Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Set of drills of different diameters

Concrete is the most versatile material used in home construction. Therefore, there are often cases when it is necessary to make holes in the concrete surface when laying cables or wires, installing equipment and furniture.

This cannot be done with a regular drill due to the high strength of the material. Only special concrete drills or drills can provide the required result. The article will tell you the types of tools, their features and methods of use.

Tool selection criteria

Tool sizes by diameter and length

To make the right choice of which drills to drill concrete with, you must first determine the volume and type of work to be performed.

To carry out small repair operations in your home, it is enough to use diamond drills with a diameter of 6 - 10 mm. If you need to hang a picture, it is better to take thinner tools with a diameter of 3 mm to 5.5 mm.

The diameter of the drill affects the depth of the mounting hole:

Dependence of diameter on drill length

According to GOSTs, all tools are marked, indicating the diameter and length, which helps to choose without error the size of the drill for a concrete screw to make a hole on a specific surface.

For example:

- Drill 6×110 mm. This is the most versatile and indispensable tool when making repairs in your homes;

- Drill 8×600 mm. Such long tools are used to drill deep holes;

- Drills 12×200 mm and 12×460 mm are used when it is necessary to drill holes for fastening furniture and laying electrical cables;

- Drill 24×460 mm. This drill is quite large in size and is often used when installing water supply and heating systems.

These are the main characteristics when choosing a drill. To learn in detail what types of tools there are for drilling and drilling holes in concrete, and how to choose the right ones for a particular case, you should watch the video in this article. Particular attention should be paid to the manufacturer.

The use of concrete drills for other materials

There is an opinion among many ordinary people that drills, regardless of their purpose, are a universal tool that can cope with any material, it’s only a matter of time. This, of course, is a misconception: anyone who has tried to drill through a brick wall or metal with a wood drill will confirm this. A wood drill is designed for drilling wood by removing chips at an angle close to a straight line; for metal, the drill also removes chips, but at an angle of about 45 degrees, gradually penetrating into it, the Pobedit drill crumbles and pierces concrete.

If you apply a concrete drill to wood, it will simply crumble the wood and the hole will look disgusting, and if you try to drill into metal, the bit will not last long, its edges will simply wear off.

Review of popular brands of tools for drilling holes in concrete

Drills used for concrete work are produced by foreign and domestic manufacturers. The cost of the instrument depends on the popularity of the brand.

How to choose the right drill bit for concrete?

Tip: When purchasing a tool, you should keep in mind that the higher the price of the product, the higher its quality and longer service life.

Good and durable tools are produced by foreign and Russian manufacturers. The best concrete drills are presented in the table:

| Manufacturer | Tool Features |

| High quality, durable and wear-resistant drills are tipped with carbide, retaining their properties even under prolonged loads that are accompanied by heat generation. Each drill is sandblasted and coated with titanium nitride, which increases their wear resistance. They are characterized by high elasticity and are resistant to bending and impact loads. A special sharpening of the solder makes it easier to insert the drill into concrete, and a spiral groove removes construction dust from the hole. |

| Rennbohr | High-quality metal is used to make the drill, and special processing protects the product from damage by corrosion. It has high strength and wear resistance, reliable protection against deformation. Retains its original shape over a long period of use. |

| Metabo | High quality, hard tipped, durable concrete drill bits. They have special heat resistance, are very durable, and have special grooves for quick removal of drilling waste. |

| Usually produced in a set of eight drills, of different diameters from 3 to 10 mm, packaged in a cardboard box. High-quality tool steel is used for production, and special processing protects against corrosion. Has high strength and wear resistance. It is not subject to deformation during frequent and long periods of operation. The U-shaped spiral on the tools helps to effectively remove dust when drilling a hole. The cylindrical shank securely secures the drill in the equipment chuck. |

| Tools with a four-spiral shape. This significantly reduces the time and labor required to remove concrete residue from a hole. |

| Tool Feature:

|

| The presence of a pobedite tip allows you to drill concrete and other building materials. The best option is to work in electric impact drills. |

| Anchor | They have an optimal price-quality ratio and a long service life. Products are made in China. They are equipped with durable carbide plates that are not destroyed even if the drill hits steel reinforcement when drilling concrete. However, you cannot drill through reinforcement with this drill. But when purchasing such a tool, you need to pay attention to the soldering of carbide plates - they must be even. |

| Used for rotary impact drilling. Peculiarities:

|

Advice: Which drills are best to use for concrete, everyone decides for themselves, based on their material capabilities. But it is always worth remembering that more budget options may be a fake, which can be immediately recognized when drilling concrete. Therefore, which drills are best to purchase, you should consult the seller.

