Laminated board is one of the most popular floor coverings, which is made by pressing a board based on wood fibers or fiberboard. The appearance of the surface will depend on the design of the top layer - it can be made to look like wood, stone, tile, etc.

Laminate consists of four layers, which are “laminated” on the outside with a special protective film. This is the reason for the name of the material.

It will be helpful to know that due to their design, the products are quite easy to use. In this regard, laminate flooring is available to specialists of various levels, ranging from beginners to experienced professionals.

How and with what to cut laminate

The nuances of working with laminate also come down to the fact that it is cut right at the installation site. This begs a logical question: how can you get pieces of laminate of equal sizes without damaging the product itself?

General information

If you choose a wood-based floor covering, people often give their preference to natural parquet or a cheaper, but no less visually pleasing option - laminate. This material is characterized by increased durability and features that will even surpass natural solutions in terms of operation.

In construction stores you can find different laminate designs. World-class companies can offer end users a wide variety of textures that will imitate natural surfaces, for example, trees of various types.

This coating has become popular largely due to the fact that laminate flooring is very easy to install using a locking system. Also, such coatings are quite easy to dismantle and reinstall.

Laminate flooring is quite easy to lay and, if necessary, cut, armed with special tools

The coating is laid in rooms where there is increased traffic. This is largely due to the fact that laminate has increased wear resistance and is not afraid of loads. If you install it in a bedroom or living room, warm wood tones will create a cozy atmosphere, and thanks to its resistance to water, you don’t have to worry about fungus or bacteria developing in the kitchen.

Cutting laminate with a grinder

It is perhaps impossible to meet a man in our country who has not heard the word “Bulgarian”. Many people don’t even know what can replace the slang name for this electric tool – angle grinder. At each specialized retail outlet you can purchase replacement attachments for grinders - grinding discs, abrasive elements for cutting metal or cutting blades for wood.

The use of this machine entails a huge danger for a person if there is no skill in handling it. To work with an angle grinder, you need to know the following nuances:

- The tool does not have any locks and the correct positioning of it depends solely on the experience of the master. In most cases, you have to work with it by weight.

- Most models of angle grinders on sale do not have a gear shift function. This means that if there is the slightest mistake, the cut will not be made according to the markings, and correcting the situation is no longer easy.

- When using an angle grinder, it is necessary to wear a protective steel casing, despite the fact that it blocks the view. Only in this case is the relative safety of using the tool guaranteed.

- Before starting work, you must make sure that the material to be cut hangs freely from the work table, since if the working part of the tool encounters an obstacle during cutting, the master’s hand may not be able to hold the tool.

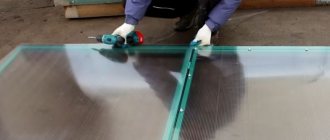

Rice. 8. Quick cutting of floor parts with a grinder before installation

However, if all precautions are taken, the grinder will provide maximum speed in the hands of an experienced specialist. With its help, you can cut in any direction and along a curved path, and practically no auxiliary devices are required to work with the tool.

How laminate works

Laying laminate flooring in only one piece is almost impossible. Laminate lamellas are most often made in a rectangular shape. On the surface of the boards there is a thin film of resin that protects the laminate from various types of influences and damage. Under the protective layer there is a layer with a shade, where the formation of a pattern occurs, which in appearance resembles wood of various types.

Next comes a layer of chipboard, which increases rigidity. The last one is a layer of melamine, thanks to which the laminate is resistant to moisture. As a result, it turns out that the thickness of such a coating will be about six to twelve centimeters. If you are sawing such products, it is very important to carefully make the edge. Otherwise, curved chips may form, which will need to be compensated for by valuable centimeters of coating. It may also be necessary to replace faulty elements with new ones.

In order not to waste valuable pieces of coating, which is quite expensive, it is better to prepare tools in advance that will allow you to make even cuts. This way you can protect yourself and install it right away without wasting additional resources.

It is important to make only even cuts - otherwise you can seriously damage the coating, which will affect your expenses.

A cutter designed specifically for cutting laminate flooring

This cutter is a bit like a guillotine. The sharpest knife, descending from above, instantly cuts the laminate like butter. The cutting line is perfect and as accurate as possible. But this tool can only cut across the boards. And if you need to cut the floorboard lengthwise, then again we turn to one of the methods described above.

