommended to use special machines with small cutters, but at the same time having impressive performance in terms of cutter rotation speed.

Cooling of the apparatus and material is carried out using a flow of cold air. The only thing that is not very convenient in this case is the need to constantly sweep away the resulting chips.

Thanks to this device, you can not only saw or cut one sheet into several parts, but also make indentations, engrave on the surface of the sheet, and even out the edge. After the cut is made, it is necessary to treat the cut area.

To do this, if the surface of the sheet is matte, it can be cleaned with a polishing wheel and then with a special polishing paste. The material is cleaned with hot water and any detergent without solvent.

Source: https://polikarbonatstroy.ru/osobennosti/monolitnyi-rezka-v-razmer.html

Scissors

The scope of application of the “tailoring” tool is very limited.

- Firstly, you can only use scissors for cutting metal or plastic.

- Secondly, you can only work with a monolithic sheet, the thickness of which does not exceed three millimeters. It will not be possible to cut thicker polycarbonate, but if you try to cut a honeycomb type of material, you will crush its edge.

Main options for carrying out work

Let's figure out how to cut cellular polycarbonate at home. The most commonly used types of tools are:

- Construction knife . You can use regular versions, but they must be very spicy;

- Large scissors

- Grinder or circular saw;

- Jigsaw;

- Wood saw

Let's look at each option separately.

Option 1: cutting with a construction knife

This is the simplest and most popular option for carrying out the work. You will need a construction knife with 25mm wide blades.

The blade of the knife for cutting polycarbonate must be well fixed in the structure

Designs with a trapezoidal blade can be used. This option is more durable, which means it is more convenient for them to work.

Trapezoidal blades are highly rigid and well suited for cutting polycarbonate

Be sure to purchase spare blades as they tend to break under stress.

The workflow looks like this:

| Illustration | Description of the stage |

The material is marked. To do this, use a tape measure and a level rod or long level. First, marks are applied to the sheet, after which a line is drawn using a pencil or felt-tip pen to create a clear guideline along the entire length of the cut.

| |

Initial cutting of the material is carried out. To do this, a guideline is placed along the line (a metal ruler is best suited for these purposes). The knife is placed on the edge and driven with force along the surface. The blade should penetrate 2-3 mm into the material in order to completely cut through the top layer along its entire length.

| |

| When using a regular knife, you can press hard on the surface . The blade is strong and you won't break it even with great force. It is most convenient to use a wooden block as a guide. | |

| The material bends along the cut line . You need to bend it on the reverse side; the plastic breaks very smoothly if you have cut the outer layer well. You can bend small pieces yourself; it is better to bend whole sheets with an assistant so as not to damage the material. If the material is not broken, then on the reverse side it is cut with a knife along the bend line. | |

| The knife cuts especially well along voids. If you need to cut material lengthwise, the honeycomb will serve as a guide; the knife cuts along it very quickly. If the end is not very even, you can correct it with a knife, carefully cutting off all excess. |

The knife is well suited for material 6 mm thick. It is very difficult to cut thicker sheets in this way, and the quality of the work is not very good. Remember that a regular stationery knife with a narrow blade is not suitable; you need a 25 mm wide option.

The main advantage of this method is the low price of the tool.

Option 2: cutting with scissors

This method is used for polycarbonate with a thickness of no more than 6 mm. To work, you need tailor's scissors or metal scissors. The main thing is that the tool is sharp, otherwise the ends will be damaged.

Before cutting polycarbonate, find large scissors

The instructions for carrying out the work are simple:

| Illustration | Description of the stage |

| Marking is being done . Using a tape measure or meter, all required dimensions are set aside, after which a solid, clearly visible line is drawn along the entire length of the cut. | |

| The material is cut along the line . With one hand you need to carefully cut the polycarbonate, and with the other bend one edge so that it is convenient for you to carry out the work. You should press the scissors firmly so that they cut the plastic clearly and do not crush it. | |

| Cutting with scissors for metal is done in the same way . If after finishing the work there are small blemishes on the ends, they are removed with a construction knife or an ordinary knife. |

Option 3: cutting with a grinder

Considering the question of how to cut polycarbonate, one cannot help but talk about the option with an angle grinder. It is characterized by high speed of work and good cutting quality.

You will need a small grinder (for a 115-125 mm disc). It is small and easy to hold, unlike larger options that weigh a lot and are therefore not very convenient in our case.