How to drill concrete

To choose what to drill into a concrete wall, you need to follow the rules:

- Choose a tool with the ability to change the speed of the process, thanks to this the drill will work carefully without damaging the surface.

- Pay attention to whether the tool has impact drilling and depth adjustment; this gives good results when working with problem areas and helps soften them.

- Choose a drill that you can hold with both hands.

- Pay attention to the power of the tool.

Drilling with a hammer drill

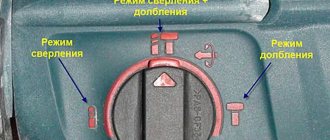

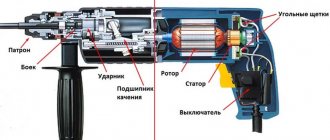

The hammer drill is the most powerful tool, suitable for large volumes of work and for drilling concrete walls.

There are 2 ways this tool works: rotation and impact. For rotation, a special type of drill bit for a concrete hammer drill is used - a drill, it comes with a Pobedit drill bit. You can tell what a concrete drill looks like by its special shank, to which a special chuck is installed.

Such drills mean:

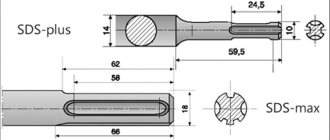

- SDS plus - has a thin shank and recesses to hold the hammer drill in your hand, the profile is symmetrical, it is easy to install this type of drill;

- SDS max - has a thick and long shank; correct installation is possible only in one position.

The pobedit tip is resistant to heavy loads. When the hole is located on the edge of the structure, drilling concrete using the impact method is not recommended, because A concrete structure may chip, and when working with ceramic tiles, the material will simply crack.

In this case, it is better to use a diamond concrete drill for a hammer drill; it has greater hardness than a Pobedit drill; you must take breaks during work to cool it; drilling at high speeds is prohibited.

Do not use hammer drilling with a diamond drill, as... Although it has great hardness, it is highly brittle and can crack.

Drilling

For small-scale work, especially in an apartment with thin walls, you can make a hole with a drill designed for drills for working with concrete. It can be either a win or a diamond product. A drill with a cylindrical shank is used for impact drills. When working, it is recommended to choose medium speed. Which drill bits for concrete are best to choose depends on the type of drill.

Drilling holes

The process of drilling a hole in concrete with an electric drill

The instructions for carrying out the work are quite simple:

- Working tools are carefully selected. With a hammer drill, due to the transverse runout, the hole is slightly larger in diameter; it is better to purchase a drill of a smaller diameter. A diamond bit cuts through concrete with minimal tolerances;

- The surface is marked for drilling holes;

- To clearly position the tool in the center of the hole, it is better to mark the starting point with a concrete punch or bolt;

- The tool is installed in a pre-designated recess and a hole is drilled in the concrete using a hammer drill;

Tip: When working with a rotary hammer or impact drill, a lot of dust is generated. Therefore, when drilling holes, you should use safety glasses, gloves and a respirator.

- Pressing with great force on the handle of the hammer drill, you gradually need to move deeper into the concrete;

- When drilling a sufficiently deep socket with a low-power impact drill, it is necessary to use several techniques, periodically cooling the drill;

- For large holes, you first need to go through the center of the intended hole with a drill of a smaller diameter, and with a more powerful one, expand the cavity to the desired size;

- Upon completion of processing, the cutting edges of the tool are inspected;

- If necessary, the drill is sharpened.

Drill sharpening

Drill cutting edge

Tip: When starting to make holes in a concrete wall, it is necessary not only to choose a high-quality tool, but also to use it correctly.

In this case, you need effective preparation of the drill, which consists of sharpening it. You can do this yourself on a sharpener with a corundum whetstone.

The operating technology is similar to restoring the cutting edge of any similar tools, but taking into account some nuances:

- Severe overheating of the surfacing should not be allowed. Exposure to high temperatures reduces the adhesion of the winch and the steel base, which reduces the strength of the connection;

- If the moment was missed and the drill got hot, it takes enough time for it to cool down so that the process occurs slowly. It is forbidden to immerse the instrument in water: due to temperature changes, cracks will appear on it;

- The drill is sharpened along a cone, or along a helical surface. In the first case, no additional devices are required;

- When sharpening to a conical shape, the edges should meet exactly in the center of the drill. If the intersection of the edges shifts: the tool will be pulled to the side during operation, and one of the edges will become blunt much faster;

- It is better to use screw sharpening when working on foam or aerated concrete, and the working part of the tool should be sharpened on a special sharpening machine.

