Frequent malfunctions and self-repair of Goodluck chainsaws

Due to the low quality of parts, Goodluck GL 5200 and 4500 chainsaws periodically require repair and adjustment. Spare parts for these saws can be purchased almost anywhere, and knowing how to install them, you can save on visiting a service center. Let's look at common faults and how to diagnose them.

Stopping the supply of lubrication to the chain

Anyone who has bought a Goodluck chainsaw is faced with the problem of oil supply to the chain; it is either completely missing or there is not enough oil for normal operation, which causes increased chain wear.

The reason in 99% of cases is incorrect adjustment of the lubricant pump. It is installed on the side of the drive sprocket; if you turn the chainsaw over, you can see the adjusting screw, with which you can increase or decrease the feed. Adjustment is carried out using a slotted screwdriver. The saw body indicates the direction of rotation of the screw to reduce or increase the feed.

If there is no flow at all, you need to check the setting. If it is normal and the screw is not fully tightened, then continue checking according to the following algorithm:

- Remove the oil intake and check its flow capacity.

- Check the oil hose for rupture or blockage.

- Check the pump drive gear for threads (the gear is plastic, the threads often break off).

- The above actions did not produce results, then the pump must be changed.

Chain rotation at idle

Another malfunction for which users of Goodluck 5200 and 4500 chainsaws contact the service center is constant rotation of the chain. There are two reasons for the malfunction:

- Incorrect idle speed adjustment; we will tell you how to adjust it below.

- rupture of the clutch spring, as a result of which it is in constant engagement, and accordingly the chain rotates.

To eliminate the malfunction, you need to replace the clutch assembly or install a spring from a donor chainsaw.

Malfunctions associated with incorrect carburetor adjustment

The carburetor is responsible for supplying and preparing the air-fuel mixture; if it is not configured correctly, the following malfunctions may occur:

- No traction or subsidence during operation.

- No idle speed.

- Strong smoke when the engine is running.

- Increased speed.

- The engine does not develop speed, but the power is felt.

- The saw stalls when you press the gas.

- The engine does not start or is difficult to start.

Troubleshooting can be done by adjusting the carburetor screws.

DIY chainsaw repair, fuel supply system

The most common breakdowns that require repair of their parts include problems with the engine and fuel supply system. It happens that it is impossible to develop the nominally maximum power of a chainsaw, or the chainsaw suddenly stalls after some time, or it is not possible to start it at all.

Fuel supply system

This happens in two cases:

- problems with the fuel mixture ignition;

- problems with the delivery of gasoline from the tank to the engine.

Finding the causes of failure and repairing a chainsaw should always start with the elements that will require the least amount of time and money, namely the spark plug. Its direct purpose is to generate a spark and ignite the gasoline mixture with air. A simple visual inspection of this element can tell you a lot and tell you where to start repairing.

- The absence of a spark in the gap indicates poor contact with the wire or a malfunction of the spark plug itself. It is necessary to check all contacts and the spark plug itself. A new spark plug is installed in the cradle, and if it also does not produce a spark, then the problem lies in the contacts and the wire itself. They need to be changed.

- A dry spark plug is the first sign that fuel is not being supplied to the carburetor at all. The cause of the breakdown is a blockage in the fuel filter element or breather. It is necessary to rinse, if this does not work, then change the filter. Manufacturers recommend changing it at least once every three months.

- Excessive fuel presence on the spark plug head indicates incorrect carburetor adjustment or incorrect starting. The repair involves simply removing the spark plug, which needs to be wiped with a dry cloth. It is also necessary to check the chambers in which the fuel burns directly.

- The candle is covered with soot. This indicates an excessive flow of gasoline mixture into the combustion chambers, poor quality of oil, incorrect carburetor settings, or incorrect proportions of oil and fuel. Repair here is carried out by washing the spark plug, then wipe it dry with a rag. The gaps should also be cleaned with a sharp needle or awl. Problems with the carburetor usually arise when its settings are lost, the membrane wears out (only replacing it will help here), or there is a blockage in its channels (should be disassembled and cleaned).

Read also: What is the difference between a chisel and a chisel?

Replacing the chainsaw filter

Repairing chainsaws with your own hands is always not an easy task, even for an experienced person who knows almost everything about technology. Most of the time is spent diagnosing a malfunction, when you need to find the source of all problems with equipment.

