What is done with a milling machine

The machines are used to work out cutting lines on wood, plastic, metal, or cutting these materials.

To understand what tasks can be performed with a milling machine, you need to understand what milling means. This is a method of processing a certain material, which is carried out with a milling cutter (a cutting tool with cutting teeth). The cutter is mounted in a special machine, which at high speed directs the blade in the desired direction, cutting off layers of a certain material.

What can be built on the machine:

- furniture;

- various architectural models (houses, scenes);

- toys;

- souvenirs;

- sculptures;

- decorative boxes;

- chess sets;

- skirting boards;

- cornices.

This is just a small part of what can be made on a milling machine. The complete list will depend on the skill and imagination of the manufacturer.

Who needs a home router?

Before going to the store, you need to determine the range of tasks to be completed. There is no point in purchasing a compact model if you need to process hardwood, but it is ideal for occasional household use.

A home router is necessary for people who often process various surfaces. When purchasing, you must take into account the availability of equipment that comes with the kit. It is advisable to purchase a universal set, which includes edge, base, profile and spiral elements.

Important! If a home craftsman will often use the device, then it is additionally necessary to purchase special copying sleeves and collets.

Types of hand routers

Hand-held devices come in 5 varieties. Each type has its own design features that affect the scope of application.

Manual type of equipment

The most common types of hand routers:

- Submersible. This is a universal device, characterized by high reliability and quality workmanship. This type of equipment is used to perform all types of milling work.

- Edging. Used for chamfering, as well as forming small recesses and depths. Used for decorative works. Such a tool is not used for domestic purposes.

- Rotary is used in construction work. The tool is used to process edges and make holes in plastic, wood or drywall.

- Lamellar is a specialized router designed for making grooves. This is not a universal tool, and therefore should not be purchased by beginners.

- The filler is another specialized device with which you can carefully make paired holes, which will subsequently be connected to each other. This tool is also not used in everyday life, and in most cases is used to make various furniture.

The choice depends specifically on the specifics of the master’s work. If you need to use equipment at home, then first of all pay attention to a universal tool.

Important! Certain samples are quite universal, while others are professional tools that can only be used to perform a narrow range of work.

Choosing a manual router

First, let's look at the design features:

- vertical stroke of the electric milling machine. It is 40–50 mm for low-power, 50–60 mm for medium-power and 60–70 mm for high-power tools;

- maximum lowering. A good tool goes down completely;

- presence of a speed controller. It allows you to competently use cutters of different diameters without causing burns during work;

- maintaining speed under load and dynamic braking function. On expensive devices - a good addition, but not necessary when choosing;

- ability to work with copy rings/bushings;

- dust removal system. It is desirable that there is a possibility of quick removal;

- milling depth limiter and rigid milling depth setting;

- cable. Pay attention to its length, thickness, flexibility. Preference for rubber cables.

Make sure there is no play during operation. To do this, place a long cutter and start shaking the power tool; there is no need to fix it. There should either be no play or be minimal, because this can lead to the cutter breaking off during operation and unknown consequences.

Edge routers

There are two types of routers: plunge router and edge router.

In a submersible router, it is possible to lower the router to a selected depth into the material. Then we fix it and start working. In edging there is no such possibility. It works according to preset parameters. Example of working with an edge router:

- We set the milling depth.

- We fix it.

- We set the parallel stop.

Basically, this router works along edges. The milling depth cannot be changed during the process.

Manual filler mill

A highly specialized tool for creating paired holes intended for connecting parts on dowels. Used in furniture production.

Small router

Such a power tool will be the optimal solution for almost any case. Even if its power is sometimes not enough, it is better to make a few extra passes than to struggle with installing a heavy tool.

If you have to make boxes or small frames, then a small router will suit you; you should not take the tool “with a reserve”.

How to choose the right manual wood router for your home

To purchase a quality device for home use, you need to study 4 criteria.

Power

This is one of the main parameters that affects equipment performance. Depending on the power, milling cutters are divided into three types:

- Easy. The power is up to 750 kW, and the weight of the milling cutter itself does not exceed 3 kg.

- On medium-sized milling machines, the power increases to 1.5 kW, and its weight is approximately 5 kg.

