Belts for Neva walk-behind tractors: types, sizes, self-tensioning

As you know, walk-behind tractors can be of two types. The first of them operate on a chain drive, and the second on a belt drive. In the second case, a belt drive is used to transmit torque from the motor to the attachments of the walk-behind tractor, and also plays the role of clutch and transmission. We propose to consider the principles of installing belts on the Neva walk-behind tractor, as well as methods for adjusting them with your own hands.

Selecting belt models for walk-behind tractors

In order to choose the right mechanism for your Neva walk-behind tractor, you need to follow a number of recommendations given by the manufacturer, as well as by experienced owners of special agricultural equipment. Let's consider the main points that you should pay attention to when choosing:

- first of all, the length of the belt used is taken into account (depending on the model of equipment, this parameter may change);

- when choosing, it is important to pay attention to the manufacturer (it is not recommended to purchase products from unknown brands);

- also, when selecting, pay attention to the cost (here we are talking about original spare parts, not analogues);

- It is not recommended to choose too cheap models, as there is a possibility of running into a low-quality product;

- before purchasing, you need to carefully study the number of the device that was previously installed on the walk-behind tractor;

- the same belt is purchased as it was installed (the same length of the belt being replaced and the belt being purchased);

- you should not try to compare the tension of two copies, since the old model stretches during operation;

- Experienced owners recommend using a second belt on a Neva walk-behind tractor from a manufacturer of wedge shape and cross section.

There are several criteria for choosing a belt. Despite all these conditions for selection, the owner of special equipment must first understand the model of the mechanism used, and then decide for himself which replacement to choose. Since the characteristic features of using equipment imply the use of various spare parts for walk-behind tractors.

Important! When selecting a mechanism responsible for transmitting torque, you should not contact the first spare parts store you come across, as you may run into selling a low-quality product.

Rules for choosing belts for Neva walk-behind tractors

The model range of Neva walk-behind tractors is not limited to just one representative.

On the contrary, there are several modifications of agricultural implements, each of which is suitable for a certain type of belt. The MB-1 walk-behind tractor, as well as the Neva MB-2 walk-behind tractor, uses primarily a V-belt drive. The use of a wedge transmission allows the unit to move in both the forward and rear directions. If the V-belt mechanism malfunctions, Neva brand machines will not work.

MB-1 walk-behind tractors are equipped with V-belt drives for forward and reverse gears. At the same time, the MB-2 modification is equipped only with a forward gear. Such a difference in the design of the two models of units does not allow the same type of belts to be used for them. On the contrary, in order to choose the right belt for the Neva walk-behind tractor, you should study a number of the following factors:

- Belt type that exactly matches your walk-behind tractor model;

- Element dimensions;

- The degree of tension of the element;

- Wedge transmission type.

By carefully studying each of these characteristics, you will be able to accurately select spare parts that are suitable specifically for your unit model.

Belt sizes for the Neva walk-behind tractor

When selecting the appropriate consumables, it is important to determine the number of the belt installed on the model of the Neva walk-behind tractor. To do this, the following recommended measures should be taken:

- the old consumable element is removed from the walk-behind tractor using a special tool and technology;

- then the device is checked for the presence of numbers (usually there are values on the outer surface);

- As a rule, the belt number used for a Neva walk-behind tractor is white, blue or orange;

- if these figures are missing due to long-term use of special equipment, then the distance between the rotating elements is measured;

- Next, you should use a special table (a table with values is available on the manufacturer’s website) to determine the size;

- also, if necessary, you can check the required parameter with the seller, since this data is also available in stores;

- then the same model is purchased, which will be freely mounted on rotating mechanisms.

Don’t forget to choose the right belt size.

It is recommended that after purchasing a new consumable item, copy the number from its surface so that you do not have to look for the values again later. The cost of this element is quite high, which is why you should have accurate information.

Important! Only after the appropriate model for the drive mechanism has been selected can you begin to replace the device (when using a device of a different size, there is a risk of damaging not only the structural integrity of the consumable element, but also the operation of the drive mechanisms can be disrupted).

