Drywall composition

The outside of the material is made of thick cardboard, and inside it is filled with a pressed mixture of gypsum. The lateral oblong sides generally have an edge with rounded or trapezoidal corners, protected with cardboard. There is no edge at the end edges.

Several types of plasterboard are produced:

- Regular (gypsum plasterboard), having a gray tint.

- Moisture resistant (GKLV). The outside is green.

- Fire resistant (GKLO). Available in pink or light purple.

- Moisture resistant (GKLVO). It has a dark green color.

- Soundproof. Manufactured in blue.

Typically, standard sheets have dimensions of 250x120 cm, with an area of 3 square meters. m. More rarely, you can find other variations: 200x120 cm (2.4 sq. m) and 300x120 cm (3.6 sq. m). The thickness of the material can reach 12.5 mm, used for wall decoration. When constructing ceiling structures, mainly sheets of 9.5 or 6 mm are used.

The image below lists the main standard dimensions of drywall, indicating the approximate weight of 1 sheet. Knowing the mass allows you to determine the approximate heaviness and bulkiness of the material, having previously assessed its possibilities of use. Work with sheets should be done with the utmost care, since if handled insufficiently carefully, they may not withstand the load and break.

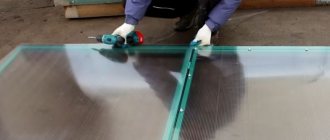

Regardless of the type chosen for finishing, all drywall is cut the same way.

Subtleties of the process

When cutting drywall, it is customary to follow some rules, such as:

- placing the sheet on a flat and stable surface;

- the surface should be dry and free of excess debris;

- Use personal protective equipment for eyes and respiratory organs, as cutting leaves a large amount of small debris and dust.

It is recommended to cut a large sheet in stages.

Also in our life, there are times when it is necessary to make a cut on an already installed sheet of drywall for a lamp, paintings or any other things. There is also a way for this case.

First, we need to make sure that the drywall is securely fastened, after which the small holes we need are carefully cut out with a jigsaw, a drill with an attachment, or an electric drill. It is recommended to cut large holes with a knife according to the markings. If you get uneven edges, they can be removed with sandpaper or a hacksaw.

There are a number of nuances when cutting out circles. The simplest way to cut a circle in drywall is to apply the desired size to the sheet, then carefully cut it in a circle with a blade, and knock out the core with a hammer (with little effort using any similar object).

There is also the simplest way, which saves time and effort - using a drill with a special cylindrical attachment. This type of attachment is usually used when cutting a locking mechanism with a latch into a door.

There is also a so-called double-sided cut, which is carried out when various obstacles arise in the path of the sheet, be it doors, openings, beams or any others.

If such a situation arises, you have to make a cut (or cut) from the desired side and the desired shape. This manipulation is quite simple, but requires concentration, accuracy and attentiveness. One side of the sheet must be cut with a hacksaw, and the other side must be carefully trimmed with a knife. Then complete the work by making a break and finishing the edge with a plane.

When cutting drywall, it folds. It is advisable to do this carefully without damaging the sheet. There are three possible ways to bend drywall. The easiest way is to attach the desired workpiece to the profile and fix it in the desired position with self-tapping screws. This method is used for small sheets measuring 20-30 centimeters and a small arc size.

A more complex and second method (for dry drywall) is to make transverse cuts in the drywall. They are done on the outside of the arch. The depth of the cut should usually not exceed four to five millimeters of panel thickness.

Let's also talk about folding the sheet for the door arch. The method has the unspoken name “wet”. First of all, the required dimensions of the arch are measured and applied to the sheet. Next, the sheet is cut off and non-through punctures are made on it using a needle roller. If there is no needle roller, you can use a regular awl.

Using a roller, sponge, rag or any other cloth, wet the pierced side with water so that the other side remains dry. After 15-20 minutes, a sheet of drywall with the wet side is placed on the template.

Next, we carefully give our panel the shape of an arc. The edges are fixed using self-tapping screws or clamps. Leave it for a day. After which the sheet can be used during installation.

