Repair sequence

1. Check the integrity of the wire running from the button (On / OFF) on the walk-behind tractor control levers to the spark plug.

Checking the integrity of the wire

2. Remove the spark plug and clean the contact with sandpaper. Check the gap between the contacts.

Unscrew the spark plug

When I was assembling the walk-behind tractor and cutters, I left the keys in the box and forgot, so for a long time I looked for the ring wrench that was included in the kit.

Having unscrewed the spark plug, I discovered carbon deposits - apparently the quality of the gasoline is not very good.

3. Screw the spark plug back in.

The walk-behind tractor does not start - we bleed the fuel supply system

A murmur was heard in the tank. After this operation, the walk-behind tractor sneezed and started up.

I think that the fuel filter still needed to be washed, because... there may have been a blockage in it that was blocking sufficient fuel from entering the combustion chamber. In any case, at the moment the walk-behind tractor has started up and is working, and I hope you will also be able to start the walk-behind tractor if it doesn’t start for you. In my case, the walk-behind tractor did not start even after stripping the spark plug. So I opened the fuel wire flap and blew into it .

The easiest ways to revive a walk-behind tractor:

and can occur with both old and new equipment. In this case, you will need to troubleshoot the engine of the walk-behind tractor.

One of the possible reasons is the absence of a spark between the electrodes or its breakdown (breakdown). In this case, it is necessary to replace the spark plug with a new one.

If there is a spark, but the engine does not start, check the spark plug insulation. If the spark plug gets wet, the tip (or rather its insulator) may be faulty. Remove the screen and install a new tip.

A frequent failure of a walk-behind tractor is popping noises and the emission of flame from the muffler (the engine does not start). The reason for this may be deformation of the flywheel key. Replace it by disassembling the starter ratchet. Open the clutch housing, remove the flywheel, remove the old key, install a new one and tighten the housing.

If the starter cord is pulled out without effort when starting, the cylinder seal may be worn out or the gasket between the filter and carburetor may not be installed correctly. To resolve, replace the seals and check that they are properly secured.

The walk-behind tractor also stalls after winter or after a long period of inactivity. In this case, gasoline does not enter the carburetor. The cause of the malfunction is the locking needle. Sediment and tar formations accumulate near it and prevent it from opening when the engine starts.

Poor quality or inappropriate gasoline may cause engine malfunction. In this case, the spark becomes wet and requires replacement of the tip. If you notice an odor uncharacteristic of fuel, replace it. What if the walk-behind tractor starts poorly and stalls?

After starting, the walk-behind tractor periodically turns off with popping noises. Make sure the spark plug is dry. If a conductive substance appears on it, this may cause a lack of spark between the electrodes. The spark plug can be replaced with a new one or the old one cleaned. To do this, it is washed, blown and calcined.

The engine started for a few seconds and then died again. Check the permeability of the sump. If the faucet is clogged, it needs to be blown out and cleaned (using gasoline). Water may also get into the fuel. In this case, you need to drain it and fill in a new one.

Replacement and adjustment

Quite often, unfortunately, there is a need to completely change the motor on a walk-behind tractor. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about products from Chinese factories have long become irrelevant. To avoid overpaying, you need to carefully analyze how productive the power plant should be. Buying a unit that is too powerful is simply irrational.

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to begin disassembly only after flushing the engine and removing oil from it. Lubricant is poured only when the engine is warmed up after a short run. Next it's time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- screen covering the cylinder.

READ Why does the walk-behind tractor reverse when you start it?

Motoblock. It won’t start, what should I do?

Then remove the crankshaft pulley. Following the pulley, it is necessary to remove the fan, reflectors, and insulating flywheel casings. Unscrew the cover, removing the rings and coupling bodies. When the washer is removed, you can press out the flywheel using a wooden block.

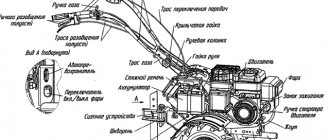

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is gained, remove the oil sprayer and locknut. After repairing and replacing damaged parts, reassemble the engine in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Replacing damaged valves for a gasoline walk-behind tractor occurs after removing:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

Often there is a need to replace rings. But be done in the process of more serious repairs. An isolated change of rings in itself is irrational both economically and technically. Additionally, a high quality ring group will usually have the same lifespan as a cylinder. They are changed at the same time.

Installation with an elastic band is advisable if a Chinese motor is installed on domestic walk-behind tractors. Rubber cushions are often used as a platform. They can be used as parts of the front shock absorber from a classic car. Along with the need to rearrange individual parts of the walk-behind tractor engine, many people have a need to install an electric starter themselves. This starter will have to be properly connected to the battery.

