Every modern chainsaw, regardless of its purpose and design features, is equipped with a fuel system. It is based on a carburetor, the main function of which is to mix the fuel mixture with pre-purified air. Any malfunction of the carburetor leads to loss of power and other problems with gas-powered garden tools. You can solve them yourself - to do this you need to study the design of the fuel unit, the features of its adjustment and methods of self-repair.

Related Posts

The chainsaw does not start: causes and solutions

Today, it is probably difficult to find an owner who does not have such a universal, practical, and multifunctional tool as a chainsaw.

This device is deeply rooted in everyday life, and this is not surprising because the chainsaw has become an indispensable assistant for us in the field of cutting wood of various types, preparing firewood for the winter, cutting down trees, and it is also used in the construction industry, etc.

Naturally, one can talk endlessly about its positive aspects and it copes with its task simply superbly . But, like any technology, no matter how unique and highly practical it is, it breaks down over time and that’s normal. Why does the Ural chainsaw shoot into the carburetor? Cause of malfunction, consequences. Why does a chainsaw shoot into the muffler? The most important thing at this moment is to correctly determine the cause of the malfunction and quickly eliminate it.

Naturally, you can turn to various kinds of services that, for a fee, will put your equipment in order. But you will have to pay a significant cost. What for? After all, you can try to determine the extent and cause of the breakdown yourself and fix it.

Since there are such minor breakdowns that can be repaired within five minutes. We will talk about them and ways to eliminate them in this article.

I feel the chainsaw is overflowing when it first starts

Although I’m not Vladlen, I suspect that the saws are mostly the same (in design), so I’ll try to suggest. It is not always necessary to pump it up before starting, but if there is gasoline in the carburetor and saw, well, you can pump it up once. Pull out the throttle handle and pull it a few times. It should not start, but sneeze somehow. Close the throttle and pull it a few times, it should start. For example, I pull my saw a maximum of 3-4 times.

Best regards, Sergei

One reason is a worn carburetor needle (or a worn or bent rocker arm) - causing the needle to leak more fuel mixture. The mixture is fed into the combustion chamber over-enriched and immediately floods the spark plug. During operation, this is not so noticeable, especially if the fuel filter is dirty - it leans the mixture. As a conclusion, replacing the filter with a new one will worsen the operation of the saw in the event of such a breakdown. The second possible reason is that the carburetor is out of adjustment, but this is too general an explanation; this can explain any breakdown.

If the problem begins to interfere greatly, then you need to contact the service. For many carburetor models, each spare part can be purchased separately; perhaps it will all come down to replacing the needle, and not the entire carburetor.

2Georgi61: But there is no need to pull slowly! You have to pull vigorously! (this is what they write in passports).

Best regards, Sergei

Someone sent me a link to how to start a saw. And that’s exactly what was recommended there.

I just bought a Shtil 250 and it starts exactly like that, i.e. At first it didn’t work, but then while it was still hot it was fine.

Tell me, is this normal for a new device or for a patient’s service?

2Georgi61: You have a Partner, I have Poulan (which is actually the same thing). And don’t blame me for this mechanism (I’m not saying this to you, but to those who believe that in order to cut down two trees once a year you need to have something cooler on your farm). Now there is no saw in front of my eyes, it’s difficult to write. But from memory it is. The throttle is fully released. The saw is warmed up and running at idle. There on the side there seem to be three screws in the recesses. One of them is the quantity screw. But I won’t lie, I’ll only be able to watch it on the weekend. Maybe someone else can tell me? Rotate it counterclockwise. In one direction the revolutions increase, at some point the chain begins to turn, in the other - the revolutions drop. So catch this edge. Then, after vigorous work, some adjustment may be required. Most likely, the speed will have to be reduced slightly. You won't be able to ruin anything with this adjustment.

2ben: Dear ben. Don't be unfounded. What don’t you like about all these arguments? They are only about user adjustments. By the way, I hate the instructions according to which you have to run to the service center for every sneeze. They were written this way so that, firstly: they were, and this is required by law; secondly: increase the profits of services. How good it is, you sell it once (you can even do it cheaper), and then you earn money for many years! And a cry: don’t twist it, you’ll break it, pour this - it’s more expensive, but cheaper, no, no. I don’t know about Shtil, I can only assume that there are such adjustments there too, you just need to remove some kind of cover.

2AA: 2ben I agree, the instructions that do not have a section about malfunctions and how to fix them yourself are complete nonsense, because there are problems that a person, even with not very well-grown hands, can fix himself. But! There have been cases when, for example, a fairly expensive milling cutter was brought in for repairs with its insides completely destroyed, and the initial reason was that the overload sensor had failed, and the hands turned out to be pockmarked. We disassembled it, threw the wiring straight through and HURRAY! It's working! We overloaded it again and here we are: stator, rotor, brushes. The price of the sensor is about 200 rubles, the cost of a complete repair is equal to the cost of the router. How shoud I understand this? Did the service blatantly impose its services? In my opinion, if you don’t know, don’t interfere!

Carburetor adjustment is quite accessible on models with a hole and a screw(s). In addition, there is a so-called fool proof, you can’t screw up more than the limiters allow. And in case of a “severe” case of misalignment, a specialist can remove this protection and revive the unit.

Plant structure

The first and practically main element of a chainsaw is the engine, namely a two-stroke carburetor (see carburetor adjustment). Its direct power can be varied, it all depends on the model of the device and its intended purpose. Chainsaw set The second no less important part of the tool is the set (saw) which consists of a chain (cutting), bar, sprocket, wheel (chain) . It is worth adding to this that completely different manufacturers provide their own specific range of this headset.

It is important that it always needs to be directly selected from the specific characteristics of the engine. Since the larger the pitch of this type of headset, the deeper the chainsaw’s cut will be, one might even say that the more powerful and productive it will be. Often chainsaw owners think about why the chainsaw shoots into the carburetor, or why gasoline does not flow into the chainsaw carburetor? But do not forget that for the device to fully operate, the engine should also not be inferior to it in terms of power.

