Brief description of the tool

Technically, a roller is a cylinder with a soft, paint-impregnated surface. The cylinder rotates around its axis, which is a handle curved so that it is more convenient to hold on to while working. The principle is simple - we dip the roller in paint, usually poured onto a pallet, and then run it along the wall, leaving an even mark without streaks, which often occur when working with a brush.

Types of rollers

Rollers are designed for painting large areas. They are used for facade work on the outside of the building and for renovations in the apartment. There are many types of this tool available in stores, and in order for a home craftsman to be able to buy exactly what he needs, he should understand the principle of operation of the roller, its design and existing types.

Operating principle and design

- Submersible type. These are traditional rollers that are dipped into a dye solution, rolled out on a flat surface to remove paint drips and soak it evenly over the sandpaper (usually using a ditch), and then begin to paint.

- Automatic. In this design, the paint enters the drum under pressure through a hose or is poured by hand. The paint, seeping through the holes, gets onto the skin, evenly distributed along its length. This approach helps save on paint.

Nature of work

Depending on the nature of the work performed, rollers are divided into two types:

- Exterior. Designed for outdoor use and have a more rigid, reinforced base. Width from 400 mm.

- Interior. Softer rollers for interior work. Width from 20 mm.

Coverage type

Rollers are distinguished by coating material:

- fur. Roller skins made from faux or natural fur are considered universal. This material ensures uniform coloring of any surface and saves material. When working with a fur roller, a minimal amount of splashes and drops is formed, and it can be used to perform even the most demanding tasks. They differ in pile length. For painting uneven surfaces, it is recommended to choose sandpapers with longer piles, however, during work, individual fibers may stick to the base;

- foam rubber. The cheapest type of skin. It is distinguished not only by low cost, but also by a short period of use. Foam rubber is not suitable for every type of paint. During operation, it leaves a lot of splashes and paints uneven surfaces poorly;

- velor As with foam rubber, working with a roller with velor sandpaper requires experience - a novice master will not be able to cope with the abundance of splashes. Velor is great for working with varnishes over a large area. Velor rollers absorb a lot of paint, and therefore the material consumption during operation will be high;

- thread They are also inexpensive types of roller skins. Thread products are durable and suitable for applying any coloring compositions to the surface, but due to the abundance of splashes during operation, consumption cannot be called economical;

- flock. Designed to work with perfectly flat surfaces. They are inexpensive, but you should be careful when working with them - flock skins create a lot of splashes.

Villi length

According to this parameter, skins are divided into three categories:

- With high pile. Designed for processing uneven surfaces. The best option for painting brick walls and concrete. The length of the villi is from 18 to 22 mm.

- With medium pile. Designed for painting wooden surfaces, plasterboard walls and ceilings. Pile length is from 11 to 12 mm.

- With short pile. Small pile allows you to save material, but you can only work with it on well-leveled surfaces. Typically, fine-pile skins are used to treat metal and wooden surfaces. Dina of villi from 5 mm.

Roller width

The width of the tool is divided into three categories:

- Short. Used for processing small areas, processing areas with limited accessibility. Width from 20 to 100 mm, diameter from 10 to 15 mm.

- Average. Used for painting walls, ceilings and floor coverings. Width varies from 150 to 200 mm, diameter from 20 to 90 mm.

- Long. Designed for professional builders performing large volumes of work. They feature reinforced fastenings and a long service life. Width from 250 mm and above, diameter from 80 mm.

What kind of work is a roller ideal for?

As we said above, this tool is suitable for painting large flat surfaces. In this case, we can make sweeping movements, in a small number of which we cover the surface with a layer of paint. In this case, both the wall and the ceiling act as such a surface. Or you can apply not paint at all, but glue to the same back side of the wallpaper. And the most convenient way to do this is with a roller. And for each of these operations a different type of roller is suitable, the choice of which we want to talk about next.

How to choose the length of the pile

The length of the roller pile determines the amount of paint it can absorb and, accordingly, the thickness of the applied paint layer. Long pile has thicker threads, short pile has thinner threads. The choice of pile length depends on the texture of the walls being painted.

- For a rough surface - putty, concrete, wood - a fur coat with a pile of medium length - 5-20 mm - is best suited.