Chinese chainsaws costing up to 10,000 rubles

The range from 7,000 to 10,000 rubles is the most competitive and the most risky for both the buyer and the manufacturer. For a buyer in this price category, the loss of money from purchasing a defective saw will seem too painful; the manufacturer has to take into account the increased demands of future owners on the one hand and the competition of brands on the other. Therefore, despite the fact that the purchase amount of 7,000 rubles and above is not yet a guarantee against problems, in this segment there is already a struggle for the buyer’s wallet. I’m glad that you can buy a working and reliable saw with up to 5,000 rubles, or with any other money. The question is who is willing to pay how much.

| № | Model | Image | Price | Advantages | Flaws |

| 1 | Einhell GC-PC 1235 I | 7200-8500 | Developed in Germany, uses Oregon tires, has a primer for pumping fuel for easy starting, is equipped with a vibration damper, and safety systems. The average length of the tire is 35 cm, and its sufficient power - 1.63 kW - allows it to perform any work. The main elements are metal. Well put together. | Despite many laudatory reviews, there are unsuccessful copies that, however, are quite easy to return under warranty. Some owners note in their reviews that it stalls when cold: in this case, initial adjustment is necessary. | |

| 2 | DAEWOO DACS 4500 | 7990-8600 | Three years manufacturer's warranty (Korea), includes a carrying bag, electronic ignition, anti-vibration system. Very powerful - 3.2 hp. Equipped with a 40 cm tire, ideal for collecting firewood, working in the garden, cutting down small and medium-sized trees. Has a metal rigid frame. | The design is not fully thought out: if you hold the tire up for a long time, there is not enough fuel, the air ducts and cooling casing fins quickly become clogged: they require cleanliness and attention. Not as many components and consumables as we would like. | |

| 3 | EFCO MT-350 S/35R | 9690-10700 | The semi-brand is a sister brand to OleoMac. Quite good power - 2 hp, is equipped with a 35 cm long tire. At the same time, it is very light for its class - 4.4 kg, and has a vibration damping system. Claims to be made in Italy (though we don't believe it). Owner reviews confirm long-term, problem-free use over many years. | Disadvantages are harder to find. Usually negative reviews are associated with defects, which, like other saws, always happen. Repairers say that the oil supply is not always adjusted correctly. In terms of reliability, when all instructions are followed, it is a very good and quite good option. Among the saws listed, its main drawback is its high price; for this money you can buy two whole saws from the first part of the review. And a set of chains and tires for return. | |

| 4 | Hitachi CS 33 EB | 10100-10900 | Brand. Manufacturer's warranty - 3 years. Easy to start. Tire - 35 cm, power - 1.68 hp. Very light - 4.2 kg without bar, chain and refills. One of the favorite saws of many regulars of specialized forums (where they are allowed to talk about something other than calm) | Price! It's even higher than our limits. Many users find that the engine power is a bit low. Demanding on fuel quality and cleanliness. Otherwise, it has practically no shortcomings. | |

| 5 | Makita EA3202S40B | 9600-10700 | Brand. Long tire - 40 cm, sufficient power - 1.8 hp. The presence of an Easy Start system for easy starting and a vibration damping system with 4 springs. An excellent option as a household saw. | It is better to replace the chain included immediately. Some users have problems with starting, which is solved by adjustment, but the vast majority, on the contrary, note an easy start. |

Chainsaw Goodluck GL 5200

The Goodluck 5200 chainsaw is almost a complete analogue of the previous model, with the exception of engine power and the ability to install a 55 cm long tire. The power of the 5200 is only 0.2 kW more, but it is immediately appreciated when the chainsaw is running, which even hums a little more powerfully.

Like the 4500, the 5200 is not intended for professionals, but for everyday users and should be used from time to time. She can handle a daily eight-hour day, but she won’t last long in this mode. The reason is the small resource and low quality of parts; this was done specifically in order to make the chainsaw as affordable as possible.

Reviews of Goodluck chainsaws

Sergey. 24 years. Barnaul.

I bought myself a Goodluck 4500 over a year ago. Satisfied. I saved a good amount of money compared to buying a household chainsaw from the well-known Shtil brand. After the purchase, I immediately started sawing boards and all sorts of rubbish at the dacha, I didn’t even break it in, I didn’t work every day, but on duty. The saw is powerful and easily copes even with thick boards; I can’t say how it cuts lumps, because I have no experience. I use Oregon two-stroke oil, it’s for the engine; to lubricate the chain, I buy regular Autol at a gas station, although I know it’s not allowed, but it’s cheaper.

I repaired it only once, the saw began to supply lubricant to the chain too quickly, the reason was that the oil pump adjusting screw had become loose due to vibration. I adjusted it and everything was fine. For those who want to save on buying a chainsaw, I recommend the Goodluck 4500.

Anatoly. 35 years. Tver.

I have owned a Goodluck 5200 chainsaw for more than two years. To be honest, I already want to buy something more reliable. There were no serious breakdowns, but I constantly repair small things. I change the shock absorbers, adjust the carburetor, often the saw simply won’t start, but after standing for a while, it starts and works fine. The consumables for it are not expensive, I try to change them in a timely manner. By the way, I want to immediately warn those who are going to buy such a chainsaw that the standard tire is of poor quality and worked for me for less than 2 months. I do not recommend buying a Goodluck 5200 chainsaw, because their quality is questionable and it’s really annoying to constantly repair it.