Features of cutting: dependence on the type of plasterboard

Regular drywall sheets do not require any special handling. In waterproof gypsum boards, the cardboard is impregnated with polymers that close the pores in it, but the edges of this type remain unprotected. Therefore, work in wet conditions is prohibited even for gypsum boards. It can cause swelling of the ends, and the result will be a damaged geometry of the products.

The thinnest arched type of gypsum plasterboard is the most demanding. It seems counterintuitive, but the fiberglass inside the sheet is to blame. It provides the reinforcement and flexibility necessary to allow the material to deform but remain intact. In this case, a mounting knife or a handsaw will be poor assistants; a power tool is the only suitable solution.

Key Tools for Cutting Drywall Sheets

Cutting drywall to specific sizes requires the presence and use of certain tools, which include:

- Electric jigsaw. Using it, it is comfortable to make cuts of considerable length. Its use allows cutting out elements with complex curved shapes.

- A utility knife or one designed for cutting drywall.

- An electric drill with large feather drills and crowns, allowing you to cut out huge round holes for sockets, switches and communications.

- A narrow shear saw with slightly toothed teeth, used for cutting wood or a hand saw for cutting plasterboard sheets.

- A planer for wood or drywall, which will be required for processing edges when cutting the material.

- A needle roller will become necessary when creating arches or other curved surfaces, for example, when forming a complex ceiling structure with many tiers.

- To take measurements and mark on sheets, you will need a pencil or marker, a construction tape measure, a square, a metal ruler or a flat metal profile 1 m long, which is used during the construction of the frame sheathing. To make long, even cuts you will also have to have a rule in place.

Offers from manufacturers

Here are visual examples of some jigsaws that will help you cope with cutting drywall of any complexity:

- Model BOSCH PST 700 E:

| Parameter | Description |

| Homeland of the brand | Germany |

| Manufacturer country | Hungary |

| Power | 0.5 kW |

| Stroke length | 2 cm |

| Cord length | 240 cm |

| Color | Green |

| Weight | 1700 g |

| Price | 4230 rubles |

Prices are valid for spring 2021.

Model BOSCH PST 700 E is a bright representative of German quality

- Model Makita 4329:

| Parameter | Description |

| Homeland of the brand | Japan |

| Manufacturer country | Romania |

| Power | 0.45 kW |

| Stroke length | 1.8 cm |

| Cord length | 200 cm |

| Color | Blue |

| Weight | 1900 g |

| Price | 3630 rubles |

The Makita 4329 model is equipped with an anti-vibration system that simplifies the operation of the jigsaw

- Model Interskol MP-100/700E:

| Parameter | Description |

| Homeland of the brand | Russia |

| Manufacturer country | People's Republic of China |

| Power | 0.705 kW |

| Stroke length | 2.6 cm |

| Cord length | 250 cm |

| Color | Gray-black |

| Weight | 2900 g |

| Price | 3900 rubles |

The Interskol MP-100/700E model is a representative of the domestic brand, practically not inferior to foreign electric jigsaws in terms of performance indicators

Knives for cutting plasterboard sheets

Due to the fact that the key tool when cutting drywall is a knife, you should familiarize yourself with its inherent parameters in more detail. Knives used for cutting sheets can be divided into 3 categories:

- Standard. The main advantage of these models is their affordable price. They have a simple design consisting of 4 components, which include a body-handle, a cover-lock, a blade adjuster and a replaceable cutting element. These knives are not highly reliable, especially when cutting plasterboard sheets. They are more suitable for performing other tasks, for example, cutting wallpaper. When cutting drywall, their cutting elements become dull rather quickly.

- Reinforced. These knives, unlike standard models, have a higher cost. Their distinctive feature is the presence of a metal guide, which is located in the body of the tool, allowing the blade to be more securely fixed, as well as ensuring rigidity during cutting.

- Professional. These models are used by specialists who often work with drywall. There are a huge number of professional knives on the market, and their distinctive features are the ergonomics of the body, the way the latch works and a slightly modified design of the tool. Their price is several times higher than the cost of standard and reinforced models and in some cases reaches up to 1000 rubles.

To cut drywall, you can use a tool of any category, but in order to finally focus on one of the options, you should consider each of them in more detail.

