The imagination of the average buyer may be amazed at the variety of tools provided by modern stores. This is especially true when purchasing auxiliary products for construction, repair and installation work of a narrow specialization, for example, a gun for driving dowels.

Of course, there are opponents of newfangled devices, who believe that all work manipulations can be done the old fashioned way. This is only partially true, since each individual case is specific and differs in the volume and speed of all work.

The tool discussed in this article significantly speeds up and improves the quality of manipulations with metal nails and any dowels. A special mounting gun greatly facilitates and reduces the work process.

Features and characteristics of the dowel gun

Having summarized the properties and parameters of various models of mounting guns, it is possible to highlight the following parameters:

— cartridge feeding: semi-automatic or manual;

— tool weight: from 3.1 to 5.0 kg (in the “charged” state);

— power: battery, gunpowder, gas or electrical network;

— system for supplying fixing elements: multi-charged or single-charged;

— gun length: from 345.0 to 475.0 mm;

— stem diameter: from 8.2 to 12.5 mm;

— temperature range for optimal operation: from -31 to +53 degrees.

Areas of application for dowel guns

In principle, from the name it is clear that the direct purpose of the mounting gun is to drive metal nails, dowels, pins or studs into various surfaces. The fixative is most often driven into the material:

- concrete;

- plastic;

— brick (silicate or ceramic);

— stone (artificial or natural);

- tree.

It is more advisable to use the tool in question for large volumes of monotonous work. The mounting gun is most often used for:

— laying various communications inside the building. It is important to take into account here that the quality of installation work directly depends on the speed of driving in fasteners. Thus, when slowly driving in initially aligned fixing parts, they often become distorted, which subsequently impairs the functioning of the electrical network, antenna wire or Internet cable, etc. In contrast, quick fixation using a mounting gun almost completely guarantees the evenness and accuracy of laying any communications. Of course, the most accurate calculations must be made and markings must be carried out efficiently;

— fixing facade siding to the building wall. When decorating siding with special nails, it is necessary to secure a huge number of elements to the wall. Carrying out such work manually is incredibly time-consuming, and if the wall is made of monolithic concrete, then the work becomes almost impossible. A mounting gun will help you complete the finishing process very quickly and efficiently;

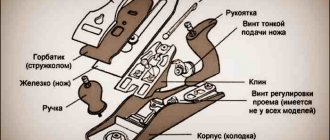

Foam mounting gun: device and principle of operation

To understand how any tool works and understand its operating principle, you just need to disassemble it down to the screw and become familiar with the purpose of each individual part. Knowing their purpose and the role they play in the tool, it will be quite easy to determine the breakdown and repair the mounting gun yourself. And it's structured quite simply.

- Frame. Essentially, it is a tube through which the foam is delivered. This is not a simple tube - in addition to the fact that it is made at an angle, it also has a special internal structure along which a rod with thickenings runs that perform the function of a valve.

- Kernel. It has a pair of bulges that are tightly ground into the corresponding places of the tube - when closed, these bulges do not allow the foam to come out and air to enter inside the gun. It is for this reason, due to the absence of air inside the gun, that the foam does not polymerize for a long time.

- A system of levers connecting the rod to the trigger - when the trigger is pressed, its movement is transmitted to the rod, as a result of which it moves and opens the passage for foam.

- For ease of use, this system of levers includes regulatory elements - by rotating a special screw, you can adjust the degree of opening of the valve and, as a result, the amount of foam released in a certain period of time.

- And, of course, the installation element, which is necessary for attaching a foam cylinder to the gun - in fact, it is a large plastic nut that is screwed onto the gun.

During the screwing process, the valve of the cylinder itself opens and is constantly in the open position. It is for this reason that the tightness of the gun is very important.

You need to pay attention to this point first. How to check the tightness of the mounting gun? Unfortunately, you can’t do this in the store, but after purchase it’s quite possible

You need to install a cylinder with a washing mixture on it, fire a couple of “shots” and remove the gun from the cylinder. If after a day, when you press the trigger, the flushing comes out of the barrel under pressure, then the gun is sealed and can be used with a full load. If not, then we take it back to the store and choose a new one. Among other things, when deciding how to choose a foam mounting gun, you should pay attention to the material from which it is made - a good gun has practically no plastic parts. Except for the installation ring, all elements of this product are made of metals.

