Features of the gating process

As we have already said, gating is done in order to lay electricity and make new sockets or switches. It is necessary to make special grooves. Before starting work, study the regulatory documents. If you break load-bearing walls, you may not only pay a fine, but also harm your neighbors’ homes.

It is impossible to make horizontal channels in houses made of panels, since in this case the reinforcing materials are damaged. It is not allowed to make grooves in seams or joints bordering the stairs if this will affect the floors. The only option in these cases is plastering work.

Wall chipping is done only in horizontal and vertical directions. The width and depth of the groove should not be more than 25 mm.

The work process also depends on the material where the groove needs to be made. For example, in plaster, this can be easily done using a chisel and hammer. But if you need to work with concrete, you need special tools.

Do not forget to carry out preparations before work. Find the places where the old wiring was installed, this will protect you from getting electrocuted. If you don't know, there is no wiring diagram, then you can use an indicator. Remove old coverings from the walls (wallpaper, paint, plaster). So that the whole house or apartment does not become dusty. Be sure to hang a wet rag or a special one on the door. Construction film.

Why is it “like having no hands” without a wall chaser?

When repairing or building, one of the most important points is the installation of communications and cable and wire products.

There are several methods for laying grooves, for example, using a grinder or a hammer drill. But the result will not please you: the groove will not be ideal, it will take a lot of time, and a huge amount of dust will have a bad effect on your health. To prevent this from happening, you need to use a professional tool - wall chaser . It will save you from all the above troubles. Before deciding to purchase such a serious tool, you can rent a wall chaser and thus test your strength.

ArendaStroyService knows a lot about good tools and puts the comfort of its customers above all else. We offer a wall chaser rental , which will help save your time, nerves, protect you from dust and most importantly, you will get the perfect result.

All our tools undergo regular testing, which ensures that we only rent equipment that is in good working order.

We invite you to take a closer look at the main features of the wall chasers that we have in stock:

- Power from 900 to 2600 W

- Disc diameter from 115 to 230 mm

- Cutting depth from 1 to 70 mm

- Groove width from 2 to 42 mm

- Weight from 4 to 10 kg

- Ergonomic handle guarantees convenience and comfort when working

- The saver system provides vibration mitigation (the engine produces strong vibration during operation, which can harm your joints, this system avoids this)

- Connection pipe for vacuum cleaner

- Power button

- Adjusting the groove depth

Materials and tools for gating

Ideally, you need to invite specialists who will do all the necessary work, but you can do everything yourself.

You will need special tools. If possible, use a strobe; when choosing, pay attention to its power. You can also cut through the wall with diamond wheels, but some parts will still have to be knocked out by hand. You can drill a large number of holes, but it is quite tedious work. As you understand, there are many options regarding which tools you can use.

IMPORTANT: you don’t have to buy expensive tools, you can just rent them.

When carrying out work, first find out what the wall is made of. This will allow you to find out whether there is reinforcement and approximately how and where it is located, the location of the electrical wiring, and the choice of tool also depends on the surface material.

The easiest way would be to chip aerated concrete or foam concrete. It is bubbly, so it is easier to destroy than a monolithic structure. After your groove is ready, do not forget to cover it with a small layer of cement, and also fill in any excess potholes. This will provide an additional protective surface.

The most difficult part will be cutting reinforced concrete. The work is complicated by the fact that there is reinforcement in the wall. Here it is necessary to use only specially designed equipment.

When purchasing tools, pay attention to the fact that it is best to immediately purchase attachments that will be useful on different surfaces.

Disc for wall chaser: main types

Modern industry offers a wide selection of cutting tools for processing stone materials: concrete, brick, granite, paving slabs, etc.

Depending on the volume of tasks performed, the following is used as a drive for a diamond wheel: a manual universal angle grinder (“Binder”), a manual wall chaser and a stationary cutting machine.

Diamond blades for processing “stone materials” have a number of advantages: durability, high cutting speed and high cut quality.