- Heavy devices have a power of 2.3 kW, and the weight can exceed 6 kg.

Medium routers are suitable for home use. Heavy tools are in most cases used in production, where it is necessary to perform specific and rather complex operations for a long time without interruption.

Important! You should not chase the most powerful pieces of equipment for your home, since the dimensions of the devices will be very large, and therefore it will become much more difficult to manage them.

Medium router - ideal choice for home

Spindle speed

The parameter directly affects the quality of the processed part, as well as the choice of material with which to work. Milling cutters have three speeds - standard slow and high:

- The standard mode operates at 20-30 thousand rpm. These are the most popular samples that can handle most materials.

- Slow devices typically have a speed of 10,000-15,000 rpm. Such devices are usually used for working with plastic.

- High speed exceeds 35000 rpm. Routers are suitable for processing the hardest surfaces.

Important! When purchasing the cheapest devices, it is necessary to take into account that the rotation speed will not be adjustable, which will affect the quality of processing.

Working stroke

The working stroke refers to the depth of processing. The cheapest samples can dive to about 50 mm, and the most powerful and professional ones - up to 80 mm. The longer the working stroke, the deeper you can dive into the working surface, and the more difficult the operations can be performed.

Additional options

When purchasing, it is advisable to pay attention to additional options that will increase safety when working with equipment:

- Overload protection. All electronic devices become hot during operation, which can create a dangerous situation, and protection will help prevent this. Most professional models are equipped with this function, since they are subject to prolonged load. Overload protection varies: on the most expensive models it is an automatic power off, on cheaper models it is a light indication.

- Protection against unintentional activation is an additional button, without pressing which the router simply will not work.

These are the main additional options that will be useful for safe operation of the device. But there are also options to improve ease of use.

How to choose a manual wood router

Types of hand routers

- Submersible (vertical) - a universal model designed for different types of work: forming holes and grooves, removing chamfers. Used by both professionals and amateurs.

- Edge trimmer – designed for processing grooves, creating grooves, and removing chamfers. Relevant for regular use by professionals; in everyday life, these works can be performed with other (more affordable) devices.

- Rotary – suitable for creating holes in wooden parts, drywall, plastic, ceramic products. Can shape edges.

- Lamellar - intended only for creating grooves.

- Filler - used to form paired holes, in demand in furniture production.

Important criteria

- Power. The optimal value is 1800-2000 W, if more, the device will be heavy and less convenient to use. If a router is required for occasional manipulations in a garage or country house, a model with a power of 600-700 W is suitable.

- Setting the speed. This function makes the device more versatile: 20,000 revolutions for solid wood products, 10,000 for plywood and plastic.

- Milling depth. For simple models, this value is 50-55 mm, which is enough for domestic needs. Professional devices have a cutting depth of up to 80 mm.

- Maintaining constant speed under load is required to protect the engine from overloads and makes working with material more predictable.

- Collet size. The element is necessary for fixing the milling element: the more collets of different sizes in the set, the more different cutters can be attached.

- Vacuum cleaner connection – allows you to connect equipment for removing dust and chips. A very useful feature when working indoors.

- Weight – modern models weigh about 4 kg. Devices that are too heavy are inconvenient to use, especially if delicate work is required.

Minor Criteria

- Soft start - this function is necessary when using powerful milling cutters; it may not be available in inexpensive devices.

- Spindle lock – makes it easier to change the cutter, but is not a required feature.

Criteria for convenient work

Modern electronic devices are equipped with additional functions that greatly simplify work. Next we will look at 4 major additions in this area.

Working stroke

This function allows you to go deeper into the material being processed. The longer the working stroke, the more complex operations can be performed with the router and the more beautiful the final result will be.

Working stroke

Smooth start

If the router is quite powerful, it is advisable to make sure that it has a soft start system, thanks to which the engine will pick up speed slowly, and therefore the risk of sudden jerks will be eliminated.

Rip fence

The stop should be placed to the side of the router. These are small metal rods that are attached with screws to the base of the equipment. The emphasis is necessary to increase comfort during work. This addition allows you to carefully guide the cutter along the workpiece, maintaining the required distance from the edge.

