Types of ceramic tiles and features of working with them

- Actually, ceramic tiles or tiles are the most widespread. It consists of sand, clay and natural minerals. It is fired and covered with glaze, which can have a different texture, receive any color and ornament. Its surface can be glossy or matte. Such tiles have a small thickness, are used for wall coverings, and can be easily cut with a glass cutter, jigsaw, or sharp chisel.

Tile

- Porcelain tiles are durable, thick floor tiles. It is formed by dry pressing and fired at a very high temperature. It practically does not wear out during operation, and is resistant to acids, alkalis and other aggressive environments. It is thicker than tiles and can be cut using a grinder or similar tool, but it is also susceptible to impacts and may crack.

Porcelain tiles

- Clinker is a durable, thick tile with a compacted base. It is made by pressing or, more often, by extrusion, which allows it to be given any shape. It can be glazed or unglazed, wear-resistant, frost-resistant, neutral to aggressive environments, and does not absorb water.

Tile

- Cotto is a durable tile for floors and exterior cladding. It is also produced by extrusion, is not glazed, and has a natural range of colors, from yellow to brown.

Cotto

- Cottoforte is a pressed tile made by double firing. The top side of the tile is always covered with an opaque glaze. These tiles are very durable and are most often used for laying floors in enclosed spaces.

Durable tiles

- Monocottura is a type of pressed glazed tile made from clay. It is strong, dense and frost-resistant.

From clay

- Majolica is a tile with a large-porous texture. The basis of the tile is red clay. The outer side of the tile is always covered with an opaque glaze, and on top of it is a colored image.

With color image

- Faience is a tile whose base is white clay. The outer surface is covered with glaze. These tiles can be used to decorate any surface, the main condition for use is dryness. Next, we’ll look at how and with what to cut ceramic tiles.

How to cut ceramic tiles with a glass cutter at home?

Of course, it is most convenient to cut ceramic tiles with a tile cutter. However, a good professional device is very expensive; it is not profitable to buy it for home use. For small-scale one-time facing work, a regular glass cutter is quite sufficient.

Conventional manual glass cutters come in the following types:

- Pobedite - with a fixed cutter made of cobalt and tungsten carbide. An inexpensive tool of low quality, it quickly becomes dull and cuts unevenly.

- Roller - with a set of round roller carbon-tungsten cutters, which are connected on a rotating plane, from 3 to 6 pieces, for alternating cutting. Makes an even cut and does not dull quickly.

- Oil-based - similar to a roller, but has a reservoir with lubricant in the handle, which reduces friction and helps to obtain a high-quality, uniform cut.

- Diamond is the best type of glass cutter for tiles. Cuts with a soldered crystal equipped with an adjustment screw. The amateur version has an artificial diamond as a cutter, while the professional version has a natural multi-faceted diamond capable of cutting tiles of any thickness.

Differences between glass cutters

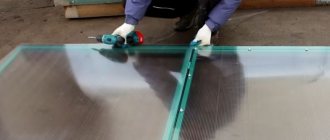

The method of cutting tiles is approximately the same for all types of glass cutters, and is not much different from

trimming window glass. You need:

- Organize your work surface: a flat sheet of plywood, plastic, or a regular tabletop.

- Soak the tiles in cold water for about half an hour.

- Place it face up and mark the cutting points.

- Draw the cut line using a ruler and marker (pencil, sharp nail).

- Press the ruler tightly and draw a straight line with the glass cutter, pressing it evenly and firmly to the surface. The direction of the cut is towards you, from top to bottom from the far point.

- Break the tile along the cut line by placing a strip under it, or use the edge of the countertop, applying pressure to the overhanging part.

- Clean and sand the cut surface.

Cutting

Ways to cut tiles without a tile cutter

Ceramics or tiles, despite their hardness, are fragile. When cutting, bulges may appear on the sides, and the tile often breaks. How to cut material without the help of others, quickly and perfectly, so that the tile does not lose its attractiveness?