In general, a diamond disc for a wall chaser for concrete is a “base” - a metal disc made of tool steel. “Diamond cutters” are fixed along the outer perimeter of the disk using laser welding.

Diamond cutters, in turn, are diamond chips sintered into a single unit with metal powder. In the center of the disk there is a landing (precise) hole of different diameters.

Depending on the purpose and cutting technology, the design of the disks has the following features:

- Dry cutting tool. It is a segmented disk. Diamond chips are located along the perimeter of the tool in sectors. Between the sectors, to localize thermal stresses, technological slots are made, ending with a technological radius boring.

- Wet cutting tool. It works in more gentle conditions, so the diamond cutters are located along the perimeter of the disk in a continuous strip. To localize thermal stresses, holes are punched evenly around the perimeter of the disk. A prerequisite for operation is the supply of water to the cutting area for cooling.

- Tool for cutting reinforced concrete (reinforced material). Discs of this type are distinguished by an increased thickness of the base (disc) and an increased content of diamonds in the diamond-metal “bundle”.

The marking of a diamond blade, as a rule, contains three main parameters, indicated in millimeters:

- Outside diameter. Selected depending on the required cutting depth.

- Disc thickness. Selected depending on cutting technology. It is not always indicated in the labeling.

- Bore hole diameter. It is selected depending on the mounting hole of the spindle of the existing power tool (“grinder”, wall chaser, angle grinder, etc.).

An example of marking is a Husqvarna D 125/22 UP diamond disc: outer diameter 125 mm, bore diameter 22 mm. Disc thickness is not specified. This indicates that the disk has the minimum possible thickness.

Advice from experts on how to ditch

It is best to have a special device that shows the location of electrical wires and fittings. It is inexpensive, but in this case you do not have to buy additional attachments for metal carving. On some instruments it is already provided by the manufacturer, but experts note that it often malfunctions and it is better to buy it separately.

On the Internet you may come across craftsmen who offer to perform work with tools that are not at all suitable for this type of work. They may recommend removing covers, guards, etc. Remember that safety is very important! To avoid injury, listen only to professionals.

Since the process is very dusty, take care to protect your skin and upper respiratory tract. It is better not to carry out work without glasses and a respirator.

Old grandfather's methods

The easiest thing to find is a hammer and chisel; every home probably has them. We make preliminary markings. Using a chisel, we make indentations. Then we direct the tip across and knock off the top of the wall using a hammer.

We work strictly along the line we have outlined. We go 2.5 cm deep along the entire length. The biggest advantage is the ease of access to the tools. But there are many more disadvantages: it takes a lot of effort and time, the contours of the recess are uneven. This option is best suited for plastering work.

A drill can speed up the work somewhat. But here you will need to drill holes every 15 mm. The resulting contours then need to be trimmed with a chisel.

Concrete structures and bricks can also be tapped using this method, but be prepared for the fact that it will take much more time, and the edges will be uneven.

Hammer work

A hammer drill has its own characteristics: to begin with, a wide but short drill is used. Make holes every 1-1.5 cm to the depth you need. When all the holes are ready, put a blade on the hammer drill, turn on the impact mode, and connect all the resulting holes.

The advantage is that there is not much dust during such work. A hammer drill can also easily make grooves in corners when it is impossible to do this using a grinder or wall chaser.

The track itself is not even, both at the edges and when deepening. Don’t forget about noise, which residents of the house don’t really like.

If you have special attachments, using a hammer drill, you can make a groove in a brick or even concrete wall.

To make the edge more even, you can use a grinder in addition to the hammer drill. Place a diamond blade on the grinder; thanks to it, you can work with brick and concrete.

Make two cuts across the entire width of the groove; they should be parallel to one another. Use a hammer drill to deepen the groove, as we wrote above. This way you will get smooth edges and good channel depth.

Disadvantages: a lot of dust, but with an industrial vacuum cleaner this can be corrected. To immediately work with an angle grinder and a vacuum cleaner, you need an assistant. The closer the vacuum cleaner is to the groove, the less dust there will be. After work, ventilate the room well.