Types of mounting guns for driving dowels

The tool discussed in this article can be presented in several versions, which differ fundamentally in the system that creates the force that drives the fastener into solid material. Depending on the principle of operation, the following mounting guns for dowels are distinguished:

— gas;

— pneumatic;

- gunpowder;

- electric.

Let's consider each option in more detail, taking into account the nuances of use, advantages and disadvantages.

1. A gas construction gun is a model that has an impact piston mechanism, which is activated by the explosion of a small portion of gas supplied from a special connected cylinder. The force of the explosion is transferred to the dowel and this energy is enough to almost instantly drive a metal fastener (pin, nail, dowel, etc.) into a solid material.

The advantages of such a construction and installation device include:

— lightness of the tool even in a charged state;

— absence of hoses, cables, wires and absolute independence from the presence of electricity;

— ease of operation;

— high impact power, which allows for direct installation work;

- multifunctionality. Gas mounting guns can replace a screwdriver or hammer drill.

In addition to the advantages, these models also have some disadvantages:

— the high price of each shot, which is due to the high cost of the gas mixture;

— it is necessary to ensure constant ventilation or ventilation of the room when working with a gas gun;

- considerable cost of tools and consumables.

2. Pneumatic construction guns are devices that operate on the expansion energy of compressed air pumped by a special compressor. This option is very popular among consumers.

Attention! For normal operation of the air gun, it is necessary to constantly maintain the average value of the supplied pressure within the range of 5.3-7.2 bar!

The pneumatic device is a little inconvenient to use, since a dense hose is connected directly to the mounting gun, supplying pressurized pressure. It somewhat limits possible movements and movements, however, modern models do not have this inconvenience and their air ducts are flexible and light. Continuing to list the disadvantages of the device, we can highlight its dependence on the availability of a source of electricity. If there are no working outlets nearby, it will not be possible to work with an air gun. Although, new modern models have special rechargeable batteries that ensure stable operation of the device for approximately 46 minutes.

Review of popular gas models

A gas gun for adjusting dowels to concrete will be an excellent choice for those who need to perform fast, reliable and high-quality installation of fasteners. Manufacturers offer a variety of models, many of which are worth considering.

Hilti GX 120

The mounting gun can work with stone, concrete monolith, sand-lime brick, and reinforced concrete products. The body of the instrument is large, weighs about 4 kilograms, is ergonomic and well balanced, so it is convenient and comfortable to hold in your hand.

Features of the mounting gun:

- The presence of a special LED indicator on the body, which signals the need to quickly replace the gas cartridge

- Reliable gas supply system, thanks to which the gun can work for several hours in a row, performing the required number of drives without interruption

- One gas cylinder will allow you to fire about 750 shots, one magazine is designed for exactly 40 fasteners

- Original design, ergonomic body shape, allowing you to work effectively and easily in the most difficult to reach places

- Successful packaging: the mounting gun is supplied in a plastic box made of impact-resistant material, where you can place both the tool itself and replacement cylinders, magazines with dowels. Also included in the kit is a device for removing nails used in installation from the gun head, high-quality safety glasses, special earplugs, an installation foot, an original branded napkin, and instructions.

All consumables (cylinders and dowels) are purchased separately from the gun. The model is very successful and is popular due to its high installation speed, high productivity, dust-free operation, and reliable fixation. The shot itself is carried out with a fairly loud sound, but this disadvantage can be compensated for by using earplugs or headphones.

Spit Pulsa 700 and 800

These are the most expensive models, the price of which starts somewhere from 70,000 rubles. But they can work with any type of surface and make it possible to set the depth of driving in fasteners by mechanically adjusting the length of the piston stroke. The force of the shot is effectively adjusted in automatic mode in accordance with the working surface.

The tool exhibits the reliability of the best industrial equipment. He works for a very long time without a break.

True, consumables need to be bought exclusively branded and quite expensive. But if reliability, quality, and performance are a priority, then this is definitely the best choice.

Toua GSN65

This mounting gun is designed to work with metal, brick, and concrete surfaces.