There are different methods for cutting clay tiles without using a tile cutter. It is recommended to begin preparation for work by soaking the material in water for 40 minutes. The following fundamental point that should not be ignored. marking. Before you start cutting, you need to make a test cut on a piece of tile. This will help keep the pressure under control and not destroy the material.

READ Adjusting the carburetor of a chainsaw caliber bp 2600 18

Using a sander to cut slabs

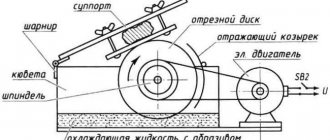

Angle grinder. A common method for cutting tiles without a tile cutter . It can be used to produce perfectly smooth pieces of material with precise dimensions for specific requirements.

She can also trim

profile to the desired size. To get a high-quality saw, you need to use a suitable blade. Available with integral tungsten carbide teeth and coated with diamond chips or chips. The finer the crumb, the better the finish.

How to cut ceramic tiles with a manual tile cutter?

A manual tile cutter is the optimal device for cutting ceramic tiles at home. For one-time applications, it is enough to use a glass cutter, a chisel, and even a nail. But if you have a major renovation project involving tiled or ceramic tiles, it makes sense to purchase this tool.

What is a manual tile cutter?

- The base is the supporting base for all other elements of the tile cutter.

- Guides for moving the cutter.

- The cutter or cutting element is a roller made of hard metal with a sharp edge, mounted on an axis.

- Handle for moving the cutter along the cutting line.

This device has significant operational advantages:

- Ease of use due to its simple design.

- Using the handle as a lever, optimizing cutting force.

- Precise and smooth cut.

- Versatility - can be used for both ceramic and tiles.

If you do not have experience with a tile cutter, we recommend that you first practice on unnecessary, split tiles to learn how to cut the tiles evenly and beautifully.

So, how to cut ceramic tiles?

- Draw a cut line on the front surface with a marker or pencil.

- Fix the tile relative to the cutting element using special clamps or your free hand.

- Apply a drop of machine oil to the roller to reduce friction and achieve an even cut.

- Raise the handle and bring the roller into contact with the front surface of the tile.

- Smoothly move the handle towards you, trying to maintain optimal pressing force. Insufficient pressure creates a cut of insufficient depth, and excessive pressure leads to cracks in the front surface.

- Remove the cut tile from the tile cutter and, placing it with the cut along the edge of the table or placing a flat strip, break it off along the cut with sharp pressure.

- If necessary, clean the edge with sandpaper or a stone.

Cutting process

Alternative tools and their features

Let's look at the most popular methods for cutting clay or porcelain tiles of applicable properties. This includes:

- Bulgarian woman with a huge disk. There are a number of types of these tools that can be used to cut ceramics. To do this, buy the appropriate diamond blade. There are several varieties on sale, depending on the grain size and cleanliness of the cut.

- Electronic jigsaw. This is a successful and very convenient tool with which you can make a clean cut, but to do this, purchase a special tile file. His virtues. versatility, in other words, you can make curved cuts with a huge radius.

- Manual glass cutter. Suitable for cutting smooth glazed tiles.

- Drilling holes with a drill. This is a successful method, but to obtain a high-quality end after cutting, you need to go through the area with additional grinding tools, for example, a file and sandpaper.

Figured breaking out

From time to time it is necessary to make crooked mowing strips. The mowing line can be not only straight, but also semicircular. These breaks are more problematic when they do not start at the edge. In such cases, you will have to first make a hole and then break out of it later.

For figured breaks, it is recommended (if possible) to use the deepest risk using any method along the entire breakout boundary. This will reduce the number of possible chips.

Figured breaking of tiles.

There is a special tool for breaking it out. pliers with a wheel. But for one-time work it is not advisable to obtain a special tool. Therefore, you can get by with ordinary pliers.

Developing a hack is very ordinary. The pliers (or pincers) are very compressed, the material crumbles or contracts and turns over sharply (only far from the bevel line of the tear, more than 5 mm). Small pieces break off. If you try to break off a large piece right away, you can ruin the whole job. A part may break off beyond the risk line.