Chainsaw Goodluck GL4500M

A modern chainsaw intended only for private use, this chainsaw will not work for a long time in difficult conditions, because it has a limited resource and safety margin. Suitable for annual firewood collection and various site maintenance tasks. It is not recommended to use the Goodluck 4500 chainsaw in construction, as it is quite bulky and heavy compared to analogues.

Appearance and quality of parts

Externally, the chainsaw looks decent, plastic body, aluminum handle, convenient controls, but at first glance it is noticeable that cheap materials were used as much as possible in production.

After the first days of use, the quality of the materials reminds itself, scratches appear on the body, because the plastic is not shock-resistant, the handle bends, the shock absorbers break. It is especially unpleasant when the saw accidentally falls. The consequence of a fall is often the breaking of the chain brake control lever, since it is made of fragile plastic. This breakdown is the most common reason why owners of the Goodluck GL4500M chainsaw contact a service center.

If you do not take into account the quality of the body parts, then overall the saw is normal. It starts easily, picks up speed, has the ability to adjust the oil supply for chain lubrication and the quality of the fuel mixture

It is also important that it is easy to find spare parts for this chainsaw, and if you have some experience and tools, you can carry out repairs yourself, but let’s not deviate from the topic and return to specifics

Characteristics of Goodluck 4500

The maximum power achieved at 9000 rpm is 2 kW. The saw is powerful and resourceful, which indicates high productivity. The engine is 45 cm3, not the largest volume, but it is quite enough. The Goodluck 4500 can be equipped with a saw set with a maximum length of 50 cm.

For a household chainsaw, a tire longer than 40 cm is not required, since this length is sufficient to perform all necessary tasks. Installing a longer tire and chain will add financial costs to operation, since a fifty-centimeter tire costs more than a forty-centimeter one. It's the same with chains.

The pitch of the chain, drive and driven sprocket is 0.325. The fuel tank is just over 0.5 liters, the oil tank is about 0.3. Fuel consumption depends on specific operating conditions and carburetor settings; based on operating experience, we can say that on a full tank the saw runs for about 30 minutes, during which time you can cut about half a cube of firewood with logs.

Equipment

The Goodluck 4500 saw package includes the following:

- chainsaw;

- headset (chain, bus);

- set of keys for maintenance (adjustment screwdriver, two hex keys, combination wrench);

- toothed hook (necessary for ease of cutting tree trunks);

- transport protective case;

- measuring container for preparing the fuel mixture;

- user guide.

This complete set allows you to begin fully using the chainsaw immediately after purchase, tensioning the chain if necessary, or eliminating minor faults. More details about the Goodluck chainsaw, its configuration and purpose are described in the video. Video with comments from the author; by watching it you can learn how to properly assemble the saw and prepare it for work.

How to Disassemble the Gas Handle on a Chainsaw

Content

Disassembly and assembly

Stihl MS 180. The tool is reliable and simple, but sometimes it requires repair, as well as any equipment. In this article, let's look at how to dismantle the Tranquility 180 chainsaw in the event of a major engine overhaul.

IMPORTANT. An experienced electrician leaked the secret to the network on how to pay half as much for electricity legally. Read more

Preparatory stage

Repair of any equipment should begin with preparatory work, and a calm 180. drink, and not an exception. At the preparatory stage, before dismantling the chainsaw with a calm 180, it is necessary to remove the side cover, chain and bar from the chainsaw. Then, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil stains and others.

When cleaning the saw, special attention should be paid to the place where the chainsaw drive sprocket is located, as this is the most contaminated area.

In areas with large oil accumulation, you can flush with clean gasoline.

Removing the handle

Direct dismantling of the 180 sedative begins with the removal of the handle, which is attached to the chainsaw body using three rubber shock absorbers. To remove it you need

Remove the plastic plugs from the inner cavity of the shock absorbers, then use a strong screwdriver to first press out the top shock absorber, and then the one closest to the rear handle.

At the rear of the handle there is a gas trigger, which is connected by wire to the carburetor; to disconnect the rod from the gas trigger, you need to unscrew two screws and disassemble the handle .

When the handle remains on the same shock absorber, it is necessary to unscrew

chain saw from the inside of the handle and bend it sideways, remove the body from the last rubber band.

READ How to Disassemble Makita 6270d Screwdriver

Removing the starter

At the next stage, the top housing cover is removed and the 4 starter mounting screws are unscrewed, after which it is necessary to remove the covers of the oil tank and fuel drum. The starter is removed quite simply and no problems arise.

After removing the starter, the open interior of the chainsaw must be cleaned, as there is usually sawdust around the starter.