Types of belts for Neva walk-behind tractors

There are three types of belts that are installed on walk-behind tractors. These include:

- V-belts;

- Forward elements;

- Reverse belts.

In order to accurately select a drive belt for Neva brand units, it is best to use a table that indicates the correspondence of the elements to a specific walk-behind tractor model.

This table will tell you how to choose a belt for the Neva walk-behind tractor, based on the modification of the agricultural unit.

Belt sizes for Neva walk-behind tractors

Another important factor when choosing drive belts for the Neva walk-behind tractor is their size.

A special table will help you determine which part is suitable for your agricultural machine. Before using the table, you should take measurements between the pulleys and rollers on which the new part will be installed. This will help determine the exact length of the new element.

Tensioning the belt of the Neva walk-behind tractor - how to do it yourself?

In the design of the Neva MB-1 and MB-2 walk-behind tractor, the location of the belts is slightly different. Consequently, the installation algorithm for both models will also have certain differences. To tighten the belt on the Neva MB-1 walk-behind tractor, you need to follow the following procedure:

- First of all, it is necessary to remove the casing from the V-belt mechanism;

- Then carefully remove the back bar from the pulley;

- Using a wrench, loosen the spring-loaded roller;

- Remove the old belt and tighten the new element;

- After this, install all previously dismantled parts of the walk-behind tractor.

How to change the belt on a Neva walk-behind tractor?

The simplicity of the basic device of the MB-1 and MB-2 modifications allows you to replace faulty drive elements without seeking help from a specialized workshop.

To do this you will need:

- Carefully remove the old belt, being careful not to damage the tension rollers and other important parts located nearby. To do this, it is necessary to sequentially dismantle the protective shield and the main factory casing, built-in for additional belt protection;

- Carefully remove the spring from the structure, which is necessary to tension the drive element;

- Unscrew the fastenings in the form of screws and the standard stops that serve to hold the belt on the standard engine pulley;

- Inspect the location of the power unit shaft handle and gearbox - they must be strictly in the same plane. In the Neva MB-1 and MB-2 walk-behind tractors, deviations in the location of the handles are possible by no more than 0.1 mm;

- If there is such a need, adjust the location of the pulleys by carefully moving the engine in its longitudinal plane;

- Adjust the installation location of the tension pulley - this is necessary for the appropriate tension of the installed belt;

- Install a new drive element - it is important to start installing the belt from the side of the gear part of the walk-behind tractor. The video will tell you in detail about manually replacing the drive element.

The procedure for replacing belts is performed in the same way for both the Neva MB-2 walk-behind tractor and its analogue MB-1. In each case, before installing a new element, it is important to inspect the installation site and thoroughly clean it of debris, if necessary.

Adjusting the belt on the Neva MB-2 walk-behind tractor is performed in the following order:

- As in the first case, remove the casing from the V-belt mechanism;

- Use a special screw to loosen the tension on the standard belt;

- Unscrew all the screws that hold the bracket to the walk-behind tractor body;

- Pull out the old belt and adjust the pulleys;

- Before installing the belt, be sure to wipe the space between all visible parts and blow out the hoses to which there is easy access;

- When installing a new belt, install one end of it on the gearbox shaft, and the other on the pulley located in the engine;

- Finally, reassemble the structure in reverse order. You can learn more about installing belts on Neva walk-behind tractors from the video.

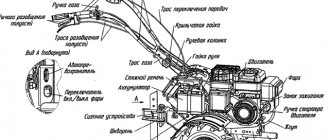

Features of the Neva walk-behind tractors

There are many modifications of this walk-behind tractor (MB-2, MB-23, etc.). Each device has its own type of belt. Mostly MB-1 walk-behind tractors are used - motor-cultivators of the old modification. It should be noted that the operation of the MB-1 and MB-2 devices is based on a V-belt transmission mechanism. This system ensures that the unit moves forward and backward, respectively; without its help, the device simply will not work. Motoblocks of the MB-1 modification have a built-in V-belt transmission for both strokes. In MB-2 editions, only one forward gear is used. Based on this, in order to choose a belt for the Neva walk-behind tractor, you should stock up on the following data:

- you need to know the type of belt that matches your specific unit model;

- belt length;

- degree of tension of the part;

- type of V-belt transmission (for certain modifications).