Long, straight and narrow pieces throughout the tile are broken off by sharply turning the pliers to the side. If you previously clamped them along the mowing strip, you run the risk (of course there should be a scratch). With all this, the tile may not break off along its entire length and the function will have to be repeated on the remaining part. Then they also carefully break off the remaining sharp protrusions.

The most common method. take a chance and get into a sharp corner. This way you can easily and quickly prepare most of the parts.

Sawing is used if you do not want to cut a piece along its entire length. In this case, several sides are cut off, and one is broken off along a solid rod or through clamps.

Focus on: glass cutter and other tools

To cut narrow (three mm wide) clay tiles without using a tile cutter, tools with a pointed cutting edge are also used. glass cutters, drills, knives and other devices.

To mark with these tools, use a ruler and apply a scratch to the top layer of the tile. It is recommended to make the cut on your own, without interruption. It is necessary to control the force of pressing on the tool so as not to destroy it and the material. After making the cut, break the tile on the edge of the table.

Nippers are used for making shaped cuts on clay tiles. First, it is recommended to mark the outside of the material with a marker. Then you need to start biting off small pieces of material from the edge of the tile, squeezing the nippers. If necessary, use file and sandpaper to make the edges of the tiles smoother.

Applying a figured cutout with pliers

How to cut tiles

Experts say that cutting tiles is most convenient with a tile cutter, because the tool was created specifically for these purposes. To obtain a straight cut, a cutting line is first applied to the tile with a pencil or felt-tip pen. The tiles are placed on the base of the tile cutter, aligning the wheel and line. Then you need to lift the handle until the wheel touches the tile, and then move it towards you with a little effort. To obtain a high-quality cut, you only need to make one pass around.

READ How to Cut Ceramic Tiles on a Wall

After the tile is cut, it needs to be divided into two parts. To do this, “wings” are installed in the area of the lower third of the tile, which can be sealed with tape so that they do not leave marks. Now you can hit the handle a little with your palm or apply more force if the tile does not crack on the first test.

If during tiling the cut is overlapped by another tile, there is no need to sand the edge. But for laying in the inner corner, a straight edge is required. To sharpen the cut, use a special grinding stone (selected depending on the type of tile) or sandpaper.

How to cut ceramic tiles with a grinder?

It is very convenient to use an angle grinder or, in common parlance, a grinder for cutting ceramic tiles at home. It can cut any tile – tile, porcelain tile, clinker, cotto. With a grinder you can make not only straight cuts, but also figured ones, and even cut holes in the tiles. It is best to use a small, not very heavy tool with a power of up to 1 kW. It is very good if the grinder has a disc rotation speed regulator.

What disc should you use to cut ceramic tiles with a grinder?

- Almost any disc is suitable for one-time use. However, if you have a large volume of facing work to do, it is better to purchase the most suitable one.

- The optimal choice would be a steel disk with a diameter of 125 mm, diamond-coated, and at least 2 mm thick.

- A thinner disc is less stable when working manually; it can create an uneven cut, break and damage the tile.

Based on the type of cutting edge, the following types can be distinguished:

- Segmented - diamond coating is present on the cutting edge itself. Thanks to the presence of segments and slots, partial cooling occurs directly during operation, and the continuous cutting time increases to 1.5 minutes. This disc is used for dry cutting only.

- Solid - has a coating over the entire cutting edge, along the rim. It requires water cooling - periodic wetting of the tiles or the use of a spray bottle. The result is a very neat cut, better than using a segmented disk.

- Combined - combines the characteristics of the above-mentioned discs. Can be used for both dry and wet cutting. Compared to segmented ones, they cool worse, and compared to solid ones, they have worse cutting quality.

Grinder

Using a grinder, you can make different types of cuts:

- Straight - the usual cutting of tiles in half or into unequal parts, into rectangular parts of tiles of any type: tiles, porcelain tiles, ceramics. To ensure an even cut, secure the tiles well with clamps or, for small cuts, use a workbench.

