The purpose of a wrench and its difference from a screwdriver

The purpose of this tool can be guessed from its name. An impact wrench is needed to tighten and loosen nuts and bolts with significant force: some models can develop a force of up to 65,000 Nm (Newtons per meter). Many craftsmen who have not encountered this tool confuse it with a screwdriver, apparently due to its external resemblance to the latter. And the main difference between the tools is the different type of cartridges. But in fact, the impact wrench has many more differences, which turn into a huge advantage when compared with a screwdriver.

So, what is the difference between a screwdriver and a wrench? Most impact wrenches are equipped with a pulse-impact clutch, but it differs from the same hammer drill clutch in that the force is directed not along the axis of the unit, but in the direction of rotation of the chuck. The impact (pulse) mechanism operates as follows: the device drive rotates the cartridge through a massive coupling element until the force reaches a certain threshold. Next, the leading element of the clutch is released from engagement and accelerates; the element accelerates within an incomplete revolution, after which it strikes the cam located on the axis of the cartridge. The massiveness of the element and the speed it gains create a high torque, thanks to which it is possible to “break off” stuck bolts and nuts.

Due to the high discharge current, even expensive, professional cordless impact wrenches can only work continuously for 15-20 minutes, which cannot be said about screwdrivers.

Based on the above differences, it is not advisable to use a wrench instead of a screwdriver.

Types of tools

The impact wrench, being a highly specialized tool, performs quite an impressive amount of work. It is difficult to say which impact wrench is better, because the type and power of the tool is selected based on the goals and tasks that it has to perform.

- Electric. A high-speed, powerful and precise unit with virtually no vibration. The electric motor of the device operates from a 220V network and is equipped with a fan for better cooling, which allows the tool to operate for a long time.

- Rechargeable. This type of impact wrench is convenient due to its mobility and allows you to work away from the electrical network. The battery device can be used in construction when installing various panels, laying communications and for performing minor installation operations.

- Pneumatic tools. As you might guess, the prefix “pneumo” means that compressed air is used to set the device’s cartridge in motion. The latter is supplied through a high pressure hose connected to the compressor. Due to the absence of a motor, pneumatic impact wrenches are distinguished by their lightness and do not cause fatigue to the operator during operation. Also, the air impact wrench is not afraid of overheating and can be used in places where the use of electric tools is unacceptable (rooms with high humidity, places with a high risk of explosion).

- Hydraulic. The drive in this tool is a hydraulic pump with a distributor. The device operates on the following principle: the force developed by the hydraulic cylinder during the translational movement of the piston is converted into torque through a ratchet wheel. A hydraulic impact wrench, depending on the model, can develop colossal force, sometimes reaching up to 65,000 Nm.

It should be noted that there are two types of hydraulic impact wrenches: snap-on and cassette. The picture below shows a socket tool.The following photo shows a hydraulic cassette type of unit. It is usually used in places where it is impossible to reach with a spanning tool.

- Petrol. This type of impact wrench is mainly used in the repair or construction of railway tracks. A gasoline impact wrench is convenient to use far from power supply, in difficult field conditions, thanks to its complete autonomy.

- Geared. This is a manual multiplier impact wrench, popularly called a “meat grinder”. A gear wrench consists of a planetary gearbox housed in a metal housing. When the handle is rotated quickly, the speed is transmitted through the gearbox to the output shaft, which begins to spin much slower than the handle, but with much increased force.

Thanks to this hand tool, you can unscrew fasteners that cannot be “torn” out of place in the usual way. It is often used in the field for trucks, buses, and tractors as a wheel impact wrench.

Impact wrench selection options

When choosing a tool, you need to decide for what purposes you are going to use the impact wrench: household or professional . Their main difference is the power and duration of continuous operation. Household appliances have low power, overheat quickly (applies to network devices), and the working units in them are made of less durable materials than in professional-class tools. The device's power of 400 W will be enough for home use. If we talk about the rotation speed of the cartridge, then for domestic needs 20-40 rpm will be enough. A professional tool should have a speed of about 1500 rpm.

When choosing a battery-powered tool, pay attention to the type of battery. Typically, household devices use nickel-cadmium batteries, which cannot be recharged if they are not fully discharged, while professional devices use lithium-ion batteries, which can be recharged at any stage of battery discharge.

But it is worth knowing that lithium batteries are afraid of being completely discharged, which causes them to lose capacity and fail.

We should not forget about additional functions that increase the convenience of working with the tool.