What does the color of a drill mean? Do you need to choose drills by color?

The production of cutting tools is regulated by numerous GOSTs, which establish requirements for the quality and technical characteristics of these types of products, including drills. Their main properties are reflected in the product labeling and serve for its classification.

These characteristics include:

exact designation (name) of the drill according to the relevant GOST; diameter; steel grade of the working part of the tool; accuracy class.

the color of the drill for metal and other materials is not standardized in any way,

since the color of the metal itself practically does not carry any information load.

by the appearance of the cutting tool, at best, one can name only a group of alloys

, to which the metal used to make the drill belongs. but this is clearly not enough to choose the right tool for yourself.

cutting tools: types, steel color grades

The metallurgical industry produces a huge range of products, part of which are alloys for the manufacture of cutting tools.

lists of relevant steel grades are given in GOSTs, according to which drills, cutters and other cutting tools for processing metal, wood and other difficult-to-cut materials are manufactured. The following types of materials are used for this:

- carbon tool steel;

- alloyed tool steel;

- high-speed;

- carbide steel grades.

The listed types are distinguished by high levels of hardness, strength, resistance to heat, corrosion and other adverse effects.

characteristics and properties depend on their chemical composition, which, in turn, determines the scope of application of products made from them, as well as its color.

A huge range of drills guarantees the consumer the optimal choice of this type of cutting tools.

steel color

Internet users often ask what color metal drills are. To begin with, we will introduce the natural colors of steel. there are not many of them. color palette includes:

- gray color and its shades - it is inherent in grades of carbon structural steel; these types are not used in the production of cutting tools;

- black and shades of anthracite color are a distinctive feature of carbon tool steel; they are also characteristic of some brands of high-speed cutters;

- the color of stainless steel in different shades is characteristic of alloyed metals, in the chemical composition of which chromium and/or nickel additives predominate or constitute a significant part.

in other words, the color of the steel can presumably determine the type of material, but not its brand. We remind you that it is the steel grade that indicates the properties of the metal and its scope of application.

black drill bits

Carbon tool steel is the most widespread and widespread material for the production of a wide range of tools and has a black color.

Hammers, pliers, chisels, files, axes, saws, chisels, and many other types of products are made from it.

There are 16 grades of carbon tool steel, 10 of which are used, among other things, for the manufacture of cutting tools.

Black drill bits made of carbon tool steel are designed for processing wood and other materials with similar properties.

This limitation is due to the fact that these alloys cannot withstand heating above 200 °C, as a result of which they quickly lose their properties and become unsuitable for their intended use.

At the same time, products of this color have high strength and hardness, which allows them to hold an edge well. In addition, black carbon drill bits are relatively cheap.

It's a completely different matter

‒ black and anthracite-colored drills made of high-speed and hard alloys.

They are designed for processing metals, stone, concrete and other high-strength materials.

They retain their properties when heated to 500 – 600 °C, which allows them to be used in intensive operating conditions.

The designation of high-speed steel grades begins with the letter P - according to the domestic classification and HSS - according to the international classification.

Hard steels are superior to any other grades of steel in terms of strength and other characteristics. For example, they retain their properties when heated to 1,000 °C.

To alloy high-speed and hard alloys, expensive additives are used: tungsten, cobalt, vanadium, titanium, molybdenum and other alloys. Their composition and content are reflected in the labeling; they cannot be accurately determined by color.

In turn, indicating the alloy grade on drills and other cutting tools is a mandatory requirement for their marking.

Stainless steel color drills

Some high-speed and hard alloys, as well as all alloyed tool alloys, can have the color of stainless steel. Drills of this shade are mainly intended for manipulating metal and other difficult-to-cut materials. Alloyed tool alloys can withstand heating up to +400 °C. In this they are inferior to high-speed and hard grades of black steel.

To improve the technical characteristics of cutting tools made from alloyed tool alloys, finished products undergo additional processing. For example, yellow drills are coated with titanium nitride, which increases their resistance to wear. The intensity of the shades of yellow, or rather golden, color indicates the thickness of such a coating.

