Required Tools

To implement the adjustment of the carburetor valves, you will need a small list of comfortable means:

- razor blade or probe;

- minus screwdriver;

- spanner wrench

Using these simple means, you can adjust most carburetors.

People invented snowmobiles that make it possible to drive on snowy roads very quickly, but at the same time, simply. Ermak snowmobiles are quality, speed and reliability.

Gardening and caring for plants and trees have always been considered one of the most difficult types of work, as they require important time and effort. The Marolex sprayer is the ideal solution for your garden.

Labor-intensive gardening work is currently carried out using a walk-behind tractor. Here you will learn what it really is, how to plant potatoes with a walk-behind tractor.

Remember that by adjusting valves we mean setting the optimal clearance, which is directly stated in the operating instructions for each specific model.

Detailed technical characteristics of the UMZ-341 engine

The engines are designed for operation in the following aspects:

— ambient air temperature from minus 20 to plus 40°С.

— relative humidity of the ambient air up to 98% at a temperature of plus 25°C

The UMZ-341 and UMZ-341E engines are a single-cylinder, four-stroke, gasoline, carburetor engine with overhead valves, spark ignition, with a horizontal motor shaft, with an inclined cylinder, and has a centrifugal all-mode speed controller and a balancing shaft.

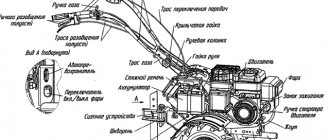

The UMZ-341 engine is designed for installation on the Agro walk-behind tractor manufactured by JSC UMPO, supplied to meet the needs of the mainland for export to countries with a temperate climate

The UMZ-341 E engine is made on the basis of the base model UMZ-341 and is intended to drive the AB-4 electrical unit.

ADJUSTING THE MOTOR

Adjusting the UMZ-341 carburetor

Adjustment of the engine carburetor is done if the engine is unstable

1 Start the engine and warm it up without load for 5 to 3 minutes.

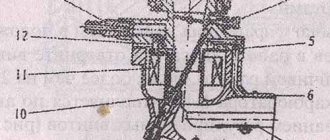

2.4 Turn out the idle speed adjusting screw 8 (Figure 3) to the position where the engine begins to work unstably and smokily by turning the screw to achieve stable, uninterrupted operation of the engine

3 By rotating the thrust screw 10, set the throttle valve to the minimum opening position when the engine is running smoothly at low idle speed, then by rotating the adjusting screw 12 to achieve a greater increase in engine speed. Use the stop screw 10 to adjust the regulated speed

4 If gasoline is poured through the float chamber of the carburetor, it is necessary to remove the float chamber and check the condition of the float, shut-off needle, and valve seat

Carburetor

Adjusting the thermal valve clearances on the UMZ-341 engine

Adjust the gaps between the valve and the rocker arm on a cold engine in this order

— remove covers 4 and 5 of the cylinder head and the starter;

— check the tightness of the cylinder head nuts;

- set the piston to the top dead center (TDC) of the compression stroke,

— loosen lock nut 6 and sleeve 7 of rocker arm 8 and, inserting a 0.08 or 0.1 mm feeler gauge plate between the fifth of rocker arm 8 and the end of valve 3, tighten sleeve 7 so that the feeler gauge plate fits into the gap without biting; tighten lock nut 6;

— check the thermal clearances between the fifth rocker arm and the end of the intake and exhaust valve stems

Install the cylinder head and starter covers in place, securing with nuts.

Note: To more accurately install the piston at top dead center, it is necessary to remove the fan casing and align the “E” mark on the end of the flywheel with the “G” pin on the crankcase housing (Figure 1, sheet 3).

Motor device

Motor malfunctions

We present the first sheet of possible flaws and methods for eliminating them from the user control; more painstakingly you can find out by studying the annotation in full.

Adjusting valves on the Neva walk-behind tractor

Let’s take, for example, the Neva MB-23 model and examine one by one how to correctly set the valve clearances (the principle is the same for all walk-behind tractors of this company). You will need 12mm and 14mm wrenches, a 10mm socket wrench, and 0.15mm and 0.2mm feeler gauges.

- Remove the starter by unscrewing the 3 bolts.

- Carefully remove the muffler, belt and protective cover of the gasoline engine.

- Using a socket wrench, remove the valve box cover.

- Make sure what the valve clearance is on the walk-behind tractor by visiting the annotation. For the Neva MB-23 engine, this is 0.15 mm for the intake valves and 0.2.4 mm for the exhaust valves.

- Make adjustments by measuring the gap using feeler gauges and tighten the nuts if necessary. When adjusted correctly, the feeler gauge should fit between the valve and the rocker arm.

- Reinstall the valve box cover, belt, protective cover, muffler and starter.