Its lubrication is carried out using special oil directly from the second tank, which is located on the hand unit. It is worth noting that the mass of this type of tank has such features that the oil and fuel intended for the engine run out at the same time.

We have figured out the general outline of the device, and most likely its basis, and now it’s time to start understanding why the chainsaw stopped working, what the reasons could be for this and how to eliminate them.

Description of the model range

Chainsaw Sturm

The line of household chainsaws is represented by modifications with power starting from 1.6 hp. up to 3.3 hp, with different weight parameters and saw accessories.

The Sturm brand recently celebrated its tenth anniversary: in 2003, individual products from its production entered our market for the first time. In such a short period of time, a lot has changed: the product range has been diversified, a wide distribution network has been created, numerous service centers have been opened, the number of which is increasing exponentially.

Despite the fact that Sturm equipment is a product of joint Russian-Chinese production, it is trusted by hundreds of thousands of people who purchase it for a variety of needs. Officially, Russia is considered the country of origin of these goods, but the full assembly stage takes place at one of 40 possible factories in China, where equipment for other world-famous brands is manufactured.

Quality, durability, a wide range of more than 2 thousand items, variability in the model range, long-term warranty obligations from the manufacturer to users - all this is just a short list of reasons why the Sturm brand is a leader in its market segment.

Each Sturm chainsaw differs from most of its analogues on the market in its high power and increased service life. The country of origin of this equipment is China, however, all saws of this brand are distinguished by proper build quality and high resistance to loads.

Currently reading: Trimmers and braids: buy a trimmer and braid inexpensively, prices in the Eldorado online store in Moscow

Causes and solutions

Undoubtedly, after reading this title, you continue to read this paragraph and this is not surprising.

Even professional chainsaws from world-famous manufacturers break down - no one is immune from this. The question is how often breakdowns occur and how serious they are. It’s one thing when you need to sharpen the chain or replace the drive sprocket, and another thing when the chainsaw doesn’t start or shoots into the carburetor. In fact, most of the problems can be fixed with your own hands, for example, when the chainsaw does not lubricate the chain or stalls.

No. 1. Chainsaw won't start

If difficulties arise with starting a chainsaw, many immediately blame the carburetor. In fact, there are several options and the cause of the malfunction can be any:

- Air and/or fuel filters are clogged. The problem can be solved by cleaning the filters.

- Lack of fuel in the tank. Yes, there is such a reason - some owners forget about such an insignificant detail as refueling a chainsaw and think that a couple of liters of gasoline will last for six months. In addition, fuel in the tank should not be stored for more than 14 days, because gasoline evaporates and the octane number is lost.

- Check the pipe from the fuel tank to the carburetor - it could be clogged or broken, so gasoline does not flow into the tank.

- There is no spark at the spark plug. Why there is no spark - there can be many reasons: there is no contact, the spark plug needs to be changed or it is flooded. Why the spark plug on a chainsaw fills is another question. But if this happens, you need to dry it and reinstall it, and then check for a spark. If there is heavy carbon deposits on the spark plug, it is recommended to replace it.

- Check the muffler for carbon deposits. If there is carbon deposits, thoroughly clean the muffler, but it is still recommended to take the chainsaw to a service center to have the cylinder and piston checked, because carbon deposits are a sure sign of improper operation of the elements of the cylinder-piston group.

- The carburetor is clogged. How to properly adjust a chainsaw so that the carburetor works well is discussed in a separate article.

If none of the above methods helped, then the reason is more serious - a breakdown of one of the connecting rod-piston group units. In this case, it is recommended to take the chainsaw to a service center.

Symptoms of malfunctions and breakdowns that require carburetor adjustment.

The following signs and malfunctions indicate the need to adjust the carburetor:

- the engine starts with effort and stalls almost instantly;

- gasoline consumption is excessively high, the exhaust is too thick, the combustible mixture in the cylinder does not burn completely;

- the factory settings of the chainsaw carburetor are lost (due to vibrations or unsuccessful attempts at adjustment);

- malfunctions of the air purification system, which led to the entry of debris into the fuel mixture distributing mechanism;

- significant wear of the piston group - carburetor adjustment in this case acts as a temporary measure.

It is clear that if dirt gets into the fuel system, one adjustment alone will not solve the problem - it needs to be flushed. If the piston is worn out, a major overhaul is required. However, in all these cases, the carburetor is also adjusted.

Before disassembling the chainsaw, you need to correctly determine the type of breakdown. Any malfunction in the operation of the saw can be classified into one of two types. The first is engine failure. Problems arise in the ignition systems, fuel supply, air supply, exhaust air mixture removal, and cylinder-piston group.

The second type is malfunctions in other systems of the unit. These are breakdowns of the emergency brake, clutch, guide bar, lubrication system and other parts.

Repair tool kit:

- keys of different sizes;

- key for removing spark plugs;

- screwdrivers of different sizes and shapes;

- saw diagram.

The reason for the inability to start the chainsaw or to reach sufficient power for operation may be the reduced pressure of the mixture in the cylinder (working pressure is not lower than 8 atmospheres). This is due to the wear and tear of the CPG elements - bearings, rings, piston or cylinder.

A preliminary inspection is carried out through the exhaust hole; to gain access to it, you will have to dismantle the muffler. For a more complete picture, it is necessary to use a compression meter. It is inserted into the hole for the spark plug, after which you need to turn the crankshaft using a starter or drill.

Only disassembling the engine will help you fully understand the problems of the CPG. After removing the crankcase from the cylinder, inspect the piston. If it is covered with chips and deep scratches, it should be replaced. When the surface of the cylinder is worked out, it is bored. Wear of the piston ring is determined by carbon deposits and loose contact with the cylinder.

No. 2. The engine stalls

The engine starts, but the chainsaw stalls at idle or under load. In this case, most often you should perform the same actions as described above.

How to adjust a chainsaw depends on exactly when the problems start:

Stalls immediately after starting:

- The fuel mixture is not prepared correctly, there is too much oil in it, so the octane number of gasoline is less than it should be, so the chainsaw only runs on choke or stalls immediately.

