A wide selection of power tools on the Russian market are designed to facilitate various types of manual work. If in the professional sphere the purchase of specialized equipment is simply necessary, then in everyday life it is not always rational to spend money on an expensive tool, which after completing a certain job may not be useful at all. The most popular power tool is the angle grinder (angle grinder). Its scope of application is not limited to metal processing - grinding wood with a grinder is done using special attachments.

Features of choosing a grinding wheel for wood

For those who don’t know “Is it possible to process wood with an angle grinder?” this article will be useful. To perform grinding and polishing of wooden products or large solid surfaces, you will need to purchase the appropriate attachment - a circle. For grinders of different sizes, nozzles are selected that are designed for a certain rotation speed. Special discs designed for wood processing must be carefully selected. The disk must match the dimensions of the tool; a special nut is used to secure it.

When working with angle grinders, it is necessary to strictly observe safety precautions and use only factory-made wheels that are suitable for a specific model of power tool.

Processing wood with an angle grinder

Coarse grinding discs for wood for angle grinders

There are several types of circles that differ in shape, material of manufacture and purpose. As a rule, a wooden workpiece must first undergo a rough surface treatment, after which it is subjected to finishing or final detailing of the coating with abrasive segments.

For such work, there is a special attachment on the grinder for sanding wood. The most popular are:

- Grinding circles. This type of sanding attachment on an angle grinder is best used to remove a layer of old paint. Also suitable for varnished coatings that cannot be removed by hand. This could be a wooden floor painted several times or a window sill. The design of abrasive discs consists of a disc and metal bristles made of elastic wire. Nozzles are available with different arrangements of steel bristles. Depending on the desired effect, the bristles can be placed along the entire perimeter of the disc parallel to the tool or perpendicular to the segment - as in a regular brush.

- Cord brushes are a disc with a coarse abrasive coating designed for rough sanding and removing uneven surfaces on a wooden surface. With the help of this tool, a piece of wood takes on its final shape. The work productivity is significantly higher compared to conventional hand tools.

- End discs. Nozzles are used when you need to level a product from the end. Miter cuts and edges of the workpiece require such processing. The technique is identical to a file, but the effectiveness of the abrasive exceeds that of a hand tool. When working with a segment, it is important to have skills, and then such a simple tool can completely replace a molding cutter in terms of edge processing.

Using a grinder for polishing wood, you can completely restore furniture covered with varnish and paint. After such cleaning, the thickness of the wooden base practically does not decrease, but the newly painted furniture will look beautiful and impressive.

When performing grinding work with an angle grinder, the choice of tool is not so significant compared to the presence of well-dried wood and the absence of cracks on the surface.

What kind of circles are there for cutting wood?

Processing wood with a grinder is a safe process, unlike cutting. The process is very dangerous; the tool is not intended for cutting wood. Soft woods are processed with an angle grinder attachment with extreme caution, because the tool may jam and be torn out of your hands. The cutting process at high speeds implies a high temperature effect on the disc material, as a result of which it can simply shatter into small pieces.

Despite the fact that the grinder is not suitable for cutting wood products, manufacturers offer various cutting discs for use. It is recommended to use the grinder as a stationary station when sawing wood.

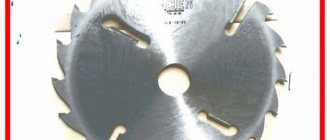

Circular saws

Circular saw attachments are dangerous when using an angle grinder. The diameter of the circle must be selected based on the parameters and dimensions of the tool in order to be able to use a protective casing.

Circular saw attachment

There are more expensive modifications of circular nozzles; they have anti-jamming protection. The design has teeth set in different directions, smaller in size, the price of such a device is different, but you should not save on your health.

Chainsaws

The chain type of nozzles has a safer design. The sawing disc, which uses a chain from a chainsaw, eliminates jamming of the tool and reduces the risk of injury during work. The design has a system that allows the main element, which is attached to the angle grinder, to continue rotating, and the chain can remain stationary.

Chain disks come in many different modifications, with the help of which it is possible to carry out gardening work or use it for collecting small firewood. A disk of a chain design can be used instead of a peeling disk for cutting out cups in a log or removing a layer of bark.

Saws with few teeth

Increased safety when working with wood is achieved by using discs with a small number of teeth. Small discs usually have 3 teeth, those with a diameter of more than 180 mm - 4 teeth. This type of cutting disc is used for cutting both along and across the grain of wood. The saw wheel makes it possible to cut grooves and make tenons of various shapes.

Four tooth disc

It should be understood that when working with an angle grinder, you must adhere to technical regulations. There is no need to install larger diameter discs bypassing the protective casing; smaller discs can be used without loss of cutting properties.

