Angle grinder (grinder) MAKITA GA4530 without soft start. Photo 220Volt

When buying a cheap angle grinder, it will probably not have a soft start option . During startup, especially with a powerful angle grinder, you can feel all the “delights” of the jerk that the grinder produces when turned on. If you have a soft starter, the power tool will begin to do its job in a comfortable environment for the user . Undoubtedly, an angle grinder with this option costs more. However, it is possible to install a soft starter on the angle grinder yourself. This will solve the issues of saving money and will facilitate further operation - a device made by yourself is easier to repair if it fails.

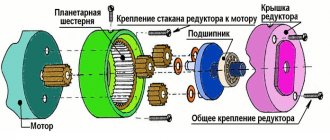

Device

In grinders without a soft start, the windings of the commutator motor are immediately supplied with a 220 V mains voltage , and to bring it into working condition an increased starting current is required. The soft starter ensures a gradual increase in voltage and, accordingly, the current during startup also does not increase abruptly.

This starting mode can be achieved using a special electronic circuit . Its main component is a semiconductor chip , which controls another, more powerful semiconductor device, a triac, which supplies power to the electric drive of the angle grinder. The thyristors of the microcircuit operate with a delay in the supply voltage until the circuit capacitor is fully charged. The principle of operation of the microcircuit is successfully combined with ensuring a smooth start of angle grinders.

Microcircuits k1182, LM358

The most famous microcircuit for the K1182 soft starter. This microcircuit was created back in Soviet times and now it is not so easy to find. There are other more affordable chips, for example, LM358. Many modern angle grinders use the LM358 chip in the factory version of the device.

LM358 chip

Double-sided cut

Quite often, when attaching a sheet to a profile in difficult places, it is necessary to perform a double-sided cut. This method is used when designing window openings, door openings, and, if necessary, bypassing beams and other complex structures. What is the best way to cut drywall in this case? First you need to make a hole of a rectangular or square shape. You can cut it using such a simple tool as a hacksaw or a sharp knife. The cutting process is not difficult:

- First you need to mark the sheet with a simple pencil and ruler;

- on one side the sheet must be cut using a hacksaw, and on the other using a knife;

- Now the drywall is cracking and being cut off on one side.

Afterwards, you need to carefully process the edge using a roughing plane to get smooth edges. When the sheet is cut, you can fix it in the required place using self-tapping screws. After installation, joints and seams are puttied and pre-glued with a special mesh.

Operating principle

The soft start device in a factory-made angle grinder is located inside the angle grinder body and is connected by contacts to the power button and the stator windings of the electric drive. It takes a certain time for the angle grinder to reach its nominal mode, and the electromagnetic field created by the uniformly increasing current and voltage through the stator windings causes the armature of the angle grinder drive to smoothly gain speed.

For grinders where the manufacturer does not provide such a device, usually in very rare cases it is possible to hide it under the body of the grinder. Most often it is performed in the form of a separate block, arranged in a break in the power cable circuit.

However, this does not change the principle of operation.

Homemade options

There are many schemes for modernizing power tools using soft starters. Among all varieties, devices based on triacs are widely used. A triac is a semiconductor element that allows you to smoothly regulate power parameters. There are simple and complex circuits that differ in design options, as well as in the supported power of the connected power tool. The design includes internal ones, which allow them to be built inside the case, and external ones, manufactured in the form of a separate module, which acts as a speed limiter and starting current when starting the angle grinder directly.

The simplest scheme

A soft starter with speed control on a thyristor KU 202 is widely used due to its very simple design (diagram 1). Connecting it does not require any special skills. Radio elements for it are very easy to obtain. This regulator model consists of a diode bridge, a variable resistor (acts as a U regulator) and a thyristor tuning circuit (supplying U to the control output with a nominal value of 6.3 volts) from a domestic manufacturer.

Due to the size and number of parts, this type of regulator can be built into the body of a power tool. In addition, the variable resistor knob should be removed and the speed controller itself can be modified by integrating a button in front of the diode bridge.

The basic principle of operation is to regulate the speed of the electric motor of the tool by limiting the power in manual mode. This circuit allows you to use power tools with a power of up to 1.5 kW. To increase this indicator, it is necessary to replace the thyristor with a more powerful one (information about this can be found on the Internet or in a reference book). In addition, you need to take into account the fact that the thyristor control circuit will differ from the original one. KU 202 is an excellent thyristor, but its significant drawback is its configuration (selection of parts for the control circuit). To implement a soft start in automatic mode, scheme 2 is used (soft starter on a microcircuit).