In addition, such a cutter is very expensive, so purchasing it can only be beneficial for professionals who install laminate flooring on an ongoing basis. If you just want to change the flooring in a couple of rooms in your apartment, then you probably shouldn’t make such a purchase.

Important: with any method, it is better to measure several times, and then cut. As a rule, they buy a little more laminate than was calculated. It is taken into account that you will have to cut some boards and then join them correctly.

Laminate cutting tools

When choosing tools for cutting laminate flooring, you should consider a number of features.

- It is important that the tools are easy to use. Convenience largely depends on the ability to use the tool and people’s preferences.

- If the tools are light and ergonomic, then with their help you can do all the work much faster. When carrying out renovation work, time is a very valuable resource.

- An important nuance when choosing a tool and making a cut is that the cut should be smooth, without any cracks or chips. However, there is no need to focus too much attention on this nuance, since some kind of irregularities can be hidden under other elements.

Electric jigsaw

A very simple tool to use that allows you to cut lamellas is a regular electric jigsaw. The jigsaw operates at very fast speeds. This means that all cuts can be made very straight. An important nuance when working with a jigsaw is the choice of a suitable file for the tool. Today, most of these tools include files for such coatings, which can be easily replaced. If we compare with other types, they have a different shape, size and position of the teeth. One way or another, if special files are not available, you can also use standard ones with small teeth, which are used for cutting metal products.

It’s quite easy to cut laminate flooring with an electric jigsaw - you don’t need any special skills, you just need to follow safety precautions

In order not to damage the layer with the image, you need to make notes and all actions with the tool from the inside out. It is better to place the covering on a table or stool so that the part of the panel to be cut is suspended. Firmly fixing the element with your hand, you need to quickly walk with a jigsaw along the intended cutting line.

Bosch has tools for cutting laminate flooring. Solutions from this German company are perfect for getting the job done. The range includes devices for cutting both straight and shaped. There are also tools to make narrow cuts.

Special files for electric jigsaws from the company are presented in a wide range. So, the company has a model in which the teeth are located on the reverse side. Such a file will not harm the coating, and the cuts will be even and smooth.

jigsaw

It is worth using special jigsaw files to cut laminate

In addition to sawing laminate, the tool can be used for working with plywood, chipboard and fiberboard.

There is also a model that is perfect for shaped cutting of laminate or other wood coverings.

Some important points.

- A narrow file will make the cut more accurate.

- If you need to make a cut in the shortest possible time, then a tool with large teeth will be the ideal solution, but the risk of damage to the material will increase.

- Always use verified equipment that has all the necessary certificates of authenticity.

Step-by-step instructions for cutting laminate using an electric jigsaw

Guillotine

To cut the desired pieces of laminate panels, you can use a guillotine. If we draw an analogy with a jigsaw, then a guillotine has a device with a mechanism. Externally, a comparison can be made with large scissors. Such a device will not make noise, and using a guillotine it is easy to cut across the panel. True, it’s not worth purchasing a tool just to make repairs in one room. The guillotine will be more useful for people who constantly lay floor coverings - specialists. It would be better to borrow such a tool for a while.

You can use a special guillotine that will help you cut the laminate evenly

A circular saw

You can make cutting using professional equipment - a circular saw.

A circular saw will also do the job well.

It is important to know that if you use a circular saw, it must have a special-purpose blade suitable for working with metal products. In addition, to operate a circular saw, you need to have a certain level of skill.

When working with a circular saw, the panel is placed face up and firmly fixed. You need to be very careful when working with such a tool. Always remember safety precautions when working with equipment that can cause harm to people. Always button your sleeves and watch your arms.

The most budget circular saws will cost about forty dollars. It makes no sense to purchase such equipment to cut laminate flooring. In addition, it is quite large, and bringing it into the house is not an option. If you have such a tool, you can use it to perform all manipulations with the laminate. It is necessary to use a disc for working with metal products, however, it is worth having experience so as not to damage the product and not harm your health.

Nuances of working with circular paper.

- You need to make markings and make cuts along the front side.

- It is important to firmly fix the part on a flat surface with the pattern facing up. It is important that the lamella is installed correctly, and not so that one person holds it with his hands, and the second makes the cut.

- If you have a machine with a “circular”, then everything is done in the same way as described above.

- If a machine is used, the laminate is not fixed, but is simply carefully brought to the cutting disc. It is important to use protective equipment and protect your eyes.