USEFUL INFORMATION: Popular interior design styles, their features and characteristics

- For smooth walls made of metal, plastic or plasterboard, you will need a fur coat with a pile length of up to 5 mm;

- Large-relief surfaces, for example, those covered with textured plaster, are painted with a tool with a pile length exceeding 20 mm.

Choosing a roller depending on the type of paint

Here we will talk about the material used to make the roller coat - the surface that is in direct contact with the paint and transfers this same paint to the surface of the wall or ceiling. All fur coats are divided into artificial or natural, as well as foam rubber and fleecy. Moreover, the length of the pile can be very different, but more on that below. And of course, the choice of a fur coat depends on what kind of paint we will use.

- Oil paint, enamel or varnish - fur attachment. Ideal would be sage or mohair (lamb or goat wool, respectively). Less expensive and of higher quality, but still an acceptable option, is artificial wool;

- Water-based paints or adhesive-based compositions - foam rollers. In addition, polyamide options (faux fur) show excellent results. Moreover, such options are also good because they wash well;

- Compositions that include solvents - polyamide rollers. As with the above paints, such tools show excellent results. But foam rollers cannot be used. Under the influence of the solvent, the foam rubber begins to decompose and its particles remain on the painted surface, greatly spoiling the appearance and quality of the applied coating.

Important! The ideal solution for working with a roller are alkyd, water-based, lime and adhesive compositions. This is because using a roller is much easier to achieve a matte finish than a glossy one.

How to choose a roller for the type of paint

The choice of a paint roller is based not only on ease of use, but also on the compatibility of the material of manufacture with the type of paint and varnish material. Efficiency when working with compositions based on water, drying oil, and polymers depends on this.

Water-based paints and varnishes

There are many painting products on the market for working with water-based compounds. Tools with terry, foam, or polyacrylic coats are used for painting. The recommended device for applying these compositions is polyamide rollers. This is due to the following qualities of polyamide fibers:

- economical consumption;

- effective absorption, which prevents splashing and smudges;

- lack of lint on the painted surface;

- Washable, so the roller can be reused many times.

Rollers with polyamide fiber coats are often used by professionals.

At the same time, the tool is easy to use, thanks to which even inexperienced craftsmen can produce effective coloring.

Solvent based paints

To apply paints and varnishes based on organic solvents, it is recommended to use rollers made of natural fur, since synthetic materials are not always resistant to the chemicals contained in paints.

For two-component compositions, tools made of velor, nylon, and microfiber are used. The disadvantage of such rollers is their high price. In addition, they need to be thoroughly washed with a large amount of solvent after painting is completed, otherwise the device will be unsuitable for the next painting. There are many options for paint rollers on the market. In order for the coloring result to be ideal, you need to take a responsible approach to choosing a tool, study consumer reviews and technical parameters. With a properly selected device, you can even carry out high-quality and beautiful painting of any surface with your own hands.

How to choose a roller for working with walls or ceilings

It doesn’t matter if you are planning to paint the walls in your entrance, or apply whitewash to the ceiling in your apartment - without a roller it will be much more difficult to do this. Now we will look at several options for rollers, listing their pros and cons.

- Thread rollers . They don't paint very well, but they do it extremely quickly. Used where quality does not play such an important role. At the same time, you should not work too actively, since the tool tends to splash paint in all directions, and it may well get on those surfaces where it should not get;

- Foam rollers . They also splatter the paint a lot. The cheapest options, which are ideal for applying not only paint, but also a primer before painting, as well as wallpaper adhesive. But foam rubber is not at all suitable for painting the ceiling. In the case of its use, bubbles remain on the surface, which subsequently peel off;

- Velor roller . It is an ideal option for those for whom quality is especially important. Such a tool is capable of leaving the most even and pleasing to the eye marks. But at the same time, they are demanding on the painter’s skill, since all your mistakes will remain visible. Therefore, you should first practice on something less noticeable in order to evaluate the correctness of the movement and application of force;

- Fur roller . Like velor, it is ideal for those for whom quality is most important. Unlike what was described above, such a tool can leave particles of fur on the surface, but only if we are talking about a low-quality option. Therefore, you need to buy such rollers in trusted stores. A fur roller is best suited for working with a sheet, as it absorbs the maximum amount of composition, which makes the work much easier.