Note! Knives with a 9 mm blade are not intended for cutting plasterboard sheets, since they do not have sufficient endurance and can break during the cut, so their use should be avoided. Their use will not only significantly reduce productivity, but can also cause serious damage to the hand.

Basically, knives with a cutting element 18 or 25 mm wide are used for cutting drywall.

Stationery knife

It is the simplest and most affordable solution, which is in high demand among non-professionals. This tool is easy to use and is suitable not only for cutting plasterboard sheets, but also for a number of other tasks. The thickness of the blade in this type of knives reaches from 0.3 to 0.6 mm and the higher this figure, the better. Externally, the models may look different, but their operational parameters are practically no different.

Knife with trapezoidal blade

This type of knife has a trapezoidal blade and is designed specifically for cutting drywall. The advantages of the models include the presence of a comfortable handle, which makes using the tool as comfortable as possible, since the force of the hand is well distributed over the material being processed. The cutting element of such a knife is characterized by high rigidity, which prevents its bending and high-quality cutting of drywall sheets. Tools of this type are available in different price segments, and their cost often depends on the manufacturer’s brand, but even the most budget ones are able to fully demonstrate themselves during use.

Knife with folding design

Most of the characteristics of this tool are similar to the previous version, however, it not only has a trapezoidal blade, but also has a folding design that allows you to conveniently and safely carry the knife with you when folded, eliminating the possibility of injury.

Disc blade knife

These models of knives are mainly preferred by specialists when cutting plasterboard sheets, since with their help even curved cuts are obtained as smooth as possible. The disk blade is fixed near a metal ruler installed along the cutting line, along which the master moves the tool pressed to the material. After this, an even cut with the same depth appears at the point where the cutting element passes. If necessary, quite significant force can be applied to the disc blade, since due to its high level of rigidity it can easily withstand significant loads.

Some models of folding knives are also equipped with disc-shaped cutting elements that move out of the body when the moving part of the handle is acted upon.

Reismus

This special cutter for cutting drywall has a unique design and appearance that is unlike other tools. The thicknesser has two cutting elements, which are located in a horizontal position parallel to each other at a specific distance. It is fixed on a plasterboard sheet and moves along it, cutting two layers of cardboard. Its cutting elements are round in shape and, if necessary, can be easily replaced with new ones. The thicknesser allows you to produce perfectly even cuts, cutting the sheet into strips up to 12 cm wide, often used in the construction of ceilings consisting of many tiers and other structures, the creation of which requires the presence of narrow strips of the same size. Its handle is also a guide from which the required cutting width is set. Subsequently, the thicknesser is placed on the end of the plasterboard sheet, cutting along its entire length.

Blade Runner

The Blade Runner cutting tool is in great demand among professionals, allowing the work speed to be doubled. This cutter is useful for anyone who cuts drywall on an ongoing basis. It consists of 2 detachable parts, held together during use by means of magnetic latches. The blades are in small blocks and, if necessary, they can be replaced with new ones. Using this tool, you can easily cut drywall with your own hands, since its two components are fixed on both sides of the sheets on strips pre-drawn on them. Next, the cutter moves along the marked line, cutting the cardboard layer simultaneously from both sides. Thanks to it, it is also possible to make curved cuts of complex shapes as smoothly as possible; it is only important that the markings are clearly and accurately applied to the surface of the material.

Having familiarized yourself with the various designs of knives, you can easily choose the most suitable option for yourself, taking into account the characteristics and optimal cost, which will allow you to cut the material into workpieces of the required sizes and shapes with extreme accuracy and evenness.

How to cut drywall correctly? 3 cutting methods

When you start working with drywall, you will be faced with the need to cut the sheet. There are several ways to cut drywall. The choice of one or the other depends on the situation. Of course, you can always use the same knife special for this material - drywall is cut with a knife in any direction, but this is not always so convenient.

Cutting tools

Sometimes it’s easier to use a power tool - it will be more reliable, faster, and more accurate.

First way

The most obvious, simple and at the same time the most common method of cutting drywall is to take a special drywall knife and get to work. In such cases, the drywall is leaned against the wall or placed on a flat surface, marks are made with a regular pencil and a line is drawn with a knife at the site of the future cut. Here we need to make a small digression.