It is important to follow safety precautions when working with a circular saw

Fraser

You can also use a router to cut laminate flooring. It is unlikely that every person has such equipment at home, however, specialists who work with furniture products usually always have a router in stock. With this tool you can make a perfect cut.

You can use a router if you have such a tool

Knife

A standard construction knife can also help with cutting laminate flooring. With its help you can cut several panels of covering. It is worth understanding that if there is a lot of work to be done, then you should use another tool.

Hacksaw (saw)

It often happens that when laying a coating, a fairly common tool is used - a hacksaw. One way or another, in order to cut panels quickly and efficiently, you need to choose the right tool. But if there are no other options available, then you can also use a hacksaw, which is used for working with wood. It is worth understanding that under such circumstances it will be much more difficult to do all the work due to the large size of the cloves. Due to this, all cuts may be uneven.

If you only need to cut a few lamellas, a hacksaw can easily handle this task.

The best solution in this case would be to use a hacksaw for working with metal products. Such a tool has many small teeth, and it will be able to make even cuts.

It is important to understand that this solution is worth using if there is not much work to do. Making cuts with non-power tools is much longer and more difficult. That is why specialists use equipment that runs only on electricity.

Bulgarian

A tool such as a grinder is used for sawing various parts, including laminate. Working with a grinder, you can make a fairly even cut. When working with the tool, you need to lay the panel with the top side where the decorations are applied. Do not forget about the use of special discs with small teeth. For example, discs that are designed for working with metal products are excellent for sawing laminate flooring.

Many people use a grinder to cut laminate flooring, however, the work needs to be done outside

Attention! When working with an angle grinder, a characteristic smell is felt, dirt and dust are formed. Carry out all work with the tool outdoors. You should not start working with an angle grinder if you do not have any experience with the tool - it can be very dangerous and lead to serious injuries. You should always remember safety precautions and wear protective elements: special protective glasses and long sleeves to protect your hands.

What is the best way to cut laminate flooring when installing it at home?

The floor covering should not have chips or cracks. To evenly cut laminate flooring at home, select a lightweight and compact tool.

Is it possible to cut laminate flooring with a grinder?

An angle grinder or grinder is used for grinding, sawing and stripping material. The laminate is trimmed in the following order:

- The panel is laid on a backing made of plywood or boards 6-10 mm high, face up.

- Apply the square to the adjacent perpendicular side along the marks and draw a line with a sharp construction or stationery knife, cutting through the decorative coating.

- The slab is cut according to the mark obtained.

- To prevent the wood from melting and the material from having the smell of burnt wood, diamond blades are used for metal.

When cutting with a grinder, a lot of dust is generated, which can clog the locking mechanism. Therefore, after cutting, carefully wipe the piece of laminate with a rag.

Panel trimming work is carried out on the street or balcony

How to cut laminate flooring with a jigsaw without chipping

The cut on the panel after using a jigsaw is smooth and without cracks. To cut laminate flooring with a jigsaw at home, set the machine to high speed and install a saw blade for laminated fibreboard flooring. If such a saw is not available, experts recommend using thin metal files with miniature teeth.

To ensure that the decorative surface does not have chips and the cutting line is smooth, the panel is laid on the surface with the decorative side down. Markings are applied to the reverse side using a simple pencil. The cutting line is moved to the edge of the table so that it is suspended. Holding the blade with one hand, the other makes a cut along the markings.

The cutting guide bar is used when cutting laminate flooring over 15 cm wide.

How to cut laminate flooring with a circular saw

An even and beautiful cut is obtained when cutting a laminated floor panel with a circular saw. At home, the instrument is placed on a table or on a base placed on the floor. The work is carried out outside or on a loggia, since sawing generates a lot of dust.

The laminate is laid on a solid base with the decorative coating on top. Strengthen it with a clamp so that the panel does not move when cutting. Markings are applied using a pencil and a square. A metal disc is installed in the saw and the cut is made with slight pressure on the saw.

The tool is smoothly moved in the direction of the line, without slowing down or rushing

How to cut laminate with a hacksaw

A hacksaw for metal has fine teeth, so the cut of the laminate is smooth and neat. The panel is laid face up on the base. Make markings and start cutting.

Attention! Experts recommend using mechanical tools if you need to cut out 1-2 parts. To cut when laying laminate in a room, use power tools or a construction cutter.

At home it is difficult to find the right power tool, but a hacksaw can be found in any household

A wood hacksaw is used extremely rarely for cutting laminate flooring, since large teeth damage the cut. Experts recommend using the tool only in cases where a sloppy cut can be covered with a plinth.