DIY repair

How to repair the injector of a diesel walk-behind tractor

You can check its operation using the fuel pump installed on the engine. After this, the nozzle is inspected and adjusted: disassembled in a clean place, then washed with kerosene or clean fuel, blown off and reassembled. In this simple way the product is returned to working condition.

What to do if a diesel walk-behind tractor does not start

First, we find the faulty area of the walk-behind tractor. There are several steps to take:

- turn on the ignition, start the mini-tractor;

- check the availability of fuel;

- see if the carburetor air damper is closed;

- check if there is fuel access to the carburetor;

- see if everything is ok with the candles.

In this video we will look at adjusting the valves of a diesel walk-behind tractor:

Trouble-shooting:

- If fuel does not have access to the carburetor, then you should unscrew and look through the fuel valve, where you need to clean the filter from dirt. You can also check the fuel level (adjustable using a float), it should be approximately 30-35 mm.

- To check the carburetor, you will first have to remove it, empty it and let air through the fitting. If everything is in order with the carburetor, then air should pass through easily. The procedure with air passage is repeated again. Only after this they begin to regulate.

- If the problem is in the spark plug, it may be dirty, then you need to clean it and check the gap between the electrodes (at least 0.8 mm).

Why is a diesel walk-behind tractor difficult to start?

Here are some reasons and their solutions:

- a dirty air filter needs to be disassembled and cleaned;

- combustion products can clog the muffler; it also just needs to be cleaned;

- incorrectly installed carburetor, then you need to reinstall it;

- malfunction of the cylinder-piston group;

- The problem may also be the use of summer fuel in winter. After all, the remaining summer fuel turns into a viscous mass that cannot be pumped into the engine. Here you just need to heat up the fuel by driving the walk-behind tractor into a warm environment.

As you can see, it’s not difficult to fix everything yourself, the main thing is to follow the specified rules and instructions, because taking care of any device prolongs its life.

What to do if a diesel walk-behind tractor runs jerkily

In this case, immediately turn off the engine and give the engine a little time to cool down, only then can you begin repairs or troubleshooting. There are several reasons for such malfunctions:

- there is a lack of oil in the engine crankcase;

- a nadir appeared on the bottom of the connecting rod;

- The oil sprayer or connecting rod (the part that connects the piston and the connecting rod journal) has broken.

What to do if thick black smoke comes out of the engine while the engine is running

This may indicate that the fuel mixture the carburetor receives is too rich, or there is a problem with the piston oil ring, or the air filter is clogged.

To eliminate this factor, perform the following actions:

- adjust the carburetor;

- change old valves;

- install new piston rings.

What to do if the engine breaks down

Basically, there are two most common causes of engine failure. This is when the engine, in principle, does not work and when it still functions, but unsatisfactorily.

If you study the first reason, you need to act as follows: first you need to turn on the ignition, check the amount of fuel in the tank, the opening of the fuel valve and the condition of the carburetor air damper, and then the flow of fuel into the carburetor. Also remove and clean the nozzle, thus removing the blockage. Another reason may be low fuel injection pressure, which can be corrected using the instructions included with this equipment.

If the engine turns over too quickly or easily with the starter, then the problem is either in the valve or in the piston rings. In the first case, you should simply remove this valve and wash it, and in the second, if the piston rings are worn out, they are replaced with new, serviceable ones.

How to adjust valves

If the process of flushing the valve does not help, then you need to carefully adjust them.

To do this, you need some tools: wrenches, screwdrivers and a feeler gauge or razor blade. To adjust means to adjust the normal valve clearances of walk-behind tractor engines. The size of these gaps is different for each model, so you need to review it in advance in the instructions. First, the engine casing is removed, then the valve cover, here adjustments are made - establishing optimal clearances. This is interesting: how to connect electrical wiring on a Zubr walk-behind tractor.

Attention! To check the size of the gap, place the feeler gauge under the valve; if this is easy, then everything is fine, but if not, then to adjust, you need to loosen the nuts and place the feeler gauge again. Then the valve box cover and casing are installed.

About the design of walk-behind tractors and valves

Motoblocks Cayman, Patriot, Texas, Foreman, Crosser, Viking, Forza, Sadko, Don are a rather complex technical device, consisting of several main working units: motor, gearbox, chassis and controls.

READ Valve Clearance 4 Stroke Trimmer

The very understanding of the design of the walk-behind tractor is of fundamental importance, because it affects the correctness of repair and adjustment work.

Let's look at who the node is in more detail:

- Engine. Based on the configuration, 2-stroke and 4-stroke engines will find application. Nowadays, 4-stroke engines are most widely used, because they have higher performance.

- Nowadays, engines are divided into diesel and gasoline. The first ones are suitable mainly for large-sized units, and the second ones – for small and medium-sized walk-behind tractors.

For more information about the operation of the walk-behind tractor motor, see the following

- Box. The torque that is transmitted from the motor to the wheels is carried out using a gearbox. It includes a gearbox, gearbox, clutch system and differential (for some models).