- Shaped cut or round holes with a diameter of 50-100 mm. The contour of the cut (circle) is marked on the front and back sides, a line is cut that approximately corresponds to the circle, albeit uneven, but not extending beyond the circle. Then segments inside the circle are cut according to the diameter. The inner segments are broken out with pliers, the edges are aligned, and then they are polished.

- A bevel is a cut of a tile at an angle. In this case, a regular straight line cut is made, then the tile is fixed and the ceramic layer is cut off at the desired angle without disturbing the outer cladding.

It is recommended to take advantage of the invaluable experience of specialists

To cut material when carrying out facing work at home, you must have the following tools:

- flat surface;

- a guide ruler with a right angle at one end, the so-called “square”;

- drill with a pobedite tip;

- glass cutter, stationery knife;

- “tweezers with a tile cutter function” - miniature tongs with a wheel for cutting tiles on one side and a transverse convex plate on the other;

- drill with attachments in the form of “crowns”;

- jigsaw with diamond wire;

- "Bulgarian".

It is important to remember that the tile material should be prepared before cutting. If you soak ceramic tiles for thirty minutes before working with them, you can solve the problems of dust, brittleness and increase their pliability.

To properly cut off a piece of tile, you need to make a clear groove on the glossy surface and then break it with a quick, confident movement. This can be done easily using different tools: a glass cutter, a drill with a Pobedit tip, a cardboard knife and a guide ruler. The procedure will be the same in all cases:

Glass cutter is the most affordable tool for cutting tiles

- Place the tiles on a flat surface with the inside down;

- make the necessary markings and draw a clear line with a pencil using a “square”;

- draw a groove along the ruler, pressing with medium force on the glass cutter or drill;

- Place a drill under the cut line, press on the tile on both sides and break it. Alternatively, you can break the tile by placing it on the edge of the table along the cut line and pressing sharply on it.

With the help of “wheel tongs” it is much easier to break tiles, since they are specially designed for this. It is enough to place the transverse plate on top so that the cut groove runs exactly in the center of the pressing plate, and then squeeze the forceps. In this case, a high-quality fracture is obtained.

Clamp the tile with pliers in the center on the marked line and press down on the handles

At home, you can make fairly suitable tools for cutting tiles if you cannot use a special tool. For example, a drill with a pobedit tip with a diameter of 6 or 8 millimeters can be sharpened on a diamond disk like a pencil. The main thing in this is not to grind off the pobedite layer and make a point without edges. The rounded shape of the tip allows you to make deep cuts when applying it to the side of the “square”.

All of the above methods are suitable for cutting wall tiles, but in cases of working with thicker floor tiles that have a dense structure, it is necessary to resort to the help of other tools.

For example, it is advisable to use a grinder along with improvised tools. At the same time, in order to complete it, the most suitable discs for cutting granite with a smooth crown and diamond discs, which allow you to quickly cut tile material.

The cutting process with a grinder is quite simple and accessible even to non-professionals

The sequence of work may be as follows:

- First, you need to draw a fairly deep line with a glass cutter or a special drill. To do this, you can run it over the outer surface several times.

- Then, using a grinder, you need to start carefully cutting along the outer edge of the cut. In this case, it is advisable to go deeper no more than 3 millimeters. By performing this procedure 2-3 times, you can get a high-quality cut.

Cutting floor tiles can be done in another way:

- We also draw a furrow on the glossy surface using the same available tools.

- We turn the tile over and make a cut with a grinder on the inside exactly along the outer marks.

- After breaking, it is recommended to sand the edges using sandpaper.

Straight and shaped cutting of tiles can be done using a grinder with a diamond blade. The productivity of such work is comparable to an electric tile cutter. Although the quality of the cut using a grinder is inferior, if you need to carry out large-scale mobile work, this tool is indispensable. After the cut, additional sanding activities will be required.

Can I use a jigsaw to cut ceramic tiles?

The advantage of this tool is that it creates a perfectly accurate and even cut, and also makes it possible to cut into very complex shapes.