However, the basic properties of tool alloys (hardness, strength, resistance to heat, etc.) are determined by their chemical composition, and not by color. It is enough for the consumer to be sure that the drills purchased are manufactured in accordance with GOST. If you wish, you can find out the detailed characteristics of cutting tools by referring to the regulatory document indicated in their marking.

Basic requirements for the material of cutting tools

Since color is not a very reliable criterion for choosing drills

and other cutting tools, let us recall their main characteristics and requirements for the metal from which they are made. The main requirements for tool alloys for drills are:

- minimum hardness (HRC) - its value is 53-57 units for wood tools and 62-64 units for metal and other difficult-to-cut materials;

- red fastness, or resistance to heat, without noticeable deterioration in properties;

- resistance to destruction.

The characteristics of the alloys are confirmed by test reports of finished products, which are attached to the certificates of compliance with GOST requirements. The buyer himself will not be able to check the quality of cutting tools, so when choosing them he will have to trust the business reputation of the supplier or seller.

The purpose of the drill can be checked by the angle of the factory sharpening of the tool. For example, wood drill bits should be sharpened at an angle of 85 +/- 3 degrees. For metal drills it is 118 +/- 2 degrees. The sharpening angle of the working edges can be easily checked using a template.

Tools made from high-speed, hard and alloy alloys can be sharpened for drilling any types of materials. Black drills made of carbon tool steel do not allow such liberties. They are suitable for drilling wood, hard rubber, plastics and some types of light alloys.

By the way, are there anyone willing to argue about the correctness of my reasoning on the topic of sharpening?

Then I invite you to the next article

Some useful tips when working with a drill

To drill a concrete surface with your own hands without any problems, you should follow the advice of experts.

Some of them can be found below:

- Before you start working on concrete, you should stock up on drills for different materials, including metal. This is because concrete drills are only used for drilling holes in concrete, ceramic, stone and other hard materials. But often, when entering concrete, the drill encounters metal reinforcement. This requires the use of a metal drill, which temporarily replaces the concrete tool used to drill through the reinforcement and then put the old one back;

- During operation, it is necessary to constantly monitor the temperature of the tool. Every 15 seconds of continuous drilling, you need to pause to cool the drill, but only naturally, without the use of water or other liquid;

- If, when entering concrete, the drill rests on a hard stone, it is better to use a punch, crush the stone, and then continue working with the same tool;

- If it is necessary to make a hole in the ceiling or load-bearing wall, it is better to replace the impact drill with a hammer drill;

- If drilling ceramics, use a concrete drill, but turn off the impact drill mode to prevent splitting of the tiles;

- A dull drill can be sharpened using a grinder by installing a diamond disc on it. If you purchase high-quality expensive tools for work, they will not need to be sharpened.

Tips on what and how to choose drills, concrete drills, and how to use them are useful for both beginners and experienced craftsmen. Drilling concrete is quite difficult, so it is better to first take into account all the recommendations of specialists and choose the right working tool.

What types of concrete drills are there?

Above we looked at what types of tips and shanks there are, now we will look at the types and sizes of drills that manufacturers offer us. The smallest diameter of a drill for concrete is 4 mm, that is, it will not be possible to drill a hole thinner, and the depth of such a hole will be no more than 6 centimeters. Of course, it is possible to find a drill of this diameter and greater length, but due to the physical properties of the metal, such a drill is unlikely to withstand rotation and impacts for long. Even with a slight deviation from the drilling axis, a long thin drill will break.

If you need to drill holes of greater depth, you will have to choose a drill of a larger diameter, since manufacturers produce concrete drills in which the dependence of length on diameter is directly proportional. So, with a diameter of 12 millimeters or more, drills with a length of 1000 mm are produced, which will be enough for through drilling of any wall, unless it is a bunker.

The maximum diameter of drills of this type is 30 mm. It is difficult to work with such a drill; the hammer drill is heavily loaded and requires more cooling time.

If it is necessary to drill a hole of a larger diameter, then core drills are used. Their peculiarity is the presence of a centering drill and a “crown” around it. Thanks to the presence of the cavity, drilling occurs much faster and with less load on the hammer drill.

Core drills also come in pobeditovy and diamond-coated ones; the rules of use and drilling methods are similar to conventional drills:

- Pobeditov set the hammer drill for impact and drilling;

- Diamond - only for drilling.