Markings on drywall are always made with a simple pencil and never applied with a marker.

Marking

The fact is that the marker will appear on the surface, no matter how you putty it. In addition, having outlined the cut line, apply some even instrument like a ruler, for example, a rule, and move the knife under the improvised “ruler”.

We cut with a knife

It is better to run a knife along the line not just once, but several times - this will result in a clearer and more even seam.

Leaf fracture

Having outlined the seam, the material is carefully folded in half.

Fold a sheet of gypsum board in half

And then they cut it on the other side.

Cutting from the other side

If the cut area is uneven, you will need a special plane to level the surface.

Second way

There is another cutting option. It is used when you need to cut out a “knight’s move,” that is, a sheet whose shape resembles the letter “g.”

Cutting with a hacksaw

A sheet of this shape is needed, for example, for doorways. In such a situation, it is better to cut the short sides using a regular hacksaw, and then cut the long sides as we have already described above.

Third way

Since arches, niches and other decorative elements are often made from drywall, it is often necessary to cut rounded shapes from it. In principle, you can cut out any shape with a knife, but it takes too long. But to speed up the process, use an electric jigsaw - everything will come out quickly and accurately.

Cutting rounded surfaces

Finally, it often becomes necessary to cut a sheet of drywall when it is already fixed to slopes or in openings. How to be in this case? All that is required is to fix the material as firmly as possible, and then draw the necessary lines with a special knife. After this, the drywall will break under pressure - exactly along the lines that you draw, and you will only have to trim its cardboard layer.

Cutting technology and further processing of plasterboard blanks

The process of cutting plasterboard sheets is not particularly difficult, but to increase the comfort of work and obtain correct markings, as well as further cutting, excellent lighting and free space in the room in which the cutting will be carried out are required.

To cut drywall at home correctly, you should perform the following steps:

- Due to its large dimensions, the material requires quite a lot of free space. To mark and cut, it must be laid horizontally on a strong and stable base. You don't need to own a workbench for this task, as drywall can be laid on a table, stools, or even the floor to carry out the cutting. If stools are used, they should be placed at a short distance from each other, which does not exceed 30 cm. If this is not observed during the procedures, pressing on the sheet can cause it to break.

- After laying the material on a solid base, markings are carried out according to the required dimensions. Marking is done using a pencil with a ruler or tape measure, and the cutting strips between them are made using a long rule or metal ruler. To draw perpendicular lines, you will additionally need a square.

- At this stage, the knife blade is tightly attached to the ruler, which is located on the drawn line. After this, the cutting element is carried out along with it along the entire length of the marked strips. Using a rule instead of a ruler is more convenient if you need to cut a sheet to its full length or width. During the first pass of the knife blade, light pressure should be applied so that only the cardboard layer is cut from the outside.

- If one of the above-described models of tools is used for cutting, then the accuracy of the procedure largely depends on the skill of the person. It should also be taken into account that the drywall does not have to be cut to its full thickness in one pass, because in this case the cut site will most likely not only be uneven, but the cutting element itself will quickly become dull and will need to be replaced.

- Next, you need to move the plasterboard sheet closer to the edge of the surface on which it is located and carefully tap the cut site on the opposite side. This procedure will reduce the integrity of the gypsum layer along the cut strip. After this, you need to grab the cut piece and bend it down with a sharp movement, which will cause the sheet to break exactly along the line.

- Finally, you need to use a knife, bending the plasterboard blank along the cut strip and finally dividing it into 2 parts. This is quite easy to do, since both pieces of sheet will be supported by only one layer of cardboard.

- Upon completion of cutting the sheet, in order to eliminate the remaining uneven nicks, which can cause inconvenience when joining different pieces of drywall together on the wall, you should clean the edges of the cuts using a plane. Processing must be carried out without pressing the tool tightly against the material, since it can begin to break. During the procedure, there is no need to achieve perfect evenness of the sides, removing only excessively protruding irregularities in the cardboard layer if they appeared during cutting. To ensure high-quality reinforcement of the joints between the sheets on the wall, the beveled edges can be cut after completing their installation, since otherwise during the work it is easy to damage the unprotected and insufficiently strong sides consisting of cardboard.

