Geography of production

The company was founded in Italy in 1972 and has been improving its products ever since. Most sources mention that the assembly of the 937 model is also Italian, but sometimes there is information that there is an assembly line in China. Given the global trend, this is more likely. However, there is no direct evidence - not a single nameplate on the inside of the saw speaks unequivocally in favor of one theory or another. The bottom line is high quality workmanship.

Even if the assembly is carried out in the Middle Kingdom, the Italians keep quality control at a decent level. This is quite enough to be satisfied with the purchase.

Purpose

Here again, everything is not as clear as it should be. Some write and talk about domestic use, others argue that the saw is a typical semi-professional. The confusion is associated with the high reliability and considerable price of the unit, which gives reason to judge it as a “farm” or construction saw, even if not for felling forests. The safety margin of components and assemblies is really large, but the totality of the features still does not allow us to classify the product as semi-professional.

According to the manufacturer, this is a saw for “high intensity residential use.” This includes construction work on the site, collecting firewood, and cutting down trees no thicker than 30 cm in diameter.

Layout

The structure of the saw is extremely simple, which is a definite advantage: the simpler the mechanism, the less likely it is to break. The aluminum crankcase of a single-cylinder two-stroke internal combustion engine is placed in a plastic housing.

The plastic is of high quality, does not crack at low temperatures and does not fade over time. The throttle and hold handles are attached to the body via spring shock absorbers. Thanks to this, vibrations from a running engine are dampened and do not have such a harmful effect on the operator’s hands.

The number of controls is minimal. The Italians followed the path of radical minimalism. They combined the air damper control drive and the electronic ignition into one lever.

Therefore, unlike most other chainsaws, it has three positions:

- Closed damper for starting the saw when cold.

- Working position of idle speed after engine seizure.

- “Stop” mode, into which the lever is moved in order to stop the engine.

In addition to this lever, there is a gas trigger with a lock against accidental pressing. The necks of the oil and gasoline tanks are located in the front and rear of the saw, respectively, and the plugs have external threads.

Most chainsaws of the 937 series do not have a primer, but a plastic seat is provided for it.

On the Internet you can find modifications with a pumping button, but this point should be clarified when purchasing. The primer doesn’t make much difference; even without it, the saw starts up cold after the third to fifth pull. The tension on the cable, even without even an additional spring, is moderate.

The top cover is secured with a plastic threaded bolt. By removing it, you can access the spark plug, as well as the nylon filter. The layout is very dense, thanks to which the saw has compact dimensions and low weight - only 4.5 kilograms with the saw set.

The tire fastening is standard - with two bolts. The tire and chain are Canadian, produced by Oregon, and are highly reliable. But the tension mechanism could be more convenient. It is located not just in front, but between the tire and the body. In the working position, you will have to “climb” there with a screwdriver, and the supplied spark plug wrench is generally inconvenient for this because of the crossbar. How can we not recall the keyless adjustment of other chainsaw models.

All chainsaws are equally different

Remember that today there are gas-powered tools on the market manufactured in different countries. However, none of the existing power measurement systems has been adopted. Therefore, taking into account the power characteristics measured according to different principles (meaning horsepower and kilowatts) will be advisable for a correct comparison of equipment.

But what unites tools from different manufacturers is this:

- the need to remove the oil and fuel mixture for a period (more than 3 weeks) of storage

- mandatory cleaning of working elements before (6-8 hour) downtime

- lubrication of drive and driven sprockets (for most models)

- tire rotation after 4-5 fill-ups

- strict adherence to the manufacturer’s recommendations in preparing the fuel mixture

- periodic (as 2-6 chains wear out) replacement of the tire and drive sprocket.

After becoming familiar with the general design and technical features of a chainsaw, it will be justifiably useful to study the specific characteristics of the tool

Question: I bought an Oleo Mac 941 chainsaw. This is my first saw. I read the instructions. It's very short.

Initially, the chain brake was turned on and it was not immediately possible to remove the cover, only after unlocking the brake until it clicked. I tried to start it according to the instructions.

It didn't work out. I found instructions for starting Shtil: “Before starting, you must unlock the throttle lever and press the gas, then turn the switch to the lower position and switch the operating modes. Next is the starter.