Soft start on a chip

The best option for manufacturing a soft starter is a soft starter circuit with one triac and a microcircuit that controls the smooth opening of a pn type transition. The device is powered from a 220 V network and is easy to assemble yourself. A very simple and universal soft start circuit for an electric motor also allows you to regulate the speed (diagram 2). The triac can be replaced with the same one or with characteristics exceeding the original ones, according to the reference book of semiconductor-type radioelements.

Scheme 2. Scheme for soft start of a power tool

The device is implemented on the basis of the KR118PM1 microcircuit and a triac. Due to the versatility of the device, it can be used for any tool. It does not require configuration and is installed into the power cable.

When the electric motor starts, U is supplied to KR118PM1 and the charge of capacitor C2 gradually increases. The thyristor opens gradually with a delay depending on the capacitance of the control capacitor C2. With a capacitance of C2 = 47 μF, there is a delay at startup of about 2 seconds. It depends directly proportionally to the capacitance of the capacitor (with a larger capacitance, the startup time increases). When the angle grinder is turned off, capacitor C2 is discharged using resistor R2, the resistance of which is 68 k, and the discharge time is about 4 seconds.

To regulate the speed, you need to replace R1 with a variable resistor. When changing the parameter of the variable resistor, the power of the electric motor changes. R2 changes the amount of current flowing through the triac input. The triac needs cooling and, therefore, a fan can be built into the module housing.

Thus, to start electric motors of various tools, it is necessary to use factory-made or home-made soft starters. Soft starters are used to increase the service life of the tool. When starting the engine, there is a sharp increase in current consumption by 7 times. Because of this, the stator windings may burn out and the mechanical part may wear out. Soft starters can significantly reduce the starting current. When making a soft starter yourself, you need to follow safety rules when working with electricity.

A soft starter is an electrical device used in asynchronous electric motors, which allows the motor parameters (current, voltage, etc.) to be kept within safe limits during startup. Its use reduces starting currents, reduces the likelihood of motor overheating, eliminates jerks in mechanical drives, which ultimately increases the service life of the electric motor.

Disadvantages of angle grinders without soft start

Cordless angle grinder Metabo W 18 LTX 125 602174850 with soft start. Photo VseInstruments.ru

In addition to providing comfortable working conditions for the user, the angle grinder with soft start has a number of other advantages.

- The absence of a large starting current during the soft start of the angle grinder , which is several times higher than the nominal value of this parameter during operation, increases the reliability of the electrical part of the power tool. In this case, the winding wires do not experience overloads and do not crack, the commutator lamellas and brushes are not subject to wear from increased sparking, and processes that worsen the connection do not occur at the contact points.

- During a uniform increase in the speed to the nominal value, the angle grinder with a soft start does not experience increased dynamic loads that arise in its absence. An instantaneous acceleration of 6000 rpm or more does not leave its mark on the gear transmission and bearing units . They fail faster, so angle grinders without such a device are more often repaired.

comparison table

The table shows the main characteristics and prices of miter saws, which will allow you to choose the option that is suitable for your purposes.

ModelPower, WDisk diameter, mmCut width/height, mmRotation speed, rpmAverage price, rub.

| STAVR PT-210/1800 | 1800 | 210 | 310 / 62 | 5000 | 9 400 |

| BISON ZPT-255-1800 PL | 255 | 305 / 75 | 11 300 | ||

| ELITECH PT 1825K | 4800 | 11 700 | |||

| PATRIOT MS 255 | 300 / 72 | 5000 | 11 800 | ||

| Hammer STL1400/210PL | 1400 | 210 | 300 / 65 | 14 600 | |

| Metabo KGS 216 M | 1500 | 216 | 305 / 65 | 18 400 | |

| Hyundai M 2500-255S | 2100 | 255 | 340 / 75 | 5100 | 18 000 |

| BOSCH PCM 8S | 1200 | 216 | 220 / 65 | 4800 | 18 700 |

| Sturm! MS5525S | 2200 | 255 | 430 / 75 | 19 500 | |

| DeWALT DWS774 | 1400 | 216 | 265 / 70 | 4500 | 28 100 |

READ How to Choose the Right Reciprocating Saw

Hyundai M 2500-255S

Compared to previous models, this cross-cutting machine stands out for its improved performance characteristics. With its help, you can work with denser materials and use larger workpieces. This allows you to effectively use the device in a carpentry or furniture workshop. To maintain cleanliness during large volumes of work, it is possible to connect a bag and a vacuum cleaner.

