April 12, 2019

Among the variety of finishing materials used in construction, plastic panels occupy a separate category. This is a modern coating that is used for finishing interior and sometimes exterior walls. They are made from polyvinyl chloride using the extrusion method. Before carrying out installation work, it is important to decide: what is the best way to cut PVC panels. The range of tools and devices offered on the market is rich in offerings for both general and special purposes. Among all the equipment, you can choose what will be used to cut plastic panels.

How to cut PVC panels

Plastic finishing material can be cut both lengthwise and crosswise. Of course, the main workpieces are cross-cut. When you need the sewn surface to be completely covered, you have to use a longitudinal cut. Before performing work, it is determined how to cut plastic panels at home or at an industrial facility. The number of blanks required for covering the surface of the walls is of no small importance.

Using many years of experience in using PVC materials in interior decoration, we will highlight what can be used to cut plastic panels:

- construction knife;

- hacksaw for metal;

- Bulgarian;

- jigsaw;

- cutter;

- wood hacksaw.

Using any of these tools will help solve the question of how to cut PVC panels, but each of them has features that need to be taken into account when performing work.

Jigsaw

This tool can be called the main one. A jigsaw is good for everyone and has a minimum of disadvantages. Panels can be cut lengthwise and crosswise. You can cut shapes with ovals and other broken things.

The jigsaw has a special feature. It tears the edge of the panel in places where there is very little to cut. At this time, very often the panels burst (especially in cold weather).

Therefore, it is worth using a file with a minimum tooth. For ourselves, we chose a Bosch metal blade with a 0.8 mm tooth. This file will protect you as much as possible from a torn cut.

If the jigsaw operates at high speeds, you can cut with such a file very quickly. This file is for metal and does not become dull when cutting plastic products.

The main advantage of a jigsaw is its versatility. You can cut PVC panels lengthwise and crosswise. In any spatial position.

The downside of a jigsaw is its weight and the presence of a wire. If the blade is chosen incorrectly, the cut will be torn.

There is one secret

When you have to prepare a lot of frame-sized sticks. For example, you need to cut 20-30 pieces at once.

And so as not to cut one thing each time, but to increase the speed. You can resort to one secret.

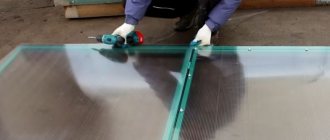

You will need clamps (presses) as in our photo. Take several at once, usually 5 pieces. Adjust them so that they do not stick out from each other and clamp them with presses. Two pieces on each side of the panel.

And cut quietly. In this way you can cut up to 5 panels at a time. You can cut more, but the Bosch file does not allow this.

You will speed up the cutting process five times and make your work easier.

Construction knife

In any household you can find a kitchen knife, sharpen it and use it to solve the problem rather than cutting off a plastic panel. But, to obtain a high-quality cut, it is better to use a construction or stationery knife. The replaceable blades that come with the tool will allow you to get a flat, smooth surface. Cutting using a knife is faster than using sawing devices. But when you have to deal with the cellular structure of plastic panels, using such a tool becomes inconvenient.

When using a construction or stationery knife, mark the panel, then lay it on cardboard or leave the cut part hanging. After this, pressing through the front and back sides of the finishing material, unnecessary parts are separated. If there remains a large area of unclaimed plastic part, then it is better to place or place a support under it to avoid breaking or distortion of the workpiece.

Which tool is suitable for cutting plastic panels?

Finishers have many ways to cut plastic in their arsenal. And everyone who carries out repairs on their own can choose any of these methods, use professional tools or improvised means, based on their needs and capabilities. Let's take a closer look at all the pros and cons of each method:

Plastic cutter. Sold at any hardware store. With its help, you can make an absolutely even cut on a PVC panel without much effort.

The only downside is that it only cuts in a straight line, so you won’t be able to make rounded cuts. If desired, you can construct the cutter yourself - from a strip of metal about 1 cm wide and 2 mm thick. One side will need to be sharpened at an angle of 45 degrees, and the handle will need to be wrapped with electrical tape so as not to cut your fingers while working.

Hacksaw

For plastic, a tool with small teeth is suitable; pay attention that the teeth on the blade are not spread in different directions. This way the cut will be even and smooth, the plastic will not become frayed.

It is convenient to use a hacksaw to cut several panels at once, stacking them on top of each other.

Jigsaw. With it, the process of cutting panels will be much faster than with a hand tool.

But there are some nuances of working with a jigsaw:

1. You should immediately turn off the pendulum stroke. 2. use a file with fine teeth. 3. adjust the speed of the saw (choose the lowest so as not to melt the cut). A jigsaw will do an excellent job of cutting stacked panels, the main thing is that the height of the stack does not exceed the length of the file.

Bulgarian. The most convenient tool for cutting PVC panels, using a grinder with a cutting disc you can make both straight and shaped cuts.

It must be remembered that when cutting plastic, the tool must operate at the lowest speed, otherwise the cut edge will melt and the panel will be damaged.

Knife. If you don’t have a more convenient tool, you can use a simple kitchen or stationery knife. The narrower the knife blade, the easier the cutting process will be.

A bread knife with a serrated blade is ideal; it leaves a smooth edge without breaking or fraying.

Hacksaw

If, when performing finishing work, the question concerns how to cut the panels evenly, then for such a case, it would be correct to use a hacksaw. When the edge of the panels is hidden from view by the starting or corner finishing profile, then use a hacksaw. If the cut area remains visible, use a metal tool.