- Carbon deposits on the spark plug or improper gap between the spark plug and the wire.

It stalls and does not work at idle:

- The muffler is clogged. It is necessary to remove carbon deposits.

- The carburetor settings are off. The idle speed on the chainsaw needs to be adjusted. This is done using adjusting bolts marked L and H. For how to adjust idle speed, see the article about adjusting the carburetor.

Stalls at maximum speed and only runs on choke

- The air or fuel filter is clogged. The seals need to be cleaned and checked.

- The breather is clogged and because of this, fuel does not flow and pumping gasoline on the chainsaw does not work. Take the needle and carefully clean the breather.

- Fuel pump malfunction. Remove the pump and check to see if gasoline is leaking from it. If it oozes, replace the sealing gasket or the pump itself.

The chainsaw does not cut under load and stalls

- The air filter is clogged. It is necessary to take out the filter, clean it well or even rinse it, dry it and install it back.

- Wrong proportion of oil/gasoline mixture. Drain the fuel and remix the oil and gasoline in the correct proportions.

Troubleshooting Tips

If the chainsaw spark plug has been flooded and you do not want to wait for the fuel to drain, there is a fairly effective and quick cleaning method.

- If the repair is carried out in the field, then the saw is installed on a flat surface (everything is easier in the workshop - a table will help), after which the explosive wire from the spark plug is pulled out and the spark plug is taken out using a key, its spark plug electrodes are wiped dry. In this case, the circuit breaking system must be turned on.

- The air filter cover is unscrewed and cleaned of dirt.

- After this, the control lever is set to the minimum throttle position, and the starting cord is pulled up to 10 times, but not less than 5. Thus, the combustion chamber is cleared of excess fuel.

- After replacing the air filter, installing the spark plug and connecting the wire, you should pull the starter cord a few more times. At the same time, the throttle valve must remain open.

If these actions are performed correctly, the saw will “come to life” again.

Most owners of chainsaws have filled the spark plugs more than once and at the same time have themselves returned the functionality of the tool more than once. Don’t be afraid of this problem: straight-growing hands and the presence of a user manual will help you continue to use the tool without going to a specialized center.

No. 3. The engine "shoots"

If during operation there are extraneous sounds similar to gunshots, then there is a problem with the muffler or carburetor. How to make a chainsaw run quietly? It depends on which node is faulty.

Shoots the carburetor:

- Ignition is too late - the air-fuel mixture does not have time to burn out in the cylinder, so the sound is similar to a small explosion.

- Lean air-fuel mixture. Too little gasoline enters the mixture - the chainsaw, or rather the jets, needs to be adjusted to increase the fuel supply. Why the chainsaw revs on its own is for the same reason.

Shoots at the silencer:

- Enriched air-fuel mixture. Why does a chainsaw “shoot”? There is too much gasoline and not enough air in the mixture, so the mixture does not completely burn out in the chamber and partially burns out in the muffler. Carbon deposits on the exhaust are a clear sign of this. The air filter needs to be cleaned or the carburetor adjusted.

No. 4. Chainsaw overheating

Why does the chainsaw get hot? The engine or tire may overheat - in any case, the fault is due to a small amount of lubricant.

- Engine overheating. The proportion of the fuel mixture is incorrect or pure gasoline is poured. Drain the fuel and make a mixture using the correct proportions of oil and gasoline, as specified by the manufacturer.

- Tire overheating. The oil pump needs to be cleaned or adjusted because... No oil is supplied to the tire.

Solving muffler problems

If the engine stalls when the operating speed increases, the culprit may be a clogged muffler spark arrester.

Cleaning steps:

- remove the muffler and plug the exhaust hole;

- if there is a constructive possibility, disassemble it;

- wash off soot using detergents;

- dry;

- assemble and mount back.

Dry cleaning is not recommended due to harmful impurities in carbon deposits. To prevent contamination, use high-quality motor oils and carefully monitor the proportions in the fuel mixture.

No. 6. The chainsaw cuts to the side

When cutting, you may notice that the result is an uneven cut. Why does a chainsaw cut crookedly? There are several reasons:

- Incorrect chain sharpening. The teeth are sharpened at the wrong angle or only in one direction. Proper sharpening is required.

- Incorrectly selected chain. At very high speeds, a difference of even 0.2-0.3 mm between the width of the groove or the width of the seat will be visible, which is why the chainsaw cuts to the side. An appropriate circuit must be installed.

- Uneven tire wear. Over time, the tire wears out on one side and then the chain pulls to the side. Rotate the tire regularly to ensure even wear on both sides. If the wear is excessive, replace the tire.

No. 7. Chain lubrication problems

For normal operation, the chain must be constantly lubricated to reduce friction between the bar and the links, and also to prevent premature wear of the links.

- If the chain on the chainsaw is not lubricated, then there is a problem with the oil pump - oil is not supplied due to a clogged channel. Lack of lubrication is the reason why the chain stretches or why the chain breaks. Clean the channels; tiny particles of chips constantly get there and clog them. The oil hose may also break. If you need to adjust the chainsaw oil pump or repair it, it is better to contact a service center.

- Oil splashes from the chain. Incorrectly selected lubricant - it is too liquid, so it does not so much lubricate the links as it splashes onto the wood. Replace the lubricant with a thicker one.

No. 8. The chain falls off

Why does the chain fall off the tire? There may be several reasons and they are all different:

- Worn drive or driven sprocket. Due to the fact that the sprocket is worn out, the grip on the chain decreases, which is why the chain flies off the chainsaw. The sprocket needs to be replaced.

- The chain has stretched. Why the chain on a chainsaw stretches is due to insufficient lubrication. The metal heats up and stretches, even by a fraction of a millimeter, but if you take into account the number of links, then even 3-4 mm is enough for the chain to fly off the bar. The chain needs to be replaced.

No. 9. The chain does not rotate

Why doesn't the chainsaw chain rotate when the engine is running even at full speed?