The grinder copes well not only with metal, but also with cellular polycarbonate

For cutting, use cutting discs for metal with a thickness of 0.8-1.0 mm. They cut the material much more smoothly, and less debris gets into the honeycombs, which is also important.

Do-it-yourself cutting is done like this:

| Illustration | Description of the stage |

Preparatory work is underway:

| |

| A board or plywood is also placed under the bottom . This is necessary so that the grinder disc does not touch the ground when cutting. The lining is located along the entire cutting length with an indentation of 3-4 cm from the cut line; its thickness should be at least 20 mm to ensure comfortable work. | |

| Polycarbonate is being cut . Work starts from the edge, the tool is carried out exactly along the line. Thanks to the high speeds, plastic is cut very easily and quickly, the main thing is to keep the tool vertical and not deviate from the line. | |

| After cutting, the elements are moved apart for cleaning . There is no need to use them for their intended purpose right away. | |

| Debris from voids is removed with a vacuum cleaner . The photo clearly shows that cutting chips fall into the honeycomb. To remove it, it is best to use a vacuum cleaner with a special crevice tool. Simply shaking it out won't work; the particles stick to the internal cavities. |

Remember one simple rule: the protective film is always removed after cutting the polycarbonate immediately before its installation. It doesn’t matter what you use to cut the material, you should remove the protective layer only after finishing the work.

Cutting with a circular saw is carried out in the same way as with a grinder. The difference is that cutting is done using a disk with fine teeth, and the tool itself is more convenient to use due to its design that fits tightly to the surface. Some versions of the tool have a special guide and a vacuum cleaner that immediately removes all debris, which is very convenient.

The good thing about this power tool is that you can use it to make straight cuts.

Option 4: cutting with a jigsaw

An electric jigsaw is great for cutting polycarbonate of any thickness. You can quickly and efficiently cut out a fragment of any shape.

A jigsaw allows you to cut polycarbonate into pieces of any shape.

For work, purchase blades with a small tooth size. The quality of cutting depends on this.

Electric jigsaw blades must have fine teeth to cut polycarbonate cleanly

The workflow in this case looks like this:

- Polycarbonate sheets are marked . If you have curved lines, then the easiest way when marking is to attach the element on which the material is being cut, and mark along it. This way you definitely won’t go wrong and will mark the polycarbonate perfectly;

The easiest way is to attach a structural element and mark a polycarbonate cutting line along it

- A polycarbonate sheet is laid out on the surface and fixed . In this case, it is very important to position it so that there is an empty space under the cutting line, since when cutting, the jigsaw blade drops down by 5-7 cm. The sheet can be fixed with a weight, but not very heavy, so that it does not deform the material;

The material is placed so that there is empty space under the cutting line for the movement of the electric jigsaw blade

- The jigsaw is installed on the edge of the sheet . You need to position it at the starting point of sawing, after which the tool turns on. Set the speed to the highest - the faster the cutting blade moves, the higher the cutting quality will be;

The jigsaw is neatly positioned on the line and turns on at the highest speeds

- Sawing is done with moderate pressure . Just move the tool along the line, turning in the right places. The most important thing is not to deviate from the line and carefully follow the mark on the jigsaw platform, which determines the cutting line of the polycarbonate;

Cut polycarbonate slowly, constantly monitoring the cutting line

- After cutting, the ends are cleaned with a vacuum cleaner . The picture below shows that chips get into the voids, which must be removed immediately after the work.

Chips get into the ends and need to be removed with a vacuum cleaner.

Option 5: cutting with a hacksaw

You can also use a regular wood saw for the job. Options with small tooth sizes are best; they damage the ends much less and fit into the plastic better. The hacksaw must be sharp.

The finer the tooth on a hacksaw, the better it will cut polycarbonate.

The workflow is simple:

| Illustration | Description of the stage |

| The sheet is marked and laid on the surface . There should be a void below the saw line so that you can cut the material with a hacksaw. You also need to fix the element as much as possible. If the sheet is large, then an assistant can hold it. | |

| The hacksaw is installed along the cutting line . You can lightly run it 1-2 times to outline the cut and not go off the intended line. On the other side, the polycarbonate is pressed by hand so that it moves as little as possible. The better you press the sheet, the better the cutting will be. | |

| You need to cut with careful, clear movements . Do not press the polycarbonate very hard, use moderate force. The cutting speed should be as high as possible, so cutting is much faster and easier. | |

| At the end you need to work especially carefully . The photo shows how the hacksaw teeth lift the polycarbonate. It is better to move your hand and press it closer to the cutting site. | |

| The cutting quality is not very high . The photo clearly shows burrs, which it is advisable to remove with a knife. After finishing work, the honeycombs are cleaned with a vacuum cleaner. |

Bulgarian

You don't have to use an expensive tool. A small grinder can do the job. The most important thing is to install a circle on the tool designed for cutting metal.