Removing the flywheel

Chainsaw flywheel Pin 180 is twisted with great force, so removing it requires a socket with a metal ring. The nut holding the flywheel is turned off at 13.

To block the crankshaft from turning, you need to unscrew the spark plug and install the piston plug through the spark plug hole, if it is not there, old lace from the starter, with the components attached to it, and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to rotate the flywheel by installing a power screwdriver or other tools between the ribs and the body; with this method of blocking from rotation, the flywheel blades are not able to withstand the load and break off.

Stihl MS 180 trigger jams. How to fix

This model has a problem. The trigger jams in the felling position (when the saw is turned on its side). problem

Calm REPAIR OF CONTROL LEVER.

Even more information about repair and choosing tools on our website www.LookTool.Ru, come in, we welcome everyone

Once the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the nut is normal, so you need to turn it to the left. When loosening the nut there is no need to remove it all the way, just unscrew it to the point where its top edge is equal to the tip of the shaft, after which a soft metal knockout is placed on the nut and a sharp blow. Thus, the flywheel jumps off the shaft from a sharp impact and can be easily removed without the help of additional tools.

READ Is it possible to put another tire on a chainsaw

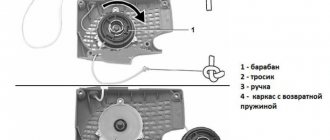

Dismantling the clutch drive and oil pump

Must be removed before dismantling. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

The high head is 19, you need to unscrew the coupling. The thread stays on it so it turns toward the side of the bar rather than toward the back of the saw.

Disconnecting and removing the coupling must immediately remove the reflector plate and drive the oil pump to do this easily, because they are mounted on the shaft without any fastening.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have a socket for 8 and an extension, with which it is convenient to unscrew the carburetor mounting nuts and the air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and choke linkage from the engine control lever and remove the lever, only then remove the air filter and carburetor.

Muffler. Pin 180 is secured with two unscrewing nuts that need to be pulled towards you; it can be easily removed.

The coil is attached to two screws; to remove it you just need to unscrew them.

Removing and dismantling the engine

The engine is held in place by four screws mounted on the bottom of the chainsaws: Calm 180. To remove, unscrew them and then carefully pull the engine out of the seat and rubber carburetor tube.

To remove the engine, the 4 crankcase screws are unscrewed and the crankcase is removed, then the crankshaft can be removed using the seal, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings have been pressed against the shaft with force, a special puller will be required for removal.

READ Chainsaw Motor Lubrication Oil

In order to remove the piston from the connecting rod, it is necessary to remove the retaining ring from the seat using a thin screwdriver, then the piston pin is squeezed out from the opposite side, after which the piston is removed to the side.

Assembly of the 180 Calm chainsaw

To assemble the stihl ms 180 saw backwards, it’s quite simple, the main thing is to adhere to the following algorithm:

- Install the piston onto the connecting rod, the arrow on the piston should point towards the Calm 180 chainsaw and on the left side of the piston. the side of the crankshaft that is intended for installing the flywheel;

- Carefully insert the piston back into the cylinder, the coil mounting location should be on the side where the flywheel is mounted on the crankshaft;

- Install the bearings, oil seals, retainer on the shaft and the lower assembly in the cylinder seat;

- Then degrease the installation site of the crankcase and the crankcase itself, after which it should be lubricated with sealant and fixed in place with 4 mounting screws;

To assemble the Steele 180, after assembling the engine, you must follow the reverse disassembly sequence. It is important to handle the process carefully and do not forget to install the linkage on the carburetor and connect the ignition wire.

Below you can see the dismantling of a calm 180 in the video, it is made for inexperienced users, it shows the whole process in detail.

Dismantling a calm 180 chainsaw and assembling it, if you have some experience, is quite simple, the main thing is before work. Clean the saw carefully and take your time. To prevent small parts from being lost, you need to use containers in which you need to lay out spare parts.

Performance properties

Created on the basis of Japanese analogues, Goodluck brand household appliances are characterized by:

- high quality of materials used;

- using the most modern production technologies to date;

- full quality control of assembly at all stages.

The Goodluck chainsaw, regardless of power and level of technical equipment, is manufactured in accordance with the requirements of mechanical engineering, assembly and operational standards, and recommendations of safety regulations.

Operating and maintenance instructions

When working, it is advisable to hold the chainsaw with both hands at the same time by the handles. It is better to stand on the side, as indicated in the instructions. For cutting, it is customary to use the upper and lower edges of a gasoline tool.

Caring for a Goodluck gasoline saw is easy. Before storing the tool, it is necessary to clean it of accumulated debris, dirt, dust, and also empty the fuel and oil tanks. The chain must be removed and placed in fresh oil. Also, to operate a gasoline saw, it is necessary to use suitable fuel, otherwise the internal systems of the tool will quickly wear out.