Replacing belts on walk-behind tractors "Neva" MB-1 and MB-2

You not only need to choose the right belt for the Neva walk-behind tractor, but also know how to install it. First make sure you have all the dimensions correct. The belt replacement processes for the units of these two samples differ from one another. For MB-1 the sequence of actions is as follows:

- the first step is to remove the casing from the V-belt mechanism;

- Next, you need to carefully remove the back bar from the pulley;

- take the key and make the spring-loaded roller weaker;

- the part itself is removed;

- The next step is to tighten the new belt;

- Ultimately, we return to their place those parts that were removed and strengthen them.

For MB-2 we see a slightly different course of action:

- the first action is similar to the previous scheme;

- then loosen the strap tension in the same way;

- next you need to unscrew the screws that secure the bracket;

- take out the belt;

- we adjust the pulleys;

- we place another part into the mechanism (remember that you first need to tension it onto the gearbox shaft, and then onto the pulley located in the motor);

- putting everything back together again.

As a rule, the belt is reinstalled if some kind of breakdown occurs during operation. But sometimes equipment owners simply want to replace the part with a newer and less worn one. In addition, there is another way to increase the productivity of the walk-behind tractor - you can install a second belt. Installing the second belt on the Neva walk-behind tractor takes approximately ten minutes.

In general, when replacing a belt on a Neva, you should take into account what developments this or that modification is based on. For example, the Neva mini (MK-100) differs from other models in that its production uses designs made back in Soviet times. The following video will tell you more about choosing a belt and replacing it.

Belt replacement

Having figured out which drive belt is suitable for installation on a similar model of walk-behind tractor, you need to proceed directly to replacing it. To do this, the master will need a standard set of tools, including a set of keys, as well as a new element that is planned to be installed.

Installing the belt will not take much time

In order not to damage important structural elements of the Neva walk-behind tractor during replacement, you must carefully follow the instructions for performing the work. First of all, you will need to remove the old belt, if this has not been done previously. The general procedure consists of the following manipulations:

- Remove the belt by disconnecting the walk-behind tractor shield, as well as the protective casing.

- Remove the spring that maintains the proper tension level.

- Unscrew the fasteners, as well as the special stops that hold the part on the pulley.

- Make sure that the gearbox shaft and motor are located in an identical plane. In this case, minor deviations are allowed, not exceeding 0.01 centimeters.

- Adjust the pulleys by adjusting the position of the power unit in the longitudinal direction. You will also need to adjust the tension pulley until the desired tension is achieved.

- Install a new belt, starting its installation from the gearbox.

It is extremely important to be careful when performing such work , since careless handling can lead to damage to the element and additional financial costs.

Be sure to read: Technical characteristics of the D-21 engine, price of new and used

Self-stretching

The tensioning procedure, which begins with cleaning the pulleys from dirt, deserves special consideration. After this, you will need to dismantle the fasteners that release the motor part and install the key on the adjusting bolt. Using it, you will need to bring the motor part closer or further to the desired degree of tension.

After completing all the necessary procedures, it is strongly recommended to ensure that there is no distortion , which is often found in equipment from this manufacturer. Before test running the engine, the adjusting nut should be slightly loosened to ensure the mobility of the installed product.

Belts for the Neva walk-behind tractor: features, dimensions, tension

All models of walk-behind tractors come in two types. One operates via a chain drive, and the second – via a belt drive. If a second structure is installed, torque from the engine is transmitted to additional attachments. The belt drive performs the tasks of clutch and transmission.

You can install the belt on the Neva walk-behind tractor and adjust it yourself.

Belt for Neva walk-behind tractor

Belt dimensions for the Neva walk-behind tractor - information necessary for every owner of this equipment. Belt type, length, tension and adjustment, V-belt transmission malfunctions are issues that we will try to sort out in this article.