Connecting the vacuum cleaner

Many routers are equipped with a special mount where you can attach a small bag to collect dust. The function is designed to protect against dust getting into the eyes and respiratory tract.

How to choose a router

Despite the apparent complexity of the machine, it is a very simple electrical tool. The equipment here is attached directly to the motor shaft (in other words, to the spindle). Thus, the design does not require different gears, gearboxes and belts. Direct transmission accelerates the cutter to maximum speed. Serious demands are placed on the mass of auxiliary devices necessary for feeding accuracy and productive sampling. They will be discussed further.

Power

The stronger the power, the greater the performance. However, a larger cutter entails a significant increase in the weight and size of the device. Many “delicate” rigs do not handle high torque well. According to power, milling cutters are divided into:

- light – up to 700 W;

- medium - from 700 to 1500 W;

- heavy - over 1500 W.

There are also models with 2.3 kW: for example, DeWalt DW626 or Makita RP 2300FC. The cutting depth of such machines increases to 70 mm.

Speed

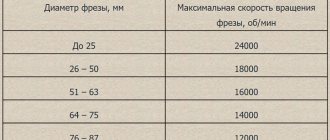

This characteristic is inversely proportional to the diameter of the recommended equipment. A large cutter operates at a lower speed than a small cutter. Low rotation speeds are used when processing metal and plastic to prevent melting or overheating. That is, when choosing a router, you need to pay attention to the speed limits.

The higher the rotation speed, the easier it is to work with hard materials and the cleaner they are processed. For high accuracy with more viscous raw materials, a lower speed is more suitable. Therefore, most milling cutters are adjusted by preset rotation speed - up to 8 positions using a special wheel. Choosing the required speed comes with experience, although the developers suggest the required values in the data sheets or on the cutters themselves.

"Submersible" mechanism

The most popular now are top plunge routers due to their versatility. The working mechanism in the head part moves smoothly up and down along rods firmly placed on the support. This installation allows you to go deeper into the material anywhere in the workpiece to the stated depth.

Installation unit for working mills

Strong fixation of the cutter shank is ensured using a collet chuck mounted on the spindle. For tightening, a button or temporary locking lever is provided, and a special open-end wrench is included in the package. When changing cutters to a smaller diameter, the maximum rotation speed must be taken into account, otherwise the thin shank will not withstand too much load.

The quality of the collets themselves also deserves attention. The chuck must ensure accurate alignment, without the slightest runout of the cutter. It is best to choose clamps with a large number of collet blades.

Sole

There are two options for making the support platform for a manual router. The budget option is made of stamped metal, and the more expensive one is made of aluminum alloys. The molded sole is of high quality. On the lower plane of the support platform there must be a special pad made of plastic or hard wood. The size of the hole in the sole - the opening - limits the maximum possible diameter of the cutter.

Features of the electrical part

A good bonus to the overall quality is the smooth release system, which prevents accidental damage to the workpiece at the beginning of processing. The location of the start key should be comfortable for the hand.

The safety button eliminates the possibility of accidental activation. In order to comfortably install a hand router on a desktop in a stationary position, you also need a start key lock button.

Modern models are equipped with constant electronics, which equalizes the rotation speed on any seals, for example, in the area of knots.

Not all tools have a safety shutdown system, but it prevents overheating. This is especially important for a professional milling machine.

The convenience of the model is added by the LED backlight, which is very convenient to work with if there is not enough lighting. The length of the power cord is also important: it should not be too short. In addition, it makes sense to evaluate the location of the wire so that it does not interfere with various maneuvers.

Power switch device

The switch of a high-quality device must be equipped with a button to block accidental activation, as well as the ability to lock it. Some types of woodworking will become inconvenient if you have to constantly hold the button in the “On” position. The locking mechanism will prevent injury.

Collet

Higher quality collets are made from hardened steel. Cone-shaped, they most closely fit the motor shaft. Cheaper options wear out quickly and cause rattling, making work more difficult. Typically, they are too small to grip the cutter shaft.

Dust extraction

It is advisable to use a special vacuum cleaner to keep the cutting area clean. The milling table must also be adapted to the dust extraction pipe: a base with good visibility, strong mounting points, a simple switch and a height adjustment system. Then the cutting depth will always be accurate.