Walk-behind tractor engine will not start

The crown is attached only to the removed flywheels. First remove all interfering parts of the motor. To remove the flywheel, in many cases you cannot do without a special key. A generator and its magnets are installed in the flywheel assembly. When the terminals and contacts of the battery are aligned, you should conduct a test run of the walk-behind tractor.

Possible reasons

Does the walk-behind tractor start and stall? Why is this happening? There may be several reasons why a motorcycle does not start when starting. These include:

- damage to the carburetor (in units with a gasoline engine);

- defective ignition and glow devices;

- low level of basic lubricant.

When unusual changes occur in the unit and its operation becomes unstable, the carburetor is checked first. In this essential unit, the formation of the fuel-air mixture (FA) and its dosage for supply to the cylinders of the internal combustion engine (ICE) take place. And if the jets become clogged , the fuel system becomes obstructed, causing the carburetor to lose its ability to guarantee engine starting.

In order to eliminate the defect, the fuel line is repaired, which involves a partial analysis of the carburetor, flushing the pump, and purging the nozzles through the fuel fitting. If the Neva walk-behind tractor does not start, the reasons may also be different. Sometimes the problem is hidden in a malfunction of the spark plugs, which play an important role in starting a carburetor internal combustion engine, or the glow plugs, which ensure the start of a diesel engine. If the igniter devices become wet, which happens due to fuel assemblies being thrown into them, the spark begins to disappear in them. In the absence of sparking, the fuel-air mixture is not ignited and, therefore, the engine cannot be started.

This problem can be solved in various ways:

- carry out minor repairs and replace non-working spark plugs with new ones;

- “burn” the flooded candles and use a flame to clean them of traces of fuel.

The equipment does not start due to a defect in the glow plugs.

In a diesel engine, fuel is ignited by contact with hot air, which is heated in the cylinder when compressed by the piston. This occurs without complications if the unit is already heated and the operating temperature in it is maintained by the heated walls of the cylinder. However, in cool weather, the engine is heated using incandescent devices, and if they break, it will not be possible to start the walk-behind tractor. If, upon inspection of a carburetor engine or diesel engine, no defective spark plugs were identified, but difficulties persist, and are also accompanied by popping noises in the muffler, it is necessary to check the functionality of absolutely all devices responsible for the flammability of fuel. A defect in them may also be a reason that the walk-behind tractor does not start. It is more correct to carry out diagnostics in a service center, where specialists will find the cause of the damage and carry out professional restoration.

Walk-behind tractor repair

Unfortunately, any equipment sometimes fails, so its owner must be able to solve problems on his own. Of course, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs free of charge.

Damage to the cultivator and walk-behind tractor often occurs due to improper operation. In the event of a severe fuel spill, heavy loads are heavily transferred or oil loss is not compensated for in time. Then the car starts to swerve, "dig in", not very good at accelerating (especially if it has an electric motor) and even stopping. But, knowing the design of the unit and the operating principle of its mechanisms, you will be able to determine the cause of the damage and make high-quality repairs.

Fuel system repair

A fuel system malfunction may be reported if the engine:

- Doesn't start;

- Kiosks under load;

- Overheating;

- Not stable at idle.

To fix the problem, first check the condition of all filters, including air and oil. If they are a little clogged. They blow with compressed air or rinse if they are very dirty. Replace them with new ones. Then the carburetor is disassembled, the parts are washed with a special cleaner, the fuel supply valve, tank and piston system are cleaned with gasoline. Once dry, reassemble carefully.

READ Chainsaw Stihl 180 Starts Poorly When Cold

When the engine is fully assembled, tighten the crankshaft by hand. It is important that the piston moves freely and the valves work correctly. Then they fill it with fresh oil, start the engine and let it idle. Be sure to check the fuel flow in the cylinder. It is possible that after such repairs the cause of the malfunction will be eliminated and the walk-behind tractor will begin to work without interruption.

Ignition system repair

You can judge a fuel ignition failure by the signs when the engine:

- It starts, but during idle time;

- It does not start even with good fuel supply;

- It works at idle speed, but with some interruptions.

To find out the reasons, first check the condition of the spark plugs: if the insulator is damaged, they are replaced. Next, inspect the electrodes and, if necessary, adjust the gap between them. Check the condition of high-voltage wires for terminal oxidation and insulation damage. Damaged wires must be replaced with new ones. Without such repairs, the spark may disappear completely or pass through the insulation into the engine housing and fail to provide ignition to store fuel.

If a spark defect is not detected at this stage, it is possible that the equipment is not starting or is delayed, hidden in the generator or coil (for models such as Neva, a cascade is used to generate the spark). To test the generator, a measuring device is connected to its terminals. Rotate the pulley of the starter walk-behind tractor and record the readings of the device. They should be in the range of 12-16 watts. If the indicators are normal, the reason is in the ignition coil and after replacing it, you can put a load on the engine. Most likely, after such a repair, its performance will be fully restored.