- Impact mechanism. The instrument can be either percussive or unaccented. An impact wrench will be useful when tightening “important” fasteners, such as car wheel nuts, where a lot of force is required both when tightening and unscrewing. An unstressed tool will not cope with such a task.

- Adjusting the tightening force. It is not recommended to neglect this function. For example, if you have to tighten nuts with “vulnerable” threads, then without a force regulator they will break off in 1 second. Also, a wrench with adjustable torque allows you to tighten connections evenly, which is useful when installing car heads.

- Gearbox type. A pistol-shaped impact wrench does not always allow you to solve all the issues during repair and installation work. Sometimes fasteners may be located in places inaccessible to “pistol” type devices. Therefore, for such purposes it is customary to use an angle wrench.

- Built-in lighting. A very convenient addition to the tool, especially when repairing a car.

Also, when choosing this tool, pay attention to how it fits in your hand, whether the handle is comfortable, how much weight the device has, where the start button is located, etc. Ergonomic parameters determine the comfort of use.

For a better understanding of which tool to choose, below is a rating of the most popular models of various types of impact wrenches.

Equipment

The main attachments for impact drivers and impact wrenches are bits, square sockets (SQ 1/2, 3/4 or 1 inch) and drill bits with hex shanks (HEX 1/4″). What stands out in this series are torsion bits with a special thinning (the so-called torsion zone) between the shank and the head, which absorbs peak impact loads and protects the tip of the equipment from destruction.

In devices with tangential impact, it is very important to minimize play in all connections, since otherwise the part (for example, an adapter, extension or socket head) will quickly break or even break. Accordingly, all accessories for working with impact must be hardened to high hardness (by the way, during the hardening process they are covered with a black oxide film, but many manufacturers get rid of it in various ways - grinding, chemical exposure, etc.).

The use of adapters when working with an impulse tool is undesirable, but if you cannot do without them, then you should remember one rule: the larger the cross-section (in this case, the intermediate link), the lower the level of torsion smoothing and, accordingly, the more efficient the transmission of torque onto a socket or bit.

Electrical corded tool

DeWALT DW 292

This is a corded impact wrench powered by a 220 V mains voltage. The unit has good torque (440 Nm), a power of 710 W and can produce 2700 blows per minute.

- the gearbox is in a metal case;

- there is a striking mechanism;

- good torque indicator.

- the reverse switch often gets touched if you work with gloves;

- There is no torque regulator.

Hitachi WR22SA

Hitachi WR22SA is a professional device that allows you to unscrew and tighten hardware with a thread diameter of no more than 24 mm (M24). The tool can be used for cars.

This corded impact wrench has a torque of 640 Nm, a power of 850 W and a speed of 1800 rpm. The entire body is made of aluminum, which increases the strength of the unit and increases heat transfer. Therefore, the tool is often purchased by car enthusiasts for the garage. With its help, you can unscrew almost any “stuck” nut on a passenger car.

- reverse is switched when you press the top or bottom of the trigger;

- high torque;

- high-quality assembly;

- presence of an additional handle;

- high performance.

Disadvantage: according to reviews from device owners, electric impact wrenches of this model are sometimes subject to overheating, which occurs in the mechanical part of the device.

DeFort DCW 12

DeFort DCW 12 can also be called mains-powered, but this impact wrench operates on 12 volts. It has a torque of 350 Nm and develops a maximum of 3300 rpm. The package includes an adapter that allows the device to operate from a car cigarette lighter. There is also an adapter with alligator clips to connect the device to the battery.

This device is mainly used for passenger cars.

- sufficient power for tire mounting;

- presence of reverse;

- small dimensions;

- car tool, since there are adapters for connecting to the battery and cigarette lighter;

- pulse mode;

- presence of a case.

- no additional handle;

- There is no adjustment of clamping force and rotation speed.

Delta Turbo-2000

The most powerful tool in this segment is the electric rolling impact wrench.

It is used mainly for trucks, when mounting wheels. Delta Turbo-2000 is a load impact wrench operating at 380 V and with a power of 1500 W.

It also has a square one-inch chuck and can produce up to 2,500 Nm of torque, which should be enough for wheel bolts.

Since the device weighs 65 kg, it is installed on a chassis.

- sufficient torque for efficient operation;

- availability of chassis;

- convenient height adjustment;

- speed regulator

- operation only on voltage 380 V;

- the movement of the unit is limited by the length of the cable.

- high price.

Varieties

If we talk about the types of impact wrenches, they can be divided into impact and non-impact tools. It is worth considering these main varieties in more detail.