The best models of wall chasers based on reviews from experts and users

Experts recommend that when choosing a wall chaser, you should focus on the tasks at hand. For example, taking into account the maximum permissible groove width, when choosing from the best, pay attention to which machine can cut a 20 mm groove and which 60 mm.

Despite the fact that a device with a power of 1-1.5 kW is suitable for household needs, it will not be possible to quickly perform a large amount of work due to frequent overheating of the engine.

When choosing a professional tool, you should not consider the most powerful ones without first studying the rating of wall chasers. Sometimes the product has increased mass and requires more effort.

To work with surfaces made of concrete and other hard materials, nozzles (diamond discs) with a diameter exceeding 220 mm are used.

Wall chaser makita SG1250

Can operate from a 220V network, has 2 cutting discs, suitable for cutting grooves up to 30 mm in width and depth. Power 1.4 kW, rotation speed 9 thousand rpm. You can use diamond or abrasive discs up to 125 mm in diameter.

Most often used for dry cutting of brick, stone, and concrete surfaces at home. The soft start system ensures operation for a long time without negatively affecting structural elements.

The makita SG1250 wall chaser is reliably protected from dust penetration.

This model's body is reliably protected from dust. The weight of the tool is 3.9 kg, so the worker can cut the surface of walls and ceilings without much effort.

Wall chaser makita sg 1251j

Belongs to the group of professional tools, power 1.4 kW, rotation speed 10 thousand rpm. Suitable for cutting grooves up to 30 mm deep on surfaces made of hard and loose materials.

Has high reliability, reduced noise level. The built-in engine speed stabilization system ensures stable operation.

Furrow maker Interskol Om 115-1300

It is characterized by its small dimensions and light design (weight 3 kg). Equipped with the ability to adjust the angle of inclination of the working disk (from 45 to 90°). The 1.35 kW engine allows you to complete work in a short time.

Cutting depth 36 mm. The model is equipped with dustproof elements that protect the gearbox, motor and bearings from contamination.

Wall chaser Fiolent B1-30

It is considered the best in its segment. Able to easily handle the processing of concrete, metal, brick surfaces. Suitable for dry cutting. The device's power of 1.1 kW allows for high-quality grating in walls; it can be used as an angle grinder for surface grinding and stripping.

The model is equipped with a reliable electric drive, so it can serve for a long time. Weight 4.5 kg, rotation speed 6.2 thousand rpm, cutting width up to 30 mm.

Wall chaser Fiolent B3-40

Refers to semi-professional tools, power 1.6 kW, rotation speed 9 thousand rpm, weight 4.3 kg, cutting depth 41 mm, saw blade diameter 150 mm.

The model easily processes surfaces made of brick and concrete, and can be used as a grinding machine (quickly transforms into an angle grinder). It has a ventilation cooling system, overheating protection, and can be connected to a vacuum cleaner.

Wall chaser Fiolent B2-30

The compact power tool is suitable for cutting building materials from brick and stone with 2 diamond wheels. It is equipped with a soft start, the winding is protected from the influence of dust, the ventilation system prevents its accumulation in the device components and provides intensive cooling.

Power 1.6 kW, rotation speed 9 thousand rpm, circle diameter 125 mm, cutting width 30 mm. There is a lock against accidental activation, electronic overload protection.

Wall chaser Zubr ZSh-1500

The model is from a Russian manufacturer, has a power of 1.5 kW, weight 5.9 kg, and a rotation speed of 7 thousand rpm. Can cut any surface up to 45 mm (width and depth).

Video on how to use a hammer drill

Wall chaser

It is considered a professional tool for creating grooves. There are 2 discs attached to the tool, the distance between the discs can be adjusted. Thus, 2 cuts are made at once. You can also adjust the depth. The wall chaser has a casing that fits tightly to the wall, and a vacuum cleaner is also attached, the process can be considered dust-free work. When working, it is important that no old wallpaper remains on the walls, as it clogs under the casing and clogs the vacuum cleaner.