- Leading sprocket. Either it is jammed, or the crown is worn out so much that it does not engage and the chain does not spin on the chainsaw. In any case, it is necessary to disassemble the sprocket to find out the exact reason why the chain does not spin. If the crown is worn out, it is necessary to replace the sprocket (or the crown itself, if the sprocket has a prefabricated structure).

- The chain brake is stuck. As a result, the sprocket is blocked by the brake mechanism, while the motor runs. It is necessary to turn off the engine and release the brake. If this happens under load, the brake mechanism will have to be changed, as well as the sprocket, because Due to the high temperature, many elements can melt and overheat.

No. 10. Chain brake does not work

All chainsaws are equipped with a main and inertial (emergency) brake. The latter turns on only when a backfire occurs. The main brake is designed to stop the chain while the engine is running. Why does the chain on the chainsaw jam and it doesn’t stop? Option two:

- The brake band is badly worn and does not provide sufficient stopping effect. The brake band needs to be replaced.

- Contamination of the tape. When working, debris may become clogged in the under-cover space: shavings, sawdust, dirt, etc. Debris is blocking the brake mechanism, so if the brake does not work, you need to clean the brake mechanism.

A chainsaw carburetor is an element that is responsible for mixing the air-fuel mixture. Not only the stability of the engine, but also the speed of operation of the entire chainsaw depends on the condition and serviceability of this important unit. In this regard, every owner of a garden tool should study the design of the carburetor, as well as become familiar with the rules for its maintenance and repair.

Features of the use of Sturm chainsaws, operating instructions

The Sturm chainsaw occupies a leading position in the domestic market among mechanized tools designed to perform technological work in wood processing.

Thanks to Oregon tires and high-quality chains, the GC series devices, developed by the German company Sturm, have proven themselves to be the best and are in great demand among consumers.

Reliability, durability, efficiency and wear resistance are the main differences between the Sturm gasoline-powered saw and its competitors.

Household and semi-professional products are suitable for sawing shrubs, small-stemmed trees and preparing firewood for the winter in summer cottages and garden plots.

Professional models are used in forestry and construction for felling and bucking large trees.

23.04.2018

Chainsaw “Sturm”: description, photos and reviews

A chainsaw is an indispensable tool in urban construction, on a personal plot and in forestry. It perfectly allows you to get rid of unhealthy trees and interfering stumps, cut a log, saw off timber.

The Sturm chainsaw combines quality, convenience and efficiency, which is why it is considered the best equipment for similar work. It enjoys well-deserved popularity among home craftsmen.

The Sturm chainsaw () is one of the undisputed favorites on the construction tools market.

Thanks to the use of high-quality Oregon chains and tires, the equipment will serve the owner well for many seasons.

A chainsaw is a technically complex tool that needs to be serviced from time to time. Cleaning, replacing filters and, of course, adjusting the carburetor of the chainsaw will help it last its entire lifespan. In this article we will look at the issue of carburetor tuning. How and why it is carried out.

You need to have a couple of tires and at least four chains in reserve. To ensure a uniform wear process, the chain should be turned 180° after three hours of operation, and after the same period of time the chain should be replaced with another one.

Timely cleaning of the tool ensures that various holes are not clogged, which can lead to difficulty or even interruption of the supply of the fuel mixture, which will affect the operating condition of the chainsaw.

If you are not confident in your abilities and are afraid of ruining the unit, then it is better to turn to professionals. Due to their experience, they will always be able to correctly diagnose the problem and efficiently correct problems in your chainsaw.

Like any special equipment, Sturm chainsaws require responsible handling and maintenance. Compliance with safety requirements is a necessary condition for the effective operation of equipment. It is necessary to master the techniques and skills of work, the rules of personal protection, take into account the inclination of the saw, the angle of felling trees.

Chainsaw Sturm

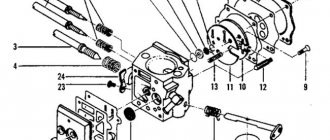

Chainsaw carburetor design

Most modern chainsaws are equipped with almost identical carburetors. They are practically no different from each other, and work on a similar principle. The only difference between cameras from different manufacturers is the material from which they are made. In expensive American, Swedish and German-made chainsaws, the chambers are made of reliable alloys, onto which protective coatings are applied. Cheap Chinese and Korean chainsaws are equipped with components made from cheap materials.

Each carburetor consists of the following elements:

- aluminum body with unibody construction. Inside the housing there is an inlet fitting, a main screw, a pulse channel, a bolt for adjusting the engine when idling;

- throttle valve - it is responsible for regulating the amount of air required to enrich the fuel mixture;

- diffuser – located next to the chamber inlet;

- sprayer - designed to supply the fuel mixture directly into the carburetor chamber;

- float chamber - it contains a float that is activated in case of insufficient fuel;

- jets - are valves that are responsible for regulating the amount of fuel.

This chainsaw carburetor circuit is as simple and effective as possible. In some models of garden tools, it can be supplemented with additional pipes, seals or filters.

The operating principle of a chainsaw carburetor is quite simple. When the engine starts, the air damper located at the bottom of the housing opens. At the same time, a vacuum is formed in the float and air chambers caused by the movement of the piston. As a result of this, the standard diffuser is activated, which begins to suck in air. The amount of air taken in depends on the degree of opening of the damper. When the piston is activated, fuel begins to flow into the chamber through the inlet fitting. Its quantity and flow rate depend on the position of the jets.

Subsequently, the fuel in the air chamber begins to mix with air. After this, the finished air-fuel mixture passes through the intake valves, from where it is directed into the combustion chamber of the saw engine.

Description of the model range

Sturm chainsaws are equipped with two-stroke engines in the power range from 1.6 hp. up to 5 hp

Chainsaw Sturm

Features of Sturm chainsaws:

- Reliability, durability, stable operation throughout the entire service life declared by the manufacturer.

- Chainsaws are produced on high-tech equipment, high-quality components and modern materials are used.