How to set up a carburetor

There are 3 adjustment screws on the carburetor of GoodLuck units:

- L - low speed and idle speed (fuel mixture quality level);

- H—maximum and average (volume of mixture);

- T - adjusting the throughput of the carburetor diffuser by adjusting the position of the throttle valve.

First, screw L is adjusted. For standard adjustment, you need to make 2-2.5 turns with the motor turned off. Screw H is installed in a similar position. Then you need to turn on the chainsaw and wait a few minutes.

After activating the tool, you need to find and adjust the maximum idle speed of the engine using the quantitative screw. The screw is then loosened about ¼ turn. For the most accurate carburetor adjustment, it is better to use a tachometer. Correctly adjusted carburetor of a Goodluck chainsaw ensures monotonous operation of the tool at maximum speed. In this case, the engine will not wear out.

Video text

Find out how to fix the most common chainsaw problems using just two standard wrenches!

1. The chainsaw does not start 0:30 1.1. Checking the fuel mixture 1.2. Checking the spark plug of a chainsaw 1.3. Checking chainsaw compression 1.4. Checking the chainsaw carburetor

Read also: How does a planetary gearbox work?

2. The chainsaw chain does not rotate 5:46 2.1. Removing the chainsaw chain from the brake 2.2. Development of a chainsaw tire sprocket

3. The chainsaw does not cut 6:45 3.1. Checking chainsaw chain teeth 3.2. Checking the sharpening of the chainsaw chain 3.3. Checking chainsaw chain lubrication

What to do if nothing helps 7:58

Stepan Latypov, director of the Belarbo enterprise, says:

A chainsaw is a valuable tool in the household today. For many owners of country houses, this unit has become indispensable. Despite its fairly simple design, the tool sometimes fails. However, almost anyone with a certain amount of knowledge in the field of technology and a set of necessary tools can repair a chainsaw on their own.

About the manufacturer

The full name of the company is Goodluck Science & Technology Co. Its founding date can rightfully be considered 2001. The main direction of its activity is the production of equipment and tools, the specialization of which is site care. It is worth noting that the direct homeland of the manufacturer is China.

The company annually produces a huge number of chainsaws and electric saws, electric trimmers, lawn mowers, brush cutters, brush cutters, pumps (water) and other such equipment. Chainsaw or electric saw, which is better?

An important, one might even say the main advantage of the company’s products is that every part used in its production is made exclusively from high-quality material. Which, through numerous checks, meets all the necessary conditions and standards regarding safety and reliability.

Moreover, due to the fact that all of his equipment has a unique function, namely supplying oil on an automatic basis, the immediate life of the equipment is significantly extended.

In addition, the manufacturer has equipped its products with the highest power, minimal noise level, a fairly small weight category, as well as anti-vibration, which is a godsend for every owner of electrical equipment.

In addition, each individual product of the company has not only durability, but a modern design. The company is in rapid development every day, as absolutely everything, even minor details regarding the production of electrical equipment, are taken into account and improved. Just imagine, every year more than eight hundred models of various types come out of the manufacturer’s machine.

Technical characteristics of GoodLuck 4500

After 10 years of operation, the chainsaw can safely be called legendary, and is especially in demand in Ukraine. An ideal assistant in solving everyday problems, but the characteristics also help to use the equipment for professional purposes. The main component is a two-stroke engine with a power of 2.7 horsepower or 2 kW. The declared volume is 45 cm3, which is quite enough for reliable operation for a long time. The maximum speed achieved is 2,700 rpm.

The Goodluck 4500 chainsaw is boldly called a compact and convenient device, because all components and assemblies are created close to each other. As a result, the weight was only 4.8 kg.

Detailed review of GoodLuck 4500

Today, GoodLuck Science & Technology Co manufactures thousands of chainsaws, power saws, trimmers, pumps and other equipment. On the market, chainsaws under this brand are sold at a very affordable price, and high popularity and positive reviews are characteristic of the in-house creation of all parts using high-quality materials. The company has all confirmed certificates and complies with safety standards.

The main advantages of the GoodLuck 4500 model include:

- It copes well with everyday duties and has a well-thought-out, convenient design;

- Availability of an automatic chain lubrication system;

- The set includes a set of keys, a chain, a tire and a measuring tank;

- There is a chain brake;

- It is a well-known model, so there are no problems with spare parts.

The chainsaw performs well when performing household tasks and even working in suburban areas. To do this, the manufacturer equipped it with a 600 ml fuel tank and a 250 ml oil tank. Based on the instructions for use, you need to use A92 gasoline and 2T oil; with proper maintenance and care, this model will work for several years without any major breakdowns. Occasionally you will have to clean the carburetor and filters.