When in use, the device does not make much noise, which ensures acoustic comfort for the operator. Long-term performance of the motor is due to the presence of protection against power surges. A special safety button prevents you from accidentally turning on the saw.

- Availability of special fastenings for permanent installation.

- Rubberized stands to reduce vibration.

- Durable load-bearing part, resistant to damage.

- Light weight, so the device is easy to move from place to place.

- High engine power.

All saws have different prices, so you can find one that suits any budget and needs. They are used in everyday life, in small production, and are lightweight, making them suitable for long-term daily use. With their help, you can repair or cut various materials much faster compared to manual labor.

Sturm! MS5525S

This model is characterized by the ability to process workpieces up to 430 mm wide, which previous models cannot do. Widely used in furniture workshops. Saw

reliable, easy to use, does not require special care, performs a full range of tasks - creates inclined, straight, combined cuts.

The use of special discs allows you to work with laminate and non-ferrous metals. Thanks to the technical characteristics, an even cut without chips and cracks is ensured. The laser pointer makes work easier and increases productivity.

- Protects the operator from dust by installing a bag.

- Steel sliding guides for increased possibilities.

- Extenders for long products.

- Powerful clamp for fixation.

- Stability due to special fastenings on the base.

How to make a starter unit for a power tool

There are quite a lot of options for independently equipping an angle grinder with a soft start device. Some of them are presented in the author's videos.

Starter unit based on LM358 chip

In the following video, the author shares his experience of independently manufacturing a soft-starter board according to a diagram taken from the Internet, based on the LM358 chip . The author made the housing for the board from a shampoo box, which speaks of the rich imagination of amateur craftsmen. The author did not just blindly copy the circuit from the Internet, but modified it by replacing the characteristics of some of its elements : transistors, diodes, resistors. The radiator for cooling semiconductor devices is taken from a tape recorder. In order to be able to place the soft start unit inside the body of the angle grinder, and not as in the case of the proposed option, a smaller board was developed.

Technology of work on the manufacture of the starting unit

The author of the following video describes in detail the work methods, components used and auxiliary technological materials for the manufacture of a soft starter. the k1182 microcircuit is taken as the basic element . The technology is not designed for use as the basis of a printed circuit board; the author calls such an assembly “surround mounting” technology. In this type of work, in addition to soldering, individual elements are fastened using fasteners, for example, this is how a triac is attached to a heat sink. The ready-made launcher is not universal for all angle grinders. On two angle grinders taken separately by the author, they reached the operating mode in significantly different periods of time.

One of the layout options for a homemade launch unit

As the initial option, the author of the following video chose a well-known assembly with the LM358 chip . Since the assembled starting unit did not fit inside the body of the angle grinder, the author “packed” only a triac with a radiator inside, due to good cooling conditions from the angle grinder’s fan wheel. The rest of the block, together with the microcircuit, was secured to the body of the angle grinder.

Using an iron as an additional load to reduce the speed of an angle grinder

This method does not specifically relate to the topic of soft start of an angle grinder. However, to understand the principle of operation of an electronic device, a dimmer , which is used to adjust the power (or number of revolutions) of an angle grinder, is quite acceptable. In the next video, the iron takes a certain power from the angle grinder, thereby reducing its speed.

The typical starter circuit diagram should be modified for each individual power tool

The author of the following video tells how he equipped his household grinder with a soft start device to increase its service life.

Important: the circuit may work perfectly for adjusting the brightness of the lamp, but for the necessary functioning of the angle grinder, upon startup, be unable to perform the task. To operate effectively, it must be “customized ,” namely, select the required resistor values, capacitor values, and possibly change the characteristics of semiconductor devices.

How to install a standard dimmer in an angle grinder to adjust speed

In the next video, the author modified the power button (made it spring-loaded) in order to use the capabilities of a purchased dimmer to adjust the speed of the angle grinder. After turning on the angle grinder, moving the button sets the required speed mode. The dimmer fixes this mode and when turned on again, it is set.

Reviews of Metabo KGS 254 M

Advantages: High-quality assembly, laser and desktop lighting are networked, high-quality bearings, good disc brake, I like the tool. 3 year warranty.

Pros: Excellent device. Powerful. There is a laser and illumination, a clamp is included. degrees are clearly set at school. at corners 45 and 0, the notch will not miss a millimeter.

Disadvantages: I see one drawback is the lack of a soft start; with a soft start they cost completely different money. You can set up a soft start yourself