- Based on the type of gearbox and clutch, not only the cost of the walk-behind tractor is determined, but also the principle of operation of these components.

- Chassis. Most walk-behind tractors have a pair of wheels of various types - pneumatic or steel, equipped with lugs. Now, the chassis contains the frame itself, on which other elements of the walk-behind tractor are located - the engine, gearbox, etc.

- Control system. Our client is left with the control of the walk-behind tractor located far from the operator’s native land, i.e. on the handle and in a certain proximity to it. This includes the clutch lever, gear shift buttons and driving configurations, engine accidents, etc.

How to adjust valves on a walk-behind tractor engine

A vehicle called a walk-behind tractor is a vehicle capable of performing various agricultural work when equipped with various attachments.

It can transport cargo, plow the land and be used as a means of transportation over short distances. To ensure efficient operation of this unit, regular maintenance is required, which includes adjusting the valves. Spare parts for engines of walk-behind tractors and generators R180N-R175N can be found in the online store https://sm-store.com.ua/zapchasti-na-dizelnie-dvigateli/zapchasti-na-dvigatel-r180n-r175n/.

Relationship between engine and valves

A walk-behind tractor is a complex agricultural unit that includes the following components:

Adjusting the valves of the Chinese engine Lifan 168F-2,170F,177F Lifan walk-behind tractor

- engine;

- box;

- running system;

- manager;

- supply system.

The engine is the power mechanism of the walk-behind tractor. There are the following types of motors:

- According to the configuration method:

- 2-stroke;

- 4-stroke.

- By type of fuel used:

- diesel;

- gasoline.

- fuel starting;

- compression of the combustible mixture;

- combustion;

- release.

Manufacturing plants currently produce 4-stroke engines with high technical performance.

Large units are equipped with diesel engines, and small and medium-sized units are equipped with gasoline engines, widespread among farmers, with a power of 4-9 hp.

An internal combustion engine is the main device in which the process of converting the thermal energy of fuel combustion into mechanical energy occurs.

The energy transformation process is carried out in 4 steps:

Fuel material enters the combustion chamber through the inlet distributor. The valve elements close, the piston moves upward, compressing the working mixture. When the spark plugs are turned on, the discharge ignites the flammable material. As the temperature rises, the mixture expands, pushing the piston down. There is a transformation of thermal energy into mechanical energy. When the valves open, gases are released into the exhaust system.

After a certain period of operation, due to heavy loads, the clearances of the intake and exhaust valves may change.

The prerequisite is wear and tear of the parts. A small gap changes the phases of gas distribution. The engine does not work with the declared power. With a large gap, mechanical vibrations appear, which lead to deformations. Due to the short-term opening of the valves, the cylinder is not filled completely. This leads to failures and malfunctions during operation, and reduced performance.

Adjusting the walk-behind tractor valves is an essential maintenance procedure.

According to technical regulations, it is done once a year. If there are deficiencies in the operation of the machine, there is an option to adjust the valves twice a year.

Using the example of the engine of a motor vehicle from the Chinese company LIFAN, we will consider a number of problems, in the event of which it is also desirable to adjust the valves on the Lifan 6.5 hp walk-behind tractor:

- if there is a “kickback” to the starter handle when starting the engine;

- if you hear a clear knock in the cylinder head while the engine is running;

- if the engine begins to run intermittently, stalls and is difficult to start “hot”, starting properly only after cooling;

- when you hear popping noises in the muffler and the walk-behind tractor loses power.

How important is correct valve adjustment?

Like its older brother tractor, the walk-behind tractor consists of several independent units:

- engine;

- chassis system;

- transmissions;

- power systems; steering control.

They are all interconnected, and the performance of the entire mechanism depends on the serviceability of each system. It is generally accepted that the engine is the heart of any self-propelled vehicle. With regard to walk-behind tractors, this statement is also true, although in this niche predominantly gasoline 4-stroke engines are used. Diesel power units can also be installed on high-power walk-behind tractors. Most power units have power in the range of 4-10 horsepower, which is quite enough to work with attachments of the appropriate size.

The task of the engine is simple and clear - converting the energy of fuel combustion into forward mechanical energy. The process of such transformation can be schematically depicted as consisting of four main stages:

- fuel injection;

- its compression;

- ignition and combustion;

- release of exhaust gases.

These stages are usually called cycles of operation of the internal combustion engine, which is where the term 4-stroke engine comes from.

READ How to Install the Ignition on a Motoblock

Fuel is admitted into the combustion chamber through the inlet valve . After the next portion of gasoline is supplied, the valve closes and the piston begins to move along the cylinder, compressing the fuel mixture. Having reached a certain degree of compression, the spark plug comes into operation, igniting the compressed mixture. As it burns, it begins to expand, pushing the piston in the opposite direction. At the end of the cycle, the exhaust valves open, removing the combustion products of the fuel mixture to the outside.