After several jerks, the engine “sneezes,” then we move the mode switch to the middle position and re-use the starter until it starts.

After starting, briefly press the gas lever to switch to idle mode.

Is this method suitable for Oleo Mac 941-C?

Does it have a combination throttle lever? (I prepared the fuel from 1 liter of 92 gasoline and 20 ml of branded oil; I pumped fuel into the carburetor with a primer before starting until the transparent button was filled).

What am I doing wrong? Or is the saw defective?

Answer: blocked the chain with the brake (does not affect the start, this is TB), pumped up the fuel with a primer, pulled the throttle lever down and pulled the starter once or twice (until it “sneezed”), then move the lever to the middle position, pull the starter, and after starting, briefly press throttle trigger and thereby reduce the speed. All.

So on my Oleo Mac 941 cx chainsaw, I don’t think it’s different on yours.

I also remembered: under the cover there is a damper to change the direction of air flow into the engine (winter/summer), it must be installed according to the season.

Question: I’ve decided to buy an Oleo Mac 941c chainsaw, but I can’t decide on the version: with a chain pitch of 3/8, or 0.325.

Which option is preferable and why?

Answer: Probably better 3/8-1.3. The saw is quite weak with 3/8 it will be easier than with 0.325.

Question: I purchased an Oleo Mak 941 cx chainsaw a year ago, it’s a good saw, it works great. It was run-in and developed a small malfunction.

When the engine has warmed up and, having cut the branches and trunks, when the lever is switched to the stop position, the engine does not turn off and continues to run for several seconds, from 10 to 20 seconds.

During initial startup, when the engine is not too hot, it stops immediately. The service center said that this is how it should be.

I don’t know if this is correct, please tell me. Maybe after running in, a lean mixture comes in and needs to be adjusted with screws L and H?

Answer: Wrong! Most likely the spark plug is incorrect or the fuel is bad.

This is called “glow ignition,” when the fuel mixture is ignited not by a spark, but spontaneously by the hot electrodes of the spark plug.

This will not immediately damage the engine, but over time it will.

When you turn off the engine, you do not shut off the fuel, but interrupt the supply of spark to the spark plug. Therefore, the carburetor has absolutely nothing to do with it. The cause may be fuel.

Use 92 gasoline from a proven gas station. Either the spark plug is “very hot” i.e. has a low heat number.

Unfortunately, neither one nor the other is covered by warranty. Try changing the fuel and spark plug, I think the problem will go away.

Let it run for 20-30 seconds at idle. In any case, this is good for the engine.

Question: In operation, the Oleo Mak 941c chainsaw, almost new, was assembled independently out of the box.

At first everything was great, but then the builders used it, I don’t know how.

In general, the cord stopped retracting all the way - about 5 centimeters remained hanging, I solved this problem by disassembling the case and winding an extra circle around the spring - now it retracts and sits in the socket with a little tightness), but another problem arose - it works for about a minute, even a little less and it stalls.

It’s as if there is no gasoline, although the tank is full. I loosened the chain tension - it didn’t help, what else can be done?

Answer: If the saw stalls at idle, simply tighten the idle speed screw clockwise.

And if under load, then the carburetor needs to be adjusted. You also need to check and clean the air filter.

Perhaps that's the problem. If nothing changes, you need to adjust the carburetor; the idle speed screw will not change anything. To do this you need to contact the service.

yourself adjustment of the carburetor of a lawn mower

is impossible without preliminary work, knowledge of the theory, and understanding of the structure of the fuel system. Annotation on carburetor repair.

Petrol mowers, like all petrol-powered garden tools, are not difficult to maintain equipment. It is possible and necessary to repair and configure without the help of others. For example, adjusting the carburetor of a lawn mower

with your own hands - it takes 5 minutes.

The carburetor from a lawn mower is a component in the power system. In it, like all carburetors, the process of mixing air and fuel (gasoline) takes place for subsequent supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, which is why the carburetor is adjusted.

Design Features

The Italian manufacturer is quite modest: it does not stuff its products with innovative super-technologies, but it ensures long-term uninterrupted operation by precise fitting of all components and high-quality processing of the necessary materials.