While writing this article, I came across one interesting fact: information about the types and sizes of belts for Neva walk-behind tractors and others is presented on the Internet mainly by online stores that offer to buy their products. In this case, errors occur very often.

Therefore, when purchasing a belt, you need to be very careful and refer to the operating instructions for your walk-behind tractor. The data on this page is collected from catalogs from Red October and from the instructions for walk-behind tractors.

There are a large number of modifications of Neva walk-behind tractors. It happens that there are different belt sizes for the MB-2 walk-behind tractor with different engines (see lines 3 and 4 of the table below)

Table of belts used for Neva walk-behind tractors and cultivators

| Type of walk-behind tractor Neva | Belt type |

| MB-1 old modification | Drive belt A-1180 VN-T GOST 1284.1-80 - GOST 1284.3-80 (forward) Drive belt 0-1400T GOST 1284.1-80 - GOST 1284.3-80 (reverse) |

| MB-1 | A53 (1380) |

| MB-2 | A-45 13×1143Li A1180Ld or A1180 GOST 1284.2-89 |

| MB-2S-9.0 PRO | A46.5 A (1213) |

| MB-3 | А52 13х1320 Li А1350Ld |

| MB-23 | A49 (data differs in different catalogues) A50 13×1270Li A1300Ld |

| MB Compact | A47 (1200 Li A47 (1230 professional A)) |

| MK-75 | FSCOUZ36 |

| MK-80 | А37 13940 Li А 970 Ld |

| MK-80R | Z31 1/2 10x805Li Z825Ld |

| MK-100 | A-100 GOST 1284.1-89 |

| MK-200 | A44 |

Table of applicability of pulleys and belts on Neva MB 2 walk-behind tractors

| Modification | Engine | Belt type | |

| Model | Ø c/v | ||

| MB-2K-6.2 | DM-1K (JSC “Red October-Neva”) | Ø25 | A1180 GOST 1284.2-89 or A45 13×1143Li A1180Ld |

| MB-2K-7.5 | DM-1K-7.5 (JSC “Red October-Neva”) | Ø25 | |

| MB-2B-6.0 | I/C 6.0 (Briggs&Stratton) | Ø19 | |

| MB-2B-6.0 PRO | Vanguard 6.0 (Briggs&Stratton) mod.117 | Ø19 | |

| Vanguard 6.0 (Briggs&Stratton) mod.118 | |||

| MB-2B-6.5 PRO | Vanguard 6.5 (Briggs&Stratton | Ø19 | |

| MB-2B-7.5 | Vanguard 7.5 (Briggs&Stratton) mod.1384320210E1DD1001 | Ø19 | |

| Vanguard 7.5 (Briggs&Stratton) mod.1384320212E1DD1001 | Ø25.4 | ||

| MB-2B-5.5M | I/C 5.5 (Briggs&Stratton) | Ø19 | |

| MB-2N-5.5 | HONDA GX200 | Ø19 | |

| MB-2B-6.5 | I/C 6.5 (Briggs&Stratton) | Ø19 | |

| MB-2S-6.0 PRO | EX17 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| MB-2S-7.0 PRO | EX21 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| More details on the types and sizes of pulley belts and cables used for Neva walk-behind tractors and cultivators of other modifications can be found here | |||

Features of belts for Neva walk-behind tractors

The range of motorcycles is quite wide.

Accordingly, the selected belt for the Neva walk-behind tractor must match the model of agricultural machinery used. The MB-1 and MB-2 walk-behind tractors often have a V-belt drive. It is thanks to the wedge transmission that the unit is able to move forward and backward. If the V-belt mechanism of the machine fails, the walk-behind tractor will not be able to function normally.

MB-1 walk-behind tractors have forward and reverse gears. MB-2 models only move forward. Because of this difference, the same belts cannot be used.

It is not difficult to select a drive belt if you pay attention to the following nuances:

- the selected type must match the model of the equipment;

- belt dimensions;

- stage of tensioning the part;

- V-belt transmission type.

If you look at the data described above, you can choose the right belt for a specific walk-behind tractor model.

Types of belts installed on equipment:

- Wedge;

- Forward parts;

- Reverse gear elements.