Rod mechanism

The functionality and performance of the tool are determined by the features of the vertical movement of its head. Two guide rods move this structure. If the cutter lowers smoothly, without using excessive force, then the unit is functioning correctly. Minus - if there are backlashes and distortions, as well as excessive resistance. This unit requires maintenance: cleaning and lubrication.

Auxiliary parts

For filigree precision work, various devices and guides, which are often included in the basic kit, are useful.

- Parallel, horizontal stop - guides the router at an equal distance from the edge of the part. It is attached to rods to the sole, and is fixed there with screws.

- A guide bar, the purpose of which is the straight feed of the router. Installation of the floor at any angle and at different distances from the edge of the workpiece.

- Bushing or copy ring. Allows you to produce parts according to a template, only a little larger in size.

- An angular stop with which you can make an exact copy of a part.

- The ruler-compass helps to work with the router along the radius.

- The support bearing stabilizes the tool during some types of edge processing.

The capabilities of a conventional router are wide, especially if the device falls into capable hands. Models with a submersible mechanism are preferable. To choose a manual wood router, you need to evaluate the main parameters - alignment, collet type, play in the racks and the depth of the hole in the spindle.

Rating of the top 10 best manual wood routers

In the article, we tried to determine the most popular tools, according to users, and compiled a list of the most popular ones. I suggest going to the list and familiarizing yourself with the presented copies.

- BOSCH POF 1200 AE.

- Kolner KER 1200V.

- BOSCH POF 1400 ACE.

- Interskol FM-40/1000E DM.

- Wortex MM 5013-1 E.

- BOSCH GKF 550 Professional.

- BLACK+DECKER KW1200E.

- Makita RT0700C.

- Makita RP2301FCX.

- ELITECH F 1800E.

Let's take a closer look at each of the presented models.

BOSCH POF 1200 AE

A reliable, vertically directed device with rich functionality. The rubberized L-shaped handles are ergonomic and very easy to use. For the sake of safety, the trigger mechanism is blocked here, and the start of work occurs smoothly, without jerking.

The spindle speed can be easily adjusted and, if necessary, blocked. The speed of revolutions is automatically stabilized. During operation, it is possible to adjust the milling depth. The delivery set includes a copy sleeve, three collets and groove cutters for wood for a hand router.

| Weight | 3.4 kg |

| Processing depth | 55 mm |

| Collet | 6 and 8 mm |

| Revolutions | 11000 – 28000 rpm |

| Power | 1200 W |

BOSCH POF 1200 AE Advantages

- rich equipment (parallel stop, copy sleeve, three collets, groove cutter, centering rod and key);

- speed adjustment according to material and task;

- keyless replacement of attachments;

- possibility of connecting a vacuum cleaner;

- transparent protective shield.

Flaws

- the work area is not highlighted.

I recently chose sets of wood cutters for a hand router for this unit. I already have the tool itself and have been using it for about a year. I was lucky, I bought it at the old price and I’m not complaining. During all the time I used it, it never let me down. Comfortable, fast, doesn’t make much noise, overall I like it and don’t plan to change it yet.

Kolner KER 1200V

A budget, but fairly high-quality version of the tool was included in the rating of manual wood routers precisely for these parameters. It is perfect for beginners, as at its price it has all the qualities of a professional device.

There is a ruler for setting the exact depth of milling, smooth speed adjustment, a durable cast sole and connection to a vacuum cleaner. In addition, it has a good set of accessories included. Equipped with protection against accidental start-up and equipped with a spindle lock, allowing you to quickly and safely change equipment.

| Power consumption | 1200 W |

| Number of revolutions | 16000 – 30000 rpm |

| Collet diameter | 6 and 8 mm |

| Weight | 3.2 kg |

| Working depth | 52 mm |

Kolner KER 1200V Advantages

- smooth speed control;

- solid aluminum sole with protective coating;

- accidental start blocking;

- rubberized handles;

- quick change of cutters thanks to spindle rotation lock.

Flaws

- no backlight.

I used to have an edge router, but it is a highly specialized tool. I decided to take a universal one and the choice fell on Kellner, the types of cutters for a manual wood router are suitable for it, you only need to buy an additional collet for 12. I am completely satisfied with the device, the assembly is good, the functionality is excellent. I recommend it to beginners!