It is much more difficult to cut a shaped hole, for example, a semicircle, since you have to watch the curved strip all the time. This procedure can be carried out using a narrow hacksaw or an electric jigsaw, with which you can make a more even cut, but for this you need to have experience in using it.

Note! Cutting the material should be done extremely carefully, avoiding breaking the edge, especially if the sheet does not have a cardboard edge.

Next, the excess drywall is slowly cut using a hacksaw in accordance with the previously marked line.

Through openings of any required shape are also made using one of the above tools. First of all, its location is marked on the plasterboard sheet, after which the edges are determined by lines. In the center of each side, closer to the inner part being cut out, a hole is drilled, the diameter of which should be equal to the width of the nail file inserted into the electric jigsaw. Typically this figure varies in the range of 8-10 mm.

Next, a file installed in a jigsaw is inserted into the hole in the off state, through which the strip is cut to one of the corners. After this, the tool should be turned off and upon completion of rotation of the cutting element, it must be removed from the device. Next, you need to turn the jigsaw in the opposite direction and, re-installing the file, insert it into the same hole, cutting to the other corner. The other sides should be cut in a similar manner, easily removing the cut fragment upon completion.

Description of the process using various tools

First, let's look at how to cut drywall in the most popular way.

Algorithm for cutting plasterboard with a stationery knife

You should start by laying the sheet on a flat surface and marking it. To mark, use a tape measure to measure the distance that needs to be cut, and put dashes to indicate where the cut will pass. To achieve a straight cut, marks need to be made in several places, then apply a level or rule to them and then draw a straight line with a pencil.

The next stage is cutting the outer layer of cardboard; for this, the stationery knife is pulled out to a distance of no more than 1.5 cm from the body, after which a cut is made with the corner of the blade, and the cut must be strictly along the marked line.

After the top layer is cut, the sheet must be placed on its edge so that the cutting line is parallel to the floor. It must be located on the uncut side. Next, crouch down a little and rest your knees in the area where the cut passes, pull the upper part of the sheet towards you, thus breaking it. After this, the sheet is lowered onto the surface with the cut side down, bent at an angle of 900 and the second layer of cardboard is cut along the corner. Cutting the sheet using a stationery knife is finished.

Cutting out a curved segment

If you need to cut a shaped piece, you can use a drywall saw. Curvilinear cutting work at home is best done by laying the sheet on several stools or placing the sheet on one edge. This is necessary for the saw to move freely, without fear of hitting any obstacle that could bend it.

Next, they begin to slowly cut out the figured cut. If you need to process a large number of sheets, you can speed up the process by using a jigsaw with a file for cutting curves on laminate.

Drywall lends itself well to mechanical cutting, as it has a low density.

Making a hole for round lamps

Using a drywall saw is convenient to cut holes for lamps or switches, but to achieve an ideal, even circle shape, it is better to use special drill bits. In order to cut a circle using such a nozzle, it is enough to mark only the center of the circle, install a crown of the required diameter and, placing a centering drill in the marked place, drill.

Straight cut with a fine toothed hacksaw

In a situation where there is neither a knife nor an electric jigsaw at hand, a fine-toothed hacksaw will help solve the problem of how to cut drywall.

To do this, draw a straight line, as if cutting with a knife, after which it is better to lay the sheet on stools and you can slowly cut it. During the operation, the hacksaw must be held at a minimum angle to the surface of the sheet, this will prevent it from clamping and reduce vibration when sawing.

There are also ways to divide the sheet into parts using a hand-held circular saw, reciprocating saws and other special tools, which probably not everyone who wants to finish drywall on their own will have.

