Drywall is a popular material for interior and exterior decoration and partition cladding. It is universal and has many advantages; it is produced in sheets. Working with drywall is inextricably linked with cutting or trimming excess parts. If the volume is large, it is quite difficult to cope without a special tool. To perform cutting as quickly as possible and without applying much effort, it is enough to purchase a knife for cutting drywall. The tool has several varieties. Each has its own characteristics.

General recommendations for choosing a tool

A knife for cutting drywall is selected taking into account the planned volume of work and the complexity of the cuts. The tool is selected taking into account three important points:

- Straight lines can be obtained using a regular knife. The blade of the tool should have a hard and thick blade. If it is too thin, breakage cannot be avoided. Stationery knives are, of course, convenient to use, but they do not allow you to make perfectly smooth edges. They require additional alignment using other tools.

- Special professional knives allow you to cut a large number of plasterboard sheets. The edges are smooth. They are not further aligned. When purchasing such an instrument, you must first hold it in your hands for some time. This allows you to understand how comfortable the handle is. This parameter of the device directly affects the quality and ease of cutting.

- Shaped holes are created using a hacksaw with thin teeth. If you need smooth edges, it is better to give preference to an electric tool.

If you are planning minor repairs with plasterboard, an ordinary stationery knife will suffice. With a large amount of work, you need a professional knife.

Utility knife

A universal or mounting knife enjoys well-deserved popularity, since, along with the possibility of using it at any stage of repair, it contains a number of advantages when working with drywall:

- The convenient ergonomic design of the handle, made of light metal or strong plastic and coated with multi-component rubber, makes cutting more comfortable and reduces the strain on your hands.

USEFUL INFORMATION: Design possibilities for plasterboard ceilings

- The blades, made of high carbon steel, have a trapezoidal shape and do not contain sections, which increases their strength and rigidity. Spare blades are usually included in the kit and replaced with new ones as needed. This combination of the cutting part and the handle allows you to cut the sheet into elements of any shape and complexity with high precision.

- The design of a utility knife may contain parts such as a belt clip or a box with spare blades in the handle. These options make this device even more convenient to use.

Important! The blade of the knife should be sharp, and its length should be adjusted to the thickness of the drywall sheet.

Types of instruments

There are many devices for cutting plasterboard sheets. Each has its own characteristics. To choose the most optimal option, you should consider the characteristics of each, and then make a choice in favor of any one.

Wallpaper or stationery knife

Refers to universal. It is used to perform various jobs. Most craftsmen use this particular tool. The advantage of a wallpaper knife for cutting drywall is its affordable cost and ease of use. The main thing is to understand that we are not talking about a device with a 9 mm wide blade, since it is intended not only for paper. For drywall, use tools from 18 to 25 mm. Knives with this width are divided into three categories:

- Standard ones cost from 30 rubles, are not durable, and over time the blade often cuts through the body, which makes working with it dangerous.

- Reinforced with a metal guide at the end to ensure rigid fixation, preventing the blade from protruding from the body.

- Professional ones costing from 200 rubles to several thousand, designed to perform a large volume of work, with an ergonomic body. The blade of some models can be fixed for precise cutting.

The thickness of the blade varies between 0.3-0.6 mm. They are standard and replaceable. The thicker the cutting part, the better. The version with a mini hacksaw allows you to get curves and shaped cuts.

With trapezoidal blade

It is considered the most optimal for cutting drywall, since the tool is designed specifically for this job. This device has several varieties:

- Ergonomically shaped, comfortable handle. When choosing such an instrument, you should first hold it in your hand and “try it on”. If holding a knife is uncomfortable, your hand will quickly get tired.

- High blade rigidity, allowing you to cut broken or straight lines. First they work with one cutting side, and then with the other.

- The cost is also quite affordable. You can buy a knife at a price from 200 to 2,000 rubles. It depends on the brand or design. There are few low-quality options for such devices.

When purchasing a knife with a trapezoidal cutting element, you should pay attention to the options. The clip will allow you to hang the tool on your belt, and the box will eliminate the need to carry spare blades with you.

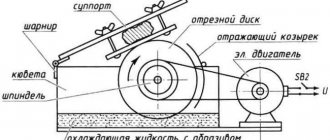

Disc cutter or ramemus

Designed for highly specialized purposes. It is equipped with two disks. They are opposite each other and cut through the plasterboard sheet on both sides. This ensures high cutting quality. The working elements are secured with wing nuts, which can be replaced if the need arises. The cost of the instrument starts from 800 rubles. The design features make it possible to obtain perfectly even cuts and strips from plasterboard sheets with a width of no more than 12 cm. The device is excellent for craftsmen working on the construction of multi-level structures and when narrow gypsum board elements are needed.

With disc blade

This device is a cutting device. It is used for cutting plasterboard sheets for several reasons:

- The tool creates straight lines. The disk of the device moves strictly along a ruler or any other guide. The cutting accuracy is almost one hundred percent.