- The models are equipped with powerful engines, an anti-vibration system, and reliable carburetor systems.

- Thanks to automatic chain lubrication, rational lubrication of the rubbing parts of the saw set and economical oil consumption are ensured.

- Optimal balancing of the structure allows the operator to work with the saw for a long time without fatigue.

- For easy starting, especially in the cold season, the fuel mixture is pumped into the carburetor using a primer.

- The presence of an instant chain brake—the response speed is 0.12 s—reliably protects the operator from possible kickback.

- The affordable price is rationally combined with decent technical characteristics of Sturm chainsaws.

Household appliances of the Sturm brand can rightfully claim the status of the most reliable and durable products for a wide variety of purposes. All of the above applies to the chainsaw range, which is represented on the world and European markets by a large number of amateur, farmer and professional class models.

The Sturm chain saw, popular in the private sector, in various variants and versions, has proven itself to be the best when used in regions with difficult weather and climatic conditions.

Adjusting a chainsaw carburetor - what does a beginner need to know?

Initially, all adjusting bolts are in the factory positions - this guarantees the absorption of the optimal amount of fuel and air. However, due to prolonged use of the saw in difficult conditions, the factory settings of its carburetor may be disrupted. Even a slight shift of one of the bolts by 1/5 of a turn will lead to serious disruption to the operation of the saw motor. Therefore, the operator must constantly ensure that the adjustment bolts are in the optimal factory-set positions.

If for some reason the operation of the node was disrupted, it will need to be configured again. For this purpose, the unit has 3 adjusting bolts. The first of them is designated by the letter H - it is needed to tune the chainsaw engine when operating at maximum speed. The second screw, marked L, is used to adjust the motor while it is running at low speeds. The third screw may be marked T, S or LA. Its task is to adjust the internal combustion engine when operating in idle speed mode.

Setting up a chainsaw carburetor must be carried out with a fully functional engine. Immediately before adjustment, you will need to inspect the air filter and, if necessary, clean it or replace it.

Signs of proper instrument tuning

It should be understood that the dimensions of all holes are very small. Even the smallest contamination can block the flow of air or fuel, which is why filter elements are installed at the inlet ports. Unfortunately, they do not always cope with the task. The following signs indicate a malfunction of the chainsaw carburetor:

- High gasoline consumption and thick smoke from the exhaust;

- The engine “does not pull”;

- Floating speed;

- The engine starts, but stalls immediately or after a few seconds;

- The engine does not start at all.

- Chainsaw shoots at carburetor

All these malfunctions are a sign that the carburetor on the chainsaw is not adjusted correctly or that it is dirty. This implies the need for adjustment, cleaning or repair. Let's look at how to do this below.

Repairing a chainsaw carburetor with your own hands allows you to eliminate all problems that arise during the operation of the device.

If the internal combustion engine spins intermittently and accelerates for a long time, then you need to tighten L counterclockwise by 1/8 of a turn. Then adjust bolt S again. These adjustments should be made until the motor functions correctly and accelerates quickly.

Then check the setting of screw H. Accelerate the motor to maximum. Watch the exhaust and how the engine spins. If blue smoke comes out of it and the saw makes a loud noise, then this means that the carburetor is creating a mixture that is too rich. The highest engine speed is less than normal. Soot forms in it. In case of such a problem, you need to turn H a little clockwise. Next, control the operation of the motor and, if necessary, repeat the setting.

If the saw squeals, this means that the engine is overheating, the exhaust is crackling, and there are misfires. This means that the mixture is unsaturated, and the highest engine speeds are higher than normal. This leads to overheating of the engine, combustion of the piston, cylinder and burnout of the spark plug. If this problem occurs, adjustment should be made by turning H 1/4 turn counterclockwise.

If fuel does not flow into the combustion chamber, this problem is caused by a clogged fuel filter, nozzles or device channels. To eliminate the malfunction, you will need to completely disassemble the filter and blow through these channels using a compressor. Carburetor fluid is used to clean the channels.

It happens that there is an overflow of fuel in the carburetor. This happens if the membrane has failed, dried out and become rough, and began to put pressure on the rocker arm attached to the needle. Then the needle is adjusted. To change the membrane, you need to remove the carburetor.

The motor runs intermittently and does not pick up speed well. This happens when the filter is clogged. It is necessary to remove the cover of the device and clean it using detergents.

A chainsaw is needed in construction, gardening, and landscaping - its presence greatly simplifies the performance of a number of wood processing tasks. The main component of this tool is the engine, the operation of which largely depends on the condition and settings of the carburetor. This is where the fuel mixture is prepared.

This means that if the saw does not start, stalls, or does not provide the required power, it is likely that the reason for this is improper operation of the carburetor. Fortunately, in many cases you can deal with this on your own.

Only for this you need to know and understand the structure and operating principle of this unit and, of course, the chainsaw itself.

Chainsaw carburetor Stihl MS 181 C BE

Chainsaw carburetors may differ in design. However, their basic elements and operating principle remain approximately the same.

This is a wind tunnel, across which there is an air damper - with its help the intensity of the air supply is regulated.

This part is where the base tube narrows - here the air flow speed increases, i.e. air is always supplied to the carburetor under some pressure.

In this area, the fuel comes into contact with the air flow. Fuel enters the atomizer from the float chamber through a nozzle (dispenser).

This is a container that allows you to keep the fuel mixture in a stable state.

Chainsaw carburetor design diagram

A chainsaw carburetor works according to the following principle:

- when the engine starts, the main damper opens and a stream of air is supplied into the air channel at a certain speed;

- the speed of the air flow, as well as the level of the float in the chamber, are regulated by the position of the damper, namely due to the difference in pressure in the float chamber and the air channel;

- fuel from the float chamber is sucked into the nozzle, and from there into the diffuser;

- passing through the diffuser, the air captures the fuel entering there;

- the resulting mixture is fed into the cylinder cavities through the intake channels.