Corresponding to the low cost, the chainsaw has low fuel consumption, so the equipment is affordable in every sense. Among the features include a centrifugal cleaning system. Cooling occurs in the standard way using air. For additional protection, the manufacturer installs an original inertia brake on the Goodluck 4500 chainsaw.

Chain Goodluck 4500

To ensure high-quality performance of functional duties, the GoodLuck model works with a 72-link chain with a pitch of 0.325. There is no need to worry about regular maintenance of the chain, because it is automatically lubricated. The Goodluck 4500 also received a 450 mm tire. For everyday tasks, these are excellent characteristics, considering that the average cost of a device is around 6,500 rubles in Russia and 2,000 UAH in Ukraine.

The most common tool malfunctions

No matter how competently the unit is operated, problems occasionally arise in the operation of its systems. To fix them, you need to determine the cause. Knowing the design of a chainsaw, we can say that most often problems arise with the operation of the engine . However, do not forget about other components that are also subject to wear.

Problems with the power plant

It can take quite a lot of time to identify the cause of an engine malfunction. Among the main signs of failure, several main ones should be noted:

- The engine does not start.

- The power plant starts to work, but quickly stalls.

- Maximum power is not achieved at idle speed.

- There are interruptions in work.

When diagnosing a malfunction, it is necessary to use the method of exceptions. It is better to start checking with those reasons that will require a minimum of time to eliminate. Most often, a power plant malfunction is associated with the ignition system. It is the condition of the spark plug that can say a lot about the operation of the entire engine. First, using a special key, you need to remove this element and then check its external condition. The performance of the ignition system can be easily determined by sparking. When a strong and stable spark appears, you should proceed to inspect the fuel supply system.

The following problems are possible in its operation:

- A clogged breather cap prevents fuel flow.

- The fuel filter is dirty.

- Insufficient fuel is supplied from the carburetor to the cylinder.

To eliminate the malfunction, you should disassemble the system and clean it thoroughly. Problems with fuel supply can be caused by contamination of the corresponding filter, which interferes with the process of creating a high-quality fuel mixture. If the chainsaw stalls under load, you should inspect the muffler, in which a large amount of combustion products could have accumulated. The most difficult problem is the malfunction of the cylinder-piston group. This applies not only to the repair of Chinese chainsaws, but also to products from well-known brands. In such a situation, it is practically impossible to do without purchasing spare parts.

Lubrication system and chain brake

When using the tool, special attention should be paid to monitoring the operation of the chain lubrication system . Most often, problems arise due to clogging of the channels through which lubricant is supplied. If there is a slight oil leak, you can continue working with the chainsaw. Otherwise, it is necessary to take urgent measures to eliminate the malfunction.

The first step is to check the tightness of the connections between the fittings and the tubes. It is quite possible that these parts will need to be replaced, but everything can be done by simply replacing the sealant. Don't forget about the oil pump, which needs to be checked visually. It must be replaced if there are cracks in the housing. Problems with brake operation most often arise due to contamination of the brake band.

Advantages and disadvantages

The proposed branded assortment of branded chainsaws organically combines an affordable price for a wide range of customers and full-fledged performance characteristics.

The owners note:

- absence of winter starting problems typical for gasoline engines;

- hassle-free access to settings for internal and removable sawing equipment;

- unpretentiousness of power units to the quality of gasoline and the ability to use a wide range of motor and chain oils of similar purposes from other manufacturers;

- The attachment point for the guide bar of Goodluck chainsaws allows you to equip the tool with more advanced and durable saw sets from other brands.

A number of reviews contain a number of complaints about the quality of threaded fasteners, the reliability of the manual starter and chain tensioner, and the imperfect design of the air intake filter.

How does a chainsaw carburetor work, on what principle does it work?

Modern car engines are no longer equipped with a carburetor. Meanwhile, previously, almost every driver knew how to adjust it. Today, chainsaws with injection engines have already begun to appear on sale, but carburetor models will hold the palm for a long time, because their cost is 5-15 times lower than that of the modern version.

The carburetor consists of several main parts:

- aluminum body;

- diffuser and air damper at the inlet;

- jets (valves for regulating fuel supply);

- sprayer (it is the one that provides injection);

- fuel (float) chamber.

The operating principle of a chainsaw carburetor is quite simple. Fuel is supplied continuously, and its quantity is regulated by jets. Air enters through the air damper due to the vacuum of air created by the piston. In the diffuser, fuel and air are mixed. It is this fuel-air mixture that enters the cylinder, causing the engine to work.

Chainsaw Goodluck GL4500M

The tool was created for gardening areas.

But, due to its high productivity and power, it is used in the logging industry. The Goodluck GL 4500 chainsaw has proven itself well when working in workshops, construction, and carpentry. Features of the Goodluck tool

- Increased saw performance

- overheat protection

- Air purification option

- Economical fuel consumption

- Durable tire.