Tool Features:

- The magazine includes 40 dowels, one gas cylinder is enough to fire a thousand shots

- The weight of the pistol is approximately 5 kilograms (although the body is smaller in size, with a battery it turns out the same)

- The design is not very ergonomic, but experts say that even this unit is easy to get used to

- The package includes: instructions, two batteries and a device for charging them

- The model provides high shot power (equal to 120 J), allows the use of dowels with a diameter in the range from 2.5 to 3.7 millimeters

- There is an option to automatically adjust the power of one shot

- The optimal cost is about 35,000 rubles

Aiken MGN 850C Gas

This model is made in China and represents a budget price segment. The cost of such a mounting gun is about 25,000 rubles. But the quality is quite decent.

What a gun can do:

- The shot power is 85J, which is quite enough for working with concrete (however, such indicators are usually demonstrated by models of well-known brands designed for working with wood)

- Light weight – up to 3.5 kilograms

- The magazine includes 40 dowels, one cylinder allows you to fire 1000 shots

- Equipment: spare cap for the head, parts for the gas cylinder, a tube with transparent lubricant, a special 4 mm hexagon, earplugs on strings, two batteries and a charger for them

- Good ergonomic body made of high-quality plastic, thick rubber, with a reliable and comfortable handle, locking latches for adjustment

- Attractive price - on average, one shot with this pistol costs about 2 rubles (while Hilti's price is 15 rubles for fasteners)

Despite the fact that this mounting gun cannot be compared with the same Hilti in terms of shot force and reliability, the device can also become an acceptable option, especially as the first tool of this type.

General principles of working with a dowel driving gun

It must be emphasized that metal dowels (or dowel-nails), exclusively used in special mounting guns, are characterized by a special structure and configuration. They bear little resemblance to classic dowels.

This type of fastener looks like a regular nail, having a special washer located near the pointed end. It guarantees high-quality, maximum tight pressing of the fastener to the underlying surface.

The essence of the process of working with a mounting gun is to fire a loaded dowel at a designated location. As a result, the rod enters the material, and the washer moves up to the head and is fixed with it.

The fasteners under consideration make it possible to fasten any materials to solid foundations (stone, brick, plastic, concrete, etc.). It is important to remember that you cannot drive dowels into porous materials, otherwise the fastener may “go” into the material or the fastening will be very fragile.

Malfunctions of the spray foam gun

Everything would be fine, but unfortunately, frequent breakdowns of polyurethane foam guns occur. In general, they all boil down to two situations - the polyurethane foam does not come out of the gun, or vice versa - the device allows foam to pass through.

Foam does not flow into the mounting gun

If the polyurethane foam does not flow through the gun, most likely it has dried inside. Much less often there is another reason - the instrument itself is clogged. Well, it very rarely happens that you get a defective cylinder.

If the composition has dried inside the barrel, then in most cases it is possible to clean it. But more often the sealant hardens in the check valve. It is very difficult to remove. You will most likely have to say goodbye to the tool. The tool can become clogged if dust or sand gets into it when replacing the cylinder.

The gun leaks foam

Sometimes, due to the poor quality of the parts, the device may leak foam at the junction of the cylinder and the flange. It happens that over time it quickly dries out and does not come out anymore. However, it is too early to calm down. Air trapped inside the gun will promote hardening.

And in some cases, the hardened sealant can block the plastic valve of the cylinder. Then it will be very difficult to change it safely. When unscrewed, the composition may continue to exit the cylinder.

It is difficult to correct such a situation; it is better to prevent it. How? I'll tell you below.

And of course, for reliable operation, maintenance of the spray foam gun is necessary. This is necessary both when replacing the cylinder and during storage. How to care for a spray foam gun and how to clean it from foam if it is to be stored for a long time is most clearly explained in the video.

How to revive a foam gun

If the foam has dried in the mounting gun so that it cannot be washed off with a cleaner, you will have to disassemble the tool and remove the hardened compound mechanically. As a result of disassembly, you can gain access to all parts. You can clean the gun barrel from dried foam using a thin, long screwdriver. The most difficult thing to clean is the flange, since the compound can completely block the ball valve, and mechanical cleaning can damage it.

Instead of special washing, you can use dimexide in its pure form. It has a unique dissolving ability and can remove dried foam. It is not recommended to use solvents intended for paints and varnishes.

Dimexide is used in medicine for compresses in the treatment of inflammatory diseases of the musculoskeletal system. This substance is included in many ointments and gels: “Capsicam”, “Ketorol”, “Dolobene”, etc.

You can see how to restore a foam gun in the video I found on YouTube.

I myself have not done any cleaning for a long time, since there was no need. After modifications, my instrument has never dried out.