BOSCH POF 1400 ACE

The productive branded unit has all the useful qualities of a vertical router and can be used as a professional tool. The depth is adjusted using a special revolving stop.

The attachments are changed in safe mode with the spindle locked, and there are a considerable number of attachments included in the kit. In addition to three collets of different calibers, there is a separate hard case with a set of six different hand router bits for wood.

You will be interested in: TOP 10 best spray gun: rating, how to choose, characteristics, reviews, pros and cons

| Chuck dimensions | 6 mm, 8 mm and ¼ inch |

| Cutter stroke | 55 mm |

| Power consumption | 1400 W |

| Rotational speed | 11000 – 28000 rpm |

| Weight | 3.5 kg |

Manual wood router: device and types of tools

Not only professional carpenters do wood carving with a hand router. The capabilities of this tool will be useful to furniture makers and finishing craftsmen. The main purpose of the router is wood processing. Although many modern models can cope with other materials.

Using a hand router and special attachments you can cut out parts of any configuration

Consumers can buy a manual router to process:

- stone of artificial origin;

- plastic;

- composite materials;

- plexiglass;

- non-ferrous metals.

The scope of application of this tool extends to the manufacture of decorative products and furniture made of wood, carpentry. Crafts created with a hand milling machine look very impressive. These unique products are widely used in everyday life. Using a router, craftsmen make beautiful picture frames, boxes, children's toys, decorative shelves, etc.

Using a router you can make wooden furniture, kitchen utensils, lining, baseboards, decorative crafts and other products

What can you do with a hand router:

- a sample of quarters;

- formation of such structural parts as folds, grooves, tenons, splines;

- profiling of the edge part (shaped and straight);

- formation of seats for installation of fittings and locking mechanisms on doors;

- decorative wood carving using a router with appropriate attachments;

- making holes;

- adjustment of parts to be connected;

- rough alignment of contours.

Types of wood routers: classification of devices

To decide which router is best to buy for your home, you should familiarize yourself in detail with the existing range of these devices. The choice of device depends on the type of work expected, its complexity and volume. For example, the need to use a router in furniture production arises constantly, while in a home workshop such a tool will be required only from time to time.

All manual milling cutters are divided into types - top type, edge and lamellar

The following types of milling cutters are distinguished:

- top type;

- edge;

- lamella

Upper type devices can be fixed or submersible. The second option is universal, and therefore the most widely used. For a home workshop, the submersible design is best suited. It is this category of devices that should be considered in more detail in order to decide which router to choose for certain tasks.

Note! A lamellar milling cutter is used to form grooves on the surface of processed products. This device belongs to the category of a highly specialized instrument that has a small number of functions.

An edge router is used for chamfering, rounding edges, forming decorative grooves and also for cutting grooves for furniture hinges

When compared with other types of hand-held power tools, the router has the simplest design. No belts, gears or other components are used to transmit torque. Router attachments are installed directly on the spindle (electric motor shaft). Due to this, a set of high speeds is ensured.

The body part of the electric milling machine is called the “head”. It moves along guide rods, which are rigidly fixed on the support platform, down and up. When the handle is pressed, the head of the tool moves down. If you release the pressure, the springs will return the structure to its previous position.

A cutter is attached to the spindle. A collet clamp is used to secure it. When the head is smoothly immersed in the material or wood, the depth is adjusted with a special stop. As the router moves further in the horizontal direction, a groove is drilled using the sharp edges of the cutter.

The cutter for a hand router is selected based on the type of material being processed and the type of operation

Vertical power up to 1200 W

A necessary tool for the workshop, capable of immediately replacing a plane, drill, or engraver. Selecting grooves for hinges and locks will become a minute task with models of low power and light weight. The Top 3 popular options in this group included milling cutters from manufacturers in Germany, Japan and Russia.

1Bosch POF 1200 AE

A small and inexpensive router is suitable for novice craftsmen and owners involved in construction and finishing on their own. Mostly designed for soft wood and simple work without maximum processing precision. The ability to adjust the speed will make it easier to work with different types of materials. The manufacturer took care of stepwise switching from 11,000 rpm to 28,000 rpm.