Gearbox repair

The following factors indicate a transmission failure:

- The working shaft is stationary, and the output shaft rotates;

- The engine speed does not match the working shaft speed;

- The engine seems to be “suffocating” from the load.

If any of these reasons occur, immediately check the transmission for oil. The oil in it should be normal, since oil prevents “dry” friction of moving parts and prevents them from overheating.

Then the gearbox is disassembled, the gearboxes are checked, and the chain tension is checked. All parts are washed with kerosene, and damaged parts are replaced with new ones. After this, the structure is assembled and removed to prevent misalignment of the gears.

Before installing the assembled gearbox on the walk-behind tractor, rotate the shafts to make sure that they rotate evenly and without the slightest rattle. The gearbox is filled with fresh lubricant and the cultivator starts. If there are no leaks under the body, they perform simple actions with the soil or the installed loader and check the functionality of the walk-behind tractor. If its efficiency is restored, then all efforts were not in vain, and repairs and maintenance were carried out correctly.

Source

Motoblock. Your reliable and devoted assistant at any time of the year. Even when there is no field work, they are often in demand as a means of transportation. But in the cold season or after a period of winter “rest,” it often happens that your walk-behind tractor starts poorly or doesn’t start at all. We will tell you later what are the reasons for this annoying failure and how to fix them yourself.

Preparing the walk-behind tractor for start-up

Difficulties with starting the engine can appear not only in used walk-behind tractors and cultivators, but also in new ones just purchased at the shopping center.

For this reason, before starting a mini-tractor for the first time, you should read its instructions, then carefully examine all connections and, of course, check the oil level in the internal combustion engine. You should study the annotation compiled by the manufacturer in order to find out what operating speed the engine has: four-stroke or two-stroke. This is important to understand, since modifications with a two-stroke engine (like the Mole cultivator) require a special combustible mixture, consisting of a mixture of fuel and oil in a special proportion.

Due to the mismatch of fuel, the special equipment will make noise, and the spark plugs and fuel line may also be damaged, which can lead to fuel pump failure, and this is a direct path to expensive repairs at a service station. determine whether the fuel is suitable for the motorcycle by the smoke that appears. If the quality of the fuel is poor, it will have a white tone, as happens when the car is tilted too much.

Fuel quality is also important for a diesel walk-behind tractor. It does not start in winter - or it starts, but soon freezes - if summer diesel fuel is poured into its engine, since at low temperatures it begins to thicken and clog the fuel line.

The start-up of motor vehicles both in the summer and in the winter must be carried out in the established order. For example, to start a Krot brand motor cultivator, the following procedure is carried out:

- open the gas tap;

- set the suction motor to the “Choke” state;

- turn off the ignition and turn the engine several times with a manual starter;

- start the motor again and move the motor to the “Run” state.

Conditions often arise when the power apparatus starts easily, but freezes after a couple of seconds. In this case, you should check the permeability of the sump. If the reason is that the tap is clogged, then it is cleaned with gasoline.

Starting a motorcycle with a diesel engine will be somewhat more difficult. Starting a diesel engine begins with “de-airing” the fuel path, that is, by ridding it of air accumulations. For this:

- open the fuel supply valve;

- untwist the connections of the outlet channel until fuel appears;

- twist the connections and blow through all the nozzles.

If after the operations the motor does not function properly, and the special equipment begins to smoke, then the reason is the old lubricant, and it must be completely changed.

The unit does not start due to insufficient volume of oil fluid, so do not forget to control this parameter. Starting a motor cultivator after winter or prolonged downtime also has its own nuances. In order to bring the unit into working position, perform the following manipulations:

- open the gas tap;

- check whether the power is turned on;

- check the presence of lubricant;

- let the gas reach about half way.

Before putting the motorcycle into operation, all connections are checked, including transmission sections, clutch, starting mechanisms, and, if necessary, they are adjusted.

Starting a gasoline and diesel unit

The equipment is equipped with gasoline or diesel engines. starting a diesel walk-behind tractor and a gasoline machine.

For this reason, it is necessary to analyze the factors due to which the unit does not start for each specific type of engine. Before purchasing a walk-behind tractor , special equipment is prepared. It is necessary to make sure that absolutely all elements are present and to make sure that the mechanisms are securely fastened.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the walk-behind tractor systems. Storing in a cool and humid area will cause the following problems:

- oxidation of contacts;

- violation of wiring insulation;

- watering of fuel and oil;

- clogged carburetor jets.

Before starting a new walk-behind tractor, absolutely all connections, clutch cable, reverse and gas are checked.

Do not turn on the device if there are clamps or twisting of the harness threads. During the first start-up, be sure to check the oil level in the crankcase. Lack of lubrication will damage the piston group. The crankshaft spins up to 1400 revolutions per minute at idle. It only takes a couple of seconds to create a scuff mark on the cylinder plane.