There is one more condition - if you have not worked with similar material before, it is better to first practice on its scraps.

Cutting technology

When cutting polycarbonate plastic panels, it is easy to damage the material or spoil the edges of the sheet, violating the technology. Experienced craftsmen advise not to skimp on the blades and cutting blades of the tool, since a dull knife makes the cut uneven and sloppy. Cutting is carried out in the following sequence:

- First of all, the area where the cutting will be done is cleared. To make the surface even, sheets of plywood or chipboard are laid out on it.

- Before cutting polycarbonate, markings are applied to the surface using a marker and a long ruler.

- Wooden blocks with a thickness of at least 40 mm are placed under the sheet of plastic on both sides of the intended line. A wide board used for movement is also laid on top along the marking.

- Straight cuts are made using a grinder at low speeds, and curved cuts are made with a jigsaw.

- After completion of the work, the chips are blown off the surface of the material with compressed air.

Note! Honeycomb plastic up to 6 mm thick can be cut in a stack by stacking several sheets on top of each other and placing plywood under them. In industrial conditions, this material is processed using a laser, which is much faster and easier than with hand tools.

Knife

Naturally, such cutlery is available in every home. However, you should use a utility knife. The sharpened tool is ideal for cutting monolithic sheets up to six millimeters thick.

They can also cut cellular polycarbonate, but only if it has one air chamber. Cutting material with radius lines is also possible, but it will require patience and time.

Important! Experts do not recommend using a knife to cut cellular material with more than two rows.

Cutting polycarbonate with a hacksaw

A hacksaw with small and thin nails is sometimes used to cut polycarbonate sheets into straight square and rectangular pieces. The process is similar to cutting with a utility knife, so if you decide to use a hacksaw, please read the appropriate step-by-step instructions above.

In this case, consider two nuances:

- Hold the hacksaw at an angle of approximately 30°;

- How best to fasten a polycarbonate sheet; if you have a machine and a vice or clamp, then use it.

But it is more convenient and, more importantly, it will cut the material better with an electric jigsaw or a construction knife with a retractable blade.

Compliance with the rules

A clear cut, without roughness, can be obtained if you follow the following operating principles:

- Place the material on a hard and level surface.

- Press the metal ruler firmly against the cut line.

- Use a utility knife with a new blade. Break off a dull tip immediately!

- Start cutting from the far edge, having first made a notch on the polycarbonate.

- When cutting a long sheet of material, you should use an assistant to fix the ruler.

- Press the knife blade against the ruler and apply pressure.

- Small roughness on the monolithic sheet should be removed with sandpaper.

Important! When cutting “thick” material, it is necessary to maintain a large angle of inclination of the blade. Do not use wooden rulers! If, after making the first cut line, the polycarbonate does not separate, cut again with a knife. You cannot bend it in hopes of breaking the material! It will not break, but bend!

Finishing the conversation about the knife, we can say that this tool is almost ideal for cutting monolithic polycarbonate.

Video description

You can also use a woodworking machine by installing the desired disk in it. This is exactly what the master did in the following video:

Electric jigsaw

If you can use a whole arsenal of different tools for straight cutting, then how to cut cellular polycarbonate or a thick monolithic sheet in a circle or other curly line remains a question. An electric jigsaw is most suitable for this work, since its thin file freely passes through any bends and does not jam between the blades.

But not just any file is suitable, but only with small and frequent teeth, not spread apart, but located in the same plane. Adjustable large teeth perfectly cut wood, the structure of which is very different from plastic. Such a file will tear it, and instead of a clean cut you will get a jagged edge.

It is best to choose files specifically designed for working with plastic Source werkman.ru

- After marking the canvas, it is placed on stands made of boards to provide clearance under the cut line and reduce vibration. If the line is curved, the canvas will have to be moved periodically, temporarily stopping work.