Specifications:

- power: 1200 W;

- adjustable rotation speed from 11000 to 28000;

- processing depth: 55 mm;

- weight: 3.4 kg.

Pros:

- mills not too hard materials well;

- has low weight;

- affordable price;

- You can connect a vacuum cleaner.

Minuses:

- weak guides;

- high noise level.

You can purchase a device that costs about 6,000 rubles at most power tool stores.

Rating of the best manual wood routers in terms of price and quality in 2021

The most popular units remain those that combine quality with reasonable cost. They are most often used at home, but they can also be useful in small workshops.

Elitech F 1800 E

The manual unit has a significant mass and demonstrates a power of 1800 W. Equipped with a spindle lock and a turret stop, there is a built-in backlight to improve visibility.

The cost of Elitech F 1800 E starts from 5,000 rublesPros

- long cord 2.5 m;

- high power;

- There is a 12 mm collet.

Minuses

- the start button becomes clogged with dust;

- weight 4.3 kg.

I like10I don't like3

Kolner KER 1200V

Inexpensive hand router suitable for home use. The working depth of the device is 50 mm, the speed is adjustable from 15,000 to 30,000 revolutions.

You can buy Kolner KER from 3,200 rublesPros

- does not heat up during operation;

- power more than 1 kW;

- rich equipment

Minuses

- makes noise during use;

- no soft start.

I like10I don't like3

Bort BOF-1600N

The 1.5 kW vertical router supports a speed of 12,000-26,000 rotations and has a nozzle stroke of 60 mm. There is a smooth switching of revolutions, the sole of the unit is cast and fits tightly to the surface.

Bort BOF price starts from 3900 rublesPros

- reliable assembly;

- moderate cost;

- five year warranty;

- smooth speed adjustment.

Minuses

- the mechanism for replacing cutters is inconvenient;

- no storage case;

- large weight - 4.8 kg.

I like10I don't like3

Top 3 best rotary hand routers for wood

Rotary units with a narrowed body are used in repair and decorative work. Important requirements are placed on precision and low weight of devices.

Bosch GTR 30 CE

The unit for drilling wood and tiles is equipped with a dust removal system and ventilation for the motor. There is illumination of the work area and stabilization of speed.

The price of Bosch GTR 30 starts from 18,000 rublesPros

- weight 1.5 kg;

- there is a speed control;

- maximum speed 30,000 rotations.

Minuses

- no soft start;

- There are no cutters included in the kit.

I like10I don't like3

Metabo FME 737

The milling machine is suitable for straight and curved cuts and starts up smoothly. There are ventilation holes on the case. The fixation of the cutter is very tight, without play.

You can buy Metabo FME from 13,000 rublesPros

- Supports speed control and soft start;

- The VC system independently selects the operating mode for the material.

Minuses

- no lighting or dust removal;

- There are no cutters included in the kit.

I like10I don't like3

Makita 3706

The compact 550 W unit is designed for making grooves and holes in wood and composite materials. It is equipped with a compass guide, collet and adapter for a vacuum cleaner, weighs 1.1 kg.

Makita 3706 price starts from 5,500 rublesPros

- light weight;

- there is a dust removal system;

- high speed up to 32,000 rpm.

Minuses

- there is no regulation and stabilization of speed;

- there is no soft start.

I like10I don't like3

TOP best edge routers

Bosch GKF 600 Professional

The cost of the device is around 12,500 rubles. The Germans continue to produce really high-quality milling cutters. This model runs on a 600 W motor. It easily picks up rotation speed up to 33,000 rpm in 1 minute. It is also convenient that the entire range of cutters is suitable for work.

The design is durable and light in weight. If necessary, the base is shifted to the required division on the router body, and then adjusted to the size using a wheel in the area of the base base.

The device is comfortable to use in your hand. The base can be removed completely. The device can be used as an engraver with high power.

Advantages

- power characteristics;

- convenience indicators;

- The adjustment is quite simple.

Flaws

- The equipment is presented with a straight base; you need to separately purchase an option with the ability to adjust the tilt.

Makita 3709

The cost of the device is around 5800 rubles. The manufacturer is a Japanese company. The device is reliable and has good performance. Operates at 30 thousand revolutions in 1 minute. The cutter plunges up to 40 mm. In fact, the device is decent, but in view of the reduced price, the manufacturer decided to save money. For this reason, the equipment was slightly damaged.