At the end of the article, I would like to note the importance of observing safety precautions when working with cutting tools without certain skills, and the fact that it is more convenient to cut gypsum board sheets with an assistant. Good luck with your work and don't forget to leave a comment about what you'd like to learn about DIY renovations. https://www.youtube.com/embed/3xVZYqWzriI

Cutting a round socket for a socket or switch

The socket or switch connector, which has a round shape, is cut out using a drill with a special crown attachment of the required diameter, or using a jigsaw or a narrow hacksaw. The first option allows you to carry out the task most easily, requiring only a few seconds of time. Cutting out any openings is often done locally, after the plasterboard sheet has been secured to the sheathing, since otherwise the strength of the material may be compromised and often even a slight distortion during transportation or installation can cause a break.

Note! To mark a round opening, you only need to determine the center of the circle without performing any additional actions.

In the case of cutting holes using a hacksaw or jigsaw, determining the middle is done using a compass, which allows you to draw a cutting line.

Next, 2 openings are drilled on the strip with a drill as close to each other as possible. After this, the hole should be carefully connected using a file, continuing to cut along the contour line.

Cutting sheets along an indirect line

When covering walls and ceilings, you always have to cut certain pieces not in a straight line. For example, you need to make a hole for a socket, switch or lamp. In such a situation, the knife cannot be used as an independent tool. To cut a hole of any diameter, you need to take a hacksaw with fine teeth.

Hacksaw

Where a knife can't do it, a drywall hacksaw can do it. With its help, you can easily cut a hole of any diameter and size. You need to cut holes using a hacksaw in the following way:

- Place the slab on a flat surface:

- apply markings in the right place;

- We take the hacksaw in our hands and cut short sections with it at the bends, at the beginning and end of the cut;

Making a hole using a hacksaw

We take a knife and cut through the gypsum board using the technology that is used when cutting in a straight line.

It is much more difficult to cut sheets along a curved vector. You can also use a knife here, but the cut will be uneven and will need to be adjusted using a plane. In this situation, it is best to use an electric jigsaw.

You can also use a metal file, as it has small and frequent teeth. Note! When using an electric jigsaw there will be a lot of dust. Therefore, you need to cover your eyes with safety glasses and wear a respirator. By following the above recommendations and rules, you can easily and quickly cut plasterboard sheets into the required pieces with your own hands.

Planers for plasterboard, possible options, pros and cons We attach cornices to plasterboard walls

Sheathing curved surfaces with plasterboard

To cover surfaces of uneven shape, the material may be bent, before which preparatory work must be done in advance. For example, if you are planning to make a slight bend to build an arch with a huge radius, 2 methods may be suitable to give the drywall the required shape.

In the first case, punctures can be made on the workpieces using a needle roller, after which they should be moistened with a spray bottle. These procedures will help wet the material, making it more susceptible to bending. Installation of the resulting curved workpiece should be done extremely carefully on the arched frame, without waiting for it to dry. Some specialists, when bending a pierced and moistened sheet, use a pre-made template, made in accordance with the dimensions of the arch opening. To do this, the prepared drywall must be laid on top of the sample, lightly pressing it on the sides with a weight. In this state, the workpiece dries, after which it is installed on the arch frame.

The second solution is to cut the drywall along its entire length required for sheathing. The cut lines must be perfectly even. If a column is to be made from it or an arch opening with a small bending radius is to be sheathed, then the cuts should be made in the same way along the entire length of the drywall, but in 2 opposing passes, maintaining an angle of 100-110 degrees. During the procedure, a small part of the material is removed from the cuts made, and the resulting grooves must have a cross-sectional shape resembling a triangle, since otherwise it will not be possible to bend the workpiece.

Description of the cutting process

Use a tape measure to measure the required distance. Use a simple pencil to draw a mark. They double-check everything again, because there will be no way to correct the work.

Then they take a utility knife and cut the cardboard along the marking line. If you have doubts about the hardness of your hand, you can cut along the guide. It is very convenient to use the rest of the profile for fastening to the wall or a long building level for this. Sometimes effort alone is not enough; after all, drywall is a fairly durable material. Then cut through several times.

They don’t try to immediately cut drywall with a knife. This is impossible. There is a hammer for this kind of work. All you need is to lightly hit the cut site on the back side of the sheet several times. The gypsum base will safely crack exactly along the cut line.

All that remains is to turn the sheet over and cut the second layer of cardboard with a knife. All is ready.

