What is a drill

Available in a number of versions based on key characteristics. The usual kit includes an additional side-mounted handle and a chuck for standard drills. A number of models are produced for timber and its processing, and a certain design is available for dowels and their installation. A drill can be used to drive piles into the ground.

In this case, the pile is installed using equipment driven by a conventional gear drill. The pile must be screw.

There is a regular drill (this also includes a dowel and a hand drill), an impact drill, a mixer drill, and a drill-driver. Not a single production, construction or repair can be done without it.

Most often, the design is with a gearbox, while pneumatic ones are without them.

Prices range from affordable for household machines to high for highly professional tools. Materials for manufacturing: high quality plastic and metal. Controls - from the simplest buttons to electronic units.

Features of choosing a tool for working on concrete

To understand what a concrete drill is and which one to choose, you need to consider the following expert advice:

- the instrument must be of the impact type;

- to obtain a neat hole, it is necessary to have a function for adjusting the speed of operation;

- presence of two handles. During operation, the tool must be held firmly; this is difficult to do with just one handle.

It is necessary to select devices with high power. Since the concrete coating is dense and cannot be drilled with ordinary drills.

Areas of application

The direction of application is not limited to one drilling. Even drilling can be carried out on various materials. Usually - wood, metal, concrete and stone, brick and tile, hard soil and even ice.

A drill for concrete requires an impact type and preferably a powerful one. A low-speed one is also suitable for drilling timber. Manual is convenient for drilling ice in winter or taking soil samples in the mountains. There may be general purpose or highly specialized models.

By type of drive there is a networked and cordless drill, by type of power - electric (electric drills), pneumatic, gasoline and manual.

Typical tool failures

Knowing the design of an electric drill, it is easy to determine the reason why one or another of its functions does not work. It should be noted that you can avoid breakdowns of power tools if you periodically carry out preventive maintenance related to replacing the lubricant of mechanical parts.

After completing drilling work, it is necessary to remove dust from the tool, especially from its ventilation holes. The nature of faults is divided into electrical or mechanical origin.

Electrical damage

This type of breakdown occurs due to exceeding the permissible load on the device and violations in its operation. They manifest themselves in the refusal of the tool to turn on, in a malfunction of the reverse or speed controller. Most often, to restore functionality, you will need to disassemble the start button and clean all places associated with the electrical contact.

The appearance of a burning smell indicates an overload in the operation of the electric motor. In this case, the condition of the brushes and windings is first checked, and the connection points of the power wire are examined to ensure there are no burns. Burning is associated with the ingress of dust, as a result of which the contact resistance increases, which leads to heating. Electrical faults are easily calculated using a multimeter and visual inspection.

Drill: its types and characteristics

Main parameters of various models:

- power: applicable to electric motor (mains or battery powered).

For lumber, an electric model with a power of up to 1 kW is sufficient; for metal, you will have to work with a more powerful one. The impact drum should be at least 700 W, the mixer – from 800. For mini-models and screwdrivers, 400 W is enough.

- Revolutions per unit of time.

Regular ones have about 3000 revolutions per minute, the same for shock ones. For mixers, 500 is enough. These types can have a normal mode, but for a drill-driver, the switching mode will be optimal. A wide range is recommended, from hundreds to a couple of thousand revolutions. High-speed models are useful for professionals, and the manual mechanism is suitable for one-time operations or far from normal conditions.

- Availability of other settings.

Models produced may have power adjustments, control variations, and speed control may be useful. Experts advise that there is no need to purchase what you won’t need. Before choosing, you should understand the conditions under which the tool will work.

- Weight of the device.

A mechanism that is too powerful and heavy can quickly tire your arms and even your back. Therefore, for permanent or regular work, it is better to turn to a lightweight device. For rare operations, a heavier drill is allowed.

An ordinary one will weigh up to 2 kg, a mixer one – up to 4 kg.

- Type of food.

It can be with a power cable or with a battery. Corded ones are more common, but battery-powered ones are much more mobile (cordless drill). The latter have the disadvantage of frequent battery drain. The former are cheaper, but may require an extension cord if they are not working near an outlet.

