Homeland of the brand and country of origin

The copyright holder of the Baumaster brand is the Russian company Sturm. Chainsaws are produced at a plant located in China.

About the brand

At the end of 2010, Sturm decided to create a separate line of chainsaws under the new brand name Baumaster. New models belong to the group of chainsaws for domestic use. They are similar in power to the Sturm modifications. But their prices are much lower.

Cost reduction was achieved through the use of cheaper cutting accessories (tire, chain) made in China, instead of the most popular Oregon company. There are only three modifications in the new brand’s lineup so far.

Repairing the chain lubrication system

Let's look at three main faults:

- Oil leakage. You should check whether the tubes are tightly connected to the pump fittings and whether there are any cracks on them. Problematic tubes are sealed with sealant or replaced.

- Insufficient oil supply. Most likely, the lubricant supply channels are clogged.

- Cracks appear in the oil pump housing. The part needs to be replaced.

Material on how to sharpen a chainsaw chain will also be useful:

Here's how to diagnose the lubrication system:

Features of Baumaster chainsaws

Baumaster chainsaws belong to the category of saws for domestic home use. They are not suitable for professional use. The equipment and technical characteristics are not much different from most chainsaws of a similar group. They use a standard set of technologies and functions:

- primer - to make starting easier;

- two compression rings - to increase service life;

- use of chrome plated cylinder;

- anti-vibration system;

- ergonomic rubberized handles;

- simplified access to filters and ease of cleaning;

- inertial chain brake operating in auto mode.

Chainsaws are compact and have a small weight, which once again indicates their focus on solving small-scale jobs.

Review of popular models

At the moment, the Baumaster brand is represented by three models. The choice is not extensive, but allows you to perform various tasks.

Chainsaw Baumaster GC-99376X

This model is the lightest in the Baumaster range. In terms of its dimensions and weight, it is quite comparable to electric chain saws. And some of them are inferior in terms of power. However, it will still find its buyer, since the power is enough to perform small everyday work on the site or at a construction site.

Technical characteristics of the power plant:

- cylinder displacement (cm3) - 37.2;

- power indicators (kW) - 1.2, (hp) - 1.6;

- revolutions at minimum load - 2600 per minute.

Saw set parameters:

- tire size (cm) – 40.5;

- the number of cutting links in the chain is 57.

Other characteristics:

- volume of oil tank for chain lubrication (l) - 0.21;

- total mass of the tool (kg) – 4.2;

- fuel tank volume parameters (l) - 0.31.

The Baumaster GC-99376X chainsaw meets all the requirements for this category of chainsaws. Easy to use and maintain, recommended for initial acquaintance with gasoline chain tools.

Customer review. When purchasing, I was attracted by the low price and the power parameters that were sufficient for me. During operation, it was necessary to adjust the carburetor, replace consumables, minor repairs and tighten fasteners. Overall the chainsaw is not bad.

Chainsaw Baumaster GC-99458X

The Baumaster GC-99458X chainsaw differs from the previous model in terms of power. The remaining parameters are almost identical, so the use of this chainsaw is not much different. Among the differences, it is worth noting the longer bar, which allows you to cut thicker trees. The chainsaw is also small in size, but the weight of the saw is 2 kg more.

Technical characteristics of the power plant:

- cylinder working volume (cm3) - 45;

- power indicators (kW) – 2.4, (hp) – 3.2;

- revolutions at minimum load - 2800 per minute.

Saw set parameters:

- tire size (cm) – 45.5;

- the number of cutting links in the chain is 66.

Other characteristics:

- oil tank volume for chain lubrication (l) - 0.25;

- total mass of the tool (kg) – 6.7;

- fuel tank volume parameters (l) – 0.55.

The chainsaw has a balanced design and ergonomic rubberized handles, which allows for increased user control over the sawing process. Baumaster GC-99458X is an excellent option for the owner of a country plot who needs to cut a small amount of firewood for a bathhouse, remove unnecessary trees and shrubs, and cut down garbage.

Customer review. The saw has been in operation for three years now. Among the complaints I can note is instability when starting, frequent replacement of spark plugs. The factory tire was replaced almost immediately. Among the advantages, it is worth noting the large number of teeth on the chain and its compact size.

Chainsaw Baumaster GC-99502X

The Baumaster GC-99502X modification is also related to the household class of chainsaws, but is closer to semi-professional chainsaws. It has a long tire, which, with the existing 50 cc engine, makes it possible to fell trees of serious thickness without any problems. As well as subsequent operations during the procurement of firewood or pre-processing of “industrial” wood. With a significant increase in power parameters, it has a slight increase in weight compared to the previous model.

Technical characteristics of the power plant:

- cylinder displacement (cm3) – 50.1;

- power indicators (kW) – 2.9, (hp) – 3.84;

- revolutions at minimum load - 3200 per minute.

Saw set parameters:

- tire size (cm) – 51;

- the number of cutting links in the chain is 78.

Other characteristics:

- oil tank volume for chain lubrication (l) - 0.25;

- total tool weight (kg) – 6.8;

- fuel tank volume parameters (l) – 0.55.

Customer review. I was pleased with the affordable price for such parameters of chain length and power. Of the minuses, I can note the increased noise level. Otherwise, the chainsaw is worth the money; the faults are the same as those of other brands of chainsaws.

Repair it yourself or send it to a service center

Most of the malfunctions of gasoline chain saws can be fixed with your own hands. True, this requires an understanding of the structure of the chainsaw and how the components function among themselves. As for the tools, the most often needed are:

- screwdrivers (slotted and power);

- combination wrench included in the kit or regular wrenches with heads of various sizes.