The principle of operation of a chainsaw carburetor

The pressure in the float chamber is approximately equal to atmospheric pressure, but a vacuum occurs in the air channels of the carburetor when the chainsaw engine starts. Opening the damper increases the air supply intensity. As a result, more fuel enters the carburetor, and the number of engine revolutions increases.

Initial running-in of the chainsaw: working with thin material

Most modern chainsaws are sold adjusted. However, it doesn’t hurt to check the quality of the factory settings - in the end, it’s you who will have to work with the tool.

When starting up for the first time, the chainsaw should operate in a gentle mode. Therefore, for several hours after start, it is recommended not to overload the engine and cut only small branches and trunks up to 10 cm thick.

Simple rules will help you insure against malfunctions of the chainsaw carburetor:

- Always mix gasoline and oil according to the manufacturer's instructions.

Proportions of the fuel mixture for a chainsaw engine - Do not prepare the fuel mixture in advance - the properties of gasoline and oil in a mixed state are lost over time. The exception is fuel for intensively used tools, however, even here the norm should not exceed approximately a week.

- Use oil designed for your chainsaw engine. A fuel mixture with a non-standard composition will seriously and permanently disable it.

- When preparing the fuel mixture, take into account the influence of climatic conditions on its components.

The chainsaw must start correctly, ensure a stable rotation speed of the sprocket and a smooth increase/decrease in power. There should be no extraneous knocks, pops or noises when the engine is running.

Currently reading: Causes of overheating lawnmower engine

Professional hand chainsaw at work

The main thing during the initial running-in of the tool is to ensure that the fuel consumption corresponds to the power used, i.e. in practice, the saw should not go out, “sneeze”, smoke or run jerkily.

The correct setting is indicated by the following:

- At idle, the tool does not stall and the chain does not move along the bar.

- The device operates without smoke.

- The engine has good throttle response.

Throttle response is the engine's ability to quickly pick up speed when the throttle lever is pressed.

Adjusting the chainsaw carburetor affects the proper operation of the device. Incorrect adjustment or lack thereof can lead to malfunctions of the unit and damage to it.

Violation of the requirements of the operating rules leads to premature failure of the chainsaw with subsequent repairs.

Any steps to set up the chainsaw are described in detail in the operating instructions for the device. The technical documentation describes in detail the sequence of actions for setting up the saw for operation. Compliance with these requirements guarantees the restoration of the original parameters of the equipment with high accuracy.

- the engine does not start;

- starts but stalls;

- works unstably;

- does not develop power, i.e. It runs fine at idle, but stalls under load.

When repairing a chainsaw with your own hands, you need to act by elimination - inspect alternately all the possible causes of a malfunction, starting with those that take the least time to check and eliminate (see here for information on the design and operation of a two-stroke engine).

Ignition system. Almost all types of engine problems listed above can be caused by ignition system failures. Therefore, when they occur, it makes sense to start troubleshooting with a spark plug. This is all the more justified since the state of the latter can provide useful information about the operation of the fuel system. So, if a problem occurs, you need to unscrew the spark plug and inspect it.

The wire is disconnected and the spark plug is unscrewed with a special wrench.

If the spark plug is dry, this means that the problem is most likely not in the ignition system, but in the fuel mixture not entering the cylinder. You can wrap the spark plug back and get to work on the fuel system. If the spark plug is heavily splashed with fuel mixture, it means there is an excess of it. This may occur due to carburetor misadjustment or violation of starting rules.

The presence of a large amount of black carbon also indicates a malfunction in the fuel system.

The ratio between oil and gasoline in the mixture may be incorrect, the carburetor may not be adjusted, or low-quality oil may be used. The spark plug is washed in gasoline, cleaned of carbon deposits with a needle or awl, the electrodes are cleaned with fine sandpaper and replaced.

In all these cases, it would be a good idea to check the gap between the spark plug electrodes. Depending on its brand, it should be in the range of 0.5-0.65 mm. You also need to check the spark plug seal. If it is worn out or damaged, the tightness of the combustion chamber may not be ensured, which leads to a decrease in compression in the cylinder and problems in engine operation.

Even if, when checking the spark plug, there is good reason to believe that the fault is in the fuel system, you need to check the spark plug for the presence of a spark. At least to be sure that everything is in order. For this:

- put the ignition cable on the spark plug;

- using pliers with insulated handles, apply the thread or nut of the spark plug to the cylinder;

- pull the starter handle and see whether there is a spark or not.

How to properly adjust the carburetor on a chainsaw?

To adjust the unit, place the tool on a hard, flat surface. It is best to adjust the chainsaw carburetor in a place protected from dust and moisture.

The node setup process should look like this:

- First you need to unscrew the mounting bolts and remove the protective housing of the saw. This will make it possible to inspect the carburetor and, if necessary, clean it;

- Next, you will need to remove the standard air filter of the instrument. If the saw is equipped with an additional foam insert, then it must also be removed;

- After this, you will need a screwdriver, which you need to tighten the bolts marked H and L clockwise until they stop. This must be done very carefully so as not to break the bolts;

- Then both screws should be unscrewed 1.5 turns in the opposite direction;

- Next, you need to start the chainsaw motor and let it run for about 7 minutes;

- As soon as the engine cylinder warms up, you will need to start turning the bolt L until the internal combustion engine begins to operate at maximum speed. Immediately after this, the bolt must be turned 1/4 turn in the opposite direction;

- Then you will need to adjust the engine to operate at high speeds. To do this, you need to connect an electronic tachometer to the engine and start turning the H bolt until the indicators on the instrument display coincide with the instructions for the recommended maximum speed in the instructions for the saw;

- In the end, all that remains is to adjust the operation of the saw’s internal combustion engine at idle speed. To do this, you need to slowly turn the T bolt counterclockwise until the motor runs stably and without failures. If the engine begins to stall, then bolt T should be turned in the direction of the clock hand.

To adjust the carburetor on a chainsaw, you should work with the adjusting bolts as accurately as possible. Over-tightening the screws will place increased stress on the engine and other important components of the garden tool.