- Cartridge option.

There are 2 main types: turnkey and quick-release. The turnkey design is more reliable, but if the key is lost, the work will stop. As for the second, it is much easier to work with, but the clamping force may be less. This causes the drill to become blocked by hard material.

As you can see, these basic criteria already create ground for thought. The choice of such a tool must be made taking into account the subsequent work. Moreover, each type of this universal tool has its own characteristics.

Electric drill

A pistol-shaped tool with a power cord running downwards - this is what an electric drill looks like. Its purpose is to produce holes in various materials.

Electric drill

Its main types:

- ordinary - minimum dimensions, functions for adjusting speed, drilling wood, plastic and metal;

- shock - a modified gearbox that gives the working body a reciprocating motion;

- drill-driver - a significant range of adjustment of rotation settings for unscrewing and tightening fasteners;

- mixing – the gearbox is reinforced for long rotation for the purpose of mixing solutions and mixtures.

The differences between the types are in the design of the gearbox and the presence of individual elements.

Various designs of controls are possible. The body is most often made of plastic, with linings made of tribological materials (rubber, polymers). There are variants in a metal case, but they are used in production conditions.

Cordless drill

A cordless drill is the most mobile. It can be used to work both indoors and climb stairs without restrictions. There is no need to carry a power cord or carry parts to an outlet. Therefore, the choice of installers and builders is on this type of device. A powerful group of models of this type are drills with a screwdriver function.

Cordless drill

What characteristics do these models differ?

- Battery parameters.

Power affects the power and duration of operation. What matters is the speed of discharge, the probability of heating, weight and size, and attitude to low temperature. Being powered by electricity, a cordless drill is extremely convenient to install.

There are several types: lithium-ion, nickel-cadmium, nickel-metal hydride. The first ones have the highest capacity and number of charge-discharge cycles. The second ones are cheap, they are not afraid of the cold, but they also quickly run out of charge. The third ones are the most environmentally friendly and are not subject to self-discharge; they cost a decent amount.

Capacitance (potential - operating time) and voltage matter. The higher they are, the better for work.

- Torque.

The higher the engine force to rotate the shaft with the working body, the better.

- Rotational speed.

Describes the tasks that the tool can perform. It is not the maximum speed that is optimal, but the ability to adjust the speed for specific materials and operating modes.

Pneumatic drill

Pneumatic drills use compressed air as power. This is a rotational mechanism for drilling work in any materials.

Pneumatic drill

An air drill (another name for a pneumatic drill) is often used for other tasks in addition to drilling. In production, it is used for drilling, countersinking and reaming holes.

The most commonly used non-industrial drills are hand-held. They come in end, corner and straight (gun-shaped body).

Main characteristics of pneumatic devices:

- required pressure of supplied compressed air;

- consumed flow;

- possibility of reverse rotation;

- chuck type and maximum diameter of the working tool;

- number of shaft revolutions.

For it, you can safely select a set of drills with a diameter of up to 10 mm; more depends on the model. Working pressure – up to 7 atmospheres, rotation power – up to 3000 rpm.

Electromagnetic

If you install a drill on a magnetic base-bed, you will get a magnetic drill.

Electromagnetic drill

An electromagnetic drill allows you to perform not only drilling with conventional drills. She can work with core drills with a diameter of up to 150 mm, thread cutting, countersinking and reaming. Processing is carried out only on metal - due to the magnetic principle of installation. This one won't fit under a tree.

Advantages of this design:

- reduced vibration level;

- independent pressing of the tool to the surface being processed;

- good hole accuracy.

The mass starts at 10 kg and directly depends on the volume of the magnet. The larger the magnet, the more spatial positions it can handle.

For professional work (so that everything goes smoothly and the drill does not jam), the usual preliminary preparation is required. The installation site is cleaned and the drilling site is accurately marked, and the accuracy and fastenings are checked. The sufficiency of space and the supply (if required) of coolant are checked.