The remaining concrete is removed using a hammer drill. This method is the most expensive. Most often, only professionals have such tools. A wall chaser can make holes for pipes up to 5 cm in diameter.

Tool

To ensure that the work of wall grooves is completed as efficiently and quickly as possible, use only professional tools. If electrical wiring is your profession, purchase one; if you are doing repairs only for yourself, rent a professional tool.

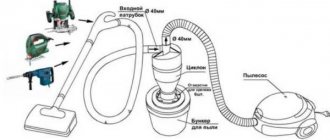

- Wall chaser + construction vacuum cleaner. Use only in pairs. If you use a wall chaser without a vacuum cleaner, you will not only not be able to breathe, you won’t even be able to see where you need to cut.

Do not use the wall chaser without a vacuum cleaner!

Drill, chisel and channel chisel for hammer drill

We will not consider perversions of the type “you can also cut out a groove with a hammer and chisel” within the framework of this article. It's unprofessional, ugly, time-consuming and expensive.

Video on the technique of working with a wall chaser

Strobe under the wallpaper

Sometimes it is necessary to make a track directly under the wallpaper. To do this, you need to remove a small strip of wallpaper. We retreat more than 5 cm from the future track, and make an incision with a stationery or mounting knife. If you need a horizontal groove, then make the cut higher.

We soak the wallpaper, bend it and attach it using tape. The resulting area where the work will take place should be more than 10 cm. We use only a hammer drill or wall chaser to avoid a lot of dust. After the work is completed, we lay the wires, putty and wait for everything to dry, then glue the wallpaper in its original place. Do this very carefully so as not to damage the wallpaper. The same work is carried out if it is necessary to groove walls for sockets.

Rosettes and finishing

To make a hole for a socket or switch, follow these steps:

- Drill a 0.8 cm diameter hole in the center. Using a crown, make a notch. This will be the outline of our socket or switch.

- Drill 8 to 10 small holes along the contour.

- Without applying force, make a hole using a crown. When working, do not damage the reinforcement, this may lead to destruction of the walls.

If the socket is not high from the floor, then the wires can be hidden under the floor.

When all the holes are ready, clean everything well from dust. We lay the cable, fill the groove with putty (gypsum, plaster, alabaster powder), and carefully level everything. We glue wallpaper on top.

Work order

- Select a PVC pipe (for wiring) or corrugated pipe of the required diameter. To do this, place the required amount of cable into the pipe section. The wires must enter freely, because You will insert them into the already mounted structure.

- Measure the outer Ø of the fasteners for the selected pipe.

Mounting diameter for corrugated pipe

When working with a hammer drill:

- Holes are drilled along the entire marked line with a Ø 8mm drill to the depth of the groove.

- Using a chisel and channel chisel, cut out a channel of the required shape and depth.

When working with a wall chaser

- Set the required width and depth of the channel on the wall chaser.

- Cut the groove along the outlined line.

- Using a hammer drill chisel or a regular chisel, cut out the channel of the required shape.

It is important to know. Divide wide channels into several lines to make it easier to remove excess plaster, and the channel itself is neater.

Pipes are fixed to the bottom of the resulting channel with fasteners, into which the wires are subsequently drawn.

It is important to know. To fix the pipes at the bottom of the groove, it is better to use a special clamp with a “comb” - it does not add width and depth to the entire structure.

Disk saving

During operation, the wall chaser disks (only metal disks are used) quickly heat up. The heating intensity depends on the quality of the disks themselves and the material used to make the wall. When gating walls, this factor should be taken into account, because... Excessive heating of the disks leads to unnecessary consumption.

Make marks in increments of 15-20 cm along the entire length of the future channel, so that when you reach them, allow the wall chaser disks to cool. As a result, the work will be completed faster, and consumables will last longer.

Question answer

How good are the complete diamond blades?