Old oil can cause the engine to not run. At the same time, the walk-behind tractor emits white exhaust gases. This begs for an absolute oil change.

It should be taken into account that the mini-tractor does not start easily if there is not enough oil. Keep an eye on this parameter before starting a carburetor and diesel walk-behind tractor. In some modifications, protection is determined by a low level. The device blocks startup and the unit freezes.

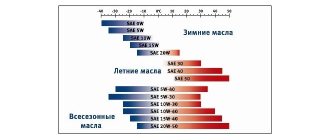

It should be remembered that any type of engine requires a specific brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is kept in strict balance.

Causes and solutions

The walk-behind tractor does not work - reasons:

- insufficient amount of engine oil;

- malfunctions in the performance of filament and ignition devices;

- malfunctions in the internal combustion engine power supply system of a mini-tractor with a gasoline engine.

Often the reasons that a walk-behind tractor does not start are due to improper operation of the spark plugs or glow plugs. This is due to the fact that the parts lost spark due to excessive humidity. It occurs as a result of throwing the fuel assembly.

If there is no sparking, then the walk-behind tractor engine will not start. How to solve the problem:

- repair or replace the damaged part with a new one;

- “burn through” the flooded spark plugs, thus clearing them of any remaining fuel.

If the diesel walk-behind tractor does not start, and the glow plugs are still functioning properly, then check the operation of all devices that are responsible for the flammability of the combustible substance.

Manufacturers recommend undergoing diagnostics at a service center so that technicians can determine the cause of the malfunction and carry out a full repair.

Mechanism repair

Starting a diesel engine after purchase can be difficult.

The problem is that air gets into the fuel supply system. If cranking for a long time (with the starter) fails to start, it is necessary to release the air plugs. To do this, open the supply valve and unscrew the connections along the channels. The final point of purging is the injectors. In order for an internal combustion engine to start , several conditions must be met. Let's list them in order:

- preparation of the mixture;

- delivery of fuel to the cylinder;

- ignition of the mixture;

- release of gases.

Fulfillment of the mentioned conditions ensures the start of any engine.

The diesel walk-behind tractor does not start well. Repair!

It should be noted that the walk-behind tractor does not start well if there is not enough oil. Just look at this parameter in advance before starting a carburetor and diesel walk-behind tractor. On some models, protection is set to a low level. The sensor blocks the start and the unit stalls.

You should keep in mind that whoever's engine type requires a certain brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of gasoline and oil. The amount of ingredients is kept in serious proportion.

Purchase gasoline for walk-behind tractors at gas stations. The service life of machines directly depends on the properties of the fuel. There is no need to start the walk-behind tractor on bad gasoline.

You will find it more difficult to start a diesel walk-behind tractor after purchase. What exists is that air is getting into the fuel supply system. If cranking for a long time (with the starter) fails to start, then the air plugs should be released. For this purpose, open the diesel supply valve and untwist what remains for our client to do is connect along the fuel channels. The final point of purging is the nozzles.

In order for a gasoline engine to start, a number of requirements must be met. Let's list them all in order:

- Preparing the fuel mixture.

- Supplying fuel to the cylinder.

- Ignition of consistency.

- Exhaust gas release.

Fulfillment of the listed criteria guarantees the start of any engine.

Difficulties during startup indicate a malfunction of components and devices. The success of the repair depends on the correctness of the diagnostics. If defects are found, they repair the diesel walk-behind tractor. Service and minor repairs are carried out by our own employees. A set of keys, locksmith tools and experienced hands will come in handy.

At the stage of preparing the fuel consistency, the following incidents are likely:

Difficulty starting

Difficulties during startup indicate a malfunction of components and elements. The success of repair work depends on the accuracy of the diagnostics. If deficiencies are found, they repair the diesel walk-behind tractor. Service and minor repairs can be carried out on your own. You will need a set of keys, a locksmith mechanism and skillful hands.

At the fuel preparation stage, the following incidents are likely:

- a lightweight filter does not let air in;

- the hole in the tank lid is boarded up;

- the fuel supply channel is clogged;

- The carburetor broke down.

After a series of unsuccessful starts, it is advisable to unscrew the spark plug.

The working part can be filled with fuel. In this case, we dry the element, then pump the cylinder through the hole. We twist the candle and start it again. If the candle is dry, it means that fuel is not entering the combustion chamber. Let us perform several operations one by one to restore the supply system:

- drain old gasoline;

- wash the tank;

- clean the special filter from dirt;

- clean the fuel supply hose;

- clean the carburetor jets;

- fill the tank with the cleanest fuel;

- open the tap;

- Clean the breathing channel in the tire.

Ignition system malfunctions

The engine will not start if there is a breakdown in the ignition system.