Gasoline

If there is no electricity at hand or it is too far away, a gasoline drill will work very well. Sometimes you can hear its name as a “cordless drill,” but the phrase is more suitable for a cordless device.

Gasoline drill

Designed for drilling a wide variety of materials. The power plant is a two-stroke internal combustion engine, the installation of the working element is in a chuck clamped with a key. This type of drill is often large and differs in size from home models.

Gasoline diagram - for a professional drill. Working conditions are difficult: strong vibration, lack of precise alignment and installation angle, various spatial positions. There are options for idle, shock, safe start and speed control. All machines provide decent vibration protection. The handles are covered with a material with an anti-slip effect. Weight – from 4 to 12 kg. Such machines are powerful - up to 9 kW and 3000 rpm.

Work in the field can be carried out on sleepers, stone and concrete. Infrastructure construction and repair is a key consumer of such models. The high developed power allows you to make holes up to 250 mm. The mining industry uses it to plant explosives in rock.

Manual mechanical

A hand drill is a kind of “hello” from the USSR, where each master had his own. The quietest design possible, the drive is muscle power.

Manual mechanical

Until some time it was used very widely as a construction tool. The availability of this hand tool is high, the design is simple and can be repaired in the field. As a mechanical drill, it is suitable for use by all craftsmen. The processing material is wood and metal; it is suitable for concrete and stone with some restrictions due to its hardness.

This drill is not very high-speed, but it’s enough to drill or tighten something at home.

How does an electric drill work and how does it work?

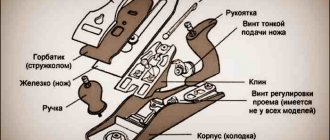

The structure and design of almost all drills are the same; what matters is the power and quality of the components. The elements of a power tool (go to products) in their standard form are:

- commutator motor consisting of a stator, rotor and graphite brushes;

- triac regulator, trigger that starts the drill;

- a gearbox designed to increase and decrease drill speed;

- a cartridge that is tightened manually or using a special key.

The design may include a power cable or battery, depending on the type of electric drill. Impact models are equipped with fixed ratchets that interact with each other and initiate a reciprocating movement, leading to the appearance of impact force.

The principle of operation of the drill is quite simple. The worker presses the start button, which “releases” an electric current to the motor brushes. They spin the rotor to the required speed; through the spindle, the rotor rotations are transmitted to the gearbox, which ensures the rotation of the cartridge. There is a drill in the chuck - and it starts to move.

The mechanism is slightly different only in impact models designed for drilling particularly durable materials, including making holes in artificial and natural stone. Additionally, some drills are equipped with a reverse mechanism, which allows you to quickly untwist the screw. Some models have drilling depth limiters, illumination of the workspace and a fixed start button, but these are all details that do not greatly affect the main functionality of the tool, although they make it easier to work with.

Which drill to choose and what to pay attention to

The types of drills are extremely varied: a cordless drill or a regular one, powered from the network, may be suitable for a master.

Main parameters and criteria for selection:

- convenience – this is the most important thing in work, otherwise the master will get tired quickly;

- functions for fixing buttons and limiting drilling depth;

- the presence of an emergency stop of the engine - its brake;

- possibility of reverse movement of the working body;

- backlight lamp;

- various positions for additional handle;

- general equipment and additional options - must correspond to what is required for the job;

- anti-vibration - no comment.

However, this is not all - more can be understood from the characteristics of the models and what is required for the specific planned work.

There is more than enough to choose from. Today's choice is rich in trademarks: from the well-known Interskol and Makita to poorly studied and new LLCs and Ltd.

Today's Tool Accessories

After some time…

...a conventional drill with an electric motor has been modernized and additional “gadgets” have appeared: the ability to drill with impact, reverse, the presence of an electric speed controller, LED backlighting, torque control, etc.

There are also cordless drill models that work autonomously and do not depend on an electrical source; Angle drills have also appeared, which will become an indispensable assistant for working in hard-to-reach places or where space is limited.