- A suitable file, preferably a new one, is installed in the jigsaw and fixed well to avoid vibration.

- On the edge of the polycarbonate at the beginning of the cutting line, make a notch with a sharp knife.

- After turning on the tool, the file is inserted into the notch strictly vertically so that the jigsaw support plates are pressed tightly against the surface of the sheet.

- Holding the tool in this position and trying not to press too hard on the blade so as not to bend it, guide along the cutting line, moving forward from yourself.

Advice! Before starting work, picking up this or that tool for the first time, it is advisable to practice on unnecessary pieces, especially if you need to cut out elements of curved shapes.

If the material is thin and you need several identical parts, you can fasten several sheets at once with clamps, placing thick cardboard under the jaws, and cut the entire stack. Jagged edges and other irregularities can be cut off with a sharp knife.

Cutting cellular polycarbonate with a jigsaw Source teplica-exp.ru

Electric jigsaw

This tool is very often used for cutting polycarbonate. When working with a jigsaw, experts recommend adhering to certain rules and then it will become the best tool for cutting monolithic polycarbonate:

- when sawing thin sheets, they must be laid on top of each other, with cardboard underneath;

- use a file with fine teeth;

- When cutting one sheet there is a risk of cracking. In this case, the teeth of the file must be perfectly sharpened, and the master must carefully ensure that the structure of the fibers of the material is not disturbed.

Preparation and marking

This step-by-step instructions for preparing the workplace are common for all types of tools used, except for the industrial laser and milling machine.

Step 1. Clear the work area of debris and unnecessary objects. This is necessary not just for reasons of cleanliness, but so that they do not interfere with the process and do not leave dents, scratches or other marks on the back of the sheet.

Preparation of the workplace

Step 2. Lay a sheet of plywood, chipboard or fiberboard on the site. Now the cutting area is as level as possible.

Step 3. Transfer and place the polycarbonate sheet on the work area. If it has a laminated, mirror or UV coating, then it should “look” up. Do not remove the protective film from the sheet until you have finished cutting the material.

Step 4. Make preliminary markings in the form of a diagram on paper, observing the scale.

Cutting drawing for polycarbonate sheet

Step 5. Transfer the markings from paper to polycarbonate. For measurements, use a tape measure, a metal ruler, and a rule; to draw cutting lines, use a black marker.

Marking a polycarbonate sheet

When working with large-area sheets, place a board on top (at least 100 mm wide) and walk only on it so as not to damage the surface of the polycarbonate. Examples of cutting material for the gable of greenhouses are shown in the image below.

Cutting a polycarbonate sheet for the greenhouse gable

Step 6. Not far from the cutting line, on the left and right, place boards at least 4 cm high and at least 10-15 wide under the polycarbonate. Their ends should “peek out” from under the sheet on both sides. The boards act as supports, necessary to ensure that the tool does not cut directly into the substrate material.

Step 7. As when applying markings, when cutting polycarbonate, do not move along the surface of the sheet itself, but along a wide board lying on it. Working as a kind of “ski,” it reduces the risk of damage and deformation of the material under the weight of the cutter.

An example of using a board base

When working with pieces of polycarbonate or sheets of small sizes, a workbench or a fairly large table is used instead of a working platform.

Secrets of the professionals

Let's listen to the advice of experienced craftsmen who give specific recommendations for cutting both monolithic and cellular material:

- It is necessary to carefully prepare the place, clearing it of any objects. Cleanliness is not only a guarantee of health, but also a condition for the absence of scratches or cracks on the material.

- Have a marker and a fairly long metal ruler on hand. They are necessary for marking and guiding when cutting material.

- When working with cellular polycarbonate, you should avoid sudden movements and use the honeycombs themselves as a guide.

- Do not forget about safety precautions and wear glasses to protect your eyes from the smallest particles.

- Following the good old proverb: “measure twice, cut once” will help you avoid unforeseen consequences and damage to the material!

Preparing the workplace and tools

The working surface must be flat, clean, dry.

Cellular polycarbonate is easy to crumple and break along the internal partitions. Sharp objects can easily punch through holes in the panel.

Before starting manipulations, you should prepare the workplace. The entire sheet must rest on the base, so its table cannot be less than 2150 mm. The length of a standard sheet is 6 or 12 meters; there should be no dangerous objects in this area.