- The electric jigsaw works quite quickly, and the quality of the cut is quite satisfactory. Speed and accuracy depend on the grain size of the file - the higher it is, the greater the speed, but the worse the quality of the cut. A fine-grain jigsaw blade for ceramic tiles cuts cleaner, but slower.

- Usually a jigsaw , but for particularly critical moments, where a cut of a very complex shape and high quality is required, a hand tool is used. Its speed is several times slower, but the quality is much higher.

- It should be taken into account that any jigsaw can only be used with low-density wall tiles . A jigsaw is not suitable for porcelain floor tiles.

So, how to cut tiles with a jigsaw?

- Prepare a work space - a flat table on which most of the tiles to be cut will be located, clamps for securing the tiles, a marker or pencil for marking.

- Soak the tiles in cold water for 1-2 hours.

- Start cutting ceramic tiles at low speeds, using medium pressure.

Cutting with a jigsaw

When working with a manual jigsaw, the technology remains the same as with an electric one, but cutting is done manually, with a special diamond-coated file and much longer. In general, working with a jigsaw takes more time, but at the same time gives an excellent result.

Alternative tools and their features

Here are some of the favorite techniques you'll need. So, they cut clay tiles using the following tools:

- Bulgarian. This is a hand-held grinding machine, which, when changing the attachment, is used for cutting metal, wood, tiles and other materials. She even copes well with porcelain stoneware. The work uses a diamond-coated disc.

- Glass cutter. This hand tool is the size of a regular pencil. Despite its miniature size, it works well with tiles, namely glazed ones. But he asks for clarity and conviction in actions.

- Drill. This tool is used to create holes and fillets. An ordinary drill or special attachments, such as a crown or a dancer, are used.

- Pliers. The sharp edges of the tool can cut through the top layer of the tile and create a fracture line. True, this will take a lot of time and effort.

Basic tools for cutting tiles

They also use a jigsaw, a circular saw with a special disc, and even an ordinary sharp nail.

How to cut ceramic tiles with a nail?

- If there is no special tool for cutting tiles in the house, and at the same time there is a need for such work, how can you cut ceramic tiles? A regular nail may be suitable for this purpose.

- The nail must be at least 100 mm (one hundred square meters) and of appropriate thickness. Old Soviet steel nails are more suitable, but in any case, one nail is only enough for 5-7 tiles, then it needs to be replaced.

- And yet, you can only cut wall tiles with a nail, but not porcelain tiles.

The technique of cutting with a nail is not much different from similar work using a glass cutter or cutter:

- A line is drawn along the front side of the tile using a nail and a metal ruler (slat).

- The cut should be smooth and as deep as possible.

- You can make 1 more cut from the back side of the tile, but maximum accuracy must be observed.

- The tile is carefully broken along the cut line in the usual way.

- Most often, the cut line needs to be cleaned and sanded.

Using a nail

As you can see, there is nothing complicated, but it’s still better not to abuse it this way. It is quite tedious, and the quality of the cut is not very good; a lot of effort will be spent on finishing.

How to make a rounding

Sometimes tiles are prepared for installation around pipes or plumbing fixtures. Then the question arises - how and with what can you cut tiles in shapes without a tile cutter.

Processing is carried out in several ways:

- using a drill;

- pliers;

- grinder;

- jigsaw;

- glass cutter.

How to get by with just pliers? For this purpose, draw a line. They make the task easier by scratching it with a nail. Then take the tool and start breaking off the unwanted material in small pieces. Wire cutters with carbide clamps work best for this task.

Inconvenient areas and curly cuts are made with pliers

As for the drill, regular drills are used to mark the outline, and then the excess is broken off with the same nippers. A more effective way to make holes of any diameter is to use special attachments: feather, ballerina, crown, etc.

Waterjet cutting of ceramic tiles at home

For the sake of fairness, we note that waterjet cutting of ceramic tiles is the aerobatics of processing porcelain stoneware, as well as hard stones. The cut is perfectly smooth, does not darken, and does not require sanding. Using this method, you can cut out any shapes you like and create artistic compositions from tiles. None of the other known methods gives such an excellent result.