Specifications:

- the motor has a power of 2000 W;

- chain pitch – 3/8”;

- the oil tank has a capacity of 2.7 l;

- fuel tank – 5.3 l;

- revolutions - 2.8 thousand per minute;

- weight – 5.1 kg.

The Goodluck chainsaw provides operator comfort and safety. It is equipped with an additional inertia brake, which quickly stops the chain when it threatens to kick back.

Operating and maintenance instructions

When working, it is advisable to hold the chainsaw with both hands at the same time by the handles. It is better to stand on the side, as indicated in the instructions. For cutting, it is customary to use the upper and lower edges of a gasoline tool.

For regular operation of the unit, it is recommended to acquire protective equipment: goggles, gloves and overalls.

Caring for a Goodluck gasoline saw is easy. Before storing the tool, it is necessary to clean it of accumulated debris, dirt, dust, and also empty the fuel and oil tanks. The chain must be removed and placed in fresh oil. Also, to operate a gasoline saw, it is necessary to use suitable fuel, otherwise the internal systems of the tool will quickly wear out.

How to set up a carburetor

There are 3 adjustment screws on the carburetor of GoodLuck units:

- L - low speed and idle speed (fuel mixture quality level);

- H—maximum and average (volume of mixture);

- T - adjusting the throughput of the carburetor diffuser by adjusting the position of the throttle valve.

First, screw L is adjusted. For standard adjustment, you need to make 2-2.5 turns with the motor turned off. Screw H is installed in a similar position. Then you need to turn on the chainsaw and wait a few minutes.

After activating the tool, you need to find and adjust the maximum idle speed of the engine using the quantitative screw. The screw is then loosened about ¼ turn. For the most accurate carburetor adjustment, it is better to use a tachometer. Correctly adjusted carburetor of a Goodluck chainsaw ensures monotonous operation of the tool at maximum speed. In this case, the engine will not wear out.

How to adjust the petrolsaw carburetor.

Adjusting the carburetor without removing it.

- “L” regulates fuel supply at low speeds;

- “H” is needed to regulate the maximum fuel supply;

- "T" idle air control.

Before starting manipulations, it is necessary to mark the initial position of the screws with paint or a felt-tip pen. The exact settings for the chainsaw carburetor for each model are in the operating instructions.

Additionally: Chainsaw Hopper 4518 reviews: 5220, reviews, technical specifications, price

However, more often it is necessary to adjust the carburetor after eliminating a malfunction of the tool. The reasons may be:

- violation of the protective cap and unbalancing of the screws;

- wear of the engine piston, requiring a different mixture composition for operation;

- unsatisfactory performance of the carburetor itself.

How to adjust the carburetor on a specific model of chainsaw? Perform the operations sequentially, following the instructions. Here is the algorithm, the general sequence of actions.

There are two stages of setup:

- basic, with the engine off;

- thin - on a warm engine, idling.

The basic setting is carried out only for the fuel screws at low and high speeds. Smoothly and slowly, close the dampers completely until they stop. Also smoothly open both screws counterclockwise 1.5 turns. After this, start the engine and warm it up for 10 minutes.

How to adjust the carburetor on a chainsaw with the engine running:

- adjust the idle speed with screw “T” by rotating counterclockwise until the engine runs stable at idle speed;

- check the speed of the speed increase; when spinning slowly, turn screw L an additional 1/8 turn;

- Set the highest rotation speed using screw H on the tachometer;

- Check the carburetor operation at idle once and for all.

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

To carry out the carburetor setup procedure successfully, you need to read the operating instructions for a specific model in advance to identify additional features of setting up the device.

Chinese chainsaw. Carburetor repair and adjustment. Carburetor diagnostics.

Chinese chainsaw will not start. Diagnostics and repair. Carburetor repair. Carburetor adjustment.

Almost any Chinese chainsaw has the same adjustments as its branded counterparts. The same screws L, H and T are present. Sometimes there are saws in which only the idle speed can be adjusted. However, according to reviews from owners and service workers, not every chainsaw can be adjusted without problems. Even for experienced repairmen, some models can take a decent amount of time before getting an acceptable result.

Video review of work

How does the Patriot pt 2512 chainsaw work?

Cutting wood with Patriot 5212 saw

Patriot pt 2512 review

Owner reviews

Oleg, Astrakhan:

“The Patriot saw is Chinese, so you don’t have to expect sky-high performance, but for a budget it works quite well. The exterior design is taken from the Japanese Zenoa. To avoid problems with the plant, I would recommend starting it with the damper closed until the flash appears. As soon as the flash appears, you can open it, add gas and work. Plus it works well at high idle speeds.

Disadvantages: weak body, not very good plastic.

Advantages: Patriot cuts well, works without problems.