For laying and cutting use:

- workbenches or tables of suitable size;

- floors covered with fiberboard or OSB under canopies;

- cleaned and leveled soil.

For convenience and to prevent damage, the approaches to the workplace are cleared of debris and foreign objects that could disturb the worker’s balance or cause him to fall. The space is cleaned from all sides, since the standard sheet width of 210 cm does not allow making a cross-section at one edge.

When making non-standard products, they first lay out the parts cut to scale on a sheet of paper. This will help avoid a lot of waste. When drawing, do not forget that inexpensive panels are most often protected with a UV coating on one side and cannot be installed with a protective layer inside the structure.

If you need to lean on a sheet while working, you should place a wide sheet of chipboard or planed board for support on which you can walk.

Marking

For marking, the sheet is laid with the protective film facing up. All lines are drawn directly on the film, which is removed after installing the part on the mounting frame.

You can draw outlines using a dark marker. For convenience, use long-length plaster rules or other flat objects. For small parts you will need a construction corner.

Knife

The knife blade must be very sharp.

Knives can cut cellular polycarbonate with a thickness of 4 and 6 mm. The tool is suitable for straight lines, but when cutting shaped parts it is better to avoid it, as the work will take a lot of time and require great care. The tool may slip along the stiffening ribs, damaging the part.

You should not use a knife to cut honeycomb material with more than two chambers or monolithic sheets.

The blade must be carefully sharpened, and new replacement blades are inserted into the office or construction tools.

The step-by-step algorithm looks like this:

- Prepare a level base.

- Lay the sheet and mark.

- Press a metal strip, usually a steel ruler, to the cutting line, which will serve as guides. Do not use wooden parts, as the blade will cut into them and get stuck. An assistant is hired to fix the long guides.

- They cut from the far edge towards themselves.

- They try again, running the knife along the furrow left, if it was not possible to separate the part from the sheet in one go.

When cutting polycarbonate, do not use the technique of cutting drywall. If the sheet is not cut through, it will not be possible to break it.

You can use a knife when cutting out the side of an arched greenhouse. To do this, the panel is laid on the assembled outer arch and, using it as a template, excess material is removed.

Angle grinder

The angle grinder wheel should be of the smallest thickness.

The grinder is used to cut polycarbonate in a straight line or with minimal bending - the tool is not used for shaped parts.

For their work, craftsmen use cutting wheels for concrete, aluminum or metal. There is no consensus on which circle is better. An important condition is that the circle should be as thin as possible.

Try different wheels and choose the one that gives the best quality cut without melting the edges or heating the panel to high temperatures.

A grinder with a high number of revolutions is not suitable; if there is an adjustment, then set the minimum rotation speed.

Sequence of work:

- Preparing the workplace.

- A wooden beam of sufficient thickness is placed under the sheet so that the circle does not reach the base and rotates freely.

- Cover the cutting area with a 24 mm thick wooden board and press down.

- Turn on the grinder and let it gain operating speed.

- The material is cut.

It is necessary to cut along the jumpers along the internal hollow channel, without capturing the stiffening ribs.

Plastic particles trapped in the honeycombs are removed with a vacuum cleaner or the cavities are blown out with a compressor. It is not advisable to use water for washing, since before installation you will have to wait for the panel to dry, which takes a lot of time.

Electric jigsaw

To use a jigsaw, you should choose plastic files.

A powered tool is optimal for cutting out shaped parts that are difficult to make with a saw, grinder or knife.

Requirements for files:

- the teeth should only be small;

- You cannot use a tool with set teeth; they must be located in the same plane.

Some manufacturers make the choice easier by producing special files with o.

Before starting work, it is advisable to test your skills and the quality of the seam by working with unnecessary pieces of material. Once you have acquired the skills and selected the right tools, you begin cutting out parts.

Process Features:

- a wooden stand of the required thickness is installed under the panel so that the saw blade moves freely without resting on the base;

- it is advisable to use a new replacement tool;

- before starting cutting, a notch is made on the end with a knife so that the beginning is even;

- polycarbonate begins to be cut after the electric motor reaches operating speed;

- do not allow a gap between the jigsaw sole and the sheet, since vibrations lead to damage to the polycarbonate;

- cutting away from themselves, moving forward.

To speed up the work, thin material can be sawed by laying it in several layers.

Hacksaw for plastic

For straight cuts, purchase a hacksaw for plastic or use a tool for cutting laminate and aluminum. The tool is distinguished by small, unset teeth.