They start sawing from the edge, smoothly moving the hacksaw along the markings, without making any effort so that the edge does not break off

How to cut laminate with a construction knife

Use a utility knife to cut the thin floor covering. At home, laminate is cut using 2-3 sheets, since the process is labor-intensive and the sharpness of the blade may only be enough for one strip.

The panel is laid on the base. Make markings. Apply a square and, pressing the knife, carefully draw along the ruler. A deep, thin cut will allow you to split the laminate, like ceramic tiles.

A stationery or construction knife is used for cutting only in exceptional cases

In some cases, a knife is used for cutting. The blade is taken out of the stationery and a homemade one is inserted. The cutter is made from an old hacksaw. To cut a panel, cut the edge with a regular blade and then finish it with a cutter.

How to cut laminate flooring with a construction cutter

A professional tool allows you to make cuts efficiently and accurately. The cutter is designed like a guillotine. Using the handle, the knife is lowered and part of the panel is cut off according to the markings. Guillotine cutting is carried out only in the transverse direction.

The construction cutter works autonomously without electricity; cutting requires physical effort

The cut after the guillotine is smooth, without chips or cracks. Professionals who lay panels purchase a cutting cutter for the job. The panel is laid on the base of the tool, a cut is made according to the markings, pressing the handle to the floor.

How to cut laminate lengthwise

Most often, transverse trimming to fit the width of the room is required. But there are times when the last stripe needs a smaller width. In this case, a longitudinal cut is made.

To correctly cut laminate along the canvas at home, use various tools. The easiest way to cut is with a grinder or circular saw. The panel is placed on the base with the decorative side down, marked and sawn.

The construction cutter is designed for cross cuts. To cut the laminate lengthwise, additional supports are placed under the panel and, if necessary, the slab is moved along the markings. To get an even cut, a barrier is installed along which the blade is guided.

Using a guillotine, oblique cuts are made if necessary.

How to cut laminate flooring for a heating pipe

When laying flooring, difficult situations may arise for cutting the panel. You can cut a hole for a pipe in the laminate using a drill with attachments, a grinder or a jigsaw. To do this, the dimensions are carefully made. If necessary, make a template from a sheet of paper and try it on a difficult area.

The hole for the pipe on one laminate panel is drilled using a drill bit. To do this, select a nozzle of the required diameter.

After laying the laminate, the hole is decorated with sealant or grout

Using a jigsaw, they also make a hole of the required size if the drill does not have a crown attachment. Make a hole to the side using a drill. Place a jigsaw blade into it and carefully make a cut according to the markings.

For decorative cutting, use a blade with a fine-toothed blade.

Sometimes situations arise when the cut location falls at the junction of two panels. To do this, two strips of laminate are assembled into one and markings are made. Using the above methods, cuts are made and the floor covering is laid.

Cutting vinyl laminate

The type of lamellas that will be used during installation determines in most cases the necessary cutting tools. If you plan to lay the flooring yourself without the help of professionals, then you should take a closer look at soft laminates.

At home, the process of sawing soft types of laminate, for example, based on cork, will not present much difficulty. These types of coatings have increased wear resistance and water protection. In addition, this laminate is quickly installed.

The easiest way to cut vinyl laminate is with a regular utility knife and a ruler.

To cut these types of coatings, you do not need to use any special tools. You will need a simple ruler, pencil and knife. You need to mark the cut line with a pencil and then just go through it with a knife. Next you just need to bend the laminate. It is also possible to make cuts in the form of shapes - for this you can use ordinary scissors.

However, to cut other types of panels with multiple layers, where there are particularly strong wood fibers or chipboards, special tools may be needed.

How to choose the right tool

Here it is worth taking into account two determining circumstances:

- properties of panels, scope of work;

- technical characteristics of the tool.

For example, what should you use to cut laminate flooring at home? There is no point in purchasing expensive, powerful electrical equipment; this amount of laminated board will perfectly help you cut a machine called: guillotine. When finishing a large area of office floor with commercial laminate, it makes sense to choose a circular saw.

How to trim installed laminate?

It happens that you need to trim the laminate that has already been installed on the floor. For an inexperienced person this can be difficult.