The base of the router is made of 90 percent polycarbonate with a transparent base. The clip is plastic. The ears are tightened using a screw. Users complain that the manufacturer should have added 8 mm collets to the kit. But, in fact, there are only 6 mm collets.

Advantages

- comfortable grip;

- engine with high power and speed characteristics.

Flaws

- the base is made of plastic.

Hammer FRZ710 PREMIUM

The device costs around 8,300 rubles. It is not even just an edgeband, but can also be classified as universal. The complete set is represented by a vertical type base with handles. There is also equipment for performing edge work. Just keep in mind that even though it is universal, it is not always useful. The motor operates at 700 W, while the system speed is at its limit. The immersion depth is 30 mm, these are not too large characteristics.

The inconvenient thing is that there is no smooth lowering. You have to turn the device on and off by releasing the handles. So the vertical base here can rather be attributed to a series of equipment “made from what was available.”

As for disassembling the device as an edging device, it is heavy in the hand and not very comfortable. When acting on a polished cylindrical part, pads are needed, then the vibration is transmitted to a lesser extent through the hand.

In general, users note that the device is suitable for home use, but cannot be used in large quantities.

Advantages

- versatility;

- 3 collets;

- decent power ratings for an edging device.

Flaws

- heavy weight;

- not entirely convenient if used as a vertical device.

Milling cutter and its features that should be known to any beginner

At first, it is better to use some inexpensive router. And it may well even be made in China. All such units, although they have different names, are of the same type and differ only in power. The latter is important only in cases where there is a need to work with large diameter cutters.

Inexpensive Chinese milling cutters are quite easy to use. Their disadvantage is their lack of high accuracy. But for any beginner it is quite sufficient. The most practical are milling cutters with a design close to that shown in the photo. Milling cutters of this design are very durable and tenacious.

Router equipment

The weight of the unit is just over 3 kg. The length of the power cord is less than 2 m. The cutter always has an 8 or 12 mm collet installed. A second, uninstalled collet is included in his kit.

The design of both collets is identical. It contains:

- a cylindrical part that ensures alignment with the cutter;

- conical part that guarantees its clamping.

The cutter is clamped only in the shank. Its working part is practically not fixed in any way. Naturally, this is a certain disadvantage. Because of this, the use of heavy cutters in tools of this type is strictly prohibited. Why? Because the mass of large cutters is quite large. And even if there is a slight imbalance, significant vibration occurs. As a result, the fixing elements of the cutter may become loose, and it may move up or down and even fly out.

These tips will help you choose a high-quality router. Click!

The next element of the kit is brushes with a fairly large cross-section, which is their undoubted advantage. Because with larger brushes the current density is lower. And thanks to this, their heating turns out to be less.

The kit also includes a dust extraction cover. As a rule, it is adapted for a regular household vacuum cleaner. It is installed on the base of the router. The presence of this device allows the operator to work cleanly.

Another device included in the router kit is a copy sleeve, which is also called a copy ring. It is used when working with templates. Its presence significantly expands the capabilities of the router.

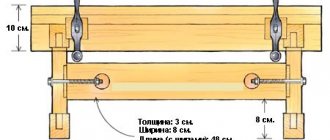

And finally, the rip fence. It is necessary when performing most operations performed with a router.

The parallel stop is attached to the router using two rods. They are inserted into the stop itself and secured there with wings. The second ends of the rods are inserted into the eyes of the sole and are also fixed there with the help of wings. Thus, a completely rigid structure is obtained, which represents a supporting surface on the edge of the workpiece.

In addition to the rip fence, there is a copy roller, which is necessary for its operation.

Each router set also includes a special key for clamping the collet. The key size is inch.

Or maybe you should buy a cordless router?

TOP best keyway routers

Makita PJ7000

In terms of price, this device is affordable to many. It costs around 16,200 rubles. It runs on a 710 W motor, with rotational speeds reaching 11 thousand per minute. The maximum diameter of the cutter is 100 mm, but its selection should be approached carefully. If there is an imbalance in the high-speed tool area, the milling cutter will produce high-power vibration. The device base is optimal. The desired angle is achieved accurately and quickly.