The Oleo-Mac 937 has a forged crankshaft and connecting rod - thanks to this manufacturing method, their service life is significantly longer. The inner surface of the cylinder is nickel-plated, forming a so-called mirror. The piston has grooves for attaching two compression rings.

Advantages and disadvantages

The main advantages of Oleo-Mac chainsaw

:

- great resource;

- small size;

- three adjustment screws that allow fine adjustment (a feature of all modern chainsaws with diaphragm carburetors)

- small size and relatively light weight of the structure compared to analogues;

- affordable price of parts, carburetor assembly;

- unpretentiousness to the quality of gasoline.

It is also worth noting a number of shortcomings:

- in small towns it may be difficult to find a repair kit for sale;

- obstacles with options, the highest requirements for the qualifications of tuners;

- the need for repeated adjustments during long-term operation.

Modification

In addition to the regular 937 model, you can also find a modification on the market with the PoverSharp badge, which is even applied to the tire. It is fundamentally no different, but the kit includes a special device for sharpening the tire. This is a plastic casing with a sharpening stone inside.

By putting one on the end of the bar and pressing the stop, you can sharpen the chain without removing it in a matter of seconds. However, users do not like this device: they say there are a lot of sparks, but there is little use. It’s better to sharpen it the old fashioned way, with a file or take it to a workshop.

Carburetor adjustment

When purchasing a chainsaw, the carburetor has factory settings and is adjusted to optimal operating modes. However, during operation, the engine (ICE), fuel pump, and carburetor wear out, resulting in the need for their repair, maintenance, and tuning. In this case, the role of the carburetor is to limit the minimum and maximum speed of the internal combustion engine.

The main criteria to determine the need to adjust the carburetor:

- the engine does not start, stalls, does not respond to pressing the accelerator;

- no idle speed;

- increased fuel consumption, the internal combustion engine does not develop power;

- wear of the piston group, carbon deposits on the spark plugs, black exhaust gases, incomplete combustion of gasoline.

The reasons for carburetor settings failure are as follows:

- violation of the fixation of the screws that regulate the minimum and maximum engine speeds due to strong vibrations or mechanical influences;

- when the internal combustion engine piston system wears out;

- clogged air or fuel filters, jets, fuel channel, broken intake valve.

To set up a carburetor, it is important to understand what parts and assemblies it consists of and the principle of its operation. This will allow you to determine the causes of the failure, what tools to prepare for adjustment and the type of repair kit if repairs are necessary.

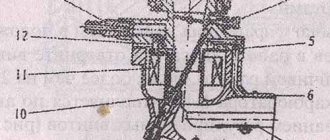

Design and operating principle

The principle of operation of the carburetor is based on mixing the fuel mixture of fuel and oil with air in a certain proportion for effective ignition and complete combustion in the internal combustion engine. It is a one-piece body, inside of which the following structural elements are located:

- fuel chamber;

- air and fuel channels;

- jets: idle and main;

- fuel mesh filter

- fuel inlet and outlet valves;

- air and throttle valves;

- diffuser;

- fuel and control membranes;

- adjusting screws;

- sealing gaskets.

There are screws located outside the housing to adjust the quality and composition of the mixture. At the top and end part there is a fuel supply pipe and a pulse channel for the fuel pump.

The carburetor operates according to the following algorithm:

- When the engine starts, the air damper opens. The air passes through the filter and bypasses the dampers (number 1 in diagram) and enters the housing.

- The fuel pump pumps gasoline into the chamber. Under pressure, an oil-gasoline mixture is sprayed through the jets (in the diagram above, position 2 is the main jet, 3,4 are the idle jets), it comes into contact with air, mixes, and then enters the combustion chamber. The engine starts to idle.

- When you press the accelerator, the second adjustable throttle opens to a certain angle (in the photo this is the second damper), fuel begins to flow through the main nozzle (position 2 in the diagram). Inside the carburetor, a larger amount of combustible mixture is mixed, which, when supplied to the combustion chamber, increases the engine speed.

- The amount of gasoline entering the chamber also depends on the settings of the adjusting screws that control the needle valves (in the diagram these are spring-loaded screws on the left and right).