Why is this happening? Sources of interruption may be the generator, high-voltage cable, cap and spark plug. An external inspection is necessary to check the cleanliness of the ignition system elements. Dirt and moisture serve as a prerequisite for high force breakdown on the body. A lack of spark occurs when the cap does not make proper contact with the main electrode of the spark plug. A weak spark indicates poor spark plug performance. The gap and type of electrodes should be checked. The gap is usually checked with a feeler gauge. As a rule, the figure is 0.8 millimeters. If necessary, remove fumes from metal elements and insulators. It is recommended to change the spark plug.

The condition of the piston category elements affects the readiness of the engine as a whole. They operate in difficult circumstances. Under loading, the rubbing surfaces heat up. The cylinder, valve and rings are responsible for a significant indicator - compression. A low compression ratio in the cylinder will indicate replacement of elements.

It is also necessary to check the intake and exhaust valves. They should be close to the saddles. The muffler is the last point on the gas path. Over time, combustion products are deposited in the walls of the muffler, and the engine freezes. For a standard passage of exhaust gases, it is necessary to clean the walls of carbon deposits from time to time.

Buy gasoline for walk-behind tractors at gas stations. The operating period of the machines directly depends on the properties of the fuel. There is no need to start the walk-behind tractor on bad fuel.

Why the walk-behind tractor won't start - let's understand the reasons

Before the start of the season, both gasoline and diesel walk-behind tractors need preparation. To do this, the owner of the unit must make sure that the design of the unit contains all the parts necessary for operation, and each of them “sits” tightly in its normal place.

Often, many walk-behind tractors equipped with a Subaru engine or engines of other well-known brands refuse to work after a long winter period of inactivity. At the same time, incorrectly chosen storage conditions for an agricultural machine also have an effect - if it has been standing in a cold, damp room, then, most likely, it will not start before the start of spring work. This is due to a number of malfunctions:

- Oxidation of contacts in electrical wiring;

- Violation of the integrity of the wiring insulation;

- Watering of oil and fuel;

- Accumulation of debris in the carburetor jets.

Before starting a walk-behind tractor, its owner must carefully inspect all the connections in the design of the unit. You need to check the movement of the throttle, reverse and clutch cables - it should be soft. If during inspection you find clamps or twisted cables, then you cannot start the walk-behind tractor.

Before starting the walk-behind tractor for the first time, you should check the oil level inside the crankcase. If the lubricant is missing, this will lead to severe damage to the piston group. Judge for yourself: at a crankshaft rotation speed of 1400 rpm, a split second will be enough for it to form several burrs on the surface of the cylinder.

Oil left over for the winter is one of the main reasons for unstable operation of the unit’s motor. It is quite simple to make sure that the walk-behind tractor is difficult to start for this very reason - after starting, white smoke will pour out of the exhaust pipe of the machine for a few seconds, after which the unit will stall.

Do not forget that both diesel and gasoline walk-behind tractors have difficulty starting due to insufficient oil. Some models of units are equipped with low level protection; owners of other machines should independently monitor the volume of oil inside the tank.

Another important factor is the gasoline you use to refuel your walk-behind tractor. If you regularly fill up with fuel of a different brand than that recommended by the car manufacturer, this may also cause the car to not start.

Why won't the walk-behind tractor start?

Malfunctions with this problem can be very different and affect different walk-behind tractor systems. First of all, you need to check the availability of all necessary spare parts and accessories, especially if the walk-behind tractor is new or vice versa. Has not been used for a long time. Before starting work, carefully check all fasteners, connections and cables and their movement. Make sure there is oil in the crankcase and enough fuel in the tank. Do not start the walk-behind tractor if the cable is difficult to pass through. This may indicate twisting of the tourniquet threads.

READ How to Make a Harrow for a Walk-behind tractor with your own hands

After the winter holidays, the most common reasons for the inability to start a walk-behind tractor are oxidized contacts, broken electrical wiring insulation, wear and tear of fuel and oil during inactivity.

In addition, the common reasons that the walk-behind tractor starts to turn on poorly are the following:

- Breakdown and/or clogging of the carburetor and its components;

- Malfunctions in the ignition system (the most common malfunction);

- Low level of lubricant or its complete absence in the gearbox;

- Problems with the cylinder.

Do-it-yourself troubleshooting

Success in self-repairing a walk-behind tractor largely depends on how correctly you diagnose the unit. The reasons that the walk-behind tractor does not start may be hidden in the following:

- Due to blockages, air does not pass through the air filter;

- The hole in the fuel tank cap is clogged;

- Debris has accumulated in the fuel supply channels;

- Carburetor failure.