Advantages

- high power levels;

- dust collector with efficient characteristics.

Flaws

- vibrations are felt;

- the body is not equipped with rubber insulating pads.

Bosch GFF 22 Professional

The cost of the router is about 16,150 rubles. It features an ergonomic solution. This applies to both the grip and the left-handed handle. The milling cutter is designed for right-handed craftsmen, and therefore it will be difficult for left-handed people to use it.

The model is also distinguished by the gear ratio of the gearbox. These are proven solutions that provide quality and reliability. The motor has 670 W. It is capable of spinning the cutter up to 9 thousand revolutions per minute. At its maximum, it can reach 105 mm.

Users are not happy with the vacuum cleaner catcher. It is recommended to be used as a last resort. It's better to use a vacuum cleaner.

Advantages

- the build quality is at the highest level;

- performance indicators.

Flaws

- operates at a noise level of 87 dB;

- the cost is high.

What to look for when choosing?

Choosing a milling machine for home use is not the easiest task, especially for those who are faced with the need to purchase such a power tool for the first time. The priority criterion should be the type and frequency of carpentry operations performed. If you need a universal machine, then it is recommended to pay attention to vertical type devices, since such options are adapted to any type of processing. For manipulations in a small workshop, the optimal solution is an additive type unit. You can restore furniture with an edging tool.

We'll tell you how to choose an electric wood router for solving everyday problems or as carpentry equipment for a hobby, and what criteria should be taken into account when choosing:

- Purpose of the machine. Electric machines come in submersible, vertical or edging types. The vertical model is the most universal, designed for all types of carpentry operations.

- Motor power consumption. High power characteristics guarantee maximum performance. This parameter allows you to increase the cutting speed of hard workpieces and deeper milling in one cycle. Power makes it possible to classify equipment into 3 groups: for home use (up to 750 Watt, weight - from 2 to 3 kg), semi-professional type (750 - 1500 Watt, weight - from 3 to 5 kg), professional models (1500 - 2300 Watt , weight – from 5 to 6 kg).

- Processing depth. The value by which the cutter is embedded into the workpiece. The parameter is calculated individually and depends on the thickness of the base being processed.

- Rotation speed setting. When working with hardwood, the speed of the cutting element becomes slower. This manifests itself in machine jerking and damage to the part. Most machines have the functionality to adjust the number of revolutions depending on the task at hand.

- Safety and durability. Safe operation of the machine is ensured by design features. It is good if the model has a protective casing, which increases the reliability of use and protects the parts and the master himself during the operation.

Sources

- https://DomZastroika.ru/instrumenty/reyting-frezerov-po-derevu-ruchnykh-na-2021.html

- https://SovetMarka.ru/top-luchshih-ruchnyh-frezerov-po-derevu

- https://marka.guru/dom-i-dacha/remont-i-stroitelstvo/luchshie-frezery.html

- https://tehnolev.ru/dlya-remonta/frezer-po-derevu/kak-pravilno-vybrat-ruchnoy-frezer-po-derevu-top-10-modeley-otzyvy.html

- https://tehcovet.ru/reitingi/dly-remonta/luchshij-frezer-2021-goda.html

- https://Revizzoro.ru/reyting-luchshikh-elektricheskikh-frezerov-2020-goda-dlya-doma-tekhnicheskie-kharakteristiki-plyusy-/

[collapse]

What is a router and what is it for?

A router is the main tool for processing the edges of wooden facades. It is used both for processing large wooden structures and when working with small products, for example, boxes. When choosing a good router, you need to rely on the goals you set.

Power classification:

- Low power (500–1200 W). As a rule, they are lightweight, compact, maneuverable, and easy to use. They allow you to perform almost all tasks in a home workshop, but there are some limitations due to power: they work with cutters up to 32 mm with restrictions on the length of the cutter.

- Medium power (1200–1900 W). Quite large machines that allow you to solve more complex problems. However, processing small parts is difficult, which makes working with them inconvenient. Equipped with cutters with 8 mm and 12 mm shanks.

- High power (1900–2400 W). Used for working with large-sized objects, for example, in the manufacture of kitchen facades.