- The principle of operation of such a tool is to supply a mixture of water and abrasive material under enormous pressure. The feed speed of such a mixture reaches 1 km per second, which is why this result is achieved.

- It is clear that such work requires special equipment. Waterjet cutting is performed on special machines, that is, on massive and rather expensive equipment. A similar machine can also be purchased and installed in a home workshop to perform very high-quality work for yourself, as well as to order. If you learn to work well on such a machine, you can earn good money from orders.

Significant advantages of waterjet cutting:

- Porcelain tiles up to 30 cm thick can be processed.

- Unsurpassed cutting quality.

- Performing cuts of any complexity.

- The edges of the cut have virtually no roughness.

- Using water for cutting and cutting eliminates the possibility of ignition and explosion of the surface being processed.

Waterjet cutting

When cutting ceramic tiles using waterjet cutting at home, you must strictly follow the instructions. And it, in turn, will be attached to the equipment. Accordingly, instructions for use for different equipment will be individual.

How to cut ceramic tiles at home?

Surely you have already realized that cutting ceramic tiles with improvised means is quite simple, if, of course, we are talking about straight cuts. But what if you need to make shaped cuts, but purchasing a special waterjet machine is not part of your plans?

Then you can get by with a set of fairly simple and inexpensive tools:

- Special pliers or nippers - used for slight curvature of cutting. A straight line is cut in the usual way, and then small pieces are cut off with pliers until the desired shape is formed. Then the cutting area is thoroughly cleaned and polished.

- A ballerina for holes is a special tool, similar to a compass, which is inserted into a drill. The tip is placed in the center of the future hole, and the cutting edge, when rotating the cartridge, cuts out a circle.

- A jigsaw, electric or manual, is designed specifically for cutting particularly complex curved lines. In this case, much better results are achieved with a manual jigsaw.

- A hole saw is also an attachment for a drill, but it does not have a straight cutting edge, but a ring with many teeth. When using a hole saw, be careful not to overheat the tiles.

- Glass cutter - a tool with rollers of different diameters is used.

Figured

It is advisable to use tiles with chipped edges and small chips for figured cutting. They work with it in such a way that this defect ends up exactly on the part being cut off. This will allow you to save a little money and save full tiles for other work.

Some tips about forgotten technologies

Are you going to lay the tiles yourself? Please note that this process is very labor intensive and will require some experience from the contractor. Beginners should be given some practical advice: if you are using a grinder to cut tiles without a tile cutter, then do not make sudden movements, because the diamond-shaped circle will damage the part that should remain clean.

Also follow safety precautions and always use personal protective equipment against dust for the respiratory system and eyes. The fragments can damage the cornea, and the dust can clog the airways.

How to cut ceramic tiles at home, without a tile cutter: safety precautions

- The tile cutter is the optimal tool for home work on processing tiles and ceramic tiles. It is not as expensive as a special machine, and at the same time gives good cutting quality. However, you can completely do without it using all the previously mentioned methods.

- It should be remembered that working with tiles is quite dangerous, and certain precautions should be taken. When working with a power tool, follow the instructions for it, watch the moving parts - cutters, discs, saws. Take care of your hands.

In addition, there is a danger of small sharp fragments and ceramic dust flying away. Therefore, it is necessary to use the following protective equipment:

- Eye protection glasses

- Clothes with elements that cover the body - high collar, long sleeves and trousers

- Work gloves for hands

- A respirator is desirable.

- When working with large pieces of tile, you must wear a hard hat

- When working with power tools for long periods of time, wear noise-isolating headphones.

As you can see, cutting ceramic tiles at home is accessible to almost everyone and is not particularly difficult. There is always the opportunity to make beautiful wall and floor cladding at home with your own hands.

Articles about the interior:

- Glass furniture in modern interior design

- What you can do for the interior with your own hands at home

- Pop art style in the interior

- High-tech design in the interior

- Apartment interior: top 100 most useful planning tips