Electrical equipment, light, lighting

Even if you want to, a chainsaw cannot be classified as a complex device. Moreover, the simplicity of the design is its distinguishing feature. But repairing a chainsaw can still be time-consuming. The difficulty lies not directly in repairing a chainsaw with your own hands, but in accurately diagnosing the malfunction. One symptom of inoperability can be caused by many reasons. Therefore, before disassembling the engine or carburetor, it is necessary to carefully analyze the symptoms of the malfunction. No instructions for repairing a chainsaw on your own can replace simple logic.

Table of contents:

Types of chainsaws

A chainsaw is a tool that cuts wood with a closed chain and is equipped with a two-stroke gasoline internal combustion engine. The ability of a chainsaw to work continuously for a certain time is the main distinguishing ability that you should pay attention to.

The main structural units of a chainsaw are: a chainsaw bar, a chain and a gasoline engine, which drives the chain and bar. Based on their scope of application and functionality, chainsaws are divided into the following categories: professional, semi-professional and amateur household.

Amateur chainsaws are used mainly in everyday life, for gardening in the countryside or at a summer cottage. Such saws are very light in weight (3-4 kilograms without chain and bar), compared to their older brothers, their vibration is very low, which makes working with this device quite comfortable. Household chainsaws are primarily designed for a short period of use (about 5 hours a week), the motor power is low, but these shortcomings are compensated by ease of operation. With the help of household chainsaws, summer residents most often do small work - harvesting firewood, cutting garden trees and pruning branches.

With a semi-professional chainsaw, you can easily perform a wider range of work - from repairs on your site to felling. The continuous operation time of such a saw is 2-3 hours per day. The power of the gasoline engine in semi-professional devices has been increased. You can achieve maximum productivity and fell trees with medium and small trunk diameters. Semi-professional chainsaws are often used for cutting knots. The only difference between such devices and professional ones is that they cannot be used continuously throughout the entire working day.

Professional chainsaws are mainly used in logging and industry. The engine power of professional chainsaws is designed to cut trees of any size and diameter. Such chain saws are made of wear-resistant material and have a particularly strong chain, which allows you to work continuously for 8-16 hours.

Chainsaw malfunctions

All chainsaw breakdowns are conventionally divided into two groups: malfunctions of the engine with all its systems and components (fuel supply system, ignition, exhaust system, cylinder-piston group) and malfunctions of other components (lubrication system, clutch, tire, chain brake).

Malfunctions in the functioning of chainsaw engines occur quite often, and it is their correction and detection that takes users the most time. They mainly boil down to the following manifestations: the engine does not start, the engine starts, but stalls or is completely unstable, the engine does not develop power, that is, it runs normally at idle, but stalls under load.

How to flush a chainsaw carburetor?

To clean the unit from heavy contamination, it is best to use a product that is sold in pressurized cylinders. The cleaner comes with a dispenser and a long thin tube, which makes it possible to spray the product in any hard-to-reach places.

It must be remembered that cleaning the carburetor on a chainsaw is done using flammable chemicals. You need to work with them wearing a special protective mask and only in well-ventilated areas.

To clean the carburetor on a chainsaw, the unit will need to be partially disassembled. The throttle valve, adjusting screws, body and other parts of the carburetor will need to be washed with the product from the bottle and set aside until completely dry. Once all the elements are dry, the assembly can be assembled and installed back on the chainsaw.

Do-it-yourself disassembly: nothing complicated

First of all, you need to prepare a place for disassembly. This could be a workbench or a regular table. In addition, you need a rectangular piece of fabric or cardboard - on it you will carefully fold the carburetor parts. And finally, a tool: for disassembly you will need a set of open-end wrenches and screwdrivers, a special cleaning compound and an ultrasonic cavitation bath.

Chainsaw carburetor repair tool

First, you will have to dismantle the chainsaw carburetor. This is done in this order:

- To get to the carburetor, you need to remove the top cover of the chainsaw, secured with three bolts.

Removing the carburetor cover

Removing the fuel hose and drive rod

Removing the throttle cable

After removing the gasoline hose, the carburetor is ready for disassembly

The carburetor must be disassembled in the order prescribed by the design and functional solutions of its elements. The parts of the chainsaw carburetor do not differ in size, so you need to fold them carefully and in order, trying not to lose anything.

Disassembling a chainsaw carburetor in the photo

After disassembly, it is necessary to carry out troubleshooting and replace damaged or worn parts. Next, the entire set should be washed with a special product, dried and wiped with a dry lint-free cloth. The jets and tubes of the assembly must be purged with compressed air, or, in order to more thoroughly remove formations on their internal surfaces, they must be treated with ultrasound beforehand.

Gasoline does not enter the chainsaw carburetor

If fuel does not enter the standard chamber, this may indicate several breakdowns at once. First of all, you need to check the air and fuel filters. During long-term operation of the saw, these elements absorb large amounts of dust, which subsequently prevents the infiltration of clean air and fuel. A slightly dirty filter can be cleaned with gasoline, but if the part is clogged with a large amount of dust, it will need to be replaced.

Another cause of malfunction is the needle. This part tends to stick, especially in Chinese-made chainsaws. In most cases, simply moving the needle will be enough to fix the problem.

If fuel does not enter the chamber, the saw owner should inspect the tool seals. After several months of using the tool, these parts lose their tightness. Over time, they begin to leak gasoline, as a result of which the tool stops starting. Repair is carried out by replacing the seals.

When starting the saw, the breather plays an important role. It is located near the gas tank cap of the saw, and performs 2 tasks at once - it maintains optimal air pressure and prevents fuel from leaking out. To check the breather, you will need to disconnect the fuel supply pipe and see how much gasoline flows out. If it does not flow out at all, it means that the standard breather is clogged with debris and dirt. In this case, you will need to clean the element and reinstall it.

If fuel does not enter the chamber, then you need to check the fuel line. Most often, to complete a budget class tool, a Chinese hose is used, which loses its tightness over time. In this case, it will be necessary to replace the line, paying special attention to the tightness of the channel joints.