Tungsten carbide discs

Tungsten carbide cutting discs have been produced relatively recently and are popular when working with an angle grinder. The universal tool is not equipped with teeth; instead of cutting elements, there are cutouts in the disk. The operation of the tool is most safe when cutting wood; it eliminates jamming when nails or thick rods of wood hit. The appearance is similar to a diamond blade for cutting concrete, the purpose is indicated on the packaging or instructions.

Tungsten Carbide Disc

The price of such a disk is high, but it is justified. It is worth overpaying for a modified tool rather than going broke on the sad consequences of using a regular saw blade.

Grinding wheels for gentle processing and their areas of application

To sand wood with a grinder, attachments of a universal design and with a special gentle coating are used. This type of machining is intended to perform certain types of work:

- The flap disc is used for grinding solid wood. The design of this segment corresponds to its name. Its working surface is equipped with a large number of trapezoidal petals of sandpaper, which overlap each other like fish scales (three-quarter overlap of the previous row). With this arrangement of the petals, abrasion of the nozzle occurs much more slowly.

This is the most common type of grinder attachment for sanding wood, which performs soft surface treatment, and the tool itself is less traumatic. To achieve the required degree of processing and high quality, the disc is selected according to its grain size. The size of the abrasive determines how quickly and efficiently the unevenness on the wooden surface will be removed.

The sanded coating at different stages of processing may remain slightly rough or be perfectly smooth without the slightest flaws or snags. The final result can be achieved by sequentially moving from abrasive discs with a coarse-grained fraction to segments for finer processing. Therefore, you will need several discs for a grinder for sanding wood, which will be changed in stages.

To use the petal attachment, certain skills are required, which means that training before performing important work will be simply necessary.

- Wheels for soft grinding. The universal attachment for grinders for sanding wood appeared on the market relatively recently and is distinguished by its special design and high functionality. Rough work is carried out by replaceable discs with the desired grain size, which are attached to the sticky base of the attachment. In this regard, the abrasive tool received the corresponding name - a sticky disc.

The main advantage of a grinder wheel for grinding wood is the quick replacement of a worn-out replacement disk: the entire procedure takes place without removing the main attachment, which is secured with a nut. First, you need to purchase a sticky attachment for grinding on an angle grinder, so that later you can replace the worn-out abrasive segment without any difficulties.

How to choose grinding attachments for an angle machine

Circles should be selected according to the main parameters:

- outer diameter (larger sizes speed up the processing process and increase service life);

- landing diameter (installation of a larger circle on a smaller one is possible using a special adapter);

- thickness (the greater the thickness, the longer the segment will last);

- grain size (the fraction must correspond to the type of processing: coarse abrasive for rough work, and fine abrasive for soft processing and creating a finishing coating);

- type of segment (special attachments for processing wooden surfaces are suitable).

Reference! The shaft diameter in modern angle grinders for wood is 22.2 mm.

What you need to know when working with an angle grinder

Renewing flooring (parquet), furniture or the facade of a house where wooden structures or individual elements are present is carried out using a grinder for grinding, which is equipped with different attachments. Therefore, it is not surprising that an angle grinder for polishing wood is a popular power tool among professionals and at home. But in order to choose the right tool for the job, you need to carefully examine the wooden surface for the presence of fungus, cracks and irregularities. A video is provided to help beginners who want to know “How to properly sand wood with a grinder.”

A grinding attachment must be selected for each angle grinder model; only in this case will safe performance of work and high-quality surface treatment be guaranteed. Before you start working with a grinder (sanding wood), you need to make sure that the disc is properly secured. The angle machine must be moved smoothly over the surface and the tool must not vibrate.

When working with an angle grinder for grinding wood, it is unacceptable to use discs of small thickness (high rotation speed and load lead to the wheel breaking, which can lead to injury).

On a note!

Wood processing also means its cutting (sawing). Sometimes, when manufacturing piece parts, you have to adjust them to the installation site even before you start grinding the sample. Some “craftsmen” (and there are many of them among friends and on the Internet) advise using circular saw blades for such operations. Strictly prohibited! Here are just the main reasons why this should not be done.

- “Bulgarian” is a high-speed machine. And although the metal from which the cutting discs are made is durable, it does not withstand this mode for long. More precisely, cutting edges (teeth), which are fixed by soldering. During intensive work, they fall off and fly apart, and with great speed. The consequences are easy to predict.

- Not all discs in size (primarily, outer diameter) are suitable for installation on angle grinders. This means you will have to dismantle the protective casing. The same thing - you can forget about employee safety.

- The structure of wood (even hardwood) is quite loose. Therefore, there is a high probability that the saw blade may jam due to constant vibration. How the “grinder” will behave in such a situation, given its power and speed, no one can predict. But it’s clear that it can easily escape from your hands.