If you believe the reviews, then the most optimal way under such circumstances would be to use an angle grinder. As experienced users advise, a grinder with a diamond-coated disk is best suited for such work. While doing all the steps, it is important to be very careful and remember to change the position of the tool without affecting it too much. Don't forget to always keep your finger on the button in case you lose control.

You can also trim laminate flooring that has already been laid on the floor, although this is more difficult to do.

In addition, you can use a not so simple tool, but it is safer - a cutter. There are special cutters that are used for working with wood - this is exactly what is best suited for cutting laminate. As professionals say, you need to make two parallel cuts the width of a chisel with a cutter. After this, you need to use a chisel to select the cut panel.

You can also use a jigsaw. You need to unscrew the protective casing so that you can get to the space under the wall, and then carefully cut off what is unnecessary. This method is not the most convenient, but it does not require disassembling the coating.

There is also such a tool as a renovator. The equipment is a grinder that can make cuts in places with difficult access. Such equipment is not cheap, but you can always order a tool from China for about thirty dollars.

Helps cut laminate and renovator

renovator

How to cut laminate flooring with a circular saw

Not everyone will buy such a tool, but those who have it will enjoy working with it.

Advantages of the device:

- high speed;

- It is possible to work with several lamellas at once.

The power of the cutting device is much higher than that of other power tools. Therefore, if you are choosing the best way to cut durable and hard commercial-grade laminate, then you should choose a circular saw.

The sequence of actions when working with a circular saw for cutting laminated boards:

- select a disc for the circular device with small teeth;

- Apply markings for cutting on the decorative surface of the board;

- The boards are placed upward with a decorative layer, one after another, on the machine, holding the panel by the edge, and slowly direct it forward towards the rotating disk.

Extreme caution must be used when operating a circular saw as it may cause injury to your hands.

How to make cuts without chipping?

To do all the work properly, it is important to properly prepare for it. The first step is to choose the tool that will be used for cutting. You need to choose based not only on the availability of equipment, but also take into account your ability to handle such tools.

Then you need to measure everything so you know how much to cut. This is a very important stage, so rushing here will be unnecessary, as you can ruin the coating. It is also important to remember the thickness of the cutting element and take this information into account when taking measurements.

After all the measurements have been taken and the cut area has been marked, you need to draw an even cut line for the laminate panel.

Once everything is finished, you need to move on to sawing the panels.

How to cut laminate correctly so that there are no chips

Subtleties of the process

When starting to work with this material, you should not only know how to cut laminate at home, but also how to do it correctly. We list just a few points related to the basics of working with laminate:

No special effort is required when cutting laminate flooring.

- in order not to crumble the edges or damage them, you should choose discs and saws with minimal and frequent teeth (for working with metal);

- if damage occurs on a cut, such a board should be laid “under the baseboard” so that it naturally hides the flaw;

- before cutting, you need to double-check the calculations several times so as not to spoil the material;

- to obtain a perfect cut on the front side, the boards must be placed with the wrong side down;

- when cutting panels directly, no special effort is required;

- Curly cuts with a jigsaw should be made using a template, gluing construction tape to the cut locations.

In conclusion, I would like to say: if you have even the slightest doubt about how to cut laminate or whether you made the right choice of tool, consult with specialists. Better yet, trust them to do the job. After all, the wrong choice of tool can result in damage to the material, which is not particularly cheap!

Which side should you cut from?

In most cases, the laminate flooring is cut crosswise to reduce the length. However, there are times when it is necessary to make a longitudinal cut.

Under such circumstances, it is better to use electrical equipment, since even a special-purpose cutter is intended only for cross-cutting. The best solution would be an electric jigsaw. Using such a device does not require any specific skills, and it also allows you to cut panels in various ways without much difficulty.

Using tools you can make both longitudinal and transverse cuts

Guillotine for laminated boards

This is a new special small machine designed to mechanically act the blade on the laminated material by pressing the handle of the device. The machine is easy to use and does not require enormous user effort.

If you are asking the question of how to cut laminate flooring at home, then you should consider this tool. Compared to a hacksaw, it works much faster and better, and when compared to an electric grinder and circular saw, it is much cheaper and easier to maintain. The machine does not require a source of electricity. The tool does not generate dust, sawdust, does not allow chips on panels and works without noise.

This is the best option for a home craftsman who has set himself the task of decorating all the floors in the apartment with laminated parquet. This laminate cutting tool should be used as follows:

- a lamella is placed on the base of the cutting device - horizontally;

- a line of markings applied to the board is drawn directly under the cutter;

- the handle goes down to the laminated board, resulting in a neat and clear cut made by the cutter.