The cyclic movement of the piston up and down due to its connection with the crankshaft leads to the conversion of the combustion energy of the mixture into rotational movement of the drive shaft of the walk-behind tractor.

During long-term operation, as a result of severe loads, valve clearances may change in one direction or another. The reasons may be different, but the main ones are considered to be wear and tear of the piston system elements. Changing the valve clearance (usually downward) negatively affects the gas distribution process. As a result, the motor power decreases and its efficiency decreases. An increase in the gap compared to the standard one leads to the appearance of uncontrolled mechanical vibrations, resulting in deformation of the valve mechanism. When the valves open for a shorter period of time, the combustion chamber is not completely filled, and this also causes a drop in engine power and affects the stability of its operation.

In order to prevent these negative processes and prevent premature wear of the most expensive part of the unit, it is necessary to adjust the valves of the walk-behind tractor’s gasoline engine with some regularity.

According to generally accepted technical regulations, adjustments are carried out approximately once a year; if the walk-behind tractor is used quite intensively, or it is already quite worn out, the frequency of the procedure should be doubled. Specific deadlines for completing regulatory activities may vary for different brands and models. You can view this information in the user manual.

Setting gaps

Adjusting engine valves means setting good clearances. Their norm is indicated in the technical passport of the walk-behind tractor. It doesn’t matter which model has its own permissible properties, which depend on the brand and type of engine of the car.

The permissible valve clearance on a walk-behind tractor for a standard unit has the following value:

- for the inlet valve - 0.10-0.15 mm;

- for output - 0.15-0.20 mm.

The following tools are required for their function:

- spanners;

- probes for 0.10 mm, 0.15 mm and 0.20 mm;

- flat screwdriver.

- The engine is expected to be cold during operation.

- Disconnect the oil bath cup from the air filter and the filter element.

- Take the key and unscrew the 4 bolts around the protective casing.

- Remove the starter, and then the flywheel protective cover of the walk-behind tractor.

- Fix the “dead center” on the end of the flywheel. The mark on the cylinder airflow edge must correspond to the zero mark of the flywheel.

- Carefully remove the valve cover with the paronite gasket, after unscrewing the 3 bolts.

- Check clearances:

- there is an inlet valve near the filter;

- near the muffler - day off.

READ Motoblock Neva Stalls Under Load

To check the interval, insert a feeler gauge between the rocker arm and the valve. If the distance is not simple or less than acceptable, use a spanner wrench and a screwdriver to adjust the elements.

If the valves are adjusted correctly, the engine runs without noise, jerking or failure.

Lifan 6.5

Adjusting the valves on the Lifan 6.5 walk-behind tractor consists of setting the correct gap under the valves. The sequence of actions will be as follows:

- Remove the casing to get to the flywheel.

- Remove the valve cover. Below it there are two valves - inlet and outlet.

- To check the intake valve clearance you will need a 0.15 mm feeler gauge, and for the exhaust valve – 0.3.5 mm. When adjusted correctly, the dipstick should pass under the valve quite freely.

- To adjust, loosen the fastening nuts using a wrench. We insert the dipstick between the valve and the piston so that it does not slip, but is held tightly enough in this position. We tighten the nut.

- We install the valve cover and flywheel housing to the area.

Adjusting the walk-behind tractor carburetor

Instability of the engine speed of the walk-behind tractor indicates that the carburetor needs adjustment. The need to perform this procedure, as a rule, arises before the start of the agricultural season, when the equipment has not been used for a long time, or after it, when the cultivator has been subjected to significant loads over a long period of operation. Time. Before proceeding with adjustments, it is necessary to warm up the engine. The work process itself looks like this:

- The screws that adjust the low and maximum throttle are screwed in completely, and then loosened about one and a half turns.

- The engine is started by a starter or manually and warms up for about ten minutes.

- The lever that controls the operation of the power plant must be set to the minimum position, but the motor must not stop.

- The throttle valve adjusting screw will help you adjust

the minimum idle speed so that

the diesel

engine runs stably, without any extraneous noise or stalling. - Rotating the screws makes it possible to accurately determine the amount of combustible mixture entering the engine.

- Tightening the screw helps enrich the mixture, and unscrewing, on the contrary, increases the volume of air entering the engine;

Use the idle screw to adjust the maximum idle speed. Do the same at minimum speed using the throttle stop screw. The essence of this adjustment is that the damper screw allows you to adjust the angle at which it closes;

The lever responsible for controlling the engine must be moved to the “gas” position. If the operation of the cultivator still cannot be called stable, the full throttle screw is adjusted until the ideal movement is observed. However, the maximum permissible auger rotation speed is 2.5.