- The cutting part of the tool does not allow skipping. The knife is pressed with force. The canvas is rigid, and the body of the handle is durable, so the device does not break.

Disc blades are durable. Even with intensive use they will last for several years. The price of a knife varies between 250-1000 rubles.

Blade Runner

At the moment, it is not the most common tool option among professionals and home craftsmen. The main feature of the device is that it doubles the speed of cutting plasterboard sheets. The knife has the following features and advantages:

- The cutting part consists of two parts, held by magnetic clamps. The blades are in special blocks, so they can be easily removed and inserted.

- A set of rollers is enough to cut 600 plasterboard sheets. Each such video costs 100 rubles, which is quite profitable and economical.

- The special belt bag with which the tool is sold makes it easier to use a tool of considerable size. It becomes easy to carry around.

- The device can cut curly and straight lines, even cut corners by pressing the top button and turning the tool.

The tool also has disadvantages. The blades can be damaged when cutting sheets 0.9 cm thick, since the halves collapse when leaving the gypsum board. Blade Runner is ideal for cutting large curves. With small ones, it is difficult to ensure accurate hits on the applied markings.

Bladerunner

A few years ago, a device for cutting plaster appeared on the market - the Bladerunner knife, which, according to sellers, forever changes the approach to working with drywall. The device uses the principle of holding the blade using magnets.

Knife Bladerunner

A simple compact device cuts the sheet on both sides simultaneously and reduces cutting time by half. Step cutting, cutting arcs and corners with this knife is performed simply and quickly while maintaining the cleanliness of the working surface.

The video shows how this tool works:

When working as a Bladerunner, there is no risk of damage, since all hand movements are only forward (from oneself), and the blades are hidden in the body. The knife is fixed on the edge of the gypsum board and as soon as it moves forward, the supports will move apart. The blades are designed in such a way that they cut gypsum boards from both sides at once, while simultaneously reducing dust formation.

The bladerunner also cuts plaster in a vertical position. One set of blades is enough to cut 1400 linear meters of plasterboard. Cartridges can be changed in a simple way - just press a button, open the case, take out the old one and insert the new one. The bladerunner is ideal for working with 12.5 and 15 mm thick sheets, as well as cutting water-resistant and fire-resistant sheets.

Regardless of what type of knife is chosen for working with drywall, the main thing is that it is of good quality. There is a wide range of such products on the market today. The choice of manufacturer is determined based on an analysis of reviews from craftsmen and personal experience.

How to use a knife to cut plasterboard sheets?

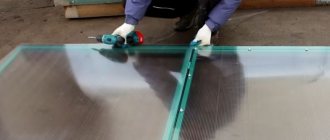

There are many types of gypsum board knives, but most often, even many experienced craftsmen, if they do not work with this material constantly and in large volumes, use a regular mounting knife. It allows you to cut straight lines. The action algorithm is as follows:

- Using a tape measure, measure the dimensions of the required fragment and transfer the points onto the gypsum board using a pencil.

- A metal ruler or building level is applied to the points. These devices serve as guides.

- Draw along the level or ruler with a knife without tearing it off. There should be only one movement, and the blade should reach 1/3 of its thickness.

- Take out the knife and lay the plasterboard with the cutting line offset beyond the edge of the working surface. If cutting is done on the floor, the drywall is placed under a piece of wood.

- Press with the palm of your hand on the part located in the canopy and break along the line marked with the blade.

- Turn the plasterboard sheet to the other side and cut it with a knife.

To cut long strips, use a starter or rack profile. You can use any guide, but with a perfectly flat surface.

Cutting process

The sheet is laid on a flat horizontal surface. Then it is marked - cut lines are drawn with a pencil, remembering that the marker will come through the putty.

The sheet is ready. Now take a knife and draw it strictly along the line. Then they bend the sheet along the cut, turn it over and run the knife again.

When they try to cut with a utility knife, its blade bends, catches on the edges and tears the material. The result is obvious - an uneven cut. The line turns out to be uneven and it is difficult to break the sheet.

How is figure cutting performed?

Direct cutting of drywall does not cause problems, but when constructing structures and for finishing, fragments of non-standard shape are often required:

- The corner is cut using a hacksaw. First a short section, and then a long one. Place the sheet over the canopy, break through and cut out.

- The holes are cut according to a template using a template in which a circle of the required size has been made. A hacksaw is inserted into it and the contour is sawed without going beyond the markings. Take out the “extra” section of the gypsum board and process the edges with a file.

- Shaped cutting is carried out strictly along a pre-drawn line. Make a cut using a blade. Edge processing is mandatory. You won't be able to get perfect edges.

Non-standard shaped incisions are difficult to make even for experienced specialists. The more you work with drywall, the easier it becomes to cut. The main thing is to choose the most suitable tool.