- The fuel supply to the chamber is limited by membranes; the supply intensity is determined by changes in pressure in the piston and is regulated through feedback from the pump and pulse valve. The operation of the fuel pump is synchronous with the engine: the higher the speed, the stronger the flow of the fuel-air mixture.

- To prevent fuel overflow, a special lever and a shut-off valve are provided in the chamber.

Carburetor fuel supply system. 1 – regulating chamber; 2 – membrane; 3 – locking needle.

Customization Tools

Since the adjustment is carried out using external screws, you will need the Phillips or flat-head screwdriver included with the saw; the width of the working part is 4 mm. To control the speed, you will need a tachometer.

Step by step adjustment

Let's look at an example of carburetor adjustment using the Oleo Mak 937 chainsaw. The principle of setting other saws is practically no different, so this algorithm is applicable for the following models: 941c, 936. There is no similarity with other, less popular models (for example Oleo Mak 362 or Oleo Mak 35) We checked, but most likely there are no serious differences.

Before setting up the Oleo Mak chainsaw carburetor, a number of conditions must be met:

- clean the air and fuel filters;

- check the condition of the jets, make sure they are in good condition and clean;

- assess the integrity of the membranes: absence of damage, cracks;

- check that there is sufficient fuel entering the chamber.

Standard carburetor adjustments do not require disassembly. There are screws on the outside that allow you to make all the necessary settings:

- L – low speed;

- H – high speed;

- S – idle.

Despite the fact that the manufacturer recommends adjusting only the “S” screw, in practice this turns out to be not enough. Before adjusting, all three screws should be tightened until they stop, and then unscrewed 1.5-2 turns.

Step-by-step adjustment is performed as follows:

- The engine starts and warms up for 3-5 minutes at medium speed.

- The tachometer is connected.

- Operation at low speeds is adjusted using the “L” screw. It is necessary to achieve 1-1.5 thousand rpm. engine without spinning the chain, and when you press the accelerator, there is no drop in speed. If a failure is detected, the screw should be unscrewed until this effect is completely eliminated.

- High engine speeds are adjusted using screw “H”. When you press the accelerator to the maximum, monitor the increase in revolutions; it is important that they do not exceed the maximum permissible value. It is recommended to set it 5-10% lower than the maximum rotation speed, so as not to provoke increased wear of the internal combustion engine.

- The carburetor is fine-tuned using the “S” screw. When the chain moves at idle, the screw should be turned counterclockwise until it stops. If the internal combustion engine stalls, then unscrew the screw clockwise until stable operation is achieved.

- After the adjustment procedures, the chainsaw is tested in real operating conditions. If necessary, perform the settings again.

Carburetor adjustment video

For clarity, the setting of the chainsaw carburetor can be seen in the video below. After viewing it, even beginners should not have any questions about setup.

Nuances of adjustment

When setting up the carburetors of Oleo Mac chainsaws, the following nuances usually arise:

- Screw markings do not match. Depending on the model, equipment supplier, or other factors, markings may differ from those described. In such cases, it is recommended to carefully study the instructions supplied with the device.

- After adjustment, you need to turn off the chainsaw and let it cool for 10-15 minutes to check its operation from a “cold” start.

- In the absence of experience or the necessary knowledge, it is not recommended to adjust the “H” screw. This is due to the likelihood of setting up a poor-quality fuel-air mixture, which can cause wear on the piston group, failures in starting and engine operation.

- At all stages, control of engine speed using a tachometer is required. A replacement for a tachometer can be an oscilloscope or a multimeter with this function.

Alternatives

Chainsaws with a name should be considered competitors of Oleo-Mac, since such uninterrupted operation is unlikely to be ensured by another Chinese clone branded with an arbitrary logo. Almost all of the major competitors with similar chain lengths and power ratings are slightly cheaper.

These are the Makita EA3203S-40, and the Husqvarna 135 (as well as its updated model Husqvarna 130), and the STIHL MS 180-16, not to mention the PARTNER P350S or the Daewoo Power Products DACS 4516. However, the Italians “make” famous Germans and Swedes big the number of horses, and eastern manufacturers - reliability and maintainability. So it turns out that an additional 3 - 4 thousand rubles for no problems for at least 5 years is not too high a price.