The accuracy of carburetor adjustment can also be determined by how the spark plug looks after a short period of time under load. If the working mixture is ideal, then there will be no soot on the spark plug, no traces of fuel, which indicate that the combustible mixture is too lean, or, conversely, too rich. However, it should be noted that carbon deposits or traces of fuel on the spark plug can indicate not only incorrect adjustment, but also more serious problems with a Chinese or domestic walk-behind tractor, including a malfunction of the ignition or cooling system.

READ How to adjust a STIHL ms 180 chainsaw

Adjusting the valve clearance of the walk-behind tractor

Over time, under significant loads, the valve clearance of the walk-behind tractor engine changes. This may be due to worn parts. Insufficient distance leads to the fact that the gas distribution stages change significantly, as a result of which it is not possible to achieve a sufficient degree of compression, the power device operates intermittently and does not achieve the declared power. In particularly serious situations, even deformation of the valves may occur. If the gap is too large, significant mechanical noise is recorded, valve timing also changes significantly, valves open too quickly, which causes the cylinder to not fill properly, power drops and malfunctions occur. Gap adjustment is necessary as soon as the engine does not operate correctly or is noisy. Ideally, the variable speed motor should be cooled.

So, first you need to get to the flywheel. It is on this part that the value of the top dead center is marked. The flywheel is hidden under a cover, so it will have to be removed. Before removing the casing, the oil bath of the air filter is removed. You can make the task easier when removing the casing if you secure all the latches with rubber bands. All bolted connections are unscrewed with a wrench, after which the cover can be removed without any problems.

On the flywheel you can see marks indicating TDC, as well as the values of 5, ten and twenty degrees. The twenty degree mark indicates the injection of a flammable mixture. The flywheel should be brought under the top dead center, focusing on the corresponding division. The valve cover is unscrewed and removed.

During the setup process you need to use the following tools:

- Screwdriver;

- Key box for 10;

- Blade thickness 0.1 mm.

According to the technical data sheet, the valve clearance of the walk-behind tractor engine is from 0.1 to 0.15 millimeters, so it can be very accurately adjusted using a knife. However, you need to pay attention to the fact that some blades have a thickness of 0.8 mm, which is unacceptable. The exact value can be found using a micrometer or from the information on the manufacturer's website. The adjustment is carried out as follows:

- Screwdriver;

- Loosen the nut, insert the blade and begin to tighten;

- You should focus on the blade while carefully tightening the nut;

- The adjustment is carried out until the free play of the valve is eliminated. It should fit snugly.

- We assemble the casing in reverse order and manually put the oil bath in place.

If all manipulations are carried out without errors, the engine will run smoothly and without unnecessary noise.

How to adjust valves on a walk-behind tractor, clearances

Adjusting the valves on a walk-behind tractor is the main work that is carried out during the maintenance of this device. Maintenance is necessary to ensure the safe operation of the walk-behind tractor, to check the reliability and strength of all components and connections. Below we will consider the question of how to adjust the valves on a walk-behind tractor , since they are more necessary elements that ensure the efficient operation of engines. Reviews of walk-behind tractors are presented on the YouTube channel of the AgroMotoCentre company. Reviews of agricultural machinery and their functional properties are also often published there. There is an option to study the video data using the link.

Features of a gasoline engine on walk-behind tractors

The gasoline engine on agricultural machinery is often the most problematic part. It has many features that need to be taken into account during maintenance and setup. Peculiarities:

- There are two types of gasoline engines - two-stroke and four-stroke;

- the majority of the parts are universal, but a number of mechanisms will require spare parts from the manufacturer;

- a full installation is carried out with maintenance, which is performed at least once a year;

- most of the engines are of Asian origin, but are of sufficient quality and easy to maintain;

- For adjustments and other processes you will need to have the necessary tools.

Important! A video about adjusting the valves and the entire maintenance process can be found on the Internet, but only a person with experience and the necessary skills should carry out the procedure, since the mechanism is very sensitive to even small defects.

In this video you will learn how to adjust the valve in a walk-behind tractor:

In the design of walk-behind tractors, internal equipment occupies an important place, since the productivity of any work depends on it. It is recommended to service the equipment annually in special services, but additional installation will also be required after a period of inactivity or after long-term use.

This approach allows you to reduce wear on parts and keep equipment in optimal condition.

Any incorrect fit will result in reduced power, worn parts and permanent problems. You can also find out that the procedure was carried out incorrectly by the lack of stability during operation.

For each gasoline version, the verification process is regulated by a number of points, including operational data described in the instructions, as well as brands and types of parts sets. With different types, the level of required parameters may vary even with the same brand of equipment itself.