If we are talking about Makita or Bosch, then they are of good quality. For Russian-Chinese wall chasers they have the character of “demo equipment”.

Is it possible to replace a wall chaser with an angle grinder?

Only if we are talking about single-disk devices and only with a small amount of work. In other cases, such a replacement is impractical.

Is it possible to do without a vacuum cleaner?

The amount of dust when cutting concrete “dry” is very large, so if it is not sucked out of the casing with a powerful vacuum cleaner, it can even be hazardous to health, especially during regular work.

The specificity of the wall chaser and its rather high price are compensated by its convenience when working with concrete for specific tasks. It is worth weighing all the considerations in order to purchase a tool and not be disappointed in it.

Construction vacuum cleaner for concrete wall chaser

A construction vacuum cleaner designed to work in tandem with a wall chaser or furrow cutter must meet all related requirements. All these requirements are related to the specifics of the tool’s operation, i.e. gating.

This construction operation involves creating grooves in stone, concrete, brick and other walls made of similar materials. In one of the previous articles, we looked at how to properly groove walls for wiring and pipes.

The problem with gating is that it involves a significant formation of dust and small construction debris, which, if it gets into the respiratory tract of the master or others, can cause serious illnesses. Thus, vacuum cleaners are used in conjunction with a similar tool.

An ordinary household appliance, with rare exceptions, cannot cope with such a task, so specialized models of industrial or industrial type are used. All of them are produced by various companies, including quite well-known ones that have won worldwide recognition.

In this case, you can select a perfectly compatible pair from one manufacturer, which in some cases provides savings and advantages in service.

One of the options that professionals prefer to combine their tools with is Makita brand products. They represent one of the budget categories that simultaneously produce wall chasers and construction vacuum cleaners suitable for working with them.

A distinctive feature of modern vacuum cleaners from this company is the presence of an outlet for connecting power tools, which is also a groove cutter. It is this option that allows you to synchronize the work of two instruments as comfortably as possible without unnecessary wires.

For this purpose, a special option is provided, which, provided that another tool is connected to the vacuum cleaner, turns on the engine of the vacuum cleaner itself when the device is started. Therefore, all generated debris will immediately fall into the collector, while leaving the surrounding space and air unpolluted.

Which vacuum cleaner to choose

The most important criterion for choosing such a device is model compatibility. First of all, this concerns adapters that allow you to connect the operation of two devices. The diameter of the mounting hole in the wall chaser must match the adapter of the hose or pipe of the vacuum cleaner. The same applies to the power of devices.

Thus, the rate of absorption of debris that a vacuum cleaner for a wall chaser has must be no less than the rate of its formation. Otherwise, additional cleaning of the room or cleaning of the tank will be required at the most inopportune moment.

Karcher is an exemplary company in every sense for the production of industrial vacuum cleaners. But this company does not produce wall chasers, although this does not prevent it from producing a cleaning tool that can remove brick, concrete and other construction dust. Such a tool has enough power, both electrical and suction.

Therefore, there is no need to worry about its effectiveness. The problem with vacuum cleaners of this brand is different. The main factor that allows you to refuse to choose this technique is the relatively small volume of the garbage container. In addition, you will have to use disposable bags for concrete dust, which is not always convenient.

The last difficulty that the consumer may encounter is the lack of the required adapter for the furrow cutter adapter in the package. You will have to buy it for an additional fee along with another hose if the diameter of the hole and the adapter do not match.

However, such equipment provides an additional exit, which is used to remove waste into the garbage chute system or directly outside the premises. In addition, such a device will be useful after use at a construction site.

Latest, but not in the quality of products from Bosch. Construction vacuum cleaners from this company, like Makita tools, are easily combined with each other, because Bosch also produces wall chasers. And, despite the rather low dust absorption rate, they are recommended for use when working with wall chasers.

Products of this brand are distinguished by the presence of a system for removing static electricity, which inevitably appears when collecting such dust, but they have a fairly small volume of waste container.