- Pulse. In another way, this instrument can be called percussion and rotational. It allows you to make movements using a special attachment. Such tools are able to regulate the operation of the torque element, as well as calculate the number of blows needed. At first, such a device makes rather long blows, and at the end of the work they become short. To top it all off, the last hit will be the hardest, making the connection quite secure this way. This type of model is most often used by professional workers.

- Unstressed. This model is most often used for domestic work. It features high torque. This type of impact wrench costs several times less than an impact wrench.

In addition, impact wrenches also differ in the type of drive. They come in several varieties.

- Geared. This model is mechanical. Inside there is a cylinder with a reduction gear. It is also called a torque amplifier. Therefore, such models are considered torque wrenches. On one side of such a device there is a handle, by rotating which you can set the rod itself with the head in motion. Most often, these impact wrenches are used to “rip off” rusted nuts, for example, on car wheels.

- Electric. This model is powered from the electrical network. It is characterized by low noise level and small size. Such a tool is quite powerful, but at the same time it consists of a simple rotating head switching mechanism, as well as adjustable tightening torque.

- Rechargeable. One of the main features of this type of model is its autonomy. It can be used both by professionals and at home. Using this technique, you can even unscrew nuts that are already covered with rust. These models also have a torque regulator, which can reach up to 500 Nm. The most popular are such impact wrenches, the impact frequency of which reaches up to 3000 per minute. For cars, impact wrenches are used that are powered by the car at 12 volts.

- Pneumatic. This model is very often used in auto repair shops, as it consists of a metal body and also has a connection system to a compressor. They come in both shock and unstressed varieties.

- Hydraulic. Such a wrench will be needed in places where great effort is required to unscrew the nuts. Its rated power reaches 10 thousand. In addition, this model is distinguished by the fact that it can be used underwater.

- Petrol. The operation of such a tool is ensured by an engine that runs on gasoline.

In addition, impact wrenches can be divided into two types.

- Angular. They have a convenient pistol shape, which allows them to be used even in inconvenient places. In these models, the axis of rotation of the spindle is perpendicular to the axis of the motor, which makes it possible to cope even with fairly dirty nuts.

- Direct. In such impact wrenches, the axis of rotation is parallel to the axis of the engine, which makes it possible to develop torque up to 4 thousand bits.

Electric cordless tool

Bosch GDR 10.8-LI

This is an impulse impact wrench, which we can say without exaggeration that it is one of the best devices in its segment . This tool runs on a Li-Ion battery with a voltage of 10.8 V, has built-in battery protection against complete discharge and overload, and is compact in size and weighs only 1 kg.

It is very convenient to use when working when the fasteners are at a height higher than the height of the master.

The device has a torque of 105 Nm, a spindle speed of 2600 rpm and a number of pulses per minute of 3100. The Bosch GDR 10.8-LI is successfully used both for household repair and installation tasks, and for professional use.

- high power;

- presence of battery charge indicator;

- short charging time;

- compact size and light weight;

- conveniently located reverse switch;

- as with all battery-powered impact wrenches, the main drawback is the short operating time;

- handle ergonomics.

Bosch GDS 18 V-LI HT

This is the most powerful cordless impact wrench with an 18 V battery, as it has a torque of 650 Nm.

Thanks to the metal gearbox housing, the device is highly durable and reliable. The device weighs 3 kg, and it can be called the lightest among devices of the “High-Torque” class, that is, among tools with high torque. Therefore, if you need a powerful and mobile tool, then it is better to choose a wrench of this particular model.

- metal gearbox housing;

- high torque.

The only downside to this tool is the price. You can buy it for about 15 thousand rubles.

Makita 6940 DW

This impact wrench is an angle tool and complements the range of cordless impact wrenches.

This model has a length of 370 mm and a height of 60 mm. Thanks to these dimensions, the side tool is effectively used in hard-to-reach places. The maximum torque value of the impact wrench is 30 Nm, and the rotation speed is 2000 rpm. In addition, the device can produce 2700 pulses per minute.

- small dimensions;

- the ability to work in inaccessible places;

- You can work with one hand due to the small diameter of the case;

- pulse operating principle;

- presence of a case.

- low torque level;

- low battery capacity.

Alkitronic EFCip series

The impact wrenches of this company are industrial tools.

Any EFCip series impact wrench has a synchronous motor (no brushes), making the drive subject to less wear and maintenance.

The body of the device is also durable, as it is made of aluminum alloy. The EFCip series units operate from a voltage of 100-235 V with a frequency of 45 to 66 Hz and can develop torque in the range from 60 to 6500 Nm.