Advice! The ideal length of a roller handle when painting a ceiling is 25 centimeters. You should not take handles that are too long. All this looks great in pictures, but in practice it is very difficult to work with such tools and you may not be able to leave even marks.

A paint roller is not easy at all

You can paint walls, floors, ceilings and other elements of a house or apartment with different paints and different tools. One of the most popular and commonly used tools for applying paint is a paint roller. The story will be about him.

There are many types of rollers and each of them is designed for a very specific type of work. Paint rollers differ not only in the area of application, but also in the size and material of the coat.

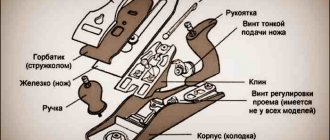

A few words about terms. A roller is a part of a tool consisting of a cylinder (plastic, wood or aluminum) with a soft coat placed on it, which absorbs paint and then, when rolled, transfers it to the surface to be painted. The design we are familiar with, consisting of a handle and a curved metal rod (clasp), on which the roller is placed, is called a machine or simply a handle.

Now that we have understood the terminology, let's talk about the classification of rollers. Domestic paint rollers are divided into four groups (GOST-10831-87 “Paint rollers. Technical conditions”) and each of them has its own letter marking: the first letter is always B (roller), the second determines the material from which its coat is made, and the third, if there is one, is the area of application. So, the first three groups are intended for painting surfaces with paint and varnish composition: group VM - fur-coated rollers, the second - VMP - fur-coated rollers for painting floors, the third - VMU - fur-coated rollers for painting concave corners. The last, fourth group is VP rollers with polyurethane foam (foam rubber) coating for working with water-based adhesive compositions. According to GOST, the fur covering of a paint roller should be made of sheepskin or a silk base covered with a pile of chemical threads.

Recently, a huge number of different imported rollers have appeared on sale. Their range is so large that it makes even a seasoned specialist think. Different countries have their own classifications of rollers. For example, Finnish manufacturers divide rollers into 7 groups.

Mini rollers

Mainly used for painting small or hard-to-reach surfaces, including corners.

Midi rollers

are one of the most common types used by amateur painters.

The difference between universal

and

professional

rollers is very arbitrary.

The criterion for such division, as a rule, is the quality of the coat and the diameter of the rod. Professional tools are characterized by a higher quality coat (they wear out much more slowly) and a rod diameter of 8 mm. Facade rollers

are characterized by the presence of internal intermediate packing and a more advanced bearing system. Due to this, in combination with the increased diameter, when working with such a tool, the roller turns more slowly and, as a result, paint splashing is sharply reduced.

Frame rollers

very easy to use, as they easily bend around uneven surfaces. In addition, they are 20-35% cheaper than traditional rollers. The peculiarity of these rollers is already indicated in their name - the fur coat is not put on a cylinder made of any material, like all other designs, but on a special frame made of wire or polymer. Unfortunately, they are still little known in Russia.

Special rollers

are divided into rollers for floors, wavy surfaces, aggressive and structural compositions, lamination and for rolling wallpaper.

But one of the leading manufacturers of painting tools, ANZA (Sweden), uses a different classification. There are three groups by size: mini-, midi- and maxi-rollers, and by application there are five groups: high-quality PERFEKTA; for all types of repairs (floors, walls, ceilings); for varnishes and enamels, when a very smooth coating surface is required; special and for simple work.

In addition to the size of the painting tool, you should definitely pay attention to the material from which its coat is made. Here the situation is even more complicated, because different companies use their own specific names to designate approximately the same fur coat materials. Here are the main groups of materials for fur coats and some of their names used by SOKEVA (Finland):

PE group - polyester (polyester): foam rubber (moltoprene), vestan (faux fur), yellow vestan (reinforced); group N - natural materials: sheep, llama, goat fur, velor, mohair, felt, rubber; group RS-polyacryl: kanekaron, modacryl (kanekaron-filts), meryl; group RA - polyamide: perlon, nylon.