- Constant changes in mode (for the same reason - the viscosity of lumber) lead to systematic overheating of the angle grinder engine. If used this way, the grinder will not last long.

That is why wood processing with its help is carried out only superficially - rough stripping, sanding, brushing. And for cutting you should use sawing tools and mechanisms (hacksaw, circular saw, electric jigsaw, and so on).

Cost of wheels for woodworking

The price of a tool for polishing a wooden surface is not high, but it depends on the material, diameter and thickness. The table shows the average cost of abrasive tools in large cities of Russia:

| Name of cities | Price of wood attachments, rubles per unit | ||||

| Petal disc | Abrasive discs for soft sanding | Roughing (cleaning) wheels | End discs | Cord brushes | |

| Moscow | from 70 to 900 | from 35 to 14900 | from 86 to 270 | from 33 to 430 | from 36 to 5400 |

| Saint Petersburg | from 95 to 800 | from 35 to 14900 | from 86 to 270 | from 33 to 430 | from 36 to 5400 |

| Chelyabinsk | from 262 to 820 | from 35 to 14900 | from 86 to 270 | from 33 to 430 | from 36 to 5400 |

| Novosibirsk | from 100 to 760 | from 35 to 9000 | from 86 to 270 | from 33 to 430 | from 36 to 5400 |

| Kaliningrad | from 57 to 660 | from 35 to 9000 | from 86 to 270 | from 33 to 430 | from 36 to 5400 |

Manual work requires the use of high-quality tools, and an angle grinder with attachments greatly facilitates the work and speeds up the process of processing a wooden surface.

How to make a grinder from a grinder?

This question can be confusing, because this is exactly what an angle grinder is - an angle grinder. But it is very universal and must be prepared for each operation. To prepare the grinder for grinding, you need to purchase a support wheel that is installed directly on the machine shaft.

To process wood, you need to stick an emery pad on this circle. The number of sandpaper is selected for the immediate moment of work. On sale you can find both a grinding wheel of the required diameter and sanding wheels of the appropriate size. Sanding wheels with Velcro are also available for sale, which are very easy and quick to change on the tool.

To convert our grinder for concrete grinding, it would be a good solution to purchase a special protective boot. It is good because it has a connection for connecting a vacuum cleaner. Well-known housings are produced by Hilti. The casing from this company has a sliding sector that opens part of the wheel for grinding in the corners.

Grinding metals with a grinder is usually performed with standard metal grinding wheels. They have different diameters, different thicknesses and different grains of the grinding surface. But, if you are going to sand an indecently rusted surface, then first you need to go over it with a metal brush. Such brushes of the required diameters are also available for sale.

Sanding wood

Wood is a unique material. It can be sanded quite well by hand, but with a grinder you can achieve very good results. Some snobs claim that you can’t grind with a grinder at all, but this is due to ignorance and inability.

The main secret is that the grinder is used at minimum speed. If the grinder has a speed switch, then there will be no problems. At high speeds, the sandpaper will become clogged with wood very quickly and very tightly. In this mode, it will not be enough for even five minutes of work. The optimal speed is no more than 6000 rpm.

Another secret is not to sand the entire area of the wheel. If you sand the entire surface, circular marks will remain on the wood. To ensure that there are no sandpaper marks left at all or that they are minimal, you need to sand only with the upper sector of the wheel. The movements of the machine should be along the grain of the wood.

READ Is it possible to lubricate an angle grinder with lithol

Using this method you can get excellent results when sanding lining. The board becomes smooth and does not retain tool marks. Just don’t get carried away and change the sanding pads on the wheel in time.

The frame is polished in a similar way. Here it is desirable that the support plate is thin around the edge. With such a plate it will be easier to sand narrow junctions of logs. Otherwise, this work will have to be completed with a chisel.

We work on concrete

If you were unable to purchase a branded protective boot with a nozzle for a vacuum cleaner, then you can make it yourself. To do this, take a used putty or glue bucket with a diameter slightly larger than the circle of the grinder. We cut off the bottom part at a height slightly higher than the assembled sanding part.

We cut a hole in the bottom for installation on the gearbox and a hole for the plastic plumbing corner outlet. Now we connect the vacuum cleaner hose to the nozzle and work quietly.

The grinding wheel must be designed for stone processing. to grind concrete and concrete surfaces the entire surface of the wheel. This will save processing time and level the surface well.

When grinding a concrete floor, you must constantly control the plane using a construction ruler, because due to the different densities of concrete, indentations can be made. To process the joints between concrete pours, it will be sufficient to achieve one level combination.

It is good to grind concrete floors and surfaces with a Matrix diamond grinding cup. If the grinder is 150 mm, then the cup is 125 mm.