The Alkitronic EFCip industrial device is a torque wrench, since the progress of its operation is monitored by a microprocessor, which, when the required torque (tightening force) is reached, turns off the engine. All necessary parameters are displayed on the LCD display located on the back of the instrument, where the control buttons are also located. In the nose of the unit, near the gearbox, there is a non-rotating gear wheel, onto which a special stop attachment is placed.

Based on the above data, the Alkitronic EFCip is the best impact wrench of all those listed above.

- high torque;

- electronic torque control:

- LCD display;

- metal case;

- possibility of installing a stop;

The main disadvantage of this unit is its high cost.

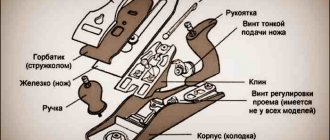

Preparing the impact wrench

In fact, electric impact drivers and impact wrenches are very simple. The housing made of aluminum alloy or durable plastic hides the motor, gearbox, rotary-impact converter and control circuits. Only a spindle with a square (SQ) section of 1/2″, 3/4″ or 1″ or with an internal hexagon (HEX) 1/4″ protrudes from the outside. The body usually has a pistol shape, less often it is linear (it is held like a regular screwdriver), sometimes with an additional handle (butterfly design). The pistol grip can be located at the end of the tool, but sometimes for better weight distribution it is placed in the middle of the body. Electric motors of impact wrenches and screwdrivers can be either commutator or brushless (valve), which have a number of undeniable advantages - they are quieter, do not spark, do not require maintenance and have a significantly longer service life. Such engines increase the operating time on a single battery charge by almost a third. To hold bits and extensions with an annular groove inside the hexagonal holder on the spindle, a spring ring or a spring-loaded ball is provided - they are also equipped with the outer square for the socket heads of impact wrenches. The use of different adapters is possible, but not advisable, since due to the torsional smoothing effect, any extra link significantly reduces the maximum tightening torque.

The transmission of rotation from the motor to the spindle in all impact wrenches and screwdrivers is carried out through a reduction gearbox. The most advanced is the planetary design of this unit, which has smaller dimensions and weight. But the torque limiting clutch (ratchet), which is standard in the design of conventional screwdrivers, is technically very difficult to adapt for operation in impact mode, so it is not used here. Accordingly, the tool user will require some experience to determine whether the correct tightening torque has been achieved.

Pneumatic

Impact wrenches operating on compressed air are practically not used in everyday life, since in addition to the tool itself, you need to purchase a compressor. These units are most often used in the professional field.

Wurth DSS1/2″

This is a premium air tool. This tool has a hammer mechanism; four positions for adjusting the tightening force; torque for loosening is 1321 Nm, and for tightening - from 60 to 835 Nm, chuck type - ½ inch.

To operate the impact wrench, only prepared air without impurities is required, that is, well purified and saturated with oil vapors. For these purposes, an air preparation unit (air preparation unit) and an oil sprayer are used, which is connected at the inlet of the tool. The oil sprayer enriches the air passing through the tool with oil vapors intended to lubricate the mechanical part of the unit.

So, if you need a powerful, reliable, low-noise pneumatic tool, then your choice of impact wrench can be completed with this model. It’s not for nothing that this unit is often used as a tire changer in car service centers.

- high torque;

- torque adjustment has 4 positions;

- convenient reverse switches located on the back of the device, which can be switched with one hand;

- the unit is not noisy;

- The handle is made of a material that prevents the tool from slipping.

- requires the use of a BPV;

- installation of an oil sprayer is required.

YATO 1/2 YT-09540

This is an air gun that has also proven itself to be a reliable and powerful tool.

The unit has: torque 1150 Nm; ½ inch square chuck; 10000 rpm; weight 2.02 kg. There are 3 positions for adjusting the twisting force, and 2 for unscrewing. Effective operation of the tool is possible at a pressure of at least 0.63 MPa.

The impact wrench is most often used in car repair shops for car wheel nuts.

- torque;

- torque adjustment;

- ergonomic handle;

- high speed.

- not recommended for use without GSV;

- An oil sprayer is required for this to work.

Tool Features

Modern impact wrenches are in most cases equipped with a shaft direction switch and a torque regulator . You can also adjust the tightening torque by changing the inlet pressure.

In many models, the air pressure is about 6.3 atmospheres, but the air flow ranges from 500 to 1200 l/minute.

But when calculating the air flow for this equipment, you need to take different measurements:

- Taking into account the amount of air passing through the tool during a minute when the trigger is pulled;

- Taking into account the amount of air and technical breaks.