Valve adjustment has its own peculiarity

Setting gaps

The steps to adjust the gaps are as follows:

- Before implementing any actions, check the engine: it must be cold;

- later, disconnect the oil bath cup from the air filter and filter element;

- using a wrench, unscrew the four bolts from the protective casing;

- After these steps, it is necessary to remove the starter and flywheel protective casing;

- Next, you should fix the dead center on the flywheel. It must correspond to the zero mark;

- carefully remove the valve cover with the paronite gasket; before doing this, you need to unscrew the three bolts;

- It's important to check the gaps. Remember that the inlet valve is located near the filter, and the outlet valve is located near the muffler. To check the intervals, you need to insert a feeler gauge between the rocker arm and the valve. If the distance deviates from the permissible value, you need to adjust these elements with a spanner wrench or a screwdriver;

- Valve clearances for gasoline engines of walk-behind tractors. Inlet valve 0.10-0.15 mm; Exhaust valve 0.15-0.20 mm.

- after which it is necessary for our client to wipe the connections with a clean rag, fully assemble the structure and turn on the walk-behind tractor to check its working condition.

Adjusting the valves of a heavy walk-behind tractor

When the valves are adjusted correctly, the engine runs silently, without any jerks or failures.

Using the proposed method of action, it is possible to correctly adjust the valves on the walk-behind tractor, while ensuring the effective operation of the device!

Cascade

Adjusting the valves on the Cascade walk-behind tractor:

- Remove the casing from the flywheel.

- Remove the valve cover.

- Turn the flywheel until the intake valve is clamped. Accordingly, the exhaust valve will be depressed.

- Next you need to achieve the correct clearance for each of the valves. According to the instructions, for the intake This is a common rumor that the parameter is 0.15 mm, for the exhaust - 0.20 mm.

- Using a feeler gauge, we check the existing gap between the valve and the piston. If the feeler gauge slips too much, or if it doesn’t pass through them at all, then we will need adjustment. If there is no probe, then use a razor blade, the thickness of which is 0.1 mm.

- To adjust, loosen the fastening nut, and then insert the feeler gauge into the gap under the valve. A good position would be for it to move quite tightly between the piston and the valve, without slipping.

- If our client still succeeds, we tighten the nuts back, and after finishing, we put the valve cover and casing in the area.

The operation scheme is designed in a similar way, so they use one method of action, exactly the same as for adjusting the valves on the popular Centaur walk-behind tractor.

Step-by-step instructions for different models

Lifan 6.5

Adjusting the valves on the Lifan 6.5 walk-behind tractor consists of setting the correct gap under the valves. The sequence of actions will be as follows:

- Remove the casing to get to the flywheel.

- Remove the valve cover. Below it there are two valves - inlet and outlet.

- To check the intake valve clearance, you will need a 0.15 mm feeler gauge, and for the exhaust valve, a 0.2 mm feeler gauge. When adjusted correctly, the dipstick should pass under the valve quite freely.

- To adjust, loosen the fastening nuts using a wrench. We insert the dipstick between the valve and the piston so that it does not slip, but is held tightly enough in this position. We tighten the nut.

- Replace the valve cover and flywheel housing.

Valve of Lifan 6.5 walk-behind tractor

Adjustment of devices Neva mb 2, Zirka 105

The process of adjusting the valves on the Neva MB 2 walk-behind tractor and a similar Zirka 105 walk-behind tractor:

- Let the engine run and then cool a little.

- We remove the casing.

- We remove the valve cover and get to the flywheels that are under it.

- Unscrew the locknut.

- The blade that we insert into the gap should pass very freely between the piston and the valve .

- Screw the entire system back.

How to properly adjust the valve of a Zip walk-behind tractor

What is the procedure for adjusting the valves on the popular zip walk-behind tractor:

- Open the flywheel.

- Unscrew the valve cover clockwise.

- We check the gap with a feeler gauge exactly as described above.

- Use a wrench to turn the nuts and loosen them a little.

- We close the system and conduct testing.

How to set up on an Agro walk-behind tractor

The valves on the Agro walk-behind tractor are adjusted as follows:

- We warm up the engine , and then give it some time to cool down.

- Remove the oil bath of the air filter.

- Next, you need to unscrew the flywheel housing, which is secured with 6 bolts.

- The marks on the flywheel are 0 (top dead center), 5, 10 and 20 (fuel injection). We compare the dead center of the flywheel with a mark located on the cylinder so that they are opposite each other.

- Next, remove the valve cover.

- Below it are two valves. Loosen the locknut, then insert a razor blade under the valve. The blade must pass freely between the piston and the valve.

- Having achieved this, tighten the nut back . Then we return the valve cover and flywheel housing to their place.

It is worth noting that identical adjustment steps are carried out to adjust the valves on the Patriot walk-behind tractor. The Agros walk-behind tractor and its valve adjustment also correspond to the MB 1 walk-behind tractor.

So, if necessary, you can use an identical scheme.

Cascade

Adjusting valves on the Cascade walk-behind tractor:

- Remove the casing from the flywheel.

- Remove the valve cover.