Even fur coats made from the same material can differ from each other in other parameters. Here are just a few examples. Mini-rollers are made from several types of foam rubber: normal and high-density with a density of 30 and 60 kg/m3, respectively. Naturally, a denser roller lasts longer. Mini foam rollers, used for high-quality painting with varnishes and water-based paints, are available in two colors: dark blue (highest quality) and thick yellow. Polyacrylic rollers made from a material called Melir, which imitates lamb fur, are available in three colors (in order of increasing quality): blue, yellow and light green, and rollers made from perlon (polyamide) come in white, light yellow and light green.

| Roller type | Coat length (L), mm | Coat diameter (D), mm | Bore hole diameter (d), mm |

| Mini rollers (small) | 50-150 | — | 15 |

| Midi rollers (medium) | 50-150 | — | 33 |

| Universal | 150-270 | 52-90 | 44-50 |

| Professional | 150-270 | 52-90 | 44-50 |

| Facade | 150-270 | 80-105 | 44-62 |

| Frame | 180, 250, 270 | 55-90 | 38 (40), 47 |

| Special | 100-500 | 36-80 | 15-60 |

When choosing a roller, in addition to the material of the coat itself, you need to pay attention to its compatibility with the paint and varnish material that you are going to use. The resistance of a fur coat to paint can be judged by the stripes applied to it - the more of them, the more resistant the material is to aggressive substances. In addition, the stripes can be used to determine the method of its manufacture and replaceability. If the stripes on the fur coat run along the roller, it means it is sewn and can be replaced. If they are located across or obliquely, then the fur coat is glued and cannot be replaced. Most coats for mini and midi rollers are glued. They are not very durable, since paints and varnishes quickly destroy the glue. Rollers with glued coats are relatively cheap because their manufacturing process is less labor-intensive. Fur coats for professional, universal, façade and special rollers are usually sewn. They last longer and can be replaced with new ones if necessary.

And to make it easier for you to navigate when choosing a roller, you can use the data from our table, which correlates the material of the coat and the acceptable types of paints and varnishes. Coats made of polyamides and polyacrylics are the most resistant to chemicals; they can be used for almost all commonly used paints and varnishes. The situation with polyesters is more complicated - they are suitable only for water-based, alkyd and oil-based paints. Coats made from natural materials are not suitable for all types of paints. The price of a roller ranges from $1.5 to $12-15 depending on the size, material and quality.

Finally, a few words about the so-called textured rollers (for creating textured surfaces). They are produced in quite a few varieties, each of which is designed for a specific type of work with textured finishing materials. With help you can roll a pattern onto a prepared surface, get a marble or “wild” stone coating, and many other options.

In order not to be mistaken in the quality of the purchased tool for painting work, be guided by the presence of the international quality certificate ISO9001.

Some tips for a beginner painter

Do not try to use a very large roller at once; it is quite difficult to work with it; it is difficult to achieve uniform coloring of the surface.

In order for the surface to be painted evenly and without drips, before applying paint to the wall, the roller must be well rolled over a special pallet, and if there is none, then over a sheet of perforated metal or, in extreme cases, cardboard or plywood. Then there will be as much paint left on the roller as needed.

If you want to use a roller to apply paint of a different color than the one you previously applied, carefully roll it over a sheet of cardboard or plywood until you are sure that the inclusions of the previous color have disappeared. Then move on to painting the surfaces.

Do not use the same roller to apply different types of paint, even if the roller has been thoroughly cleaned with the appropriate solvent.

If you need to protect the roller from drying out for several days, then carefully pack it in a whole plastic bag and tighten it tightly.

If you need to store the roller for a long time (for several months), place it in a tin can of suitable length and diameter, fill it with paint and carefully wrap everything in a plastic bag.

And in conclusion, it is still necessary to say about machines (handles) for rollers (price $ 1.5-15). They differ not only in the size of the clasp, but also simply in the overall length. There are short (about 30 cm), medium (40-45 cm) and long (more than 50 cm) machines. If you need to paint something very high, then special extension handles are produced for this purpose. The length of such handles ranges from 0.7 to 4 m ($ 25-45).

There are several other elements that are designed to make working with the roller more convenient and of high quality. Increasingly, you can find pallets ($0.8-2), sets consisting of a roller with a pallet ($3-6), stands for the roller ($1.5-2) and scrapers ($0.3) for sale. cleaning it. The tray provides a place where the paint is poured and a surface on which the roller can be pre-rolled to ensure uniform impregnation.