Each of these malfunctions is quite easy and quick to fix with your own hands. If this is not the cause of the breakdown, and the unit still does not start, then you should unscrew the spark plug and check for oil stains on it. If you find oil or thick carbon deposits on the spark plug, the part needs to be cleaned and dried. In addition, the cylinder of the walk-behind tractor will also need drying - to do this, you need to sharply pull out the starter cable several times.

It is often difficult to start a walk-behind tractor due to the lack of fuel in the combustion chamber. In this case, the candle will be completely dry. If this is the cause of the breakdown, then the following measures will need to be taken:

- Completely drain the old fuel;

- Thoroughly rinse the fuel tank;

- Clean the air filter from blockages;

- Blow out the fuel supply hose with compressed air;

- Blow out the carburetor jets;

- Fill the tank with fresh gasoline;

- Open the fuel tap;

- Blow out the breathing passage inside the fuel tank cap.

Before restarting, you will need to manually prime the fuel by pressing the fuel pump primer several times. After starting the engine, be sure to give it time to warm up, after which you can start working with the walk-behind tractor.

If all of the above steps did not help, and the walk-behind tractor still does not start, then check the intake and exhaust valves - if they do not fit tightly to the seats, the parts will need to be adjusted by turning the corresponding screws clockwise.

Also, if the walk-behind tractor does not start, we advise you to pay attention to its muffler - after prolonged operation, carbon deposits accumulate on its walls, which must be regularly removed using compressed air.

DIY walk-behind tractor repair

Unfortunately, any equipment sometimes breaks down, so its owner needs to be able to troubleshoot problems on his own. Of course, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs free of charge.

Often, damage to a cultivator or walk-behind tractor occurs due to improper operation: they fill with bad fuel, allow heavy loads, or do not replenish the loss of lubricant in a timely manner. Then the car begins to stall, stall, pick up speed poorly (especially if it has an electric motor), or even stops starting altogether. But, knowing the structure of the unit and the operating principle of its mechanisms, you can identify the cause of the damage yourself and carry out quality repairs.

Fuel system repair

A breakdown of the fuel system can be confirmed if the engine:

To eliminate the malfunction, first check the condition of all filters, including air and oil. If they are slightly clogged, blow them with compressed air or wash them; if they are heavily soiled, replace them with new ones. Then the carburetor is disassembled, the parts are washed with a special cleaner, and the fuel mixture supply valve, tank and piston system are cleaned with gasoline. After drying, carefully carry out the reverse installation.

After the engine is completely assembled, the crankshaft is cranked by hand - it is important that the piston moves freely and the valves work flawlessly. Then pour in fresh lubricant, start the engine and leave it to idle. Be sure to check the flow of fuel into the cylinder. Perhaps, after such repairs, the cause of the malfunction will be eliminated, and the walk-behind tractor will begin to function without interruption.

There is no spark on the walk-behind tractor - let’s look into the problem

Another common reason that a walk-behind tractor will not start is due to a problem with the unit’s ignition system.

Faults may be hidden in the cap, magneto, spark plug or high-voltage wire of an agricultural machine. When inspecting the ignition system, first of all you need to carefully check each part for blockages. If the spark is lost, the reason for this is often moisture or dirt getting on the elements of the ignition system. Also, often an agricultural machine does not start due to the inability to form a spark - the reason for this is poor contact between the central electrode and the spark plug cap.

If you do not find dirt or moisture in the ignition system, and the walk-behind tractor does not start, then be sure to check the integrity of the electrodes and the gap between them. As a rule, a special probe is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove carbon deposits from the insulator and metal elements of the ignition system.

Why does the walk-behind tractor start up and immediately stall?

Review of walk-behind tractor malfunctions: mechanisms for eliminating them, starting and stalling, repairs, video, problems in the ignition system, lack of fuel

- Preparing the walk-behind tractor for start-up

- Why does it stall under load?

- Device and main characteristics

- Doesn't develop speed

- Why does the walk-behind tractor work intermittently?

- The walk-behind tractor starts and stalls

- Why the walk-behind tractor stall under load

- Why does the walk-behind tractor work intermittently?

- Why does the walk-behind tractor shoot into the muffler?

- Walk-behind tractor engine is difficult to start when hot

- Fuel system repair

- Ignition system repair

- Transmission repair

- Why the walk-behind tractor stall when the air damper is open

- What to do if the walk-behind tractor engine does not start well when hot?

- Why does a walk-behind tractor engine have difficulty starting when hot?

- The main problems of the walk-behind tractor engine

READ Imported Engine for Motoblock Ural

Checking equipment before launch

Depending on its basic configuration, the cultivator can be equipped with a gasoline or diesel internal combustion engine. There are certain differences between these motors. Consequently, the reasons why the cultivator does not start may also be different.

Before starting the equipment, it must be prepared. During this, you should carefully inspect all working mechanisms and make sure that their fastenings are secure. Sometimes nodes refuse to work simply due to prolonged downtime. This is due to improper storage conditions. For example, if the equipment is kept in damp and cold rooms.