To simplify the selection process, it is worth using a table. It indicates the correspondence between belts and equipment models.

Types of belts for Neva walk-behind tractors

The basic devices of the most popular agricultural implements of the Neva brand include two working shafts - a crankshaft and a distribution shaft.

To operate each of them, the factory design of the models includes belts, which, according to the method of transmitting torque, are divided into conventional and chain transmissions. To maintain the function of the chain system, the MB-1 and MB-2 walk-behind tractors are equipped with factory sprockets. Frictional force is responsible for the continuous operation of a conventional transmission in the design of these agricultural units.

The belts used in the factory design of the Neva MB-1 and MB-2 walk-behind tractors differ in the following factors:

- the location of the belts - depending on this, elements are allocated for the drive part, as well as for forward and reverse;

- cross-sectional shape - according to this factor, V-belts, round, toothed and flat belts are found on sale;

- the type of arrangement of the belt and shaft with each other - according to this criterion, angular, semi-cross elements, as well as open transmission are distinguished;

- material of manufacture - most often the equipment manufacturer uses parts made of reinforced fishing line, covered with dense technical rubber and an additional coating that protects the fishing line from wear;

- thickness - depending on this factor, there are belts on the market that are divided among themselves according to the diameter of the inner and outer circumference.

Each of these parameters directly affects the gear ratio. The torque that the element can withstand during its operation in the walk-behind tractor depends on it.

Belt sizes for Neva walk-behind tractors

When selecting drive belts, you need to pay special attention to their sizes. You can use the table provided to determine the part you need.

You should first measure the distance from the pulleys to the rollers; a new element will be mounted to them. This will allow you to select more accurate belt dimensions.

Belt size for walk-behind tractor

When planning to replace a damaged element, you should first find out which belt is on the Neva walk-behind tractor in a particular modification. To do this, you will need to perform a simple algorithm of actions that allows you to find out the dimensions of the installed element and replace it with a similar one:

- Remove the product from the walk-behind tractor.

- Check the element for numbers indicating its size. As a rule, they are located on the outside of the product.

- Particular attention should be paid to the color of the number, which can be white, blue or orange.

- If the markings wear off, you should take measurements yourself.

Be sure to read: Clutch basket MTZ-82

For this purpose, the distance between the rotating units for connecting which the product is used is measured, and then its size is determined using a special table posted on the equipment manufacturer’s website. Reliable information about the size can be obtained from the component seller if you show him the dismantled old element.

Tensioning the Neva walk-behind tractor belt: algorithm of actions

The Neva MB-2 and MB-1 walk-behind tractors are characterized by different belt arrangements.

Therefore, the installation diagram of the parts will be different. Tensioning the belt on the MB-1 model is performed in a certain way:

- Initially, the casing is removed from the V-belt mechanism;

- Carefully remove the back bar from the pulley;

- The key loosens the spring-loaded roller;

- The old element is dismantled and a new one can be installed;

- Pre-dismantled spare parts of the unit are installed.

It is worth considering how to replace the belt for units of the MB-1 model range:

- The shield and casing of the V-belt system are removed;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts that secure the bracket are loosened;

- The forward drive belt is removed;

- New elements are installed and tensioned, everything is secured and previously removed parts are returned to their place.

The belt adjustment on the Neva MB-2 walk-behind tractor is carried out as follows:

- The casing is removed;

- The screw loosens the tension of the standard belt;

- All screws holding the bracket to the unit body are removed;

- The old part is pulled out and the pulleys are adjusted;

- Before installing the belt, the spaces between the elements are thoroughly wiped, the hoses are blown out;

- A new belt is being installed. One end is connected to the gearbox shaft, the other to a pulley located in the motor;

- The structure can be completely restored.

More details on how to tighten the belt on a Neva walk-behind tractor can be found in the video provided.

Basically, they tighten a new element when the walk-behind tractor breaks down. Much less often, replacement is performed in advance to prevent malfunctions during operation of the unit. In any case, you need to carry out the work of replacing the belt carefully, since if it is over-tensioned, its breakage is inevitable.