For a better joint between the pieces, the cut site needs to be cleaned. Sometimes quite large notches remain there. Aesthetically, they do not interfere, because the seam area will still be puttied. But the accuracy of the connection may be affected.

Chamfering is the name of this procedure. This can be easily done with sandpaper or a large file. But we recommend purchasing a special plane for such purposes. Moreover, it costs very democratically.

Cleaning the cuts is done with smooth movements, without strong pressure. Don't try to achieve perfect smoothness. It is enough to remove large rags.

Someone will ask: why was a hacksaw needed? For cutting through holes. After all, you can’t just knock them out with a hammer. Practice shows that a sheet of drywall breaks anywhere, but not along the markings. For through holes, the technique is slightly different.

A hole is drilled in the sheet along the marking line of such a size that a hacksaw blade can fit in. Then, with the same hacksaw, three sides of a square or rectangle are cut out. The fourth side does not need to be sawed. It is enough to cut through the cardboard on one side with a knife, and then knock out the unnecessary piece with a hammer. The cardboard on the other side is also cut through with a knife.

Corner squares and rectangles are cut out in drywall in the same way. One side is cut out with a hacksaw, the other with a knife and hammer.

Advice. There will be very few nicks at the cut site if you hold the knife or hacksaw perpendicular to the sheet of drywall. The lower the blade is tilted, the larger the rags you will end up with.

Helpful Tips for Successfully Cutting Drywall Sheets

In order to avoid irreparable mistakes when cutting material, it is necessary to take into account some nuances and adhere to a number of the following recommendations:

- When cutting drywall, it is better not to use a grinder, since using it will not only be noisy, but will also generate a huge amount of gypsum dust that will need to be removed.

- If you need to use a hammer when cutting sheets, it should be exclusively rubber, since a metal tool can cause severe damage to the material being processed. When wielding it, you should also calculate the force of the blows without putting in a lot of effort.

- To reduce the number of notches along the cutting strip on the sides of the sheets, it is necessary to hold the knife or hacksaw at a right angle, since the lower the slope of the cutting element, the larger the nicks on the cardboard will be.

- All key cuts should be made before attaching the drywall to the sheathing, since if this fails, the sheet will need to be replaced with a new one. The damaged workpiece can be used when making inserts. The exception is cutting out openings and sockets for sockets and switches, which are best done after installing drywall on the frame.

- It is not recommended to make complex designs in material with thin partitions, for example, openwork mesh, since in this case it is highly fragile.

- When cutting a sheet completely, this procedure is often performed on the floor. After making a cut along its strip, you should place a beam under the drywall, and then you need to press on 2 parts of the canvas, easily breaking the material along the line previously passed by the cutting tool.

From all that has been written above, we can conclude that there is nothing difficult in carrying out work with drywall. Even a person who does not have the relevant experience can cope with this task, and if there are any doubts, everyone can first practice on a small-sized workpiece, making sure that cutting is easy. Having become familiar with how and what to cut drywall at home and adhering to the given technology, the use of high-quality tools will allow you to complete all the work quickly and at a high level, avoiding various mistakes and possible damage to the sheets.

Video on how and with what to cut drywall at home with your own hands:

Preparation and application of markings

To cut drywall, you will need the following:

Materials:

sheet of drywall.

Tools:

- stationery knife;

- line;

- roulette.

Adviсe:

- use a knife only with a sharp blade;

- if you intend to attach plasterboard both to the ceiling and to the walls, then first you need to sheathe the ceiling, and only then proceed to the walls;

- If you need to cut drywall along a complex path, cut the length first and then the width.

Remember that when working and attaching drywall, it is very important to use as many whole slabs as possible. This way you will reduce the cost of materials, there will be less work, and the cladding process will go faster

Therefore, you need to carefully measure and study the surface you are working with, and then make a plan for using the slabs so that you have to cut them as little as possible.

If you need to attach drywall over a larger area, we recommend using 3.6m boards instead of 2.5m boards. This way you will save time and material.