This device is capable of cutting a large number of panels quite quickly and efficiently. A practical and useful tool that is worth purchasing for professional installation of laminate flooring.

Which tool is best for cutting laminate flooring at home?

If you choose the right tools, you can install the coating quite effectively and in the shortest possible time. Cutting must be done in a separate room.

| The nuances of cutting laminate with different tools | 1. If laying on the floor, it is better to place the sections under the baseboard. It follows from this that chips are not so bad, and you can use an electric jigsaw with a cutting part for any purpose. If chipping is to be avoided, a specific cutting part is required. 2. You can also do cutting using a grinder. You must use a diamond-coated disc. Cutting is done from the scenery side. 3. “Circular” is also used to cut from the face of the panels. It is important to follow safety regulations. 4. Vinyl-based panels can be easily cut with a regular knife. 5. The laid laminate can be cut using a jigsaw or renovator. |

You can use any tool, the main thing is to have the skills to work with it and to properly prepare for cutting laminate

Hacksaw as the most affordable option

You could say this is the opposite of the previous tool. If you equip your angle grinder with a high-quality cutting wheel, you can get not only a productive, but also a neat assistant. But cutting laminate flooring with a grinder without experience is still not recommended. There is nothing particularly difficult in handling angle grinders, but at least before work you should practice on rough panels. As for the equipment itself, experienced parquet floorers recommend using a wheel with 48 teeth in a 160 mm format. This cutter will allow you to perform serial cutting, which is useful not only as a way to save time, but also from the point of view of maintaining straight edges - at least, the cleanliness of the cut will be ensured in the lamellas placed in the middle of the batch being opened. By the way, to obtain a 100% accurate cut, you can install the same rough elements in place of the outer panels.

conclusions

Based on the above, we can conclude that there is a wide variety of tools for cutting coatings.

You need to choose depending on the size of the room and financial capabilities.

For example, specialists who professionally lay coatings must be armed with special equipment. However, those who want to install roofing at home can get by with cheaper solutions.

If you do not have special equipment, you do not need to purchase it - you can cut the laminate using a hacksaw

The primary task when installing laminate flooring is to avoid the occurrence of chips and cracks. In this regard, it is important to calculate everything properly.

You can cut laminate flooring using almost any equipment with a cutting part. It is important to do everything carefully. It is worth choosing a tool based on your skills, planned amount of work and funds.

The most optimal solution for cutting coatings is an electric jigsaw, since this tool is universal and does not require any specific skills to work with it.

If you have any doubts about laying and cutting laminate flooring, it is best to trust the professionals. There is only a risk of spoiling the material, which will greatly affect the funds.

Convenient laminate cutter

You can trim a standard laminate board correctly using a machine with a guillotine installed.

It is important to remember that the board consists of 5 layers, namely unrefined paper, which prevents the penetration of moisture into the coating, high-density fiberboard, moisture-resistant film, decorative paper, and acrylic resin. They cut the laminate without chipping, so as not to spoil the integrity of the board, and it is advisable not to use a regular knife

We advise you to study - Wood varnish - choose from a modern variety

You can quickly and efficiently trim laminate flooring using a convenient cutter

When working with the machine you need:

- Follow safety rules;

- Work carefully;

- Follow the instructions from the manufacturer.

It is strictly forbidden to cut without a pre-marked line along which the disk placed on the cutter is installed. Using the machine, the cutting will be carried out efficiently, quickly and simply, and if the technology is violated, not only the material can be deformed, but also harm your hands.

Special cutter, guillotine for laminate

A home craftsman should definitely not purchase this expensive tool. Moreover, he is very bad at cutting laminate lengthwise. For the $40-50 they are asking for it, it is better to buy a more expensive jigsaw. The device consists of a base and a handle with a blade for cutting lamellas.

The principle of its operation is quite simple. Place the laminate board on the base and lower the handle down. However, there are some peculiarities when working with this tool. Here they are:

- As mentioned above, this guillotine does not cut lengthwise well;

- It does not cut very neatly; the cut piece looks like a stub. Even a sharp cutter blade literally tears the laminate;

- You need to apply a lot of force, and the blade quickly becomes dull. My hands get very tired. Thick laminate over 8mm may not be cut;

- Only used for cutting laminate. Those. This device will no longer be useful on the farm. This means it is not suitable for home use.