Polycarbonate is placed on the edge of the work table so that the base does not interfere with the movement of the canvas. The top is pressed with a wooden or metal strip. To prevent cracking, the canvas is positioned at a minimum angle.

The secret of success depends on how firmly the slab is fixed between the base and the clamp - the slightest vibrations lead to cracking along the cut line and jamming of the tool.

Hacksaw for metal

It is impossible to cut parts longer than 40–50 cm in length with a standard hacksaw due to the design features.

For work, replaceable blades installed in handle holders are used. The direction of the teeth should be forward, away from the handle.

The cutting speed will be low, but the quality of the cut will be good.

It is important to reliably strengthen the workpiece between the stand and the clamp. They work smoothly, without jerking, which can cause scuffing.

The angle between the part and the canvas should be 30–40 degrees.

Laser and milling machine

Shaped cutting is done with a laser.

If you need to obtain a large number of shaped parts, it is better to contact a professional organization. As a rule, such enterprises have laser cutting machines.

Cutting of monolithic sheets is often carried out on large milling machines with program control.

Even if you have a milling machine at home, it will be difficult to choose a replacement tool and operating modes so as not to damage the polycarbonate during the milling process.

Material with protective film

A person who is faced with the need to cut a so-called laminated material for the first time has a question: is it possible to cut such polycarbonate and how to do it?

In this case, the main rule is that the mirror material, which has a protective film, must be laid with the decorative side up.

You should not try to cut with a hacksaw or handsaw - nine times out of ten you will not get a clean cut. As a rule, during work, irregularities will begin to appear and particles of material will peel off. The best option would be to use an electric tool.

Tools

Bulgarian

The first tool that almost everyone has that can work with polycarbonate is a sander. Moreover, you should not use expensive tools: even an inexpensive and small grinding machine will do the job perfectly. To make even cuts, you need to install a 125 circle intended for metal. The only thing you need to pay attention to. This is an experience because the tool has a high speed and if you have not worked with it before, it is advisable to cut polycarbonate from this material before cutting. Where can I get them? Contact the craftsmen who make polycarbonate structures.

READ How to fix a bit in a screwdriver

Stationery knife

Perfectly cuts polymer plastic and stationery knives. Moreover, even beginners can handle it. The main thing is that the knife is of good quality and the work is done slowly. The blade of such tools is very sharp, and you can not only make the wrong cut, but also get injured. A stationery knife is suitable for honeycomb sheets with a thickness of 4-6 mm, but working with 8 mm sheets is quite difficult. It is almost impossible to cut polycarbonate on thicker sheets, so experts recommend using a knife only where the material needs to be cut, and even then, on sheets up to 10 mm thick.

Electric jigsaw

A household, most common electric jigsaw is also quite suitable for working with polycarbonate sheets, you just need to install a file with fine teeth on it, otherwise the material will tear and not be cut. This tool, like a grinding machine, is quite easy to use, but to be completely confident in the quality of the work, it is advisable to practice in advance. An electric jigsaw is very popular, especially when you have to cut monolithic polycarbonate with complex decorative shapes or make curves.

When you only need to cut one sheet. The risk of cracking increases significantly. To avoid damaging the material, work only with very well sharpened tools. There are craftsmen who use scissors when working with polycarbonate. This is also quite acceptable. The main thing is that the tool used does not disturb the structure of the paintings.

Hacksaw

Beginners are usually interested in: is it possible to cut and how to cut cellular polycarbonate with a hacksaw or a handsaw? If you lack experience, it is advisable not to use these tools: the blades along the cuts may crack. It is best to work with power tools. But for beginners and experienced professionals, it is important that polycarbonate sheets are reliably protected to prevent vibration and stress in the material, which can also have bad consequences.

Laser cutting

In addition to the above methods, you can perform laser cutting. But to work with a laser machine you need to have the appropriate skills. In addition, not every craftsman has such a tool, so laser cutting of polycarbonate is available only to those who professionally process polycarbonate. But, if laser work is possible, you should use it because it guarantees:

- High speed;

- No defects;

- Excellent cutting quality;

- Cutting accuracy: when working with a laser, dimensional accuracy of up to 0.05 mm is observed;

- You don't need to lock sheets while you work.

Monolithic polycarbonate canvases can be used with any cutting material designed for working with metal or wood, even a standard metal cutter.