#1. To cut drywall like a pro, use quality tools. If the sheets are large (120 cm wide), then it is better to cut them by leaning them against the wall at a slight angle. And small sheets (up to 60 cm wide) can be cut on the floor. If this is your first time cutting drywall, it is better to practice doing it on the floor. First you need to decide which side to cut the drywall from. To do this, make sure that the sheet of drywall is facing towards you. It is on this side that the incision will be made.

If you don’t know what is the best way to cut drywall, then from our experience we can tell you that in most cases, it is best to use a good utility knife. But sometimes you have to use other tools. For example, a hacksaw for drywall is convenient to use for cutting holes of various shapes.

The minimum set of tools you will need when cutting drywall.

#2. First, you need to use a tape measure to determine the size of the slab to be cut. Do this very carefully, otherwise the slab may simply not fit - it will turn out to be either too small or too large. Also make sure that the vertical edges are aligned with the center of the sheathing, otherwise the slab joints will not be rigid enough. Measure using a tape measure and make a mark in the desired location with a pencil. In our example, we want to cut the slab in half, so we make a mark in the middle.

Marking a sheet of drywall.

#3. To get a perfect straight cut, use a gauge. If you want to achieve professional-level results and you have to cut drywall often and a lot, then we advise you to get a large cutting bar and not use homemade or homemade tools.

Slide the strip along the drywall until it reaches the desired mark.

Using a rail to cut drywall

Processing plasterboard sheets after cutting

The edge of the plasterboard, along which the working tool “walked”, does not look aesthetically pleasing. To make it smooth and even, ready for the filling process, use a plane and chamfer. For this purpose, you can use a regular knife. The chamfer is removed to 2/3 of the gypsum board thickness, maintaining an angle of 45°.

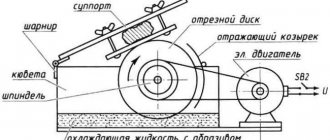

How to cut a profile for gypsum boards

To do this, we recommend using:

- hacksaw for metal;

- metal scissors;

- jigsaw with metal saw;

- manual or table-top cutting machine;

- Bulgarian

Some useful tips

- Drywall should only be cut on a stable and level surface, otherwise the material will bend and will be much more difficult to work with.

- Make sure that the drywall is dry (it is afraid of moisture and can be damaged).

- Cut large sheets in several steps.

- The frame for gypsum plasterboard can be created from small parts of a metal profile, the main thing is that these pieces are securely fastened to the wall.

- When working with a profile, you don’t have to worry about the fact that the cuts are not quite even and neat - the profile will still “hide” under the drywall.

As you can see, there is nothing difficult in working with drywall. To secure the material, we recommend watching a video on how to cut drywall with your own hands:

You might also be interested in:

The nuances of cutting drywall depending on its type

Drywall sheets can be specialized, for example, waterproof. The paper on these is impregnated with polymers. They close the pores in the cardboard, making it resistant to moisture and reliable protection for the compressed gypsum powder inside.

However, the edges of even waterproof plasterboard are not protected. Accordingly, the workplace should not be wet. Once in the gypsum, water will cause it to swell and change the geometry of the building sheet.

Arched drywall

Arched plasterboard stands separately. It is as thin as possible, only 6.5 millimeters in thickness. It would seem that such a sheet would be easier to cut than a centimeter sheet. However, fiberglass is laid inside the arched panel.

It reinforces drywall and gives the flexibility necessary to deform the sheet intended for curved doorways and ceilings.

Because of the fiberglass inside, the arched material is more difficult to cut than simple drywall. It's better to use a power tool. A mounting knife or a hand saw “goes hard.

Edge processing

After trimming, the edges need to be sanded a little so that they are smooth. This can be done with sandpaper. It is necessary to carefully walk along all edges and remove chips and nicks. Finally, we carry out one more stage - fascia. The essence of this treatment is that you need to cut off a few millimeters of gypsum from all sides. To do this, take a distance approximately equal to two-thirds of the sheet thickness. The approximate angle at which the chamfer is removed with a knife or plane is 45 degrees.

After the cardboard is installed, it is necessary to fill all the gaps between the sheets. Once the seams are dry, start wallpapering or painting. Typically, sheets of drywall are attached to the profile. For better strength it is made of metal.