- Turn the flywheel until the intake valve is pressed. Accordingly, the exhaust valve will be depressed.

- Next you need to achieve the correct clearance for each of the valves. According to the instructions, for the inlet this parameter is 0.15 mm, and for the exhaust - 0.20 mm.

- Using a feeler gauge, check the existing gap between the valve and the piston. If the dipstick slips a lot, or it does not pass between them at all, then we will need adjustment. If there is no probe, then you can use a razor blade, the thickness of which is 0.1 mm.

- To adjust, loosen the fastening nut, and then insert the feeler gauge into the space under the valve. Its optimal position would be a fairly tight movement between the piston and the valve, without slipping.

- If everything works out, tighten the nuts back , and then put the valve cover and casing back in place.

You should also approach valve adjustment on a Ural walk-behind tractor based on the instructions described above.

The operating scheme is arranged in an identical way, so you can use one algorithm of actions, exactly the same as for adjusting the valves on the popular Centaur walk-behind tractor.

Relationship between engine and valves

A walk-behind tractor is a complex agricultural unit that includes the following components:

- engine;

- box;

- running system;

- manager;

- supply system.

The engine is the power mechanism of the walk-behind tractor. There are the following types of motors:

- According to the configuration method:

- 2-stroke;

- 4-stroke.

Manufacturing plants currently produce 4-stroke engines with high technical performance.

Large units are equipped with diesel engines, and small and medium-sized units are equipped with gasoline engines, widespread among farmers, with a power of 4-9 hp.

READ How to Make a Clutch on a Motoblock

An internal combustion engine is the main device in which the process of converting the thermal energy of fuel combustion into mechanical energy occurs.

The energy transformation process is carried out in 4 steps:

- fuel starting;

- compression of the combustible mixture;

- combustion;

- release.

Fuel material enters the combustion chamber through the inlet distributor. The valve elements close, the piston moves upward, compressing the working mixture. When the spark plugs are turned on, the discharge ignites the flammable material. As the temperature rises, the mixture expands, pushing the piston down. There is a transformation of thermal energy into mechanical energy. When the valves open, gases are released into the exhaust system.

The prerequisite is wear and tear of the parts. A small gap changes the phases of gas distribution. The engine does not work with the declared power. With a large gap, mechanical vibrations appear, which lead to deformations. Due to the short-term opening of the valves, the cylinder is not filled to 100 percent. This leads to failures and malfunctions during operation, and reduced performance.

Adjusting the walk-behind tractor valves is an essential maintenance procedure.

According to technical regulations, it is carried out once a year. If there are deficiencies in the operation of the machine, the valves can be adjusted twice a year.

Using the example of a motor vehicle from the Chinese company LIFAN, we will consider a number of problems, in which case it is also desirable to adjust the valves on a Lifan 6.5 hp walk-behind tractor:

- if there is a “kickback” to the starter handle when starting the engine;

- if you hear a clear knock in the cylinder head while the engine is running;

- if the engine begins to run intermittently, stalls and is difficult to start “hot”, starting properly only after cooling;

- when you hear popping noises in the muffler and the walk-behind tractor loses power.

Lifan 6.5

Adjusting the valves on the Lifan 6.5 walk-behind tractor consists of setting the correct gap under the valves. The sequence of actions will be as follows:

- Remove the casing to get to the flywheel.

- Remove the valve cover. Below it there are two valves - inlet and outlet.

- To check the intake valve clearance you will need a 0.15 mm feeler gauge, and for the exhaust valve – 0.2.4 mm. When adjusted correctly, the dipstick should pass under the valve quite freely.

- To adjust, loosen the fastening nuts using a wrench. We insert the dipstick between the valve and the piston so that it does not slip, but is held tightly enough in this position. We tighten the nut.

- We put the valve cover and flywheel housing in place.

Carburetor walk-behind tractor

As for the carburetor, it is part of the engine power supply system. It plays the role of a conventional mixer that mixes liquid fuel with air to obtain a fuel mixture, which later enters the engine cylinders. Structurally, it consists of the following:

- float chamber;

- diffuser;

- spray;

- throttle and air dampers;

- mixing chamber;

- jet, etc.

This is a description of a standard carburetor; different models of walk-behind tractor, such as Huter, Profi, Plowman, Champion, Carver, Husqvarna, use different carburetors, respectively, and the adjustment will be different.

Adjustment of devices Neva mb 2, Zirka 105

The process of adjusting the valves on the Neva MB 2 walk-behind tractor and a similar Zirka 105 walk-behind tractor:

- We let the engine run, and then it doesn’t cool down enough.

- We remove the casing.

- We remove the valve cover and get to the flywheels that are under it.

- Unscrew the locknut.

- The blade that we insert into the gap should pass very freely between the piston and the valve.

- Screw the entire system back.

After a certain period of operation, due to heavy loads, the clearance of the intake and exhaust valves may change.