So before you start painting, choose a suitable roller, get a paint tray and other necessary accessories, and then the work will be a pleasure for you.

Decorative rollers - what are they and how to use them

Unlike brushes, rollers allow you to very quickly and easily paint various patterns and images on the wall surface. Especially for this, there are decorative rollers that have irregularities on the working surface, the imprint of which creates a particular pattern on the wall.

Typically, such rollers are made of foam rubber or rubber, since fleecy options will not be able to ensure partial application of paint in the right places. This means that all the rules that we listed above apply to such rollers.

Working with such a tool is not so difficult, but you need to understand that correcting an error will be very, very problematic. Therefore, before work, it is recommended to practice on something necessary, see how the pattern is laid out and how to move the working surface.

Types and their application

The modern market for construction materials and tools offers a wide selection of rollers. The classification directly depends on the purpose of the tool, the material of the coat, as well as the type of paint and varnish material. As for fur coat materials, rollers are distinguished from:

- — Foam rubber – the shape is quickly restored, the material is quite elastic. When painting, no bubbles appear, an even layer is formed on the surface. However, not all paints are compatible with this material; it is best suited for water-based emulsions.

- — Velor – for final painting, suitable for alkyd paints, as well as oil and water-dispersion paints.

- — Polyamide – for water-dispersion based paints, the length of the pile varies from 8 to 20 mm, selected depending on the type of paint and the type of surface to be painted. For rough surfaces it is better to choose long pile. And for smooth ones - short.

- — Faux fur – for coloring decorative surfaces, can be reused. Pile length may vary.

- - Natural fur - mainly sheepskin rollers. They absorb paint strongly, but distribute it evenly over the surface. They are used for all types of paint, but are not suitable for whitewashing with lime. Disadvantage - some fibers may remain on the surface.

- — Felt – universal rollers, suitable for any surfaces and paints.

As for the purpose of the rollers, there are models for painting the interior and exterior and for giving the walls a certain texture and pattern. In the latter version, the cylinder can be made of foam rubber, rubber, plastic, wood, and so on.

Tips for using a roller

- Rollers belong to the category of rough painting methods if it is necessary to process small parts. Use them exclusively for flat surfaces of sufficient area;

- When painting walls or ceilings with a roller, be careful in the corner areas. If you move the roller unsuccessfully, you will leave traces of paint on the ceiling or whitewash on the wall. These problem areas are traditionally treated with a brush;

- Many people think that using a wide roller can process the surface faster. This is partly true, but with experience and strength. After all, wide models of rollers collect more paint, and they themselves are heavier. So manipulating such a tool can be quite difficult, as your hands will get tired. And it will be much more difficult to control movements.

Roller size

There are types of rollers for painting surfaces that differ in size. In this case, only the dimensions of the cylinder itself are taken into account, and the handle can be anything. According to this criterion, the tools are:

- Mini. In this case, we are talking about a cylinder with a diameter of no more than 9 cm and a maximum height of 15 cm. Most often, the products are used for finishing hard-to-reach surfaces or coverings with a small area.

- Midi. The diameter remains the same - 9 cm, and the height is slightly larger - up to 20 cm. Such tools are considered universal and are recommended for finishing at home. With their help, you can quickly paint walls, despite the fact that the rollers themselves weigh little.

- Maxi. As the name implies, such products are distinguished by their large dimensions. Their length reaches 30 cm, and their diameter is 8 cm. This type of roller is a professional tool, so the cost is appropriate. Most often the product is used for facade work.

Roller cylinders of different sizes

Some craftsmen immediately buy a maxi size roller to speed up finishing indoors, but this is not the best solution. The fact is that such a tool absorbs a significant amount of paint, so it becomes very heavy. In this case, the area of the internal walls is not enough to transfer all the absorbed paint to the surface, and the tool will remain heavy throughout the entire work. It’s better not to rush, but to paint everything with midi and mini rollers.

For painting the outside, on the contrary, it is not recommended to use the first two options. The fact is that their diameters are larger than those of maxi, so the paint splatters better, which makes it impossible to work quickly. Exterior paint dries very quickly, so speed of application is very important.