The models also differ from each other in the mounting dimensions of the spindle square and connecting thread . Threads can be inch or metric. And different sizes of the spindle square can cause difficulties in providing replacement heads for some domestic devices. But with foreign instruments, things are different, since in this case the squares are unified and have certain sizes.

But impact heads for impact wrenches can have either a standard length or be extended. The impact head differs from the usual one in shape and wall thickness. And in order to evenly distribute forces at high tightening torques, they are equipped with recesses on the inner edges. There can be four, six or twelve faces .

There are two materials used for the production of heads:

- Chromolybdenum;

- Chrome vanadium.

Heads based on chrome-molybdenum are more durable.

And some manufacturers also offer customers special types of heads designed for complex procedures. Quite popular are those with which you can twist the nuts with a given tightening, making it impossible to break the thread .

For a number of models, the spindle can be simple, or maybe extended up to 150 mm. And some options are equipped, in addition to heads, with an extension and a cardan so that you can carry out work in hard-to-reach areas.

Impact wrench bodies are made from lightweight composite materials.

Advantages and disadvantages

The key advantage of pneumatic devices is their high speed and ease of operation. They can be used by a beginner, an elderly person or a person with disabilities.

There are also disadvantages - the fact that individual components and parts are of poor quality, but this applies exclusively to inexpensive options.

Hydraulic impact wrenches

This type of tool is the most powerful of all listed. They are mainly used for unscrewing or tightening fasteners in places where a very strong connection is required.

PLARAD FSX / SX-EC

This is a cassette hydraulic impact wrench with a torque of 250 to 45,000 Nm. The tool has a very durable and at the same time lightweight body.

Due to the fact that the cassettes are removable, they can be quickly selected to the desired nut size.

- high torque;

- small weight of the tool;

- quick release cassettes.

Disadvantage: high cost, which is typical for industrial tools.

PLARAD MSX/MX-EC

This is an end analogue of the above-described unit. It also has a durable and lightweight body, but has a huge torque of 65,000 Nm.

At the same time, the minimum torque of this device is 200 Nm. There is a shock absorber in the front part of the body to dampen beating and vibration during operation. The handle can be rotated 360°, which allows you to use the impact wrench in hard-to-reach places.

- colossal torque;

- rotating handle;

- anti-vibration shock absorber.

Disadvantage: high cost.

Principle of operation

The main part of the pulse tool is the impact mechanism, which converts rotational motion into rotational-impact. Let's take a closer look at it. Where does the huge torque come from, given the relatively low power of the drive electric motor, and at the same time there is practically no reactive force? No miracles, ordinary physics. Let's take it in order. Moment is a force multiplied by the length of the lever, in our case, by the distance from the projection of the spindle axis onto the nut to the outer corners of the hexagon, where the force is applied. In turn, the force is determined by the change in the magnitude of the impactor impulse in the impact wrench and the impact time, which mainly depends on the degree of compliance of the fastener being tightened (or unscrewed). For example, when running along a thread, the resistance is low, so the impact mode is not activated.

The mass rotating under the action of the electric motor gradually accumulates energy, and then instantly comes into contact with the striker, imparting significant torque to it, after which, thanks to the special design of the striker mechanism, it begins to rotate freely again. In this case, the only reactive force acting on the tool body is the influence of the motor armature, therefore, even when a significant moment is transferred to the working attachment (socket head or bit), the recoil on the device handle is very small. The impact energy is almost completely transferred to the bolt, nut or screw being tightened, and since the impact is close to elastic, almost all the kinetic energy is spent on rotating the fastener. Depending on the type of impact mechanism, for each rotation of the spindle the impact is applied either once (for a powerful tool) or twice (for most standard models) times. There are several design options for the assembly in question, but they all have the same goal - to allow the firing pin to rotate independently of the firing pin, accumulating energy and then almost instantly transferring it to the firing pin before the process is repeated.

The maximum torque of some impact wrenches exceeds 1000 Nm, but it must be remembered that such results are achieved only when tightly tightening screws or screws of a sufficiently large diameter, when the resistance to rotation is high and short blows follow with a high frequency (up to 3600 per minute).

Gasoline impact wrenches

As mentioned earlier, these are completely autonomous and powerful impact wrenches with gasoline engines.

Impact wrench BG-1

This is a track tool used in laying and repairing railway tracks.

The unit has a torque of 1000 Nm; power 2.3 hp; minimum number of rpm – 200; maximum rpm – 500; weight – 18 kg.

- autonomy and mobility;

- torque.

The disadvantages of this tool include its weight, which creates a noticeable load on the operator’s back and arms.