When choosing what to cut plastic panels with, pay attention to the ease of performing the work. When using a hacksaw on wood, the workpiece will vibrate a lot and will need to be held firmly. And when using tooling for metal, the vibration effect will be little noticeable, but the tool will need to be held almost parallel to the plane of the workpiece. This is due to the thickness of the blade holder, which is larger than the blade.

In both cases, the panel is placed facing the cutting tool so that all chips and imperfections remain on the wrong side.

Rules for cutting panels

If the panels are just brought in from the street, especially if the temperature there is low, in this case you cannot immediately begin work. They need to warm up for some time, since when cold they become even more fragile and the material can easily be damaged.

Before you start cutting, you need to mark where the cuts will be. A felt-tip pen is best suited for these purposes. It is clearly visible on the panel and can be easily washed off later.

While working, we must not forget about safety precautions; it is better to wear gloves and goggles. The thing is that when the panels break, they form very sharp fragments, and there is a danger of getting hurt by them.

In general, this material is very fragile, so you need to work with it very carefully and carefully. Therefore, if someone else is asking themselves: “How do they cut plastic panels?” - then we can safely say that there are many options

And in the end you will definitely find the most suitable one.

Therefore, if someone else is asking themselves: “How do they cut plastic panels?” - then we can safely say that there are many options. And in the end you will definitely find the most suitable one.

6 Best Dog Breeds for Families with Young Children Many families decide to get a dog around the time they have their first child. But which dog breeds are best for families.

What is it like to be heir to the royal throne? 7 Surprising Facts Royal heirs are entitled to a range of benefits, but until recently these were also limited by ancient traditions formed over time.

How to tell your daughter or son that there will be another child in the family. Are you expecting another child? Congratulations! You might want to share this joy with your family and friends, but what about your older children? When

11 Weird Signs That You're Good in Bed Do you also want to believe that you please your romantic partner in bed? At least you don't want to blush and apologize.

15 most beautiful wives of millionaires Check out the list of wives of the most successful people in the world. They are stunning beauties and are often successful in business.

10 mysterious photographs that will shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures captured were truly incredible.

Cutter

This device is convenient when speed and high-quality cutting of the end of the workpiece is important to solve the problem. The speed of operation of such a tool is high, while the quality is better than any of those described above. But, during work, you need to carefully inspect the panel for possible chips and lay it inside out towards the cutter, and with its face towards the supporting surface. This is due to the fact that the cutter can push the surface of the PVC workpiece by 2-5 millimeters.

The tool simplifies and speeds up installation work. Buying a cutter will forever close the question of how to cut a plastic panel, and other methods will no longer be relevant. When using it, it is important to remember that it will not be possible to trim in place with such a tool.

We cut other types of panels

Cutting MDF differs from cutting chipboard panels. The high density of the material quickly dulls the saw teeth, so it often has to be sharpened or completely replaced. Unfinished MDF can be cut using a conventional machine, but laminated board requires a machine with an additional bottom saw

This is especially important when cutting slabs with a double-sided finish coating.

Fiberboard can be cut at home using an electric or manual jigsaw. Of course, the file must be sharp, with a fine tooth; the jigsaw must be set to maximum speed. Install the fiberboard horizontally on a support that should not interfere with sawing (between two tables or chairs, for example), secure it with clamps if necessary.

The electric jigsaw should be held with both hands, pressed firmly against the surface, and moved smoothly, strictly along the marking line, without jerking or pressing. The same applies to working with a hand jigsaw.

In cases where it is necessary to cut many sheets of material, it is more convenient to contact a specialized company. This will save you time and effort.

Jigsaw

Using such a power tool will help you cope with cutting panels and will reduce labor intensity compared to a hacksaw or construction knife. It is convenient to use a jigsaw when preparing a large number of workpieces.

When performing work, the cut location is first marked on the front surface, and then smoothly cut to the required size, drawing the tool along the marking line. Cellophane or other material is placed under the support foot of the jigsaw to prevent scratches on the PVC panel. In the case of simultaneous cutting of several workpieces, they are held together with plastic clamps or wrapped with transparent tape. In this case, it is better to isolate the front surface from tape (lay a sheet of paper).

How to cut PVC panels correctly?

When cutting, place the panel on the front side

. To successfully cope with the task, it is worth knowing some secrets of cutting plastic. This will significantly reduce the number of rejected and damaged panels, and will save the novice craftsman from wasting time, money, and, above all, from injury.

- If you are carrying out finishing work in the cold season, do not cut panels that have just been brought in from the street. Let them warm to room temperature. The best option is to keep them at room temperature for at least 1 night. Otherwise, the plastic, which becomes brittle in the cold, will break off in large pieces, and cracks may appear along the entire length of the panel.

- Regardless of which cutting method you choose, the panels should be placed face up (photo above), otherwise the panel may become deformed and its installation will be difficult. In addition, if you make an incision from the inside out, the front side may become covered with microcracks, which will only reveal themselves over time, ultimately ruining the design. It will not be superfluous to mark the cutting line in advance; a simple pencil or felt-tip pen (which can easily be erased from the surface after finishing work) and a student’s ruler are suitable for this.

- To cut several PVC panels at the same time, you need to stack them and provide a two-point support for this stack so that the panels do not sag. It is also worth resting the opposite edge of the stack against the wall, otherwise the panels will move during cutting and you will end up with parts of different lengths.

Bulgarian

To carry out such work, using a large angle grinder will be inconvenient and unnecessary. A small grinder with a thin metal disc (0.8-1 mm) is best suited.

If it is necessary to simultaneously cut a large number of panels, they are fastened together and markings are applied. The cut is made from the front or back side. The quality of the end is obtained without defects. This power tool allows you to efficiently cut a panel or several at once.