In these cases, the following malfunctions may occur:

- oxidation of ignition system contacts;

- loss of properties of fuel and oil;

- violation of electrical wiring insulation;

- clogged carburetor jets.

Before starting a new cultivator for the first time, you need to carefully check all connections, gas and reverse functions, as well as the integrity of the clutch cable. The latter should move smoothly, and during startup the operator should not make much effort. The engine cannot be started if the cable is twisted or caught between parts.

Starting must be carried out with a sufficient amount of oil in the engine crankcase. In the absence of lubrication, the piston group of the equipment will be subject to increased wear. In most models, the crankshaft is capable of rotating at speeds up to 1500 rpm. Thus, a few seconds are enough for the cylinder to partially deform.

To partially avoid problems with starting the engine, you need to drain the old fuel and oil after each use of the equipment. If you do not do this, the gasoline will gradually succumb to watering. The same goes for motor oil.

When preparing the cultivator, special attention is paid to the condition of the electrical wiring. If its insulation has been damaged, the wires will need to be removed and cleaned. When restarted, the equipment should start.

Why is a diesel walk-behind tractor difficult to start?

| Cause | Solution |

| Low room temperature | You need to pour hot water (not boiling water) into the radiator itself |

| Nozzle clogged | The injector needs to be replaced or cleaned. |

| Fuel is frozen | It is advisable to heat it up or even replace it with a better and fresher one. |

| Carburetor contamination | It should be removed, cleaned and adjusted |

| Muffler clogged with combustion products | The owner must disassemble the muffler, inspect it, wash it in fuel and clean it with a special scraper |

| Low injection pressure | Adjust pressure to normal level |

| The engine turns over too quickly and easily with the starter |

- The valve stem is stuck;

- The piston rings are completely worn out.

- Be sure to remove the valve and wash it thoroughly;

- It is important to replace the specified spare parts with diesel walk-behind tractors.

In any case, you should carefully study the instructions and follow the specified rules, because such care for your “assistant” can improve productivity and save time for the owner, who in the near future will no longer be involved in repair work and purchasing additional parts.

How to start a cultivator - the correct procedure

Often, household equipment does not start because its owner does not know the correct procedure for starting. In this case, you need to carefully re-read the cultivator operating manual. If it is not there, then you need to adhere to the algorithm that is suitable for most models.

To start the motor cultivator, you need to perform the following steps:

- First you need to move the fuel valve lever to the “Open” position;

- Then you need to close the throttle valve;

- After this, the ignition lever will need to be moved to the “Open” position;

- Next, the gas lever needs to be moved slightly to the left;

- Then you need to smoothly pull the starter lever until resistance is felt. Immediately after this, the lever must be returned to its original position and pulled sharply;

- The cultivator engine will start. You need to wait about 2 minutes until the engine warms up. As the internal combustion engine warms up, you should gradually open the throttle valve;

- You can adjust the optimal engine speed using the throttle position adjustment lever.

After completing all of the above steps, the farmer can start using the cultivator. To stop the engine, move the fuel valve lever to the “Off” position.

How to start a walk-behind tractor

The algorithm for starting the Neva walk-behind tractor is as follows. Before each use of the unit, it is necessary to check the oil level in the engine, if the amount is insufficient, the most expensive part of the cultivator can quickly become unusable. If the oil was filled a long time ago, it may deteriorate and also lead to engine failure. Some engine manufacturers, including Lon Chin, Subaru, install a sensor for the quality and quantity of oil poured into their devices, so such a check is not needed here - the electronics will do everything for you.

The next step is to add fuel, the type of which should be clarified from the operating instructions for the specific cultivator model.

For two-stroke engines, oil and fuel are poured into 1 tank, but in a certain proportion, which is indicated on the oil bottle.

Next, you should inspect the unit from all sides and check the fastening of the main mechanisms. These listed actions can be considered a preparatory stage when starting any cultivator, without exception. Now you can proceed to directly starting the engine.

But here the differences in actions begin, and everything will depend on what fuel the engine runs on:

- On gasoline. You should set the fuel choke lever to the “Start/Run” position, open the tap and turn off the ignition. You need to operate the recoil starter several times, then turn on the ignition and pull the starter. The engine starts, and the position of the lever should be switched to the “Operation” mode. Some models of cultivators are equipped with an electric starter - to start the engine you only need to turn on the ignition and start the device.

- On diesel. Due to the property of this type of fuel to freeze in cold weather, the first step is to warm up the unit. When using a motor cultivator for the first time after purchase, you should pull the starter several times or unscrew the fuel supply valve and each fuel supply mechanism. When opening the tap, wait until the fuel drains, screw it back on and proceed to the next connection until you reach the nozzle. You can open all the taps and put the lever in the middle position. Next, you should take the decompressor, press it and pump it several times. After this, you need to let go and pull again until it returns to its original state. All that remains is to press the decompressor and the starter. After these simple steps, the engine will start.