Quite often, such a malfunction as leaking gasoline is observed in a Chinese chainsaw with a volume of 38 cubic meters.

We invite you to familiarize yourself with Cherry plum wine: simple recipes for making a drink at home from red and yellow fruits, with and without seeds, and also how to make it in Polish?

Advantages of Baumaster chainsaws

Baumaster chainsaws have all the positive qualities of household chainsaws. This is primarily compactness and light weight. Sufficient engine parameters in terms of power.

The main advantage of the Baumaster brand is the low price of the products compared to similar chainsaws.

Baumaster chainsaws have a standard set of functions that make operation easier:

- easy access to filters for replacement or cleaning;

- unobstructed access and way to tension the chain;

- easier starting of a chainsaw (primer, etc.);

- ergonomic handles for use;

- balanced distribution of weight and load;

- automatic chain lubrication mode;

- high-speed inertial brake of the chain mechanism;

- The housing is made of plastic, resistant to low temperatures and shocks.

The quality of Baumaster chainsaws meets all the requirements for gasoline-powered equipment. Chainsaws undergo mandatory certification and testing.

Disadvantages of chainsaws

Based on reviews from customers of Baumaster chainsaws, it is worth noting that the use of cheaper Chinese components has slightly reduced the quality of the product. The owners' complaints are related to the tire, chain, as well as the ignition system and carburetor. There are negative reviews associated with increased noise from the operation of the chainsaw.

Another disadvantage is that it belongs to the category of household gasoline tools. It is recommended to operate the chainsaw not for very long and in optimal load conditions. It is advisable to stop more often to take a break from work.

The most common tool malfunctions

No matter how competently the unit is operated, problems occasionally arise in the operation of its systems. To fix them, you need to determine the cause. Knowing the structure of a chainsaw, we can say that most often problems arise with the operation of the engine. However, do not forget about other components that are also subject to wear.

Problems with the power plant

It can take quite a lot of time to identify the cause of an engine malfunction. Among the main signs of failure, several main ones should be noted:

- The engine does not start.

- The power plant starts to work, but quickly stalls.

- Maximum power is not achieved at idle speed.

- There are interruptions in work.

When diagnosing a malfunction, it is necessary to use the method of exceptions. It is better to start checking with those reasons that will require a minimum of time to eliminate. Most often, a power plant malfunction is associated with the ignition system. It is the condition of the spark plug that can say a lot about the operation of the entire engine. First, using a special key, you need to remove this element and then check its external condition. The performance of the ignition system can be easily determined by sparking. When a strong and stable spark appears, you should proceed to inspect the fuel supply system.

The following problems are possible in its operation:

- A clogged breather cap prevents fuel flow.

- The fuel filter is dirty.

- Insufficient fuel is supplied from the carburetor to the cylinder.

Lubrication system and chain brake

When using the tool, special attention should be paid to monitoring the operation of the chain lubrication system. Most often, problems arise due to clogging of the channels through which lubricant is supplied.

If there is a slight oil leak, you can continue working with the chainsaw. Otherwise, it is necessary to take urgent measures to eliminate the malfunction.

Popular faults and DIY repairs

Among the most common malfunctions of Baumaster chainsaws is the failure of the cutting set. Its repair is not advisable; replacement is recommended. There are also many complaints about the ignition system. To eliminate this problem, it is mainly proposed to replace the spark plugs.

Below is a video on what to do if the chainsaw is almost new and won’t start. In the video, the chainsaw has a primer fault. It was replaced and the carburetor was repaired.

A video is also presented that shows in detail the process of disassembling a Chinese-made chainsaw. The chainsaw is most likely fake. The analysis is presented in detail, step by step, allowing you to see the filling of the chainsaw.

Engine

In most cases, the following problems occur in engine operation:

- the engine stopped starting;

- the engine starts, but after a while it stalls;

- the engine is not able to develop the required power;

- The engine is extremely unstable.

How to check crankshaft seals

The presence of oil seal leaks can only be checked by getting to the crankshaft itself and carefully examining it for leaks. You can see how to do this correctly in the video:

How to check compression on a chainsaw

At a compression level below 8 atmospheres, the engine will not have enough power, which means the chainsaw will not be able to fully function.

To measure compression you need:

- Remove the protective cover and unscrew the spark plug.

- Insert the tip of the compression gauge into the hole where the spark plug should be located.

- Using the starting cord, rotate the piston and remember the maximum readings of the measuring device.

How to properly install a piston on a chainsaw

The work of replacing the piston for most models of modern chainsaws is carried out according to the following algorithm:

- The top and side covers are removed.

- The candle is unscrewed.

- The stoppers are removed from the shock absorbers and the handle is disconnected from the body.

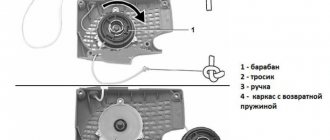

- The drive sprocket and starter are removed.

- A piston stopper is installed in the spark plug hole and the nut securing the flywheel and clutch is unscrewed.

- The flywheel, clutch, and worm drive of the oil pump, located immediately behind the clutch mechanism, are removed.

- The screws securing the carburetor and air filter are unscrewed, after which these components are removed along with the engine control lever.

- The ignition coil is removed, as well as the muffler.

- The saw is turned upside down and, by unscrewing the screws securing it to the body, the engine is disconnected.

- The pan is unscrewed and the piston is removed.

- Since the piston is removed only together with the crankshaft, to disconnect it it is necessary to remove the retaining rings.

- The old piston is replaced with a new one, but as carefully as possible. This is caused by the high fragility of compression rings.

- The crankcase is put in place, and sealant is used instead of a gasket.

All subsequent actions are carried out according to the reverse algorithm of disassembly.