Remember that the minimum proportion of oils for such saws is 1:25 or 1:30, as for Husqvarna 1:50 will not work, otherwise it will quickly break.”

Source

Chainsaw Goodluck GL4500M – factory model parameters

This high-quality household model differs from most market analogues in its balanced design, good traction reserve and ease of manual repair. The Goodluck chainsaw is equipped with a durable gasoline engine with a forged piston and an enlarged steel cylinder, the walls of which are coated with a protective chrome alloy. The model’s engine is complemented by a reliable manual starter, an improved vibration suppression system and a modified 2-chamber carburetor.

The saw blades of Goodluck garden tools are equipped with easily replaceable metal bars and hardened steel chains. The tension of the installed saw set is carried out using the built-in side sprocket. For intensive chain lubrication, the Goodluck saw's base unit includes a high-quality oil pump. The manufacturer equipped the model with an effective inertial lever brake, which is instantly activated when there is a reverse impact as a result of the rotating chain hitting a nail or metal wire.

The main factory parameters of household garden tools include:

- built-in cylinder volume – 45 cm3;

- fuel/oil tank – 550/260 ml;

- pitch of the installed chain – 0.325 “;

- weight – 5.2 kg.

The Goodluck GL 4500 chainsaw is equipped with comfortable rubberized handles located in the middle and rear part of the model. This makes it more convenient to use in limited space.

Chainsaw device

The simple design of the tool allows you to repair the chainsaw yourself. The main elements of the unit are the following:

- Power point.

- Clutch.

- Oil pump.

- Chain transmission.

- Chain catchers and brake system.

Depending on the brand, some changes may be made to the design of a particular instrument. For example, the engine can be located horizontally or vertically. In professional saws, the second option is most often used. Thanks to the horizontal arrangement of the power plant, the dimensions of the tool are significantly reduced, which is important for home use. Knowing the structure of the unit, you can quickly understand how to disassemble a chainsaw.

Frequent malfunctions and self-repair of Goodluck chainsaws

Due to the low quality of parts, Goodluck GL 5200 and 4500 chainsaws periodically require repair and adjustment. Spare parts for these saws can be purchased almost anywhere, and knowing how to install them, you can save on visiting a service center. Let's look at common faults and how to diagnose them.

Stopping the supply of lubrication to the chain

Anyone who has bought a Goodluck chainsaw is faced with the problem of oil supply to the chain; it is either completely missing or there is not enough oil for normal operation, which causes increased chain wear.

The reason in 99% of cases is incorrect adjustment of the lubricant pump. It is installed on the side of the drive sprocket; if you turn the chainsaw over, you can see the adjusting screw, with which you can increase or decrease the feed. Adjustment is carried out using a slotted screwdriver. The saw body indicates the direction of rotation of the screw to reduce or increase the feed.

If there is no flow at all, you need to check the setting. If it is normal and the screw is not fully tightened, then continue checking according to the following algorithm:

- Remove the oil intake and check its flow capacity.

- Check the oil hose for rupture or blockage.

- Check the pump drive gear for threads (the gear is plastic, the threads often break off).

- The above actions did not produce results, then the pump must be changed.

Chain rotation at idle

Another malfunction for which users of Goodluck 5200 and 4500 chainsaws contact the service center is constant rotation of the chain. There are two reasons for the malfunction:

- Incorrect idle speed adjustment; we will tell you how to adjust it below.

- rupture of the clutch spring, as a result of which it is in constant engagement, and accordingly the chain rotates.

To eliminate the malfunction, you need to replace the clutch assembly or install a spring from a donor chainsaw.

Important! The clutch mechanism has a left-hand thread, so it unscrews clockwise. In order to unscrew it, you need to lock the piston through the spark plug hole using a cord with knots tied to it

Malfunctions associated with incorrect carburetor adjustment

The carburetor is responsible for supplying and preparing the air-fuel mixture; if it is not configured correctly, the following malfunctions may occur:

- No traction or subsidence during operation.

- No idle speed.

- Strong smoke when the engine is running.

- Increased speed.

- The engine does not develop speed, but the power is felt.

- The saw stalls when you press the gas.

- The engine does not start or is difficult to start.

Troubleshooting can be done by adjusting the carburetor screws.

Cylinder-piston group

It happens that the engine does not start or functions poorly due to low pressure in the cylinder. The malfunction may consist of a piston, cylinder or bearings that have become unusable, or piston rings that have sunk. You can look at the problem in general terms; to do this, you need to remove the muffler and inspect the system.

You can measure the compression in the engine by placing a compression gauge in the spark plug hole. After time, you can draw conclusions based on the results of the measurements. The problem can only be resolved by completely disassembling the system. If scratches or chips are visible on the piston, it needs to be replaced. The piston ring must be installed in its correct place, clean and intact.