The prerequisite is wear of parts. A small gap changes the valve timing. The engine does not operate at the stated power. Mechanical vibrations occur when there are large gaps, which lead to deformation. Due to the short opening of the valves, the cylinder is not filled completely. This leads to glitches and glitches, reducing productivity.

Adjusting the walk-behind tractor valves is essential for maintenance.

The walk-behind tractor can do a very wide range of work, but for this purpose you need some effort from those who are not familiar with this unit. We are talking not only about replacing failed parts and gadgets, but also about timely adjustment of some device components.

Specifically, how correctly and correctly the valves are adjusted determines the correct operation of the walk-behind tractor engine.

And it doesn’t even matter whether we are talking about walk-behind tractor , or whether we are considering a Vityaz 8hp walk-behind tractor and its correct adjustment, whether we are talking about adjusting the valves on a diesel walk-behind tractor, or whether valve adjustment is required on a Forte petrol walk-behind tractor...

It is better to do this after each season, but there are cases when such adjustment is required 2 or more than 2 times during a given period of work. The main indications for this are atypical noise in the carburetor area, tapping - that is, uncharacteristic sounds during operation of the walk-behind tractor.

If this is found, if the valves do not maintain the dz adjustment in the walk-behind tractor, then you need to immediately inspect and decide on actions, especially since this procedure is quite simple and can be done on your own.

A cart for a walk-behind tractor is a useful device that you can assemble with your own hands.

Sources:

https://kultivator.by/kak-vybrat/147-sovety-sadovodu-i-ogordniku/99-kak-otregulirovat-klapana-na-motobloke.html https://yasenevo-flowers.ru/motobloki-i-kultivatory /regulirovka-klapanov-na-dizelnom-motobloke.html

Troubleshooting startup problems

Often, repair of a walk-behind tractor engine is needed because the engine will not start. If such a problem occurs after winter storage, you can suspect:

- clogging of fuel or oil with water;

- oxidation of electrical contacts;

- insulation damage;

- the appearance of solid debris in the carburetor.

To prevent these problems, it is necessary to carefully inspect any connections before each start-up. If you notice the slightest tightening of the cable, especially if it is twisted, you cannot start the engine.

Even before the very first start, it is necessary to assess whether there is enough oil in the crankcase. If there is a deficiency, rapid destruction of the piston group is likely. In less than a second, the cylinders will be covered with burrs.

In this case, very serious repairs will be required, and sometimes even replacement of damaged parts. Sometimes instability in the functioning of the device is provoked by leaving the lubricant for the winter. If this is the case, in the first few moments after start-up, clouds of white smoke will pour out of the exhaust pipe. Immediately after this, the power plant will stall.

Diesel walk-behind tractors may also not start due to lack of oil. Only a few models are equipped with systems that protect against a drop in lubricant level. Most people will have to monitor the health of the walk-behind tractor themselves. It is also worth considering that failures occur due to the systematic use of unsuitable fuel. If the usual recommendations do not give much effect, you need to remove the candle and look for oil stains.

Oil, especially carbon deposits, should be carefully cleaned. Then the candle must be dried. The cylinder also needs to be dried. A very simple technique is used for “drying”: repeated sharp pulling of the starter cable. The question often arises: what to do if the walk-behind tractor does not start and smokes black smoke.

Typically, this manifestation indicates that the engine is overfilled with gasoline. You should also be wary of damage to the piston group. If both assumptions turn out to be incorrect, you need to contact the service center. Further attempts to troubleshoot problems on your own may lead to worsening damage.

You can deal with this problem if:

- pour out the old fuel;

- thoroughly clean the gasoline or diesel tank;

- clean the air filter;

- clean the fuel hose and nozzles with a jet of compressed air;

- add fresh fuel;

- After opening the fuel line, blow out the channel located in the gas tank cap.

In some cases, the failure is due to gasoline getting into the oil sump. It is necessary to check whether this problem exists after any adjustment or adjustment of the carburetor.

Adjusting the valve clearance of a walk-behind tractor

If the lubricant becomes clogged with fuel constantly, you need to look at the carburetor needle. It is likely that this particular node has become a weak point. It is worth noting that sometimes the walk-behind tractor engine shoots into the muffler, and perhaps even with a flame.

READ Adjusting the Carburetor of Riobi Chainsaw 40 40

The most likely reason is incomplete combustion of fuel. It is provoked by:

- omissions in the ignition system;

- excessively saturated fuel mixture;

- unjustified heating of this mixture.

When the walk-behind tractor does not want to operate, interruptions in the ignition system must be looked for thoughtfully and consistently. Magneto, caps, spark plugs and high-voltage wires are examined.

Finding even minor contaminants is of paramount importance. If everything is clean, you need to inspect the ignition wire contacts. Next, check the stability of the electrodes and measure the distances between them using a special probe.