Read also: Calcium carbide plus water

When purchasing a walk-behind tractor, the sales consultant must explain to you in detail how to start the selected unit. Before using the equipment on your site, carefully read the operating instructions for the walk-behind tractor. If you follow all the manufacturer's recommendations, the unit will last a long time.

Some craftsmen are able to start a walk-behind tractor without a starter (used when it fails). To do this, remove it, then thread a tight rope with a knot at the end into the hole in the rim located behind it and wind it 4 times around this part of the walk-behind tractor. Next, pull the resulting piston up and turn off the decompressor.

Subtleties of using a walk-behind tractor after the winter break:

- The first thing you need to do is check the gas tank. For proper winter storage, the tank should be completely filled with gasoline, which is drained in the spring, and then fresh fuel is added.

- If the tank has remained empty all winter, then there is a high probability of dirt and rust forming in it, to remove which the contents of the tank are drained, the tank itself is removed, washed and returned to its original place.

- Air filter. It must be removed and cleaned in accordance with the operating instructions.

- Carburetor. Unscrew the drain plugs on it, from which the remaining fuel should flow. After finishing the draining, screw in the plugs.

- The same procedure must be carried out with the fuel tap. If it is clear that gasoline is flowing into these mechanisms, then the leak should be eliminated.

- Engine oil dipstick. It should be pulled out and wiped with a rag, after which you need to put the dipstick back and unscrew it again. Using it you need to determine the presence of oil, which should be no less than the top mark on the dipstick. If the oil level is lower, add the required amount. In addition to the oil level in the engine, it is necessary to evaluate its quality. If it looks like a black slurry and has a rather unpleasant burning smell, then it should be drained completely and a new one filled in.

- Next, how to tighten the belt on a walk-behind tractor. You should move on to the drive belt, namely, its tension roller. Its tension must be checked in this way: first release the control lever (the roller must also be released, without the need to pinch the belt), and then pull out the lever (the roller tensions the belt). If the roller tension is incorrect, the rod should be thrown over the links of the adjusting chain.

- Next in line is the main gearbox, in which you should check the oil level by inserting a regular wire into it. The amount of oil should be as specified in the instructions for the walk-behind tractor.

- Wheels and cutters. Examine their stoppers - if the quality is poor, they should be replaced.

Now the engine starts, and it should be warmed up with good gas for 3-5 minutes. But here some problems may arise.

Why won't the cultivator start?

The main reason why equipment does not start is the presence of old oil in the crankcase. This will be indicated by white smoke emanating from the exhaust system. To solve this problem, you will need to completely drain the old oil and clean the carburetor. After this, you need to fill in new lubricant.

Often the cultivator does not start due to lack of oil in the crankcase. Before starting, the farmer must check the amount of composition inside the tank using a dipstick. Sometimes cultivators are equipped with special protection that automatically triggers when there is a lack of oil. In these cases, a special sensor issues a command to block the start, causing the engine to instantly stall.

When using equipment, you need to remember that each cultivator model runs on one specific brand of gasoline. To refuel a 2-stroke internal combustion engine, you need to prepare the fuel mixture in advance. In this case, you should adhere to the proportions specified in the equipment operating manual.

To extend the life of the cultivator, only clean fuel should be used to refuel it. The working life of the piston group of the engine and the carburetor of the equipment depends on the presence of harmful impurities in it.

The walk-behind tractor will not start: reasons, how to repair it correctly

Owners of walk-behind tractors, cultivators, motorized towing vehicles and other mini-equipment sooner or later face a typical problem - their workhorse does not start or starts, but stalls when the air damper is opened, begins to “shoot”, gasp or “sneeze”. To eliminate this annoying problem, you need to find out the reason why it occurs, and then carry out the proper repairs. This problem occurs on equipment made in China, Japan, and Korea.

Why does the walk-behind tractor work intermittently?

The engine part of such equipment is made from wear-resistant materials. However, this cannot completely guarantee that there will be no malfunctions. Sometimes during operation the walk-behind tractor operates intermittently or partially stalls. Also, the presence of a problem is indicated by extraneous noise, knocking, crackling and other sounds that should not exist. The reason may be:

- cylinder failure;

- weak heating of the motor unit (determined by jerks in operation);

- loosening the ties between the engine and the starter;

- low quality gasoline or incorrect proportions of mixed fuel;

- broken starter cable (you can replace it with a new one yourself);

- piston wear;

- ratchet failure.

You need to apply for a technical inspection if the performance of the MB has decreased. This is the main symptom of failure of one or more parts.