Chain lubrication system repair

The first step is to check the spark plugs. You need to disconnect the wire that goes to the latter and unscrew it with a special key. Based on the condition of the spark plug, you can determine possible problems:

- a dry spark plug indicates that there is no access of the incendiary mixture to the cylinder; the ignition system has nothing to do with it. The cause of the breakdown may be a clogged conductive tube or a problem with the carburetor. It is necessary to clean the fuel line and check the functionality of the fuel pump and carburetor. If one of the mechanisms does not work, it is necessary to replace it with a new one, since repairing the latter is impossible in the absence of professional skills;

- A wet spark plug indicates an excess of fuel mixture in the cylinder or water getting into it. It is necessary to dry the spark plug, remove any remaining liquid and blow out the cylinder chamber - with the fuel supply turned off, start the starter. Then you should put the spark plug on and start it again. When checking, you need to measure the gap between the electrodes; an indicator from 0.5 to 0.65 mm is considered acceptable. In case of damage or signs of abrasion, the gasket must be replaced. If after the above operations the spark is good, there may be a problem with the quality of gasoline. Absence or unevenness is an ignition problem. There is a possibility of damage to the supply wire or spark plug. If the new spark plug does not respond, it is necessary to inspect the starting system in more detail;

- a spark plug with a black coating of soot is evidence of the possible use of low-quality lubricant, an imbalance in the “gasoline-oil” balance in favor of the latter, or a clogged one of the filters. Clogging leads to a loss of power of the chainsaw and its subsequent stoppage. The dust does not burn completely and settles on the cylinder walls as a layer of black soot. You need to change the fuel, clean the fuel filter, wash and dry the air filter. Remove soot from the candle using an awl or needle, and clean the contacts with medium-sized sandpaper.

In the previous section, one of the reasons for the lack of fuel supply to the cylinder was already mentioned - contamination of the fuel filter. It is checked by the intensity of the stream from the fuel hose; if it is weak, the filter needs to be cleaned, and in case of severe wear, it needs to be completely replaced. Preventive replacement is recommended once every three months.

Poor fuel flow may indicate a clogged tank cap breather. Cleaning is done with an awl.

Another sign of a problem is the absence or poor supply of the fuel mixture. This is due to several possible reasons:

- air filter contamination (washing and subsequent drying);

- problems with the carburetor - one of the options is possible: settings failure, damaged membrane, clogged channels.

The ability of ordinary people to regulate the carburetor is reduced to a minimum - idle speed adjustment. But even the correct setting of the latter will significantly increase the power of your chainsaw. Plus, incorrect factory settings are possible, evidence of the latter is:

- increased vibration and damaged protective cap;

- harmony of the cylinder-piston group;

- carburetor clogging;

- inability to start and instant stop after start;

- a drop in productivity with increasing consumption of the combustible mixture.

The adjustment takes place in two phases: basic, with the engine turned off, and final, with the engine running, preheated. Adjustment is made using adjusting screws; for basic adjustment, screws “L” and “H” are used, the third one, “T”, is not touched for now. We wrap them all the way, and then 1.5 turns in the opposite direction.

Currently reading: How to distinguish a Chinese Stihl MS 660 chainsaw from the original

During final adjustment, turn the “T” screw counterclockwise to achieve minimum speed. The engine must run stably and the chain must remain in place. If after adjustment the engine stalls, you need to return the screw to its original position, the chain continues to move - then unscrew the screw. We test debugging using:

- acceleration - speed should be gained quickly;

- maximum number of revolutions - in case of ignition interruptions, loosen screw “H”;

- operation in idle mode - the chain should not move, the speed should be increased as quickly as possible.

Additionally, use the instructions to properly debug the carburetor mechanism.

Problems with the chainsaw may be due to a malfunction of the chain lubrication system.

Possible malfunctions:

- oil smudges - you need to check the tubes for cracks and tightness of the connection with the fitting. Seal problematic tubes with sealant or replace them;

- lack of lubrication - clean clogged oil channels;

- Cracks in the oil pump - replace.

The mechanism may not work because the space under the protective cover is clogged or the brake band is worn out. In the first case, cleaning is needed, in the second - replacement of the part.

Many parts of the saw are subject to natural increased wear, so it is necessary to have the following parts in stock: saw chain, its guide bar, sprocket, anti-vibration protection components.

Any chainsaw is equipped with a two-stroke single-cylinder carburetor engine. Early models of chainsaws were equipped with contact ignition, but now almost all manufacturers use electronic ignition, so there is no need to constantly clean the contacts and adjust the gap between them.

The air-fuel mixture to operate the engine is mixed in the carburetor. Using a special damper, you can manually lean or enrich the fuel mixture for a specific purpose - for example, for cutting hard wood.

Both the health of the engine and the performance of the chainsaw directly depend on the good technical condition of the carburetor. Let's take a closer look at how a chainsaw carburetor works.

If there is a significant (small is considered normal) oil leakage, you need to check the tightness of connecting the tubes to the pump fittings. They may fall off or crack. Violation of the tightness of the oil line, in addition to drips, can also lead to insufficient lubrication of the chain. The pump begins to suck in air, which affects its performance. Violation of the tightness is eliminated by replacing the tubes or sealing them with sealant.

The most serious failure of the lubrication system is cracks in the oil pump housing. In this case, it will have to be replaced.

Why does a chainsaw shoot into the carburetor?

If, during startup and operation of the tool, its owner hears sounds reminiscent of gunshots, this indicates a malfunction of the unit in which the fuel is mixed. The reason for this, most likely, is the following malfunctions of the chainsaw carburetor:

- overdrawn ignition - in this case, the fuel does not burn out, which leads to specific sharp shots;

- supplying a mixture with a low concentration of gasoline to the carburetor - to correct the problem, you will need to adjust the jets.

If the shooting sound comes from the muffler, then the problem is the fuel mixture is oversaturated with gasoline. If there is too little air in the fuel, it will burn not only in the chamber, but also in the muffler. This will be evidenced by a large amount of carbon deposits on the inner walls of the muffler.